Master Your Engine Dynamometer Sourcing for Optimal

Introduction: Navigating the Global Market for engine dynamometer

Engine dynamometers, or engine dynos, are essential tools in the automotive and engineering sectors, enabling precise measurement of engine performance parameters such as torque and horsepower. For international B2B buyers, particularly those operating within Africa, South America, the Middle East, and Europe, understanding the intricacies of engine dynamometers is crucial for making informed purchasing decisions. As the global market continues to evolve, having a comprehensive grasp of this equipment can significantly impact operational efficiency and product innovation.

This guide delves into various aspects of engine dynamometers, including the different types available, materials used in their construction, manufacturing processes, quality control measures, and leading suppliers. Additionally, it explores cost considerations and market trends, providing insights that empower buyers to navigate their sourcing strategies effectively.

By equipping buyers with the knowledge to evaluate options critically, this guide ensures that decision-makers can select the right dynamometer for their specific applications. Whether you are a manufacturer looking to enhance your testing capabilities or a research facility aiming to optimize performance evaluations, understanding the dynamics of engine dynamometers is key to achieving your operational objectives. Embrace the opportunity to streamline your procurement process and enhance your competitive edge in the global marketplace.

Understanding engine dynamometer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| AC Dynamometer | Utilizes alternating current to measure power output. | Automotive testing, engine performance. | Pros: High precision, versatile. Cons: Higher initial cost. |

| Brake Dynamometer | Measures torque and power using a brake system. | Engine testing, R&D, emissions testing. | Pros: Effective for heavy-duty engines. Cons: Requires more space. |

| Chassis Dynamometer | Tests vehicle performance by measuring power at the wheels. | Automotive diagnostics, tuning. | Pros: Real-world performance data. Cons: Limited to vehicle use. |

| Eddy Current Dynamometer | Uses electromagnetic induction to measure torque. | Engine R&D, performance tuning. | Pros: High accuracy, low maintenance. Cons: Complexity in setup. |

| Hydraulic Dynamometer | Employs hydraulic resistance for torque measurement. | Heavy machinery testing, industrial engines. | Pros: Suitable for large engines. Cons: Can be less efficient. |

AC Dynamometer

AC dynamometers measure engine performance using alternating current technology. They are particularly suitable for automotive testing and engine performance evaluations, allowing for high precision in power measurements. When purchasing an AC dynamometer, buyers should consider the initial investment, as these systems tend to have a higher upfront cost. However, their versatility and accuracy can justify the expense for businesses focused on performance optimization.

Brake Dynamometer

Brake dynamometers are designed to measure engine torque and power through a braking mechanism. Commonly used in research and development (R&D) and emissions testing, they provide valuable insights into engine performance under load. Buyers should assess the space requirements, as brake dynamometers often require a more extensive setup. Their effectiveness for heavy-duty engines makes them a preferred choice for manufacturers dealing with larger vehicles.

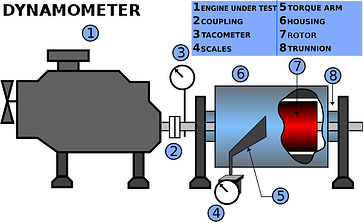

Illustrative Image (Source: Google Search)

Chassis Dynamometer

Chassis dynamometers test vehicle performance by measuring power output at the wheels, providing real-world performance data. This type is widely used in automotive diagnostics and tuning, making it essential for businesses focused on vehicle performance enhancement. Buyers should be aware of the limitations, as chassis dynamometers are primarily limited to vehicle applications. However, their ability to simulate actual driving conditions offers significant advantages for tuning and diagnostics.

Eddy Current Dynamometer

Eddy current dynamometers utilize electromagnetic induction to measure torque, making them suitable for engine research and development as well as performance tuning. Their high accuracy and low maintenance requirements appeal to B2B buyers looking for reliable testing solutions. However, the complexity involved in setup can be a drawback, and companies should consider their technical capabilities when opting for this type of dynamometer.

Hydraulic Dynamometer

Hydraulic dynamometers measure torque through hydraulic resistance, making them ideal for testing heavy machinery and industrial engines. Their robust design accommodates larger engines, but buyers should consider efficiency, as hydraulic systems can sometimes be less effective compared to other types. Evaluating the specific needs of the application and the engine size will help buyers determine if a hydraulic dynamometer is the right fit for their operations.

Related Video: Dynamometer and Types of Dynamometers – Theory of Machine

Key Industrial Applications of engine dynamometer

| Industry/Sector | Specific Application of Engine Dynamometer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Engine performance testing and validation | Ensures compliance with performance standards and regulations | Accuracy of measurements, data acquisition capabilities |

| Aerospace | Testing of aircraft engines and propulsion systems | Improves safety and efficiency of aerospace vehicles | Certification and testing standards, reliability of equipment |

| Energy & Power Generation | Testing of generators and turbines | Optimizes energy output and operational efficiency | Environmental regulations, compatibility with existing systems |

| Heavy Machinery | Performance assessment of construction equipment engines | Enhances machine reliability and reduces downtime | Durability, load capacity, and service support |

| Research & Development | Engine research for innovation and efficiency improvements | Drives technological advancements in engine design | Customizability, data analysis tools, and support services |

Automotive Manufacturing

In the automotive sector, engine dynamometers are crucial for performance testing and validation of new engine designs. They measure parameters such as torque and RPM to ensure engines meet regulatory standards and performance benchmarks. For international buyers, particularly in Europe and South America, sourcing a dynamometer that offers precise measurements and robust data acquisition systems is essential. Additionally, compatibility with various engine types and ease of integration into existing test setups are key considerations.

Aerospace

Aerospace applications of engine dynamometers focus on testing aircraft engines and propulsion systems. This testing ensures that engines perform efficiently and safely under various conditions. For buyers in regions like the Middle East, where aviation is rapidly growing, selecting a dynamometer that complies with stringent certification standards is vital. Furthermore, reliability and the ability to simulate real-world operating conditions are significant factors for successful integration into aerospace testing labs.

Energy & Power Generation

In the energy sector, dynamometers are employed to test generators and turbines, helping optimize their performance and energy output. This application is particularly relevant for buyers in Africa, where renewable energy sources are increasingly being utilized. When sourcing engine dynamometers, businesses must consider environmental regulations and the dynamometer’s compatibility with existing energy systems. Additionally, the ability to conduct thorough performance analyses can lead to improved operational efficiency and reduced energy costs.

Heavy Machinery

Heavy machinery manufacturers utilize engine dynamometers to assess the performance of construction equipment engines. This application is critical for enhancing machine reliability and minimizing downtime, which is essential in competitive markets like South America and Europe. Buyers should prioritize dynamometers that can withstand high loads and provide accurate performance data over extended periods. Moreover, sourcing support services for maintenance and calibration can significantly impact operational success.

Research & Development

In research and development environments, engine dynamometers are utilized for innovative engine research aimed at improving efficiency and reducing emissions. This application is essential for companies looking to stay ahead in technology and regulatory compliance, especially in Europe, where environmental standards are stringent. Buyers should seek dynamometers that offer customizability and advanced data analysis tools to facilitate in-depth research. Support services for troubleshooting and updates are also critical to maintaining cutting-edge capabilities in engine testing.

Related Video: How An Engine Dyno Works

Strategic Material Selection Guide for engine dynamometer

When selecting materials for engine dynamometers, it is crucial to consider their properties, advantages, and limitations. The choice of material can significantly affect the performance, durability, and cost-effectiveness of the dynamometer. Below, we analyze four common materials used in engine dynamometers: Steel, Aluminum, Composite Materials, and Stainless Steel.

Steel

Key Properties:

Steel is known for its high tensile strength and ability to withstand high temperatures and pressures. It typically has a temperature rating up to 600°C and can handle significant mechanical stress.

Pros & Cons:

Steel’s durability makes it ideal for heavy-duty applications, but it can be prone to corrosion if not properly treated. The manufacturing process is relatively straightforward, but the weight of steel can be a disadvantage in portable applications.

Impact on Application:

Steel is compatible with various media, including oil and coolant systems, making it versatile for different engine types. However, its weight can impact the dynamometer’s portability and ease of use.

Considerations for International Buyers:

Buyers from regions with high humidity, like parts of Africa and South America, should ensure that the steel is treated for corrosion resistance. Compliance with standards such as ASTM A36 is also essential for ensuring quality and performance.

Aluminum

Key Properties:

Aluminum is lightweight and has good thermal conductivity, with a temperature rating typically around 300°C. It is also resistant to corrosion due to the formation of a protective oxide layer.

Pros & Cons:

The primary advantage of aluminum is its low weight, which enhances portability. However, it has lower tensile strength compared to steel, making it less suitable for high-stress applications. Manufacturing aluminum parts can be more complex and costly due to the need for specialized techniques.

Impact on Application:

Aluminum is suitable for applications where weight reduction is critical, such as in mobile dynamometers. However, it may not perform well under extreme mechanical stress.

Considerations for International Buyers:

European buyers, particularly in Germany, may prefer aluminum for its recyclability and lower environmental impact. Compliance with DIN standards for aluminum alloys is crucial for ensuring quality.

Composite Materials

Key Properties:

Composite materials combine different substances to enhance properties like strength and weight. They can withstand high temperatures and offer excellent corrosion resistance.

Pros & Cons:

Composites are lightweight and can be tailored for specific applications, but they are often more expensive than metals and may require specialized manufacturing techniques. Their long-term durability can vary based on the resin used.

Impact on Application:

Composites are ideal for applications requiring a balance of strength and weight, such as in advanced dynamometer designs. However, compatibility with certain fluids must be assessed to avoid degradation.

Considerations for International Buyers:

In regions like the Middle East, where temperatures can be extreme, selecting high-quality composites that can withstand heat is vital. Buyers should ensure compliance with international standards for composite materials.

Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance and can handle high temperatures (up to 800°C). It combines the strength of steel with the durability of corrosion-resistant alloys.

Pros & Cons:

The main advantage of stainless steel is its longevity and resistance to rust, making it suitable for harsh environments. However, it is heavier and more expensive than regular steel, which can affect cost and portability.

Impact on Application:

Stainless steel is ideal for applications exposed to moisture and corrosive substances, ensuring a longer lifespan for the dynamometer. Its weight may be a concern for portable units.

Considerations for International Buyers:

Buyers in humid regions should prioritize stainless steel for its corrosion resistance. Compliance with ASTM A240 standards is important for international buyers to ensure quality.

Summary Table

| Material | Typical Use Case for engine dynamometer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications | High tensile strength | Prone to corrosion | Medium |

| Aluminum | Portable dynamometers | Lightweight | Lower tensile strength | Medium |

| Composite | Advanced dynamometer designs | Tailored properties | High manufacturing cost | High |

| Stainless Steel | Harsh environments | Excellent corrosion resistance | Heavier and more expensive | High |

This guide provides international B2B buyers with the necessary insights to make informed decisions regarding material selection for engine dynamometers, ensuring they choose the right material for their specific needs and conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for engine dynamometer

The manufacturing and quality assurance processes for engine dynamometers are critical for ensuring performance, reliability, and compliance with international standards. For B2B buyers, especially those from Africa, South America, the Middle East, and Europe, understanding these processes can significantly impact procurement decisions and partnerships.

Manufacturing Processes

1. Material Preparation

The manufacturing of engine dynamometers begins with the selection of high-quality materials. Common materials include:

- Steel and Aluminum: For structural components due to their strength and lightweight properties.

- Special Alloys: Used for parts that require enhanced durability and resistance to wear.

- Electronic Components: Sourced from reliable suppliers to ensure precision in measurement.

Material preparation involves cutting, machining, and treating the materials to meet specific mechanical properties. This stage often includes:

- Heat Treatment: To improve the strength and durability of metal parts.

- Surface Finishing: Processes like anodizing or powder coating are applied to protect against corrosion.

2. Forming

Forming processes shape the prepared materials into components. Techniques include:

- CNC Machining: Utilizes computer-controlled machines for precise shaping of parts.

- Welding: For assembling structural components together, ensuring robust joints.

- Casting: Some manufacturers may use casting for complex shapes that are difficult to machine.

Each forming technique is chosen based on the specific requirements of the dynamometer design and the intended application.

3. Assembly

The assembly stage brings together all the components, including mechanical, electrical, and software systems. Key steps in this process are:

- Integration of Sensors and Electronics: Ensuring that torque, RPM, and other critical measurements are accurately captured.

- Calibration: Each dynamometer must be calibrated according to manufacturer specifications to ensure precision in measurement.

- System Testing: Preliminary tests are conducted to check for functionality before final assembly.

4. Finishing

Finishing processes enhance the dynamometer’s aesthetics and functionality:

- Quality Control Inspections: Each unit undergoes rigorous inspections to meet quality standards.

- Final Assembly: Includes the installation of user interfaces and any additional features required by the customer.

- Packaging: Proper packaging ensures that the dynamometer is protected during shipping.

Quality Assurance

Quality assurance in engine dynamometer manufacturing is paramount. It involves multiple stages and adherence to international standards.

Relevant International Standards

International standards provide a framework for quality assurance:

- ISO 9001: This standard focuses on quality management systems and is essential for manufacturers aiming to demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: For manufacturers catering to the oil and gas industry, adherence to API specifications can be critical.

Quality Control Checkpoints

Quality control is integrated throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspects raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to detect and rectify defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished product to verify performance against specifications.

Common testing methods include:

- Load Testing: To ensure the dynamometer can handle specified loads without failure.

- Calibration Tests: Verifying measurement accuracy across operational ranges.

- Environmental Testing: Assessing performance under varying temperature and humidity conditions.

Verification of Supplier Quality Control

For B2B buyers, verifying a supplier’s quality control processes is crucial:

- Supplier Audits: Conducting on-site audits can provide insights into the manufacturing processes, quality control systems, and adherence to standards.

- Quality Assurance Reports: Requesting detailed reports on quality control measures, including test results and compliance with international standards.

- Third-Party Inspections: Engaging independent organizations to conduct inspections can provide unbiased verification of quality claims.

Quality Control and Certification Nuances

International B2B buyers should be aware of specific nuances related to quality control and certification:

- Regional Compliance: Different regions may have unique compliance requirements. For instance, manufacturers selling in Europe must comply with CE standards, while those in the Middle East might need to adhere to GCC standards.

- Documentation: Ensure that suppliers can provide all necessary certifications and documentation for compliance verification.

- Cultural Considerations: Understanding local business practices and quality expectations can enhance communication and collaboration with suppliers.

Conclusion

Navigating the manufacturing processes and quality assurance protocols for engine dynamometers is essential for B2B buyers. By understanding these processes, international buyers can make informed decisions, mitigate risks, and ensure they procure high-quality products that meet their operational needs. The emphasis on rigorous quality control and adherence to international standards not only guarantees product reliability but also fosters long-term partnerships based on trust and performance excellence.

Related Video: BMW Car PRODUCTION ⚙️ ENGINE Factory Manufacturing Process

Comprehensive Cost and Pricing Analysis for engine dynamometer Sourcing

The sourcing of engine dynamometers involves a complex interplay of various cost components and pricing influencers. Understanding these elements is essential for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary materials used in engine dynamometers include high-grade metals for structural integrity, advanced sensors for accurate measurements, and electronic components for data acquisition. The choice of materials directly impacts both performance and cost.

-

Labor: Labor costs can vary significantly depending on the manufacturing location. Regions with higher labor costs may yield better craftsmanship and quality control, while lower-cost regions might focus on volume production.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, and equipment maintenance. Efficient manufacturing processes can help keep overhead costs low, which is beneficial for pricing.

-

Tooling: Custom tooling is often required for specialized dynamometers, impacting initial costs. Buyers should consider whether they need off-the-shelf solutions or custom designs, as this can affect lead times and pricing.

-

Quality Control (QC): Rigorous QC processes ensure reliability and performance. Implementing high QC standards may increase costs but ultimately lead to fewer failures and better long-term satisfaction.

-

Logistics: Transportation costs can be significant, especially for heavy equipment like dynamometers. Factors such as shipping methods, distance, and customs duties must be accounted for in the total cost.

-

Margin: Supplier margins can vary widely based on their market position, brand reputation, and the level of service they provide. Understanding typical margins in different regions can aid in negotiations.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly influence pricing. Larger orders typically attract discounts, making it crucial for buyers to assess their needs carefully.

-

Specifications/Customization: Customized solutions tailored to specific applications can incur additional costs. Buyers should weigh the necessity of customization against standard options that may be more cost-effective.

-

Materials and Quality: Higher-quality materials and certifications (like ISO) can increase costs. However, investing in quality can lead to lower maintenance and replacement costs over time.

-

Supplier Factors: The supplier’s location, reputation, and experience can affect pricing. Established suppliers may charge a premium for their reliability and support services.

-

Incoterms: Understanding shipping terms is essential for budgeting. Incoterms define responsibilities for shipping costs, insurance, and risks, which can greatly impact the final price.

Buyer Tips

-

Negotiation: Engage suppliers in open discussions about pricing and be prepared to negotiate. Establishing a long-term relationship can often yield better pricing and terms.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the upfront price. Consider factors such as maintenance, operational efficiency, and potential downtime.

-

Pricing Nuances: Be aware of regional pricing differences. For example, European suppliers may offer higher quality but at a premium, while suppliers from Africa or South America may provide competitive pricing with varying quality.

-

Research and Compare: Utilize resources such as manufacturer directories and industry reports to compare prices and understand market trends. This will empower buyers to make informed decisions.

Disclaimer

Prices for engine dynamometers can vary widely based on the factors mentioned above. The information provided is for indicative purposes only and should not be used as the sole basis for purchasing decisions. Always consult multiple suppliers and conduct thorough market research to obtain accurate and up-to-date pricing.

Spotlight on Potential engine dynamometer Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘engine dynamometer’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for engine dynamometer

Engine dynamometers are essential tools for measuring engine performance, and understanding their technical properties and industry terminology is crucial for B2B buyers. This section outlines the key specifications and common trade terms that will assist decision-makers in making informed purchases.

Key Technical Properties

-

Torque Measurement Range

– Definition: This specification indicates the range of torque that the dynamometer can accurately measure, usually expressed in Newton-meters (Nm) or foot-pounds (ft-lb).

– B2B Importance: Buyers must ensure that the dynamometer’s torque measurement range aligns with the engines being tested. A mismatch could lead to inaccurate readings and affect product development timelines. -

RPM Range

– Definition: The revolutions per minute (RPM) range specifies the operational limits of the dynamometer in terms of engine speed.

– B2B Importance: Understanding the RPM capabilities is critical, especially for industries focusing on high-performance engines. Selecting a dynamometer that can accommodate the necessary RPMs ensures comprehensive testing and reliability of results. -

Power Rating

– Definition: This property defines the maximum power output the dynamometer can handle, typically measured in kilowatts (kW) or brake horsepower (bhp).

– B2B Importance: Knowing the power rating helps buyers assess whether the dynamometer can sustain prolonged testing of high-power engines without overheating or failing. -

Data Acquisition System

– Definition: A data acquisition system is integrated into the dynamometer to collect and analyze performance data during testing.

– B2B Importance: A robust data acquisition system enhances the accuracy of test results and allows for real-time monitoring. This capability is essential for manufacturers aiming to optimize engine performance and comply with regulatory standards. -

Calibration Tolerance

– Definition: Calibration tolerance refers to the permissible deviation from the true value that the dynamometer can maintain during measurements.

– B2B Importance: High calibration tolerance is critical for ensuring consistent and reliable performance data. Buyers should prioritize dynamometers with lower tolerances to enhance testing accuracy.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: Refers to companies that produce parts or equipment that may be marketed by another manufacturer.

– B2B Importance: Understanding the distinction between OEM and aftermarket parts is vital for buyers looking for quality and compatibility in engine testing equipment. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– B2B Importance: Knowing the MOQ helps businesses plan their purchasing strategy and manage inventory effectively, especially for bulk orders. -

RFQ (Request for Quote)

– Definition: A formal document requesting pricing information from suppliers for specific products.

– B2B Importance: Submitting RFQs allows buyers to compare pricing and terms from multiple suppliers, facilitating informed decision-making and budget management. -

Incoterms (International Commercial Terms)

– Definition: A set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions.

– B2B Importance: Familiarity with Incoterms is essential for understanding shipping costs, risks, and responsibilities, particularly when importing engine dynamometers from other countries.

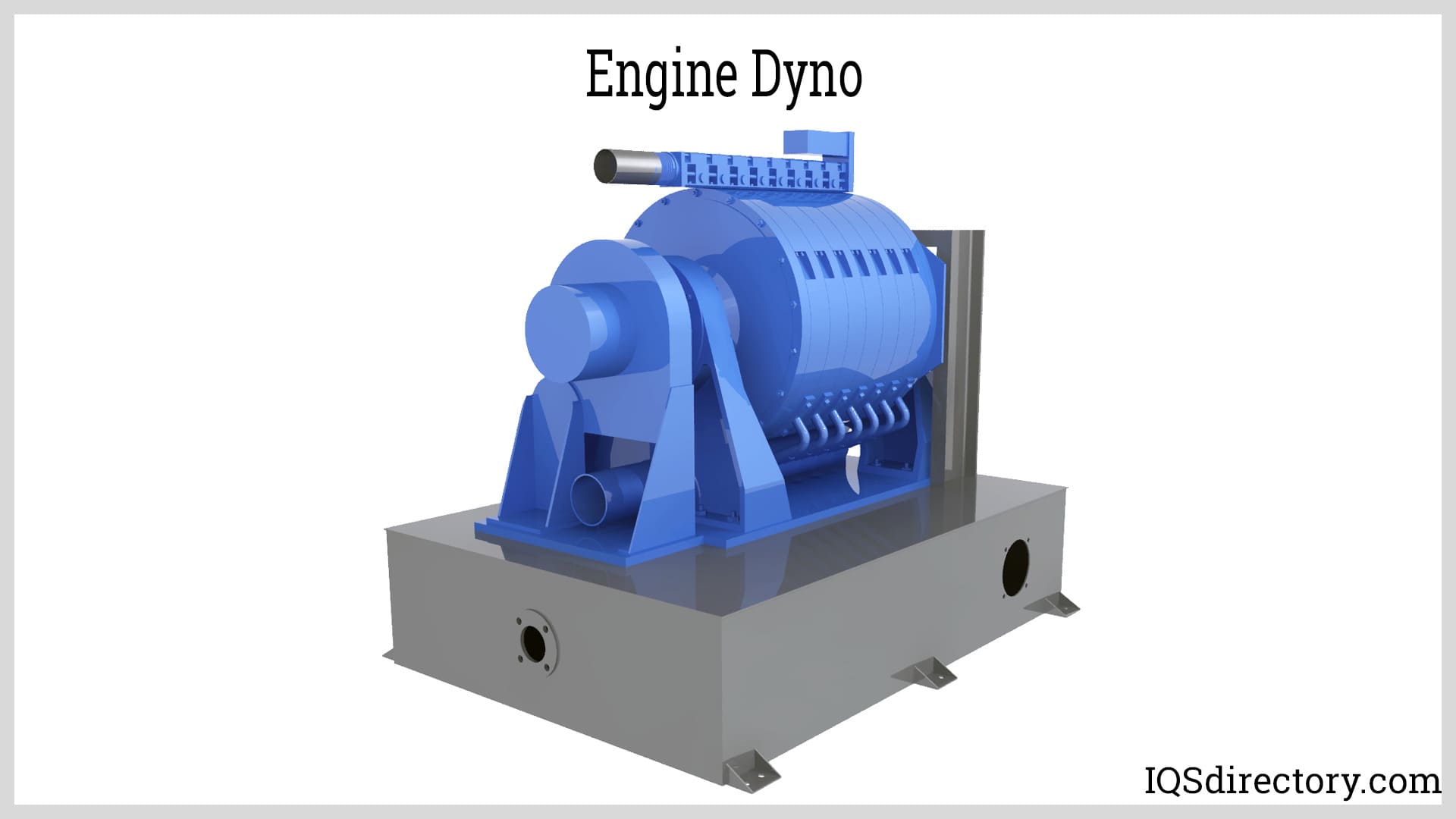

Illustrative Image (Source: Google Search)

- Lead Time

– Definition: The time taken from placing an order to the delivery of the product.

– B2B Importance: Buyers need to consider lead times when planning production schedules, as longer lead times can delay project timelines and affect overall productivity.

By comprehensively understanding these technical properties and industry terms, international B2B buyers can make well-informed decisions when purchasing engine dynamometers, thereby enhancing their operational efficiency and product quality.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the engine dynamometer Sector

Market Overview & Key Trends

The engine dynamometer market is experiencing a transformative phase driven by technological advancements, increased demand for automotive testing, and the push for energy efficiency. Global factors such as stringent emission regulations, the rise of electric vehicles (EVs), and the growing emphasis on performance testing in automotive engineering are shaping market dynamics. In regions like Africa and South America, burgeoning automotive industries are fostering local demand for high-quality testing equipment, making it essential for international B2B buyers to identify reliable suppliers who can meet specific regional requirements.

Emerging trends include the integration of digital technologies, such as IoT and AI, into dynamometer systems. These technologies facilitate real-time data analysis, predictive maintenance, and enhanced performance metrics, which are crucial for manufacturers striving for competitiveness. Furthermore, the demand for portable dynamometers is rising, particularly in mobile testing scenarios prevalent in developing markets. Buyers should also be aware of the increasing trend towards customization, where manufacturers offer tailored solutions that cater to specific testing needs and regulatory requirements.

As the market evolves, understanding the competitive landscape is vital. Key players are increasingly focusing on R&D to innovate and improve dynamometer capabilities, emphasizing durability and accuracy. Buyers should actively seek partnerships with manufacturers that not only provide high-quality products but also demonstrate a commitment to technological advancements and customer service.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone of modern business practices, and the engine dynamometer sector is no exception. The environmental impact of manufacturing processes is under scrutiny, prompting businesses to adopt greener practices. B2B buyers must consider suppliers that prioritize sustainable production methods, such as using renewable energy sources and reducing waste throughout the manufacturing process.

Ethical sourcing is equally important, as buyers are increasingly looking for suppliers that ensure fair labor practices and transparency in their supply chains. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management can serve as indicators of a supplier’s commitment to sustainability and ethical practices. Furthermore, materials used in dynamometer construction should be evaluated for their environmental impact; opting for recycled or sustainably sourced materials can significantly enhance the overall sustainability profile of the equipment.

Buyers should also engage with suppliers about their sustainability goals and initiatives. By fostering partnerships with manufacturers that align with their values, companies can not only enhance their corporate social responsibility (CSR) profile but also meet the growing consumer demand for environmentally responsible products.

Brief Evolution/History

The evolution of engine dynamometers dates back to the late 19th century, when the need for engine testing began to arise alongside the automotive revolution. Early models were rudimentary, primarily measuring basic parameters like torque and RPM. Over the decades, advancements in engineering and technology led to the development of more sophisticated systems capable of providing detailed performance analytics.

By the mid-20th century, dynamometers became essential tools in automotive testing laboratories, enabling manufacturers to optimize engine performance and efficiency. Today, modern dynamometers incorporate advanced digital technologies and automation, allowing for unprecedented precision in testing and analysis. This historical progression not only highlights the importance of dynamometers in the automotive industry but also underscores the ongoing need for innovation in response to evolving market demands.

Related Video: How Global Trade Runs on U.S. Dollars | WSJ

Frequently Asked Questions (FAQs) for B2B Buyers of engine dynamometer

-

What key factors should I consider when vetting suppliers for engine dynamometers?

When vetting suppliers, prioritize their experience in manufacturing engine dynamometers, checking for industry certifications such as ISO 9001. Request references from previous clients to gauge reliability and service quality. Evaluate their production capabilities, including technology used and production volume. Additionally, consider their customer support and after-sales service, as these are crucial for long-term partnerships, especially in international trade. -

Can engine dynamometers be customized to meet specific requirements?

Yes, many manufacturers offer customization options for engine dynamometers. Discuss your specific needs regarding size, power capacity, and additional features with potential suppliers. Customization can also include software integrations for data analysis or specific testing protocols. Ensure that the supplier provides clear documentation outlining the customization process, costs, and lead times to avoid misunderstandings. -

What are the typical minimum order quantities (MOQ) and lead times for engine dynamometers?

MOQs for engine dynamometers can vary significantly depending on the supplier and the complexity of the equipment. Generally, you may expect MOQs ranging from one unit for standard models to larger quantities for custom designs. Lead times can also differ; standard models may take 4-6 weeks, while customized units might require 8-12 weeks. Always confirm these details before placing an order to ensure they align with your project timelines. -

What payment terms should I expect when sourcing from international suppliers?

Payment terms can vary by supplier and region. Common methods include wire transfers, letters of credit, or payment upon delivery. It’s essential to negotiate terms that provide security for both parties. Consider using escrow services for large transactions to mitigate risks. Additionally, be aware of any international payment fees or currency conversion costs that may apply, especially when dealing with suppliers from Africa, South America, the Middle East, or Europe. -

How can I ensure the quality of the engine dynamometers I am purchasing?

Request quality assurance documentation, including certifications and test reports, from your supplier. Many reputable manufacturers conduct rigorous testing on their equipment before shipment. Inquire about the materials used and the manufacturing process to ensure compliance with international standards. If possible, arrange for a factory visit or third-party inspection to assess the quality firsthand, especially for larger orders. -

What logistics considerations should I keep in mind when importing engine dynamometers?

Logistics can be complex when importing engine dynamometers. Consider shipping costs, customs duties, and import regulations specific to your country. Work with a freight forwarder experienced in handling industrial equipment to streamline the process. Ensure that the supplier provides proper packaging and handling instructions to prevent damage during transit. Additionally, factor in delivery timelines to align with your operational needs. -

How can I handle disputes with suppliers effectively?

To manage disputes, establish clear contracts that outline terms, conditions, and dispute resolution processes upfront. In the event of a disagreement, maintain open communication with the supplier to resolve issues amicably. If necessary, refer to the terms outlined in your contract regarding mediation or arbitration. Keeping detailed records of all correspondence and agreements will aid in resolving disputes efficiently. -

What certifications should I look for in engine dynamometers to ensure compliance with international standards?

Look for certifications such as ISO 9001 for quality management systems and ISO/IEC 17025 for testing and calibration laboratories. Additionally, CE marking is essential for compliance with European safety, health, and environmental protection standards. If you are sourcing from outside Europe, inquire about compliance with local standards specific to your region. These certifications not only ensure quality but also enhance the credibility of the supplier in international markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for engine dynamometer

In the competitive landscape of engine dynamometer procurement, strategic sourcing emerges as a critical factor for success. By focusing on reputable manufacturers, international B2B buyers can ensure they acquire high-quality dynamometers tailored to their specific needs. Key takeaways include the importance of understanding the diverse types of dynamometers available—such as hydraulic, eddy current, and portable options—and their applications across industries like automotive and aerospace.

Investing in advanced dynamometer technology not only enhances testing accuracy but also contributes to operational efficiency and innovation. Buyers should prioritize suppliers that offer robust customer support and maintenance services, which are crucial for maximizing the lifespan of these sophisticated instruments.

As global markets continue to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for reliable engine testing solutions will only grow. Now is the time for buyers to engage with trusted manufacturers, request quotes, and explore customized solutions that will meet their operational demands. By embracing strategic sourcing practices, businesses can secure a competitive edge and drive future growth in their respective markets.