Your Ultimate Guide to Sourcing Types Of Fasteners

Introduction: Navigating the Global Market for types of fasteners

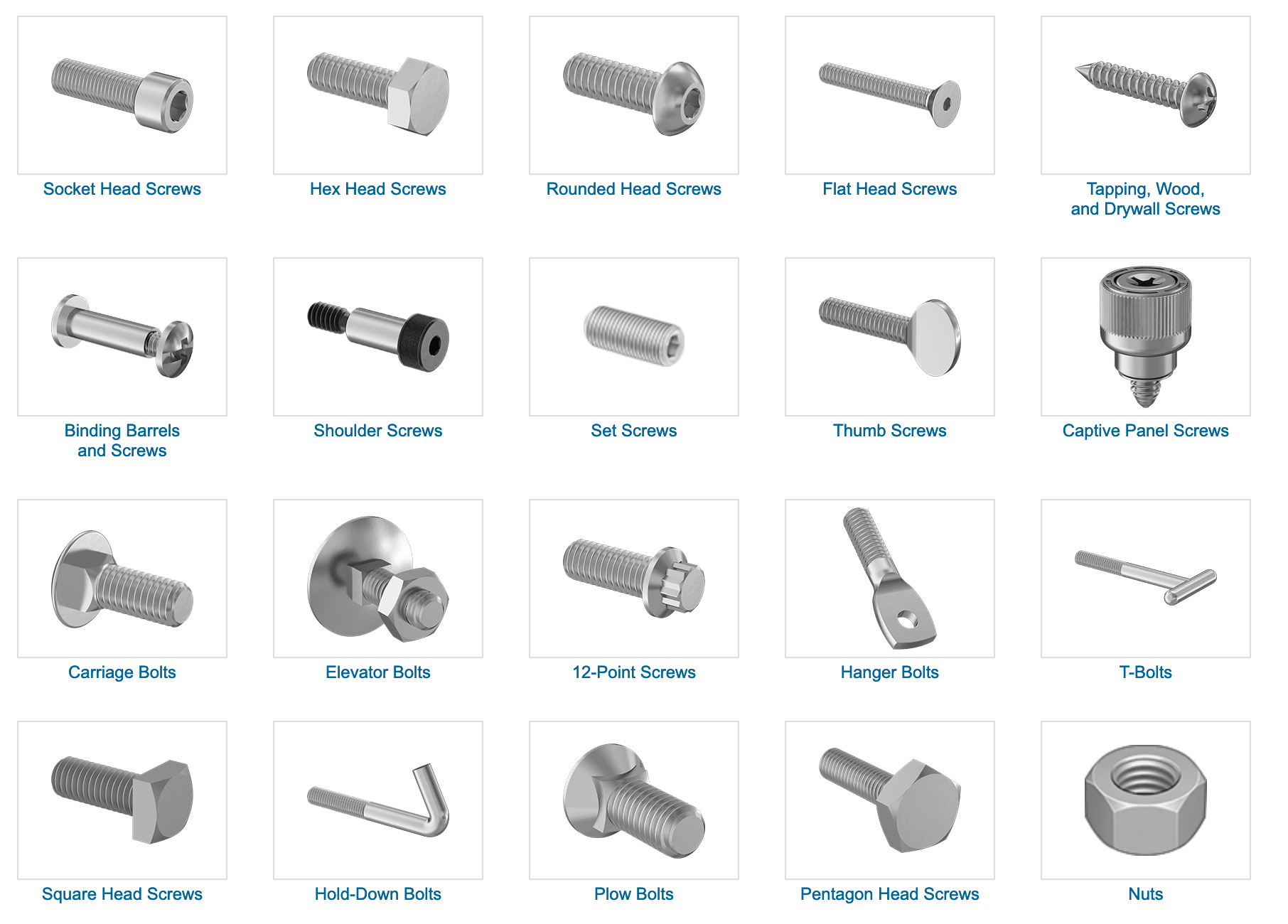

Fasteners are the backbone of countless industries, acting as the essential components that hold together everything from intricate machinery to large-scale construction projects. For B2B buyers operating in diverse markets across Africa, South America, the Middle East, and Europe, understanding the various types of fasteners is not merely beneficial—it is critical for ensuring quality, safety, and efficiency in operations. This comprehensive guide delves into the vast array of fasteners available, including nuts, bolts, screws, rivets, and more, alongside their specific applications and material compositions.

The scope of this guide extends beyond mere identification of fastener types; it encompasses an exploration of materials—from steel and stainless steel to brass and aluminum—each offering unique properties that cater to different project requirements. Additionally, we will address manufacturing quality control standards, sourcing strategies, supplier selection, cost considerations, and market trends that impact procurement decisions.

By empowering international B2B buyers with in-depth knowledge and actionable insights, this guide serves as a valuable resource for informed sourcing. Understanding the intricacies of fasteners not only enhances product selection but also fosters better supplier relationships and contributes to overall project success. Whether you are sourcing for construction projects in Saudi Arabia or manufacturing in Poland, this guide is your key to navigating the global fastener market effectively.

Understanding types of fasteners Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bolts | Headed fasteners with a threaded shaft | Machinery, construction, automotive | Pros: Strong connections, reusable; Cons: Require nuts for use, can be more expensive than screws. |

| Nuts | Internally threaded, typically hexagonal | Used with bolts in various assemblies | Pros: Provide secure fastening; Cons: May require specific sizes and types for compatibility. |

| Screws | Threaded fasteners that can self-tap | Woodwork, electronics, machinery | Pros: Versatile, easy to use; Cons: Can strip if over-tightened, not always reusable. |

| Rivets | Permanent fasteners deformed to secure materials | Aerospace, construction, automotive | Pros: Strong, permanent joints; Cons: Not easily disassembled, limited to specific applications. |

| Washers | Flat or shaped discs used to distribute load | Machinery, construction, plumbing | Pros: Prevents damage to surfaces, enhances load distribution; Cons: May be overlooked in assembly, require proper sizing. |

Bolts

Bolts are essential fasteners characterized by their head and threaded shaft, typically used in conjunction with nuts. They are particularly suitable for applications requiring a strong, durable connection, such as in machinery and construction. When purchasing bolts, B2B buyers should consider the material (e.g., stainless steel for corrosion resistance), thread type, and length, as these factors significantly impact the bolt’s performance in various environments.

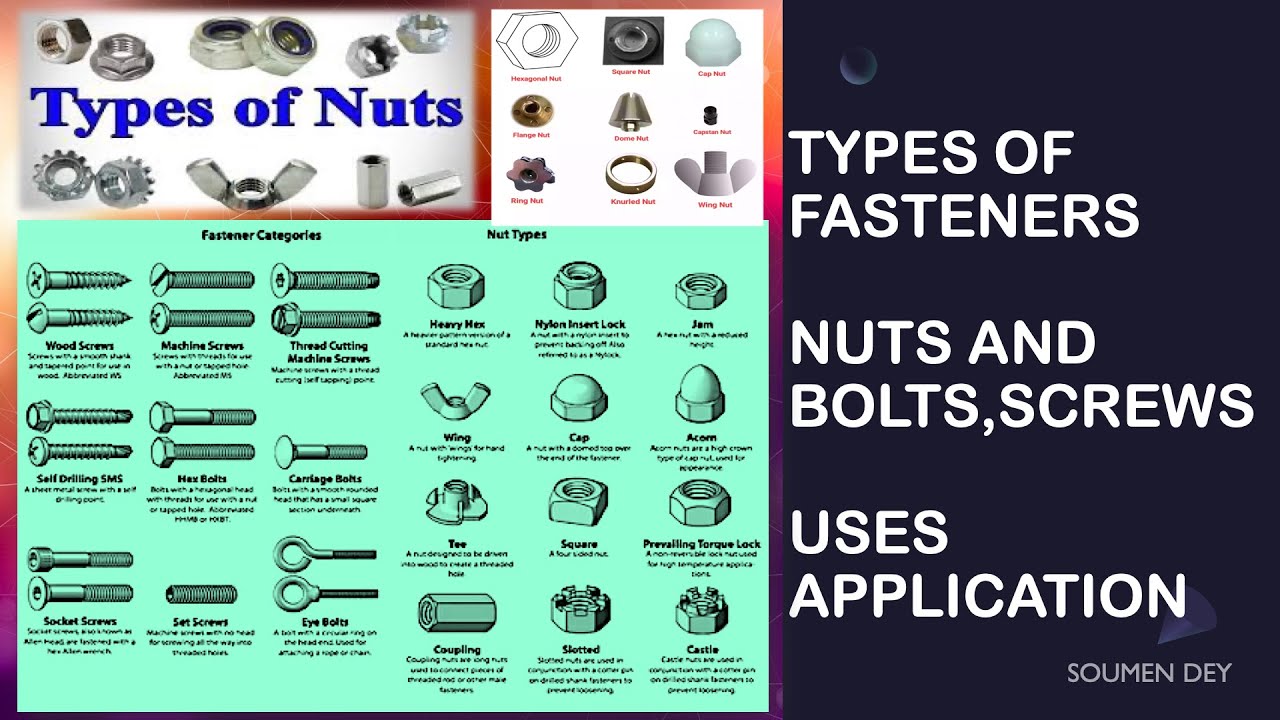

Nuts

Nuts complement bolts and provide the necessary grip to secure assemblies. They are typically hexagonal and come in various materials, including steel and brass. In B2B contexts, selecting the right nut involves understanding the specific requirements of the corresponding bolt, such as thread pitch and size. Buyers should also consider whether locking nuts are needed to prevent loosening under vibration, a common challenge in industrial applications.

Screws

Screws are versatile fasteners that can be driven directly into materials without needing a nut. Their design allows for self-tapping capabilities, making them ideal for wood and soft materials. B2B buyers should assess the type of screw based on the intended application, such as machine screws for machinery or wood screws for carpentry. The choice of material and coating (e.g., galvanized for outdoor use) is crucial to ensure longevity and performance.

Rivets

Rivets create permanent connections by deforming their ends, making them ideal for applications where disassembly is not required, such as in aerospace and automotive industries. When considering rivets, buyers must evaluate factors like material strength and the thickness of the materials being joined. The installation process is also a key consideration, as it requires specific tools and techniques, which can impact labor costs and project timelines.

Washers

Washers are often an overlooked but critical component in fastening applications. They serve to distribute the load of a fastener and protect the surface of the material being fastened. In B2B purchasing, the type of washer (flat, lock, or fender) should align with the specific requirements of the assembly to ensure optimal performance. Buyers should also pay attention to the material and size to prevent issues such as loosening or surface damage during operation.

Related Video: Fasteners | Types of Fasteners |Fasteners in hindi

Key Industrial Applications of types of fasteners

| Industry/Sector | Specific Application of types of fasteners | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural connections in buildings | Ensures safety and durability of structures | Compliance with local building codes and standards |

| Automotive | Assembly of vehicle components | Enhances vehicle performance and safety | Availability of specialized fasteners for different vehicle models |

| Aerospace | Fastening aircraft parts | Critical for safety and performance in flight | Strict adherence to aerospace material specifications and certifications |

| Manufacturing | Machinery assembly | Increases efficiency and reduces downtime | Sourcing from reliable suppliers to ensure quality and consistency |

| Electronics | Assembly of electronic devices | Ensures reliability and longevity of products | Compatibility with various electronic components and materials |

Construction

In the construction industry, fasteners play a pivotal role in ensuring the structural integrity of buildings. They are used to connect beams, columns, and other essential components, providing stability and support. For international buyers, especially from regions like Africa and the Middle East, sourcing fasteners that comply with local building codes is crucial to meet safety standards. Additionally, selecting corrosion-resistant materials is vital in areas with high humidity or extreme weather conditions.

Automotive

Fasteners in the automotive sector are integral to the assembly of various vehicle components, including engines, chassis, and body panels. Their reliability directly affects vehicle performance and safety. B2B buyers from Europe and South America must consider the specific requirements of different vehicle models when sourcing fasteners, ensuring compatibility and adherence to automotive industry standards. The availability of specialized fasteners can also impact production efficiency and cost-effectiveness.

Aerospace

In the aerospace industry, the use of fasteners is critical for the assembly and maintenance of aircraft. They must meet stringent safety and performance standards due to the high stakes involved in air travel. International buyers should focus on sourcing fasteners that comply with aerospace material specifications and certifications, which can vary significantly between regions. Additionally, understanding the specific requirements for weight and strength can help ensure the safety and reliability of aircraft components.

Manufacturing

Fasteners are essential in the manufacturing sector, where they are used to assemble machinery and equipment. They help increase operational efficiency and minimize downtime by ensuring that machines operate smoothly. For B2B buyers, sourcing high-quality fasteners from reliable suppliers is vital to maintain consistency and quality in production processes. Additionally, considerations around lead times and bulk purchasing can significantly impact manufacturing schedules and costs.

Electronics

In the electronics industry, fasteners are used to assemble devices and secure components on circuit boards. The reliability of these fasteners is crucial for the longevity and performance of electronic products. Buyers should prioritize compatibility with various materials and components when sourcing fasteners. Moreover, understanding the specific requirements for size, strength, and corrosion resistance is essential to ensure the final product meets industry standards and customer expectations.

Related Video: Nuts 101 Overview – The Types of Fastener Nuts | Fasteners 101

Strategic Material Selection Guide for types of fasteners

Fasteners are critical components in various industries, and their material selection significantly influences performance, durability, and cost. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the properties and applications of different fastener materials is essential for making informed purchasing decisions. Below is an analysis of four common materials used in fasteners: steel, stainless steel, aluminum, and brass.

Steel Fasteners

Key Properties: Steel fasteners are known for their high tensile strength and versatility. They can withstand significant loads and are suitable for a wide range of applications. However, their performance can be affected by environmental conditions, particularly in terms of corrosion resistance.

Pros & Cons: Steel fasteners are generally cost-effective and readily available. They can be manufactured in various grades, such as low-carbon and high-carbon steel, allowing for tailored performance characteristics. However, they are prone to rust if not treated, which can limit their use in corrosive environments.

Impact on Application: Steel fasteners are ideal for applications involving heavy machinery, construction, and automotive sectors. However, they may not be suitable for environments with high humidity or exposure to chemicals unless properly coated.

Considerations for International Buyers: Compliance with standards such as ASTM or DIN is crucial, especially in regulated markets. Buyers should consider sourcing from manufacturers that adhere to these standards to ensure product quality and reliability.

Stainless Steel Fasteners

Key Properties: Stainless steel fasteners contain chromium, providing excellent corrosion resistance and durability. They can withstand high temperatures and are suitable for both indoor and outdoor applications.

Pros & Cons: The primary advantage of stainless steel fasteners is their resistance to rust and corrosion, making them ideal for marine and chemical applications. However, they are generally more expensive than carbon steel fasteners, which can impact budget considerations.

Impact on Application: Stainless steel fasteners are commonly used in food processing, pharmaceuticals, and marine environments due to their hygienic properties and resistance to corrosion. They are also suitable for high-temperature applications.

Considerations for International Buyers: Buyers should be aware of the different grades of stainless steel (e.g., 304, 316) and their specific applications. Understanding local regulations regarding materials in sensitive industries is also important.

Aluminum Fasteners

Key Properties: Aluminum fasteners are lightweight and have good corrosion resistance. They are non-magnetic and offer excellent thermal and electrical conductivity.

Pros & Cons: The lightweight nature of aluminum makes it an excellent choice for applications where weight reduction is critical, such as in aerospace and automotive industries. However, aluminum fasteners are generally less strong than steel fasteners, which limits their use in heavy-load applications.

Impact on Application: Aluminum fasteners are ideal for applications requiring a combination of strength and weight savings, such as in aircraft and high-performance vehicles. They are also suitable for environments where rust is a concern.

Considerations for International Buyers: Buyers should consider the specific alloy used, as different aluminum alloys have varying properties. Compliance with international standards for aerospace and automotive applications is essential.

Brass Fasteners

Key Properties: Brass fasteners, an alloy of copper and zinc, offer good corrosion resistance and excellent electrical conductivity. They are also aesthetically pleasing due to their shiny appearance.

Pros & Cons: Brass fasteners are ideal for electrical applications and decorative purposes due to their conductivity and appearance. However, they are softer than steel, which can limit their use in high-stress applications.

Impact on Application: Brass fasteners are commonly used in electrical fittings, plumbing, and decorative hardware. Their resistance to corrosion makes them suitable for use in humid environments.

Considerations for International Buyers: Buyers should be aware of the specific applications where brass is suitable and ensure compliance with relevant standards. The availability of brass fasteners can vary by region, so sourcing from reliable suppliers is crucial.

Summary Table

| Material | Typical Use Case for types of fasteners | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery, construction | High strength and versatility | Prone to rust without treatment | Low |

| Stainless Steel | Food processing, marine applications | Excellent corrosion resistance | Higher cost compared to carbon steel | High |

| Aluminum | Aerospace, automotive | Lightweight and good corrosion resistance | Lower strength than steel | Medium |

| Brass | Electrical fittings, plumbing | Good conductivity and aesthetic appeal | Softer, limiting high-stress applications | Medium |

This analysis provides valuable insights for B2B buyers looking to select the appropriate fastener material based on their specific application needs and environmental conditions. Understanding these factors will aid in making informed purchasing decisions that align with industry standards and project requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for types of fasteners

Fasteners are integral components in various industries, ranging from construction to automotive manufacturing. Understanding the manufacturing processes and quality assurance protocols associated with fasteners is crucial for B2B buyers, particularly in diverse markets such as Africa, South America, the Middle East, and Europe. This section will provide an in-depth look at the manufacturing stages, key techniques, international quality standards, and verification methods for fastener suppliers.

Manufacturing Processes

1. Material Preparation

The first stage in fastener manufacturing involves selecting and preparing the raw materials. Common materials include steel, stainless steel, aluminum, and brass. Each material has specific properties that make it suitable for different applications.

Illustrative Image (Source: Google Search)

- Material Selection: Buyers should consider the intended use, environmental factors, and mechanical properties when selecting materials. For instance, stainless steel is favored for corrosion resistance, while carbon steel is preferred for strength and cost-effectiveness.

- Quality Inspection of Raw Materials: Before moving to production, raw materials undergo inspection to ensure they meet required specifications, including tensile strength and chemical composition.

2. Forming

The forming stage is where raw materials are shaped into fasteners using various techniques.

- Cold Heading: This technique involves forging metal at room temperature to create heads on bolts and screws. It is efficient and minimizes material waste.

- Machining: For precision fasteners, machining processes like turning and milling are employed. This is common for custom or specialty fasteners.

- Thread Rolling: This method creates threads on bolts and screws without removing material, improving strength and surface finish.

3. Assembly

Some fasteners, like multi-part assemblies (e.g., anchors or specialized nuts), require assembly. This may involve:

- Inserting Components: For example, lock washers may be added to nuts to enhance security.

- Heat Treatment: This process enhances the mechanical properties of fasteners, improving their strength and resistance to wear.

4. Finishing

The final stage involves applying finishes to protect the fasteners and enhance their appearance.

- Coating: Options include zinc plating, anodizing for aluminum, or black oxide, which can improve corrosion resistance and aesthetics.

- Quality Control: Each batch of finished fasteners undergoes inspection to ensure they meet specifications for dimensions, strength, and finish.

Quality Assurance

Quality assurance is critical in fastener manufacturing, ensuring products meet international and industry-specific standards.

Relevant International Standards

- ISO 9001: This standard focuses on quality management systems. Suppliers should have certifications that demonstrate compliance, ensuring consistent quality and customer satisfaction.

- CE Marking: In Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Specification: For fasteners used in the oil and gas industry, compliance with American Petroleum Institute (API) specifications is essential.

Quality Control Checkpoints

- Incoming Quality Control (IQC): This initial inspection verifies that incoming materials meet specified standards before production begins.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, inspections are conducted to ensure adherence to specifications. This includes monitoring critical dimensions and material properties.

- Final Quality Control (FQC): After production, a thorough inspection of finished fasteners is performed to ensure they meet all quality and performance standards.

Common Testing Methods

- Tensile Testing: Measures the strength and ductility of fasteners.

- Hardness Testing: Assesses the resistance of fasteners to deformation.

- Corrosion Resistance Testing: Evaluates how well fasteners withstand corrosive environments.

Verification Methods for B2B Buyers

To ensure the quality of fasteners sourced from suppliers, B2B buyers should implement robust verification methods.

Supplier Audits

Conducting regular audits of suppliers can help verify their adherence to quality standards. This includes reviewing manufacturing processes, quality control procedures, and compliance with international standards.

Quality Reports

Requesting quality reports from suppliers can provide insights into their quality management practices. These reports should detail test results, production processes, and any corrective actions taken to address quality issues.

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality assurance practices. These inspections can be performed at various stages, including raw material inspection, in-process checks, and final product assessment.

Quality Control and Certification Nuances

International buyers, particularly those in Africa, South America, the Middle East, and Europe, must be aware of regional differences in quality assurance practices.

- Cultural Considerations: Understanding the local culture and business practices can facilitate better communication and collaboration with suppliers. This is particularly important in regions with varying levels of industrial maturity.

- Regulatory Compliance: Different countries may have specific regulations regarding fasteners. For instance, the European Union has strict regulations on materials used in construction. Buyers should ensure that their suppliers comply with these regulations to avoid legal issues.

- Language Barriers: Engaging with suppliers who speak the same language can help mitigate misunderstandings regarding quality specifications and requirements.

By understanding the manufacturing processes and quality assurance protocols related to fasteners, international B2B buyers can make informed decisions, ensuring they partner with reliable suppliers who meet their quality expectations. This diligence not only enhances product reliability but also strengthens supply chain integrity across different markets.

Related Video: fasteners manufacturing process – Ananka Fasteners

Comprehensive Cost and Pricing Analysis for types of fasteners Sourcing

Understanding the cost structure and pricing for fasteners is essential for international B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. This analysis will help buyers navigate the complexities of sourcing fasteners effectively.

Cost Components

The cost of fasteners is influenced by several key components:

-

Materials: The type of material used significantly impacts cost. Steel fasteners are generally less expensive than stainless steel or brass due to material availability and processing costs. High-quality materials may incur a premium but can enhance durability and reduce long-term expenses.

-

Labor: Labor costs vary by region and can influence the final price of fasteners. Regions with higher labor costs may lead to increased manufacturing expenses, which can affect overall pricing.

-

Manufacturing Overhead: This includes utilities, facility costs, and other indirect expenses associated with production. Companies with efficient manufacturing processes can keep overhead lower, potentially passing those savings on to buyers.

-

Tooling: Custom tooling for specific fastener designs can add substantial costs. For high-volume orders, the investment in tooling can be amortized over larger production runs, reducing per-unit costs.

-

Quality Control (QC): Implementing stringent QC measures ensures that fasteners meet industry standards. While this adds to the production cost, it ultimately protects buyers from potential failures and the costs associated with warranty claims or product recalls.

-

Logistics: Transportation costs fluctuate based on distance, shipping method, and incoterms. Buyers should consider logistics as a significant factor in the total cost, particularly for international shipments.

-

Margin: Suppliers typically add a profit margin to cover their costs and achieve profitability. Understanding the supplier’s margin expectations can aid in negotiations.

Price Influencers

Several factors can influence pricing beyond the basic cost components:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly impact pricing. Larger orders often qualify for bulk discounts, whereas smaller orders may incur higher per-unit costs.

-

Specifications/Customization: Custom fasteners tailored to specific applications or standards may come at a premium. Standardized fasteners typically offer better pricing due to economies of scale.

-

Quality/Certifications: Fasteners that meet international standards (e.g., ISO, ASTM) often carry higher prices due to the associated testing and certification processes. Buyers should evaluate whether the certification justifies the cost based on application needs.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may offer premium products at a higher price, while newer entrants might have competitive pricing to gain market share.

-

Incoterms: Understanding shipping terms is crucial. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can impact the total landed cost of fasteners, influencing purchasing decisions.

Buyer Tips

To optimize sourcing and pricing strategies, international B2B buyers should consider the following tips:

-

Negotiate: Leverage volume and long-term contracts to negotiate better pricing. Building strong relationships with suppliers can lead to favorable terms.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the purchase price. This includes considering potential failures, maintenance, and replacement costs associated with inferior fasteners.

-

Pricing Nuances: Be aware of currency fluctuations and import tariffs that can affect pricing. Countries may have different regulations impacting costs, especially in regions like the Middle East and Africa.

-

Market Research: Conduct thorough research on local suppliers in target markets. Understanding local market dynamics can help buyers identify competitive pricing and reliable sourcing options.

In conclusion, a comprehensive understanding of the cost structure, pricing influencers, and strategic buyer tips will empower international B2B buyers to make informed decisions when sourcing fasteners. It’s crucial to approach each procurement with a holistic view of costs and potential savings, ensuring long-term value and efficiency in operations.

- Disclaimer: Prices and cost estimates are indicative and may vary based on market conditions, supplier negotiations, and specific project requirements.*

Spotlight on Potential types of fasteners Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘types of fasteners’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for types of fasteners

Fasteners play a pivotal role in various industrial applications, making it essential for B2B buyers to understand their technical properties and trade terminology. This knowledge not only aids in selecting the right fasteners but also enhances negotiation and procurement processes across international markets.

Key Technical Properties of Fasteners

-

Material Grade

– Fasteners are manufactured from various materials, each with distinct characteristics. Common materials include carbon steel, stainless steel, and aluminum. The material grade indicates the strength and corrosion resistance of the fastener, which is critical for ensuring product longevity and reliability in specific environments.

– B2B Importance: Selecting the appropriate material grade can significantly affect the performance and lifespan of components, especially in industries like construction, automotive, and aerospace. -

Thread Pitch

– This specification refers to the distance between threads on a bolt or screw. It can be measured in threads per inch (TPI) or in millimeters for metric fasteners. The thread pitch is vital for ensuring compatibility between fasteners and the components they will secure.

– B2B Importance: Incorrect thread pitch can lead to improper fastening, resulting in potential failures or safety hazards. Understanding this property helps buyers avoid costly mistakes. -

Tensile Strength

– Tensile strength measures how much force a fastener can withstand before breaking. It is usually expressed in megapascals (MPa) or pounds per square inch (psi). Fasteners with higher tensile strength are suitable for high-stress applications.

– B2B Importance: Buyers must assess the tensile strength required for their specific applications to ensure safety and performance, particularly in load-bearing scenarios. -

Corrosion Resistance

– Fasteners may be treated or coated to enhance their resistance to corrosion, which is critical in environments exposed to moisture, chemicals, or extreme temperatures. Common treatments include galvanization, anodizing, and the use of stainless steel.

– B2B Importance: Understanding corrosion resistance helps buyers select fasteners that will maintain integrity over time, reducing maintenance costs and enhancing durability. -

Tolerance

– Tolerance refers to the allowable deviation from specified dimensions, crucial for ensuring proper fit and function in assembly processes. This includes variations in diameter, length, and thread specifications.

– B2B Importance: Accurate tolerances prevent assembly issues and ensure that fasteners perform as expected, which is vital for manufacturers looking to maintain quality control.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is essential for ensuring compatibility and quality in fastener procurement. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest number of units a supplier is willing to sell. It can vary significantly between suppliers and product types. Knowledge of MOQ is essential for budgeting and inventory management. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to request pricing and terms for specific fasteners. This process allows buyers to compare offers and negotiate better deals. Familiarity with RFQ processes can streamline procurement. -

Incoterms

– International Commercial Terms (Incoterms) define the responsibilities of buyers and sellers in international transactions, particularly regarding shipping and delivery. Understanding these terms is crucial for managing logistics and cost expectations. -

Lead Time

– Lead time refers to the time taken from placing an order to delivery. It includes manufacturing and shipping durations. Recognizing lead times helps buyers plan projects effectively and manage supply chain expectations.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions that enhance project efficiency and cost-effectiveness in sourcing fasteners. Understanding these aspects also facilitates smoother negotiations and builds stronger supplier relationships.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the types of fasteners Sector

Market Overview & Key Trends

The global fasteners market is experiencing robust growth driven by several factors, including increasing industrialization, infrastructure development, and the booming automotive sector. As countries in Africa, South America, the Middle East, and Europe continue to invest in infrastructure projects, the demand for reliable fastening solutions has surged. In particular, regions like Saudi Arabia are focusing on mega projects such as NEOM, creating a significant market for fasteners in construction and engineering applications.

Illustrative Image (Source: Google Search)

Emerging technologies are reshaping sourcing trends in the fastener industry. The adoption of Industry 4.0 technologies, such as IoT and AI, is enhancing supply chain efficiency and transparency. These technologies enable real-time tracking of fastener production and delivery, allowing buyers to make informed decisions based on data analytics. Furthermore, digital marketplaces are becoming increasingly popular, providing international B2B buyers easier access to a broader range of suppliers and products.

Additionally, there is a notable shift towards customization and specialty fasteners. As manufacturing processes evolve, buyers are looking for fasteners tailored to specific applications, such as aerospace, automotive, and renewable energy sectors. This trend emphasizes the need for suppliers to innovate and offer diverse product lines that meet unique specifications.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical concern for international B2B buyers in the fasteners sector. The environmental impact of fastener production, particularly in terms of energy consumption and waste generation, necessitates a focus on sustainable practices. Buyers are increasingly seeking suppliers that prioritize eco-friendly manufacturing processes, such as using recycled materials and minimizing emissions.

Ethical sourcing is also gaining traction, as companies are held accountable for their supply chain practices. Buyers should verify that their suppliers adhere to ethical labor practices and environmental regulations. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical sourcing.

Moreover, the use of “green” materials, such as bioplastics or sustainably sourced metals, is on the rise. Fasteners made from these materials not only reduce environmental impact but also appeal to consumers who prioritize sustainability. Buyers should consider integrating these eco-friendly fasteners into their projects to enhance their corporate social responsibility (CSR) profiles.

Brief Evolution/History

The fasteners industry has evolved significantly since its inception, reflecting broader technological advancements and industrial needs. Early fastening methods included simple wooden pegs and nails, which were gradually replaced by metal fasteners as metallurgy improved. The industrial revolution marked a pivotal moment, introducing standardized fastener sizes and mass production techniques, significantly enhancing the availability and reliability of fasteners.

In recent decades, the fasteners sector has seen innovations such as the development of high-strength alloys and corrosion-resistant coatings, addressing the demands of modern engineering applications. Today, fasteners are integral to numerous industries, from construction to aerospace, demonstrating their critical role in facilitating global trade and commerce. As the market continues to evolve, international buyers must stay abreast of these changes to make informed sourcing decisions.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of types of fasteners

-

What criteria should I use to vet suppliers of fasteners?

When vetting suppliers, consider their industry experience, reputation, and financial stability. Request references from previous clients and check for certifications such as ISO 9001 for quality management. It’s also beneficial to evaluate their production capabilities, including technology and workforce skills, as well as their ability to meet specific standards required in your region, such as ASTM or DIN specifications. Conducting site visits can provide further insights into their operations and quality assurance processes. -

Can fasteners be customized to meet my specific requirements?

Yes, many manufacturers offer customization options for fasteners, including size, material, and finish. When seeking custom solutions, provide detailed specifications, including dimensions, load requirements, and environmental considerations. Engage in discussions early in the sourcing process to understand the supplier’s capabilities and limitations. Ensure that any customizations comply with relevant industry standards to avoid future complications. -

What are the typical minimum order quantities (MOQs) and lead times for fasteners?

MOQs for fasteners can vary significantly based on the type, material, and supplier. Standard fasteners may have lower MOQs, while custom fasteners often require larger orders. Lead times typically range from a few weeks to several months, depending on production schedules and material availability. Always clarify these details upfront to align with your project timelines and avoid delays in your supply chain. -

How can I ensure the quality of fasteners I source internationally?

To ensure quality, request material and process certifications from the supplier, such as certificates of compliance or test reports. Establish a quality assurance protocol that includes inspections at various stages of production. Consider third-party quality audits or using local inspection services to verify that the fasteners meet your specifications before shipping. Implementing a clear return policy for non-conforming products can also mitigate risks. -

What payment options are typically available for international fastener purchases?

Payment options may include wire transfers, letters of credit, or PayPal, depending on the supplier’s policies and your negotiation. Letters of credit are often preferred for larger transactions as they provide security to both parties. Clarify the payment terms, including deposits and final payments, and understand any currency exchange implications. Establishing a reliable payment method can help maintain a good relationship with your supplier. -

What logistics considerations should I keep in mind when importing fasteners?

When importing fasteners, consider shipping methods, customs regulations, and potential tariffs. Choose reliable logistics partners who specialize in international shipping and understand the specific requirements for fasteners. Ensure that all documentation, including commercial invoices and packing lists, is accurate and complete to avoid delays at customs. Additionally, factor in lead times for shipping and potential delays due to regulatory checks. -

How should I handle disputes with suppliers regarding fasteners?

Establish a clear communication protocol to address issues as they arise, documenting all correspondence. If a dispute occurs, refer to your contract terms, which should outline procedures for conflict resolution. Consider mediation or arbitration as alternative dispute resolution methods to avoid lengthy legal battles. Maintaining a professional and collaborative approach can often lead to a more favorable resolution for both parties. -

What certifications should I look for in fasteners sourced from international suppliers?

Look for certifications that validate the quality and safety of fasteners, such as ISO 9001 for quality management systems, ISO 14001 for environmental management, and specific product certifications relevant to your industry. Depending on your market, you may also need compliance with regional standards like CE marking in Europe or ANSI standards in the U.S. Request documentation to verify these certifications, ensuring that the fasteners meet the required safety and performance criteria for your applications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for types of fasteners

Fasteners are a vital component in the manufacturing and construction sectors, underpinning the integrity of countless applications across industries. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the diverse types of fasteners—such as nuts, bolts, screws, and rivets—enables you to make informed sourcing decisions that align with your project requirements.

Key Takeaways:

– Strategic Sourcing: Prioritize suppliers who offer a comprehensive range of fasteners, ensuring compliance with international standards and certifications. This will mitigate risks related to quality and performance.

– Material Considerations: Choose the right material for your application—be it steel, stainless steel, aluminum, or brass—based on environmental conditions and mechanical requirements.

– Cost Efficiency: Evaluate total cost of ownership, factoring in durability, maintenance, and lifecycle, to optimize your procurement strategy.

Looking ahead, the fastener market is poised for innovation, driven by advancements in materials and manufacturing technologies. Engage with reputable suppliers and stay abreast of market trends to secure your competitive advantage. By making strategic sourcing decisions today, you can ensure the success of your projects tomorrow.