Master Sourcing Strategies for Reliable DC Power Supply

Introduction: Navigating the Global Market for dc power supply

Navigating the complexities of the global market for DC power supplies is essential for B2B buyers seeking reliability and performance in electronic systems. As the backbone of modern technology, DC power supplies deliver stable and adjustable direct current, crucial for diverse applications ranging from industrial machinery to sensitive electronic devices. Understanding the nuances of these power supplies enables buyers from regions such as Africa, South America, the Middle East, and Europe to make informed decisions that directly impact efficiency and operational success.

This guide offers a comprehensive exploration of DC power supplies, including their various types—such as linear, switching, and programmable power supplies—alongside critical insights into materials, manufacturing processes, and quality control standards. Additionally, we delve into the supplier landscape and cost considerations, providing a holistic view of the market dynamics.

By addressing common FAQs, this resource empowers international B2B buyers to navigate sourcing challenges effectively. With actionable insights tailored to specific regional needs, decision-makers can leverage the right DC power supply solutions to enhance competitiveness and drive innovation across industries. Ultimately, this guide serves as a vital tool for those looking to optimize their power supply strategies and ensure the seamless operation of their electronic systems in an ever-evolving marketplace.

Understanding dc power supply Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Linear Power Supply | Simple design, stable output, low noise | Laboratory equipment, audio devices | Pros: High stability, low ripple. Cons: Less efficient, bulkier. |

| Switching Power Supply | High efficiency, compact size, converts power efficiently | Industrial machinery, consumer electronics | Pros: Lightweight, versatile. Cons: More complex, potential EMI issues. |

| Programmable DC Power Supply | Allows dynamic voltage and current adjustments | Testing, research and development environments | Pros: Flexible control, ideal for testing. Cons: Higher cost, may require training. |

| Uninterruptible Power Supply | Provides backup power, protects against power surges | Data centers, hospitals, critical infrastructure | Pros: Ensures operational continuity, surge protection. Cons: Higher initial investment, maintenance required. |

| DC-DC Converter | Adjusts DC voltage levels for specific applications | Renewable energy systems, electric vehicles | Pros: Efficient voltage regulation, compact. Cons: Limited by input voltage range. |

Linear Power Supply

Linear power supplies are recognized for their straightforward design and the ability to provide stable, low-noise outputs. They are particularly suitable for sensitive applications such as laboratory equipment and high-fidelity audio devices. When considering a purchase, B2B buyers should weigh the benefits of high stability against the trade-offs of size and efficiency, as these units tend to be bulkier and generate more heat, necessitating additional cooling solutions.

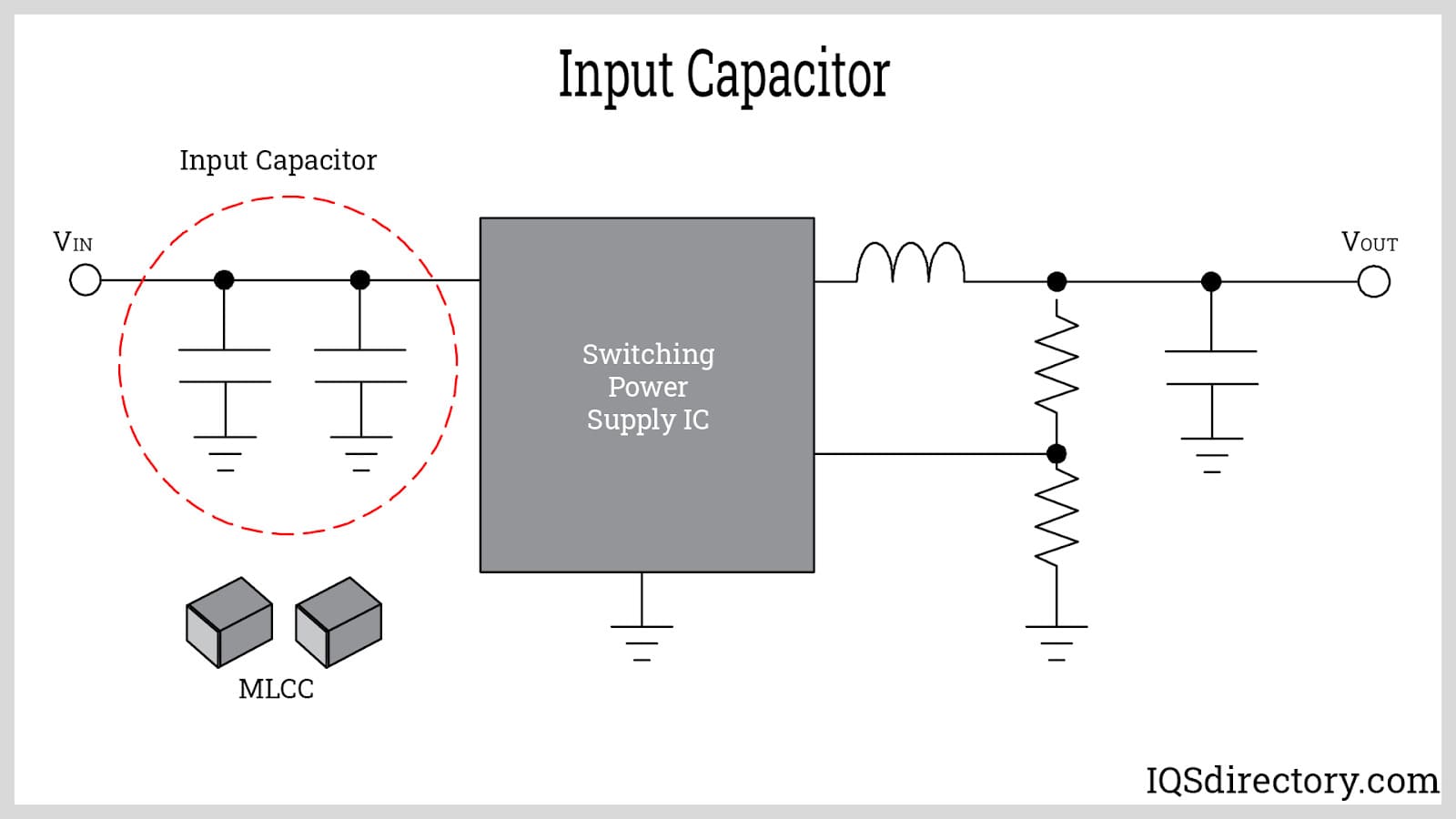

Switching Power Supply

Switching power supplies are designed for high efficiency and compactness, making them ideal for applications in industrial machinery and consumer electronics. They convert electrical power efficiently, allowing for significant space and energy savings. However, buyers must be cautious of the complexity and potential for electromagnetic interference (EMI). A thorough assessment of application requirements is essential to ensure compatibility and mitigate any risks associated with noise.

Programmable DC Power Supply

Programmable DC power supplies offer the unique advantage of allowing users to dynamically set voltage and current levels, making them invaluable in testing and research settings. Their flexibility is a major selling point, as they can adapt to varying power requirements. However, buyers should consider the higher cost associated with these units and ensure that their team is adequately trained to utilize the programmable features effectively.

Uninterruptible Power Supply

Uninterruptible Power Supplies (UPS) are critical for applications requiring continuous operation, such as data centers and hospitals. They provide backup power and protect sensitive equipment from power surges. While UPS systems ensure operational continuity, they come with a higher initial investment and ongoing maintenance costs. Buyers should evaluate their infrastructure’s power needs and potential risks before making a purchase, ensuring they select a UPS that aligns with their operational requirements.

DC-DC Converter

DC-DC converters are specialized devices that adjust DC voltage levels, making them essential for applications in renewable energy systems and electric vehicles. They excel in battery-powered devices where efficient voltage regulation is crucial. B2B buyers should carefully assess the input voltage range and output specifications when selecting a DC-DC converter, as these factors can significantly impact performance. Their compact and efficient design makes them a vital component in modern electronics.

Related Video: All Power Supply Cable Types EXPLAINED

Key Industrial Applications of dc power supply

| Industry/Sector | Specific Application of dc power supply | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics Manufacturing | Testing and Prototyping of Circuit Boards | Ensures reliable performance and quality assurance | Look for programmable power supplies with precise voltage control |

| Telecommunications | Powering Base Stations and Communication Equipment | Supports uninterrupted service and network reliability | Evaluate efficiency ratings and compatibility with existing systems |

| Medical Equipment | Operating Imaging Devices (MRI, CT Scanners) | Guarantees accuracy and safety in critical healthcare settings | Prioritize high-voltage and low-noise power supplies |

| Renewable Energy | Charging and Managing Battery Systems | Enhances energy efficiency and sustainability | Consider input voltage ranges and regulatory compliance |

| Automotive | Powering Electric Vehicle (EV) Charging Stations | Facilitates the transition to electric mobility | Assess charging speed capabilities and integration with grid systems |

Electronics Manufacturing

In electronics manufacturing, DC power supplies are critical for testing and prototyping circuit boards. They provide a stable and adjustable voltage, allowing engineers to simulate real-world conditions and ensure that designs meet specifications. For international buyers, particularly in regions like Africa and South America, sourcing programmable power supplies with precise voltage control is essential to maintain quality assurance and reliability in production processes.

Telecommunications

DC power supplies are essential for powering base stations and communication equipment in the telecommunications sector. They ensure that networks remain operational, providing uninterrupted service to customers. Buyers from the Middle East and Europe should evaluate the efficiency ratings of power supplies and their compatibility with existing systems to guarantee network reliability, especially in areas with fluctuating power quality.

Illustrative Image (Source: Google Search)

Medical Equipment

In the medical field, DC power supplies are used to operate imaging devices such as MRI and CT scanners. These power supplies must provide high voltage and low noise to ensure accuracy and safety during medical procedures. B2B buyers, particularly in Europe and the Middle East, should prioritize sourcing high-voltage power supplies that meet stringent regulatory standards and ensure optimal performance in critical healthcare settings.

Renewable Energy

DC power supplies play a vital role in charging and managing battery systems within renewable energy applications. They enhance energy efficiency and sustainability by providing reliable and adjustable power for solar and wind energy systems. International buyers, especially from Africa and South America, should consider the input voltage ranges of power supplies to ensure compatibility with local energy sources and regulatory compliance.

Automotive

In the automotive sector, DC power supplies are crucial for powering electric vehicle (EV) charging stations. They facilitate the transition to electric mobility by providing fast and efficient charging solutions. Buyers from regions like Europe and the Middle East should assess the charging speed capabilities of power supplies and their integration with grid systems, ensuring they meet the growing demand for EV infrastructure.

Related Video: Diode Tutorial & How to build an AC to DC power supply

Strategic Material Selection Guide for dc power supply

When selecting materials for DC power supplies, international B2B buyers should consider the properties, advantages, and limitations of various materials. This analysis focuses on four common materials used in the construction of DC power supplies: aluminum, copper, stainless steel, and plastic. Each material has unique characteristics that can significantly impact the performance and suitability of the final product.

Aluminum

Key Properties:

Aluminum is lightweight and has excellent thermal conductivity, making it suitable for heat dissipation in power supplies. It typically has a temperature rating of up to 150°C and is resistant to corrosion when anodized.

Pros & Cons:

The primary advantage of aluminum is its low weight and good thermal properties, which facilitate efficient heat management. However, it can be more expensive than other metals and may require additional coatings to enhance corrosion resistance. Manufacturing complexity is moderate, as aluminum can be easily extruded and machined.

Impact on Application:

Aluminum is particularly effective in applications where weight is a concern, such as portable or compact DC power supplies. Its compatibility with various electronic components makes it a favorable choice in many sectors, including telecommunications and automotive.

Considerations for International Buyers:

Buyers in regions like Africa and South America should ensure compliance with local regulations regarding material specifications. Standards such as ASTM B221 for aluminum extrusions may be relevant. Additionally, the availability of aluminum may vary by region, impacting lead times.

Copper

Key Properties:

Copper boasts excellent electrical conductivity and thermal performance. It can handle high temperatures (up to 200°C) and has good corrosion resistance, especially when coated.

Pros & Cons:

Copper’s superior conductivity makes it ideal for applications requiring efficient power transmission. However, its high cost and weight can be drawbacks, particularly for large-scale power supplies. Manufacturing processes can be complex due to the need for precise machining and soldering.

Impact on Application:

Copper is widely used in wiring and connectors within DC power supplies, ensuring minimal energy loss. Its high thermal conductivity also aids in heat dissipation, making it suitable for high-performance applications.

Considerations for International Buyers:

Buyers should be aware of copper’s fluctuating market prices and potential supply chain issues. Compliance with standards like ASTM B170 for copper may be necessary, particularly in regulated industries.

Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance and strength, with a temperature rating of up to 300°C. It is also resistant to oxidation, making it suitable for harsh environments.

Pros & Cons:

The primary advantage of stainless steel is its durability and resistance to corrosion, which extends the lifespan of power supplies. However, it is heavier and more expensive than aluminum, and its manufacturing can be more complex due to the material’s toughness.

Impact on Application:

Stainless steel is ideal for outdoor or industrial applications where exposure to moisture and chemicals is a concern. Its robust nature makes it suitable for environments in the Middle East where high temperatures and humidity can affect performance.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM A240 for stainless steel. Understanding local sourcing capabilities is crucial, as stainless steel may be less readily available in some regions.

Plastic

Key Properties:

Plastics, particularly high-temperature thermoplastics, can withstand temperatures up to 120°C and offer good electrical insulation properties. They are lightweight and can be molded into complex shapes.

Pros & Cons:

The primary advantage of plastic is its low cost and versatility in design. However, plastics may not offer the same level of durability or heat resistance as metals, which can limit their use in high-performance applications.

Impact on Application:

Plastic is often used for enclosures and insulation in DC power supplies, providing protection against environmental factors. It is suitable for consumer electronics and applications where weight and cost are critical factors.

Considerations for International Buyers:

Buyers should consider compliance with standards such as UL 94 for flammability and other relevant safety standards. Additionally, local regulations regarding plastic use and recycling should be taken into account.

| Material | Typical Use Case for dc power supply | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Heat sinks, enclosures | Lightweight, good thermal conductivity | Higher cost than some alternatives | Medium |

| Copper | Wiring, connectors | Excellent electrical conductivity | High cost, heavier | High |

| Stainless Steel | Industrial applications, enclosures | Corrosion resistance, durability | Heavy, expensive | High |

| Plastic | Enclosures, insulation | Low cost, versatile design | Limited durability, heat resistance | Low |

This guide provides a comprehensive overview of the materials commonly used in DC power supplies, equipping international B2B buyers with the insights needed to make informed decisions that align with their operational needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for dc power supply

DC power supplies are integral components across a variety of industries, and understanding their manufacturing processes and quality assurance protocols is crucial for international B2B buyers. This section provides a detailed examination of the typical manufacturing stages and quality control measures involved in the production of DC power supplies.

Manufacturing Processes for DC Power Supplies

The manufacturing of DC power supplies can be broken down into several key stages, each critical for ensuring product performance and reliability.

1. Material Preparation

The first step involves selecting and preparing high-quality materials. Common materials used include copper for winding, silicon for semiconductors, and various plastics for housing. Manufacturers typically conduct material inspections to ensure compliance with specifications.

- Key Techniques:

- Use of advanced material analysis techniques (e.g., spectroscopy) to confirm material properties.

- Sourcing materials from certified suppliers to guarantee quality.

2. Forming

In this stage, raw materials are shaped into the necessary components for the power supply. This includes winding copper wire into transformers and manufacturing circuit boards.

- Key Techniques:

- Surface Mount Technology (SMT): For placing electronic components on the circuit board efficiently.

- Die Casting: For creating metal parts, ensuring durability and heat dissipation.

3. Assembly

The assembly process brings together all components, including transformers, capacitors, and circuit boards. This stage is critical for ensuring that all elements fit together correctly and function as intended.

- Key Techniques:

- Automated Assembly: Utilizing robotic systems to enhance precision and speed.

- Manual Assembly: Employed for intricate components where human oversight is beneficial.

4. Finishing

This final stage includes the application of protective coatings, labeling, and packaging. The goal is to ensure the product is ready for shipping while maintaining its integrity.

- Key Techniques:

- Conformal Coating: Protects electronic components from moisture and dust.

- Quality Packaging: Ensures that products are safeguarded during transport.

Quality Assurance Protocols

Quality assurance in DC power supply manufacturing is vital to meet international standards and customer expectations.

Relevant International Standards

International standards such as ISO 9001 are essential in the manufacturing process. This standard focuses on quality management systems and ensures that manufacturers consistently meet customer and regulatory requirements.

Illustrative Image (Source: Google Search)

- Industry-Specific Standards:

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: Relevant for power supplies used in oil and gas applications, ensuring safety and reliability.

Quality Control Checkpoints

Quality control is integrated throughout the manufacturing process, typically encompassing the following checkpoints:

- Incoming Quality Control (IQC): Inspects raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitors the production process at various stages to identify defects early.

- Final Quality Control (FQC): Conducts comprehensive testing on finished products before they are shipped.

Common Testing Methods

Testing methods for DC power supplies vary but commonly include:

- Load Testing: Ensures the power supply can handle its rated load without failure.

- Thermal Testing: Assesses the performance of the unit under various temperature conditions.

- Electrical Testing: Checks for voltage, current, and ripple specifications to ensure compliance with design requirements.

Verifying Supplier Quality Control

International B2B buyers can take several steps to verify the quality control processes of their suppliers:

- Audits: Conduct regular on-site audits to evaluate manufacturing practices and quality control systems.

- Quality Assurance Reports: Request detailed reports that outline the QC processes, including results from testing and inspections.

- Third-Party Inspections: Engage independent inspection agencies to validate the quality of products before shipment.

Quality Control and Certification Nuances for International Buyers

For buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification can significantly impact sourcing decisions:

- Regulatory Compliance: Different regions have specific regulations that manufacturers must adhere to. Buyers should ensure that their suppliers are compliant with local and international standards.

- Cultural Differences in Quality Expectations: Recognizing that quality perceptions may vary across cultures can help buyers communicate their needs more effectively.

- Supply Chain Transparency: Engaging with suppliers who offer transparency regarding their manufacturing processes and quality control can enhance trust and collaboration.

Conclusion

In conclusion, understanding the manufacturing processes and quality assurance protocols for DC power supplies is essential for B2B buyers aiming to make informed purchasing decisions. By focusing on material preparation, forming, assembly, finishing, and quality control measures, buyers can ensure they source reliable and efficient products that meet their specific needs. Additionally, leveraging international standards and conducting thorough supplier evaluations will help mitigate risks and enhance operational success in a competitive global market.

Related Video: 18650 Cell Manufacturing Process, Automatic Production Line

Comprehensive Cost and Pricing Analysis for dc power supply Sourcing

Understanding the cost structure and pricing dynamics of DC power supplies is crucial for international B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. This analysis outlines the key components that influence pricing and provides actionable insights for making informed sourcing decisions.

Cost Components

-

Materials: The quality of materials used in manufacturing DC power supplies significantly impacts the overall cost. Components such as capacitors, inductors, semiconductors, and heat sinks vary in price based on performance specifications and supplier sourcing. Buyers should consider sourcing from reputable suppliers to ensure quality without excessive costs.

-

Labor: Labor costs can fluctuate based on geographic location and the complexity of the manufacturing process. Regions with lower labor costs may offer competitive pricing, but this can affect the quality and reliability of the product. It is essential to evaluate the labor standards and training of the workforce involved in production.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Efficient production processes can help mitigate these costs. Buyers should inquire about the supplier’s operational efficiencies, as these can translate into cost savings.

-

Tooling: The initial investment in tooling for specialized DC power supplies can be significant. Custom designs may require unique molds or assembly lines, which can increase costs. Understanding the tooling requirements for specific products can help buyers negotiate better pricing.

-

Quality Control (QC): Rigorous quality control processes ensure that products meet industry standards and certifications. Suppliers with robust QC practices may have higher upfront costs, but this often leads to lower failure rates and reduced long-term costs for buyers.

-

Logistics: Shipping costs can vary widely based on the supplier’s location, the shipping method, and the delivery time frame. Buyers should consider the total logistics costs when evaluating suppliers, especially for international shipments.

-

Margin: Suppliers typically incorporate a profit margin into their pricing. Understanding the industry standard margins can help buyers gauge whether a quoted price is fair or inflated.

Price Influencers

-

Volume/MOQ: Pricing often decreases with larger order volumes. Buyers should assess their needs to negotiate minimum order quantities (MOQs) that offer cost savings without overcommitting to inventory.

-

Specifications/Customization: Custom specifications can significantly impact pricing. Buyers should clearly define their requirements and understand how these affect the cost structure.

-

Materials: The choice of materials can lead to variations in price. High-performance materials may command a premium but can enhance product longevity and efficiency.

-

Quality/Certifications: Products with recognized certifications (e.g., ISO, CE) typically carry higher costs due to the assurance of quality. Buyers should weigh the benefits of certified products against their budget.

-

Supplier Factors: Established suppliers may charge more due to their reputation and reliability. However, emerging suppliers may offer competitive pricing to gain market share. Evaluating supplier stability and track record is crucial.

-

Incoterms: The agreed-upon shipping terms can influence the final cost. Buyers should familiarize themselves with Incoterms to understand their responsibilities and potential costs associated with shipping and customs.

Buyer Tips

-

Negotiation: Engage in open discussions with suppliers about pricing, especially when committing to larger orders. Understanding their cost structure can provide leverage during negotiations.

-

Cost-Efficiency: Evaluate total cost of ownership (TCO), which includes initial purchase price, installation, maintenance, and operational costs. A lower initial cost may lead to higher long-term expenses.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and local tariffs that can affect pricing. Establishing contracts in a stable currency can mitigate risk.

-

Research and Comparison: Conduct thorough market research to compare pricing among different suppliers and regions. This can reveal significant differences based on local economic conditions and supplier capabilities.

-

Long-term Relationships: Building long-term partnerships with suppliers can lead to better pricing and service. Suppliers are often willing to offer discounts or improved terms for loyal customers.

Disclaimer

The prices discussed in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific product requirements. Buyers are encouraged to conduct their own research and engage directly with suppliers for the most accurate pricing information.

Spotlight on Potential dc power supply Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘dc power supply’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for dc power supply

Key Technical Properties of DC Power Supplies

Understanding the essential specifications of DC power supplies is crucial for B2B buyers to make informed purchasing decisions. Here are several critical technical properties that should be considered:

-

Output Voltage: This specification indicates the voltage level that the DC power supply can deliver. For many applications, it’s essential to select a power supply that matches the voltage requirements of the equipment being powered. A mismatch can lead to equipment failure or inefficient operation.

-

Output Current: Measured in amperes (A), this property specifies the maximum current the power supply can provide. It’s vital for buyers to ensure that the power supply can handle the current demands of the connected devices without overheating or failing.

-

Ripple Voltage: This term refers to the small, unwanted AC voltage superimposed on the DC output. Ripple voltage can affect the performance of sensitive electronic devices, making it important for buyers to choose a power supply with low ripple voltage for applications requiring high precision, such as in laboratory settings.

-

Efficiency: Expressed as a percentage, efficiency measures how much input power is converted into usable output power. Higher efficiency reduces energy costs and minimizes heat generation, which is particularly important in applications where thermal management is critical.

-

Load Regulation: This property indicates how well the power supply maintains its output voltage when the load changes. A power supply with good load regulation ensures consistent performance even as the demand for power fluctuates, which is vital for maintaining the stability of connected devices.

-

Material Grade: This refers to the quality of materials used in the construction of the power supply. Higher-grade materials often enhance durability and reliability, which are crucial for long-term operation, especially in harsh environments.

Common Trade Terminology

In addition to technical properties, familiarity with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify quality suppliers and assess compatibility with existing systems.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is critical for budgeting and inventory management, particularly for international buyers who may need to account for shipping costs and minimum order sizes.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. Buyers should provide detailed specifications in their RFQs to ensure accurate quotes and avoid misunderstandings.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities, which is vital for international procurement.

-

Lead Time: This term refers to the amount of time it takes from placing an order until the product is delivered. Understanding lead times is essential for effective project planning and ensuring that operations run smoothly without delays.

-

Warranty: A warranty is a guarantee provided by the manufacturer regarding the condition of the product and the commitment to repair or replace it if necessary. Buyers should carefully review warranty terms to protect their investments and ensure long-term support.

By understanding these technical properties and trade terminologies, international B2B buyers can navigate the complexities of sourcing DC power supplies more effectively, ensuring they choose the right products for their specific needs while fostering strong supplier relationships.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the dc power supply Sector

Market Overview & Key Trends

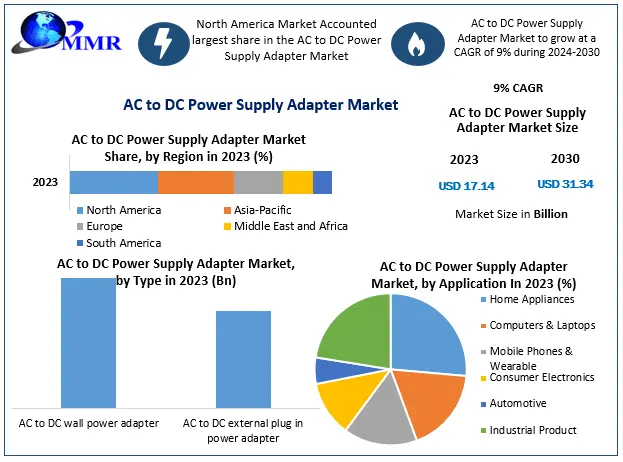

The global DC power supply market is experiencing significant growth, driven by several factors including the increasing demand for electronic devices, advancements in renewable energy technologies, and the ongoing shift towards electric vehicles (EVs). As industries across Africa, South America, the Middle East, and Europe embrace digital transformation, the need for reliable and efficient power sources has intensified. B2B buyers must stay attuned to emerging technologies such as programmable DC power supplies, which offer enhanced flexibility for testing and development applications.

Key trends shaping the market include the rise of smart power supplies equipped with IoT capabilities, enabling remote monitoring and control. This trend is particularly relevant for sectors like telecommunications and data centers, where real-time performance insights are crucial. Furthermore, the increasing emphasis on energy efficiency and compact design is driving the adoption of switching-mode power supplies (SMPS), which provide high performance while minimizing space and energy consumption.

In addition, the competitive landscape is evolving with a growing number of suppliers entering the market, offering a diverse range of products tailored to specific applications. This influx of suppliers provides buyers with more options but also necessitates careful evaluation of quality, reliability, and service support. For international B2B buyers, understanding local regulations and standards is essential for ensuring compliance and optimizing procurement strategies.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a pivotal consideration in the sourcing of DC power supplies. The environmental impact of manufacturing processes, materials used, and energy consumption during the product lifecycle are critical factors that buyers must evaluate. Selecting suppliers who prioritize sustainable practices can significantly reduce the carbon footprint associated with power supply systems.

Ethical sourcing is equally important, particularly as global supply chains become more interconnected. Buyers should seek manufacturers that demonstrate transparency in their sourcing practices, ensuring that materials are obtained responsibly and ethically. Certifications such as ISO 14001 (Environmental Management) and Energy Star can serve as indicators of a supplier’s commitment to sustainability.

Furthermore, the use of ‘green’ materials in the production of DC power supplies—such as recyclable components and low-impact manufacturing processes—can enhance a company’s sustainability profile. Buyers in Africa, South America, the Middle East, and Europe are increasingly recognizing the value of incorporating sustainability into their procurement strategies, not only to meet regulatory requirements but also to enhance brand reputation and customer loyalty.

Brief Evolution/History

The evolution of DC power supplies has been marked by significant technological advancements since their inception. Initially, linear power supplies dominated the market due to their simplicity and reliability. However, with the increasing demand for compact and efficient solutions, switching power supplies emerged in the late 20th century, revolutionizing the industry. These power supplies offered higher efficiency and a smaller footprint, catering to the growing needs of consumer electronics and industrial applications.

Today, the focus has shifted towards programmable and smart DC power supplies, which integrate advanced features such as remote monitoring and control. This evolution reflects the broader trends of digital transformation and the Internet of Things (IoT), positioning DC power supplies as essential components in modern electronic systems. For B2B buyers, understanding this historical context can provide valuable insights into the technological capabilities and future directions of the DC power supply market.

Related Video: Global trade will never be the same again, says Christine Lagarde | Power & Politics

Frequently Asked Questions (FAQs) for B2B Buyers of dc power supply

-

What criteria should I use to vet potential DC power supply suppliers?

When vetting suppliers, consider their industry experience, product certifications, and customer reviews. Look for suppliers with established reputations in your target market, particularly those familiar with the standards and regulations in Africa, South America, the Middle East, and Europe. Verify their manufacturing capabilities, quality control processes, and after-sales support. Engaging in direct communication to assess their responsiveness and willingness to provide technical support can also be a strong indicator of a reliable partner. -

Can I customize my DC power supply orders to meet specific requirements?

Yes, many manufacturers offer customization options for DC power supplies, allowing you to specify voltage, current ratings, and form factors. When discussing customization, ensure you provide detailed specifications and ask about the design process, lead times, and any additional costs associated with custom features. Collaborating closely with the supplier during the design phase can lead to a product that perfectly fits your operational needs, enhancing performance and efficiency in your applications. -

What are the typical minimum order quantities (MOQs) and lead times for DC power supplies?

MOQs vary by supplier and can range from a few units to several hundred, depending on the product type and customization level. Standard lead times typically range from 4 to 12 weeks, depending on the complexity of the order and the supplier’s production capacity. Discussing your needs upfront can help you negotiate favorable terms. If you require smaller quantities, consider suppliers that specialize in low-volume orders or have existing stock of standard models to expedite delivery. -

What payment terms are commonly offered for international orders of DC power supplies?

Payment terms can vary widely among suppliers, but common practices include upfront payments, payment upon delivery, or payment after receipt of goods. For international transactions, it’s advisable to use secure payment methods, such as letters of credit or escrow services, to mitigate risks. Discussing payment terms early in the negotiation process can help you establish clear expectations and ensure a smooth transaction, particularly when dealing with suppliers across different countries and currencies. -

What quality assurance measures should I expect from my supplier?

Reliable suppliers should adhere to stringent quality assurance practices, including ISO certifications and compliance with industry standards such as CE, UL, or RoHS. Request documentation that outlines their quality control processes, including testing methods for voltage regulation, thermal performance, and reliability. A robust QA program is crucial to ensure that the products you receive meet your specifications and perform reliably in your applications, reducing the risk of failures and associated costs. -

How should I approach logistics and shipping for international orders?

When dealing with international suppliers, it’s essential to clarify logistics arrangements upfront. Discuss shipping options, costs, and estimated delivery times, as well as who will be responsible for customs clearance and duties. Working with a logistics partner experienced in international trade can help streamline the process and avoid delays. Ensure that the supplier provides tracking information and that you understand the implications of Incoterms (International Commercial Terms) on your order. -

What steps should I take if I encounter disputes with my supplier?

In the event of a dispute, start by reviewing your contract and any communication with the supplier. Attempt to resolve issues amicably through direct communication, as many disputes can be settled through negotiation. If necessary, escalate the matter to a formal dispute resolution process, such as mediation or arbitration, as stipulated in your contract. It’s advisable to document all interactions and maintain records of agreements to support your case. Consider seeking legal advice if the situation escalates. -

Are there specific certifications I should look for in DC power supplies?

Yes, certifications can indicate the quality and safety of DC power supplies. Look for compliance with international standards such as ISO 9001 for quality management, CE marking for European safety compliance, and UL certification for product safety. Additionally, RoHS compliance is essential for ensuring that products meet environmental regulations regarding hazardous substances. Ensuring your supplier provides these certifications can help mitigate risks associated with product quality and regulatory compliance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for dc power supply

In the rapidly evolving landscape of DC power supply solutions, strategic sourcing emerges as a vital practice for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe. Selecting the right DC power supply—whether linear, switching, or programmable—can significantly impact operational efficiency, reliability, and overall system performance.

Key takeaways include the importance of understanding specific application needs, evaluating supplier capabilities, and considering total cost of ownership rather than just initial purchase price. By focusing on these aspects, buyers can ensure they are making informed decisions that align with their operational goals.

As industries become increasingly interconnected, the demand for reliable and efficient DC power supplies will only grow. Buyers are encouraged to leverage the insights shared in this guide to identify and engage with reputable suppliers who can meet their unique requirements. Embrace this opportunity to enhance your sourcing strategy and position your business for success in a competitive global market. The future of power supply solutions is bright—be proactive in securing the best options for your needs today.