Master m Code for Enhanced CNC Precision and Competitive

Introduction: Navigating the Global Market for m code

In an increasingly interconnected global market, understanding the intricacies of M-code is essential for B2B buyers aiming to enhance their manufacturing processes. M-code, or machine code, is critical in controlling the operational aspects of CNC machines, such as tool changes, spindle movements, and coolant activation. Mastery of M-code not only streamlines production but also enhances the precision and quality of outputs, making it a cornerstone of effective manufacturing.

This guide serves as an exhaustive resource for international buyers, particularly those from Africa, South America, the Middle East, and Europe, including markets like Mexico and Saudi Arabia. It delves into various types of M-code commands, their applications across different materials, and best practices for manufacturing and quality control. Additionally, it provides insights into supplier selection, cost considerations, and current market trends, enabling buyers to make informed sourcing decisions.

By equipping yourself with the knowledge contained in this guide, you will be empowered to navigate the complexities of M-code. This not only enhances operational efficiency but also fosters competitive advantage in your respective markets. Whether you’re optimizing production timelines, reducing costs, or ensuring high-quality standards, understanding M-code will be a game-changer in your sourcing strategy.

Understanding m code Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| M00 | Program Stop; halts execution until manually resumed. | Used in quality control checks during machining. | Pros: Ensures precision; Cons: Can slow production. |

| M01 | Optional Stop; halts execution if enabled. | Ideal for setups requiring frequent adjustments. | Pros: Flexibility in operation; Cons: May disrupt workflow if misused. |

| M02 | End of Program; signals completion of the machining cycle. | Common in automated processes for job completion. | Pros: Clear job completion; Cons: Requires careful programming. |

| M03/M04 | Spindle Control; M03 for clockwise, M04 for counterclockwise rotation. | Essential for milling and drilling operations. | Pros: Versatile spindle control; Cons: Incorrect use can damage tools. |

| M08/M09 | Coolant Control; M08 to activate, M09 to deactivate. | Critical in high-speed machining for tool longevity. | Pros: Enhances tool life; Cons: Mismanagement can lead to overheating. |

M00 – Program Stop

M00 is a fundamental M code used to pause machine operations until the operator intervenes. This feature is particularly beneficial in environments where quality control is critical. Buyers should consider M00 for applications requiring meticulous checks, as it enables operators to verify workpieces before proceeding. However, frequent use can lead to production delays, so it’s essential to balance its application to maintain efficiency.

M01 – Optional Stop

M01 allows for an optional stop in the machining process, which is only activated if the machine is configured to do so. This feature is advantageous for setups that need regular adjustments or inspections. B2B buyers should assess whether their operational flow can accommodate potential interruptions, as improper use may lead to workflow disruptions. Its flexibility can enhance productivity when used judiciously.

M02 – End of Program

M02 signifies the end of a program, indicating that the machining cycle is complete. This M code is crucial in automated processes, ensuring that machines can safely conclude operations without manual input. Buyers should ensure that their programming accurately reflects job completion to avoid unnecessary machine downtime. While it provides clarity in job status, any errors in programming could lead to operational inefficiencies.

M03/M04 – Spindle Control

M03 and M04 are essential for controlling spindle rotation, with M03 enabling clockwise rotation and M04 for counterclockwise. These commands are vital in milling and drilling operations where directionality affects cutting efficiency. B2B buyers should prioritize these codes for their versatility in machining applications. However, incorrect implementation can lead to tool damage, necessitating careful programming and operator training.

M08/M09 – Coolant Control

M08 and M09 are used to manage coolant flow, with M08 activating and M09 deactivating the coolant system. This functionality is crucial in high-speed machining, where overheating can damage tools and materials. Buyers should consider the operational environment when integrating these codes, as proper coolant management can significantly enhance tool longevity and machining efficiency. However, mismanagement can lead to overheating issues, affecting overall productivity.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of m code

| Industry/Sector | Specific Application of m code | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Tool change management in CNC machining | Enhanced precision and reduced downtime in production | Availability of compatible CNC machines and m code standards |

| Automotive Manufacturing | Automation of assembly line processes | Increased efficiency and lower labor costs | Supplier reliability and integration capabilities |

| Oil and Gas | Control of drilling operations | Improved safety and operational efficiency | Compliance with local regulations and technology compatibility |

| Metal Fabrication | Custom part production and machining | Greater customization and faster turnaround times | Material quality and sourcing of specialized tools |

| Electronics Manufacturing | Circuit board assembly and testing | Higher quality assurance and reduced defects | Access to advanced machinery and skilled labor |

Aerospace

In the aerospace sector, m code plays a critical role in managing tool changes during CNC machining processes. This application ensures that tools are automatically adjusted based on the requirements of the specific part being produced. By utilizing m code for tool management, aerospace manufacturers can achieve enhanced precision in their components while significantly reducing machine downtime. For international buyers, particularly in regions like Europe and the Middle East, sourcing CNC machines that support standardized m code is essential to maintain compatibility and optimize production efficiency.

Automotive Manufacturing

Automotive manufacturing relies heavily on m code to automate assembly line processes. This includes controlling the sequence of operations, managing tool changes, and coordinating robotic arms. The benefits include increased operational efficiency and reduced labor costs, which are vital in a competitive market. Buyers from South America and Africa should consider suppliers that provide robust automation solutions compatible with existing systems, ensuring seamless integration and scalability.

Oil and Gas

In the oil and gas industry, m code is utilized to control drilling operations, allowing for precise adjustments in real-time. This application is crucial for improving safety and operational efficiency, as it enables operators to respond quickly to changing conditions. International buyers, especially from regions with stringent regulations like the Middle East, need to ensure that their equipment complies with local standards and that the technology used can be integrated with existing drilling systems.

Metal Fabrication

Metal fabrication companies use m code for custom part production and machining. This application allows for the creation of highly customized components tailored to client specifications. The value lies in greater customization capabilities and faster turnaround times, which are essential for meeting client demands. Buyers should focus on sourcing high-quality materials and specialized tools that can handle complex machining tasks efficiently, particularly in emerging markets in Africa and South America.

Electronics Manufacturing

In electronics manufacturing, m code is crucial for the assembly and testing of circuit boards. It enables precise control over the placement and soldering of components, resulting in higher quality assurance and reduced defects. For international buyers, especially in Europe, sourcing advanced machinery that supports sophisticated m code applications is vital. Additionally, ensuring access to skilled labor who can operate and maintain these machines is essential for maintaining production quality and efficiency.

Related Video: Types Of Flowmeters And Their Industrial Applications.

Strategic Material Selection Guide for m code

When selecting materials for applications involving M-code in CNC machining, international B2B buyers must consider various factors that can significantly impact product performance and overall project success. Below are analyses of four common materials frequently used in conjunction with M-code, along with their properties, advantages, disadvantages, and specific considerations for buyers from diverse regions, including Africa, South America, the Middle East, and Europe.

Aluminum

Key Properties: Aluminum is lightweight and has excellent corrosion resistance. It can withstand moderate temperatures and pressures, making it suitable for a variety of applications.

Pros & Cons: The primary advantage of aluminum is its low density, which contributes to reduced shipping costs and ease of handling. It is also relatively inexpensive compared to other metals. However, aluminum can be less durable under extreme conditions and may require additional coatings for enhanced wear resistance.

Impact on Application: Aluminum is compatible with various media, including water and certain chemicals, but may not perform well in highly acidic or alkaline environments.

Considerations for International Buyers: Buyers should ensure compliance with regional standards such as ASTM or DIN. In regions like the Middle East, where temperatures can soar, selecting the right aluminum alloy is crucial for maintaining performance.

Stainless Steel

Key Properties: Stainless steel is known for its high strength, durability, and exceptional corrosion resistance, particularly in harsh environments. It can withstand high temperatures and pressures.

Pros & Cons: The key advantage of stainless steel is its longevity and resistance to rust and corrosion, making it ideal for applications in the food and medical industries. However, it is more expensive than aluminum and can be challenging to machine, which may increase manufacturing complexity and costs.

Impact on Application: Stainless steel is highly compatible with a wide range of media, including corrosive substances, making it suitable for applications in chemical processing.

Considerations for International Buyers: Buyers should be aware of the specific grades of stainless steel required for their applications and ensure compliance with international standards. In Europe, for example, the EN standard is often referenced.

Carbon Steel

Key Properties: Carbon steel is known for its high tensile strength and hardness, making it suitable for heavy-duty applications. It typically has a lower corrosion resistance compared to stainless steel.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness and ease of availability. It is also relatively easy to machine. However, its susceptibility to rust and corrosion can be a significant drawback, necessitating protective coatings or treatments.

Impact on Application: Carbon steel is compatible with various media but may not be suitable for corrosive environments without proper treatment.

Considerations for International Buyers: Buyers should consider the environmental conditions of their application locations, especially in humid or coastal areas where corrosion is a concern. Compliance with local standards is also essential.

Polycarbonate

Key Properties: Polycarbonate is a thermoplastic known for its impact resistance and lightweight nature. It can withstand a wide range of temperatures but is less durable than metals.

Pros & Cons: The advantage of polycarbonate is its flexibility and ease of fabrication, allowing for complex shapes and designs. However, it is less suitable for high-temperature applications and can be more expensive than some metals.

Impact on Application: Polycarbonate is compatible with many non-corrosive media, making it ideal for protective covers and enclosures in various industries.

Considerations for International Buyers: Buyers should ensure that the polycarbonate meets regional safety and manufacturing standards. In regions like South America, where UV exposure can be high, selecting UV-resistant grades is crucial.

Summary Table

| Material | Typical Use Case for m code | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight components | Low density, cost-effective | Less durable under extreme conditions | Low |

| Stainless Steel | Food and medical applications | High strength and corrosion resistance | More expensive, challenging to machine | High |

| Carbon Steel | Heavy-duty machinery parts | Cost-effective, easy to machine | Susceptible to rust, requires treatment | Medium |

| Polycarbonate | Protective enclosures | Impact resistance, flexible fabrication | Less suitable for high temperatures | Medium |

This guide provides a strategic overview for international B2B buyers to make informed material selections for M-code applications, ensuring compliance with regional standards and optimizing product performance.

In-depth Look: Manufacturing Processes and Quality Assurance for m code

Understanding the Manufacturing Processes for M Code

Manufacturing processes for M code involve several critical stages that ensure precision and quality in production. Each stage plays a vital role in the overall outcome of the manufacturing cycle, which is particularly important for B2B buyers who require high-quality components and systems.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Materials: Choosing the right materials is crucial. Metals such as aluminum, steel, and titanium are commonly used, depending on the application and required properties.

– Cutting and Shaping: Initial shaping is done through techniques like laser cutting or water jet cutting, which prepare the materials for further processing.

– Surface Treatment: This may include processes such as annealing or coating to enhance material properties, ensuring they meet industry standards. -

Forming

– Machining Processes: This includes CNC machining where M code commands are executed to shape materials accurately. Techniques such as turning, milling, and drilling are common.

– Bending and Stretching: For certain applications, forming techniques like bending and stretching may be applied to achieve specific shapes and dimensions.

– Casting and Forging: Depending on the component’s complexity and volume, casting or forging may be utilized to create robust parts. -

Assembly

– Component Assembly: This stage involves the integration of various components into a final product. M code can control automated assembly processes to ensure precision.

– Welding and Joining: Techniques such as MIG, TIG welding, or adhesive bonding may be employed to join parts securely.

– System Integration: For complex systems, integrating electrical, mechanical, and software components is essential to ensure functionality. -

Finishing

– Surface Finishing: Techniques such as polishing, anodizing, or painting are applied to enhance the aesthetics and durability of the product.

– Quality Checks: Final inspections are conducted to ensure all specifications are met before the product is delivered.

Quality Assurance Protocols

Quality assurance (QA) is paramount in manufacturing processes, especially in industries where compliance with international standards is required. For B2B buyers, understanding these protocols is essential for evaluating suppliers.

Relevant International Standards

- ISO 9001: This standard focuses on quality management systems and is applicable across various industries. It emphasizes consistent quality, customer satisfaction, and continuous improvement.

- CE Marking: Particularly important in Europe, CE marking indicates that products meet EU safety, health, and environmental protection standards.

- API Standards: For buyers in the oil and gas sector, API standards ensure that products meet specific safety and quality requirements.

Quality Control Checkpoints

- Incoming Quality Control (IQC): This is the first checkpoint where raw materials and components are inspected upon arrival. Verification against specifications ensures only quality materials are used.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor process parameters and ensure adherence to standards.

- Final Quality Control (FQC): This involves a comprehensive inspection of the finished product to confirm it meets all specifications before shipment.

Common Testing Methods

- Dimensional Inspection: Utilizing tools like calipers and micrometers to verify the dimensions of components against design specifications.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or X-ray inspection ensure structural integrity without damaging the parts.

- Functional Testing: For complex systems, functional tests confirm that all components operate as intended.

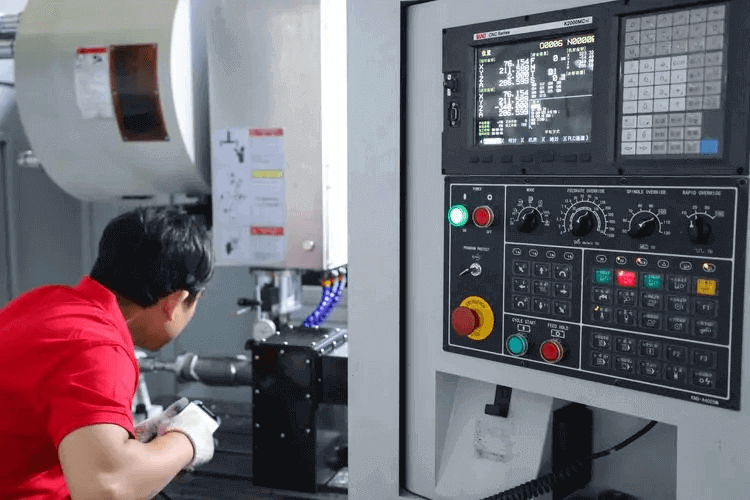

Illustrative Image (Source: Google Search)

Verifying Supplier Quality Control

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, ensuring supplier quality is critical. Here are actionable steps to verify supplier QC:

- Conduct Audits: Regular audits of suppliers help assess their compliance with quality standards. Focus on their manufacturing processes, documentation, and overall quality management systems.

- Request Quality Reports: Ask for detailed quality control reports, including inspection results, defect rates, and corrective action plans.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of supplier capabilities and product quality.

- Check Certifications: Ensure suppliers possess relevant certifications (e.g., ISO 9001, CE) and keep updated on their compliance status.

Quality Control and Certification Nuances

Different regions have varying requirements regarding quality control and certification, which can affect international trade:

- Africa: Buyers should be aware of local standards and certifications that may differ significantly from international standards. Engaging with local regulatory bodies can provide clarity.

- South America: Some countries may have specific import regulations that necessitate compliance with local quality standards, adding layers to the certification process.

- Middle East: The region often adheres to both international and local standards, requiring suppliers to be flexible in meeting diverse regulatory demands.

- Europe (e.g., Mexico, Saudi Arabia): In Europe, CE marking is mandatory for many products, while in Saudi Arabia, local certification bodies may impose additional requirements.

In conclusion, understanding the manufacturing processes and quality assurance protocols related to M code is essential for B2B buyers. By leveraging the insights provided in this guide, international buyers can make informed decisions, ensuring they partner with suppliers who meet their quality and compliance needs effectively.

Related Video: Inspection and Quality control in Manufacturing

Comprehensive Cost and Pricing Analysis for m code Sourcing

When sourcing M-code for CNC machining, understanding the comprehensive cost structure and pricing analysis is crucial for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. This section outlines the key cost components, pricing influencers, and provides actionable buyer tips.

Cost Components

-

Materials: The raw materials used in manufacturing CNC components significantly impact pricing. Common materials include metals (e.g., aluminum, steel) and plastics, each with fluctuating market prices. Buyers should consider sourcing materials locally to mitigate costs related to import tariffs and shipping.

-

Labor: Labor costs vary by region and the complexity of the manufacturing process. Skilled labor in Europe may be more expensive than in Africa or South America, which can affect the overall cost of M-code production. Understanding local labor markets and potential wage rates can help buyers negotiate better pricing.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and administrative expenses. Overhead can vary based on the supplier’s operational efficiency, technology used, and location. Buyers should inquire about these costs during negotiations.

-

Tooling: The cost of tooling can be substantial, especially for custom M-code applications. Tooling costs can be amortized over larger production volumes, so buyers should consider the minimum order quantities (MOQs) that make tooling economically viable.

-

Quality Control (QC): Ensuring product quality is essential, especially in industries like aerospace and automotive. The cost of QC processes can vary, depending on the level of certification required (e.g., ISO 9001). Buyers should assess the QC measures implemented by suppliers to gauge their impact on pricing.

-

Logistics: Shipping and handling costs can significantly influence total expenses, particularly for international buyers. Factors such as Incoterms, shipping mode (air, sea, land), and distance from the supplier can lead to variations in logistics costs.

-

Margin: Suppliers typically apply a profit margin to cover their costs and generate profit. This margin can fluctuate based on market demand, competition, and the supplier’s positioning. Understanding industry standards for margins can provide insight into pricing fairness.

Price Influencers

-

Volume/MOQ: Higher order volumes often lead to lower unit prices due to economies of scale. Buyers should negotiate MOQs that align with their production needs while maximizing cost efficiency.

-

Specifications/Customization: Custom M-code solutions can drive up costs due to additional design and manufacturing efforts. Clear communication of specifications and expectations can help streamline the process and reduce costs.

-

Materials and Quality/Certifications: The choice of materials and quality certifications can impact pricing. Premium materials and stringent quality standards typically result in higher costs.

-

Supplier Factors: The supplier’s reputation, experience, and location can influence pricing. Established suppliers with a proven track record may charge a premium, but their reliability can justify the cost.

-

Incoterms: Understanding the implications of various Incoterms (e.g., FOB, CIF) is vital for international buyers. These terms dictate who is responsible for shipping costs and risks, thus affecting the overall pricing strategy.

Buyer Tips

-

Negotiation: Leverage competitive quotes from multiple suppliers to drive down prices. Be prepared to discuss your requirements and flexibility on specifications to achieve favorable terms.

-

Cost-Efficiency: Analyze the Total Cost of Ownership (TCO) rather than just the upfront price. Consider long-term factors like durability, maintenance, and potential downtime.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, suppliers in emerging markets may offer lower initial costs but could lack certain certifications or quality assurances prevalent in developed markets.

In conclusion, a comprehensive understanding of the cost components and pricing influencers related to M-code sourcing can empower B2B buyers to make informed decisions. By focusing on negotiation strategies and the total cost of ownership, buyers can optimize their procurement processes and achieve better financial outcomes. Keep in mind that prices may vary significantly based on the factors discussed, and it’s advisable to seek indicative pricing from multiple sources to establish a reliable benchmark.

Spotlight on Potential m code Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘m code’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for m code

Key Technical Properties of M Code

-

Material Compatibility

M Code is often utilized in applications involving various materials like metals, plastics, and composites. Understanding the compatibility of the M Code with specific materials ensures optimal performance and reduces wear on tooling. Buyers should prioritize suppliers who can provide M Code that works effectively with their chosen materials to enhance production efficiency and reduce operational costs. -

Tolerance Specifications

Tolerance refers to the permissible limit of variation in a physical dimension. In CNC machining, M Code commands must be able to achieve specified tolerances, often in the range of ±0.01 mm or tighter, depending on the application. For international B2B buyers, confirming the tolerance capabilities of M Code is crucial for ensuring product quality, especially when dealing with precision engineering projects that require high levels of accuracy. -

Cycle Time

Cycle time refers to the total time required to complete a process from start to finish, including all M Code operations. Reducing cycle time without sacrificing quality is essential for maximizing productivity and profitability. Buyers should inquire about the cycle times associated with specific M Code implementations to ensure they align with their production goals and timelines. -

Power Requirements

Different CNC machines require varying levels of power to execute M Code commands effectively. Understanding the power requirements helps in assessing the machine’s efficiency and the potential need for additional infrastructure. Buyers in developing regions, such as Africa and South America, should evaluate the electrical infrastructure and machine specifications to ensure compatibility and avoid operational disruptions. -

Software Integration

M Code often interfaces with CAD/CAM software for seamless operation. The ability to integrate with existing software systems can enhance productivity by automating processes and reducing manual input errors. Buyers should assess the compatibility of M Code with their current software solutions to streamline operations and improve overall workflow.

Common Trade Terms in M Code Usage

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of M Code, OEMs often provide the necessary specifications and codes tailored for specific machines. Understanding OEM relationships is vital for buyers to ensure they receive high-quality, compatible components that meet their production needs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In the realm of M Code, knowing the MOQ helps buyers plan their purchases effectively, ensuring they meet production requirements without overcommitting resources. Buyers should negotiate MOQs with suppliers to align with their production schedules and cash flow needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. For M Code, an RFQ allows buyers to compare pricing, lead times, and terms from various suppliers, facilitating informed purchasing decisions. Buyers should provide detailed specifications in their RFQs to receive accurate quotations and avoid misunderstandings. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. They clarify who pays for shipping, insurance, and tariffs, impacting overall costs. For B2B buyers from diverse regions, understanding Incoterms ensures clear communication regarding shipping terms and responsibilities, which is crucial for budgeting and logistics planning. -

Lead Time

Lead time is the period between the initiation of a process and its completion. In the context of M Code, lead times can vary based on the complexity of the machining process and the supplier’s capabilities. Buyers should consider lead times when planning production schedules to ensure timely delivery of products and maintain customer satisfaction.

Illustrative Image (Source: Google Search)

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their operational efficiency and ensure successful procurement processes in the dynamic landscape of CNC machining and M Code applications.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the m code Sector

Market Overview & Key Trends

The m code sector, integral to computer numerical control (CNC) machining, is witnessing significant transformations driven by technological advancements and globalization. One of the primary global drivers is the increasing demand for precision manufacturing across various industries, such as aerospace, automotive, and consumer electronics. This demand is further fueled by the rise of Industry 4.0, which emphasizes automation, data exchange, and smart manufacturing processes.

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several key trends are emerging. First, the integration of artificial intelligence (AI) and machine learning in CNC operations is enhancing predictive maintenance and operational efficiency. This shift allows manufacturers to minimize downtime and optimize production schedules. Additionally, there is a noticeable trend towards localized sourcing, driven by the need to mitigate supply chain risks exacerbated by global disruptions, such as the COVID-19 pandemic.

Moreover, sustainability is becoming a critical factor in sourcing decisions. Buyers are increasingly looking for suppliers that prioritize eco-friendly practices, including energy-efficient machinery and waste reduction. The adoption of advanced materials, such as biodegradable composites and recycled metals, is also gaining traction, offering new opportunities for differentiation in the marketplace. As these dynamics unfold, B2B buyers must stay informed and adaptable to leverage these trends effectively.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer a mere buzzword; it has become a crucial consideration in the m code sector. The environmental impact of manufacturing processes, including resource depletion and emissions, necessitates a commitment to ethical sourcing practices. For B2B buyers, this translates into a demand for suppliers who demonstrate a robust environmental stewardship commitment.

Ethical supply chains are increasingly important as consumers and businesses alike prioritize transparency and sustainability. Buyers should seek out suppliers with recognized certifications, such as ISO 14001 for environmental management or LEED for sustainable building practices. Additionally, the use of “green” materials—such as recycled or responsibly sourced metals—can significantly reduce the carbon footprint associated with production.

Investing in sustainable practices not only helps mitigate environmental impact but can also enhance brand reputation and customer loyalty. B2B buyers should consider the long-term benefits of partnering with suppliers who align with their sustainability goals, as this can lead to improved operational efficiencies and reduced costs over time.

Brief Evolution/History

The evolution of m code can be traced back to the early days of CNC machining in the 1940s and 1950s, when numerical control (NC) systems were introduced. Initially, these systems relied on punched tape to control machine tools, limiting their flexibility and complexity. As technology advanced, G-code and M-code emerged as the standard programming languages, allowing for more sophisticated control over machining operations.

Over the years, m code has evolved to accommodate the increasing complexity of modern manufacturing processes. Enhanced functionalities, such as tool management and spindle control, have been integrated into m code, enabling greater precision and efficiency. This evolution continues to shape the landscape of CNC machining, influencing how international B2B buyers approach sourcing and production decisions in an increasingly competitive global market.

Related Video: Global trade will never be the same again, says Christine Lagarde | Power & Politics

Frequently Asked Questions (FAQs) for B2B Buyers of m code

-

What should I consider when vetting suppliers for M-code products?

When vetting suppliers, prioritize their experience and specialization in M-code products relevant to your industry. Check for certifications such as ISO 9001, which indicates quality management systems. Additionally, review their track record for reliability and adherence to timelines. Request references from previous clients, particularly those in your region, to assess their performance. Utilizing supplier evaluation frameworks can also help you systematically assess potential partners. -

Can I customize M-code solutions to fit my specific manufacturing needs?

Yes, many suppliers offer customization options for M-code solutions to accommodate unique operational requirements. Discuss your specific needs during the initial conversations, including any particular functionalities or integrations with existing systems. Ensure that the supplier can provide detailed documentation and support for customized solutions. Be aware that customization may affect lead times and costs, so clarify these aspects upfront. -

What are typical minimum order quantities (MOQ) and lead times for M-code products?

MOQs for M-code products can vary significantly by supplier and product type. Generally, smaller orders may be more feasible with suppliers who have flexible manufacturing capabilities. Lead times can range from a few weeks to several months, depending on the complexity of the order and the supplier’s capacity. Always inquire about these factors during negotiations to align expectations and avoid delays. -

What payment options are commonly available for international M-code transactions?

International transactions often include payment methods such as wire transfers, letters of credit, and escrow services. Discuss payment terms early in the negotiation process to ensure mutual understanding. It’s advisable to use secure payment methods to protect against fraud. Be aware of currency exchange rates and transaction fees that may apply, particularly when dealing with suppliers in different regions. -

How can I ensure quality assurance and certifications for M-code products?

Request documentation of quality assurance processes and certifications from your suppliers. Common certifications include ISO standards and industry-specific quality certifications. Additionally, inquire about their testing and inspection protocols to ensure compliance with your quality requirements. Consider scheduling audits or site visits to verify their manufacturing practices firsthand, which can provide deeper insights into their operations. -

What logistics considerations should I keep in mind when sourcing M-code products internationally?

Logistics are crucial in international sourcing, especially regarding shipping methods, customs clearance, and delivery timelines. Work closely with your supplier to understand their shipping options and associated costs. Ensure they have experience with international shipping regulations in your region. It’s also wise to establish a clear communication plan for tracking shipments and addressing any potential delays or issues. -

How can I effectively resolve disputes with M-code suppliers?

Establish clear communication channels and document all agreements in writing to minimize disputes. If issues arise, address them promptly with the supplier, aiming for a collaborative resolution. Utilize formal dispute resolution mechanisms, such as mediation or arbitration, specified in your contract. Ensure your agreement includes a clause detailing how disputes will be handled to safeguard your interests. -

What role do cultural differences play in international B2B sourcing of M-code products?

Cultural differences can significantly impact negotiations, communication styles, and business practices. It’s essential to research and understand the cultural norms of your suppliers’ countries, particularly regarding negotiation tactics and decision-making processes. Building relationships based on respect and understanding can facilitate smoother interactions. Consider engaging local intermediaries or consultants to bridge any cultural gaps, enhancing collaboration and trust.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for m code

In conclusion, strategic sourcing for M-code presents a vital opportunity for international B2B buyers to enhance their operational efficiency and competitive edge. Understanding the nuances of M-code, including its application in controlling various machine functions, is crucial for optimizing manufacturing processes. By leveraging data-driven decision-making and mathematical optimization, companies can effectively manage their resources, reduce costs, and improve delivery timelines.

Key Takeaways:

- Maximize Efficiency: Implementing M-code in CNC machining can streamline operations, leading to better utilization of both human and material resources.

- Cost Management: Understanding M-code intricacies allows for precise planning and execution, which is essential for managing project costs effectively.

- Customization and Agility: The flexibility of M-code supports the make-to-order production approach, enabling manufacturers to meet specific customer requirements swiftly.

As global markets continue to evolve, B2B buyers from Africa, South America, the Middle East, and Europe should prioritize strategic sourcing of M-code solutions. By investing in training and resources, businesses can position themselves for success in a competitive landscape. Now is the time to embrace these advancements and drive your organization towards greater innovation and profitability.