Your Ultimate Guide to Sourcing Torsional Spring

Introduction: Navigating the Global Market for torsional spring

Navigating the global market for torsional springs requires a nuanced understanding of their critical role in various applications, from automotive to industrial machinery. Torsional springs are essential components that store and release rotational energy, making them indispensable in countless mechanical systems. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, sourcing the right torsional spring can significantly impact product performance and reliability.

This comprehensive guide delves into the multifaceted world of torsional springs, covering key topics that empower buyers to make informed decisions. Readers will explore the different types of torsional springs available, including single and double torsion varieties, and the materials used in their manufacture, such as stainless steel, carbon steel, and specialty alloys. The guide also addresses crucial aspects of manufacturing and quality control processes, highlighting reputable suppliers and their capabilities.

Moreover, it provides insights into cost considerations and market trends, ensuring buyers understand the financial implications of their sourcing decisions. A dedicated FAQ section will address common queries, enhancing the overall buying experience. By equipping B2B buyers with knowledge and actionable insights, this guide aims to streamline the sourcing process, ensuring that organizations can confidently select the right torsional springs to meet their specific needs.

Understanding torsional spring Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single Torsion | Utilizes a single coil to store and release energy. | Automotive, Electronics, Appliances | Pros: Simple design, cost-effective. Cons: Limited torque capacity. |

| Double Torsion | Comprises two coils, enhancing torque and resilience. | Industrial Machinery, Robotics | Pros: Higher torque, better energy efficiency. Cons: More complex, potentially higher cost. |

| Left-Hand Wound | Wound in a counter-clockwise direction. | Specialized Equipment, Fixtures | Pros: Customization for specific applications. Cons: Limited availability compared to right-hand wound springs. |

| Right-Hand Wound | Wound in a clockwise direction, the most common type. | General Manufacturing, Furniture | Pros: Widely available, versatile. Cons: May not suit all specialized needs. |

| Custom Torsion | Tailored designs based on specific application requirements. | Aerospace, Medical Devices | Pros: Optimized for unique applications. Cons: Longer lead times, higher costs. |

Single Torsion Springs

Single torsion springs are characterized by a single coil that stores energy when twisted. They are typically used in applications where space is limited and moderate torque is required, such as in automotive mechanisms and household appliances. For B2B buyers, the straightforward design translates into lower costs and easier manufacturing processes. However, they may not provide the torque needed for more demanding applications, making it essential to assess the specific requirements before purchasing.

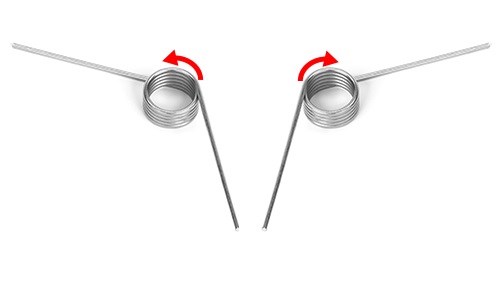

Double Torsion Springs

Double torsion springs consist of two coils, which allows them to handle higher torque loads and provides greater resilience. These springs are ideal for applications in industrial machinery and robotics, where energy efficiency and performance are crucial. Buyers should consider their need for enhanced torque and durability, as double torsion springs can be more expensive and complex to manufacture. However, the investment can lead to improved operational efficiency in demanding environments.

Left-Hand Wound Springs

Left-hand wound torsion springs are designed to twist counter-clockwise and are often customized for specific applications. They are commonly found in specialized equipment and fixtures where unique design requirements exist. While they allow for tailored solutions, B2B buyers may face challenges in sourcing these springs due to their limited availability compared to right-hand wound options. It is vital for purchasers to confirm compatibility with their applications.

Right-Hand Wound Springs

Right-hand wound springs are the most prevalent type, coiling in a clockwise direction. Their widespread availability makes them suitable for general manufacturing and furniture applications. Buyers benefit from the versatility and cost-effectiveness of these springs; however, they may not meet the specific needs of specialized projects. Assessing the torque and load requirements is essential to ensure they are the right fit for the intended application.

Custom Torsion Springs

Custom torsion springs are engineered to meet specific requirements for various industries, including aerospace and medical devices. These springs offer tailored solutions that optimize performance for unique applications, but they often come with longer lead times and higher costs. B2B buyers should weigh the benefits of customized designs against the potential for increased expenses and delays. Understanding the application’s demands is crucial for making informed purchasing decisions.

Related Video: Torsion Spring Leg Types

Key Industrial Applications of torsional spring

| Industry/Sector | Specific Application of Torsional Spring | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Door latch mechanisms | Enhances safety and reliability of vehicle doors | Material durability, corrosion resistance, and precise dimensions |

| Electronics | Power tools and devices | Provides consistent torque and reliable operation | Compatibility with existing designs and load specifications |

| Renewable Energy | Wind turbine blade pitch control | Optimizes energy capture and efficiency | Custom design capabilities and resistance to environmental factors |

| Commercial Lighting | Adjustable lighting fixtures | Improves user experience through adjustable brightness | Material strength and flexibility to withstand repeated use |

| Construction Tools | Clutch mechanisms in power tools | Increases tool efficiency and user safety | Sourcing from reputable manufacturers with quality certifications |

Automotive Applications

In the automotive sector, torsional springs are crucial for door latch mechanisms, ensuring that vehicle doors securely close and remain locked during operation. This application not only enhances safety but also contributes to the overall reliability of vehicles. For international buyers, especially in regions with varying environmental conditions, it is essential to consider materials that offer corrosion resistance and durability, ensuring longevity and performance.

Electronics Applications

In electronics, torsional springs are often utilized in power tools and devices to provide consistent torque. This reliability is vital for maintaining operational efficiency and user satisfaction. Buyers should focus on sourcing springs that are compatible with their existing designs and meet specific load specifications to avoid performance issues. Additionally, understanding the manufacturing capabilities of suppliers can help ensure timely delivery and quality assurance.

Renewable Energy Applications

Torsional springs play a significant role in the renewable energy industry, particularly in wind turbine blade pitch control. By optimizing the angle of the blades, these springs help maximize energy capture, enhancing the efficiency of wind turbines. For buyers in this sector, sourcing custom-designed torsional springs that can withstand harsh environmental conditions is critical. This includes evaluating the materials used and ensuring they meet the necessary performance standards for durability and reliability.

Commercial Lighting Applications

In commercial lighting, adjustable lighting fixtures often incorporate torsional springs to allow users to modify brightness levels easily. This flexibility improves the user experience, making spaces more adaptable to different needs. Buyers should prioritize sourcing springs that exhibit both strength and flexibility, ensuring they can endure repeated adjustments without losing functionality. Additionally, understanding the supply chain and lead times is crucial for maintaining project timelines.

Construction Tools Applications

Torsional springs are integral to the clutch mechanisms found in various power tools used in construction. They enhance tool efficiency and contribute to user safety by providing controlled torque release. International buyers should consider sourcing from reputable manufacturers that adhere to quality certifications, ensuring that the springs meet the required performance and safety standards. Additionally, assessing the manufacturing process can help guarantee the springs are tailored to specific operational requirements.

Related Video: Torsion spring design 2

Strategic Material Selection Guide for torsional spring

When selecting materials for torsional springs, it is crucial for international B2B buyers to consider several factors, including the material’s mechanical properties, cost-effectiveness, and suitability for specific applications. Below is an analysis of four common materials used in the manufacturing of torsional springs, focusing on their properties, advantages, disadvantages, and implications for buyers, particularly from regions like Africa, South America, the Middle East, and Europe.

1. Music Wire

Key Properties: Music wire is known for its high tensile strength and excellent fatigue resistance. It typically operates well in temperatures up to 200°C and offers good elasticity.

Pros & Cons: The primary advantage of music wire is its cost-effectiveness and availability. However, it has limited corrosion resistance, making it unsuitable for applications exposed to moisture or corrosive environments.

Impact on Application: Music wire is ideal for general-purpose applications where high strength and low cost are required. However, its lack of corrosion resistance can be a significant drawback in humid or chemically aggressive environments.

Considerations for International Buyers: Buyers should ensure compliance with ASTM A228 standards and consider the availability of music wire in their region, as sourcing may vary significantly.

2. Stainless Steel (Type 302)

Key Properties: Stainless steel, particularly Type 302, offers excellent corrosion resistance and can withstand temperatures up to 300°C. It maintains strength and shape under varying thermal conditions.

Pros & Cons: The key advantage of stainless steel is its durability and resistance to rust and corrosion. However, it is more expensive than music wire and can be more complex to manufacture due to its toughness.

Impact on Application: Stainless steel torsion springs are suitable for applications in food processing, marine environments, and any area where corrosion is a concern.

Considerations for International Buyers: Buyers from Europe should be aware of compliance with EN 10088 standards, while those in South America may need to consider local regulations regarding stainless steel sourcing.

3. Oil Tempered Spring Steel

Key Properties: Oil tempered spring steel is known for its high fatigue strength and excellent resilience, with a temperature tolerance of up to 250°C. It also exhibits good wear resistance.

Pros & Cons: This material is highly durable and cost-effective for high-stress applications. However, it requires additional processing for corrosion resistance, which can increase manufacturing complexity.

Impact on Application: Oil tempered springs are commonly used in automotive and industrial applications where high performance is critical. The need for additional protective coatings must be factored into the design.

Considerations for International Buyers: Buyers should verify compliance with ASTM A313 standards and consider the availability of oil tempered steel in their local markets, particularly in regions with less developed manufacturing capabilities.

4. Phosphor Bronze

Key Properties: Phosphor bronze is known for its excellent corrosion resistance and electrical conductivity. It operates well in temperatures up to 150°C and provides good fatigue resistance.

Pros & Cons: The primary advantage of phosphor bronze is its corrosion resistance and suitability for electrical applications. However, it is generally more expensive than steel options and may not provide the same level of tensile strength.

Impact on Application: This material is ideal for applications in electronics and marine environments where corrosion resistance is paramount.

Considerations for International Buyers: Buyers should ensure compliance with JIS standards for phosphor bronze and consider the higher costs associated with sourcing this material, especially in regions where it is less commonly used.

Summary Table

| Material | Typical Use Case for torsional spring | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Music Wire | General-purpose applications | Cost-effective and widely available | Limited corrosion resistance | Low |

| Stainless Steel (Type 302) | Food processing, marine environments | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Oil Tempered Spring Steel | Automotive and industrial applications | High fatigue strength | Requires additional corrosion protection | Medium |

| Phosphor Bronze | Electronics, marine environments | Excellent corrosion resistance | Higher cost and lower tensile strength | High |

This guide serves as a strategic resource for international B2B buyers, helping them make informed decisions about material selection for torsional springs based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for torsional spring

The manufacturing process and quality assurance for torsional springs are critical aspects that international B2B buyers must understand to ensure they are sourcing high-quality components. This section provides a detailed overview of the typical manufacturing processes involved, quality assurance protocols, and how buyers can verify supplier compliance with international standards.

Manufacturing Processes

1. Material Preparation

– Selection of Material: Torsional springs can be made from various materials, including high-carbon steel, stainless steel, and exotic alloys like Inconel and Monel. The choice of material depends on the application requirements, such as load capacity, corrosion resistance, and temperature tolerance.

– Wire Sizing and Cutting: The selected material is then formed into wire of specific diameters, ranging from 0.015” to 0.500” (0.381 mm to 12.7 mm). Precision cutting ensures that the wire lengths are accurate for subsequent forming processes.

2. Forming

– Coiling Techniques: Advanced CNC machines are utilized for the coiling process, which involves winding the wire into a helical shape. This can include single or double torsion configurations depending on the design specifications.

– Bending and Shaping: After coiling, the spring is further shaped by bending the legs to meet specific design requirements. This step may involve mechanical or laser-assisted bending to ensure high precision.

3. Assembly

– Integration of Components: If the torsional spring is part of a larger assembly, it may need to be integrated with other components during this stage. Proper alignment and positioning are crucial to ensure the spring functions correctly within the system.

– Final Adjustments: Any necessary adjustments are made to ensure that the spring meets the required specifications for load and deflection.

4. Finishing

– Surface Treatment: To enhance durability and resistance to corrosion, torsional springs often undergo surface treatments such as galvanizing, powder coating, or oil tempering. These treatments can significantly extend the lifespan of the springs in their intended environments.

– Final Inspection: Before packaging, each spring is subjected to a final inspection to confirm it meets all design specifications and quality standards.

Quality Assurance

International Standards

– ISO 9001 Certification: A fundamental requirement for torsion spring manufacturers is compliance with ISO 9001, which ensures a quality management system is in place. This certification indicates that the manufacturer follows systematic procedures to maintain quality throughout the production process.

– Industry-Specific Certifications: Depending on the application, additional certifications may be necessary. For example, CE marking is crucial for products sold in the European Union, while API certification is important for springs used in the oil and gas industry.

Quality Control Checkpoints

– Incoming Quality Control (IQC): Materials received are inspected for compliance with specifications. This includes checking the chemical composition and mechanical properties of the wire.

– In-Process Quality Control (IPQC): During manufacturing, operators perform regular checks to monitor the forming and bending processes, ensuring that they adhere to the design parameters.

– Final Quality Control (FQC): After finishing, each spring undergoes rigorous testing, including load testing and dimensional checks, to verify that it meets all required specifications.

Common Testing Methods

– Load Testing: Springs are subjected to load tests to ensure they can withstand specified forces without permanent deformation.

– Dimensional Inspection: Using calibrated tools, manufacturers verify that the springs meet the specified dimensions and tolerances.

– Fatigue Testing: This assesses the spring’s performance under repeated loading cycles, helping to predict its lifespan.

Verifying Supplier Quality Assurance

1. Supplier Audits

– Conducting regular audits of potential suppliers is essential for B2B buyers. These audits should evaluate the supplier’s manufacturing processes, quality control measures, and compliance with international standards.

2. Quality Reports

– Requesting detailed quality reports from suppliers can provide insights into their quality management practices. These reports should include information on testing methods, pass/fail rates, and corrective actions taken on non-conforming products.

3. Third-Party Inspections

– Engaging third-party inspection agencies can add an extra layer of verification. These agencies can perform independent assessments of the manufacturing process and final products, ensuring that they meet the required standards.

Quality Control Considerations for International Buyers

Regional Compliance Nuances

– Buyers from Africa, South America, the Middle East, and Europe must be aware of specific regional compliance requirements. For instance, different countries may have varying standards for material sourcing and environmental impact, which can affect the choice of suppliers.

Cultural and Communication Factors

– Understanding cultural differences in business practices is vital. Clear communication regarding quality expectations and specifications can prevent misunderstandings and ensure that suppliers deliver products that meet international standards.

Building Long-Term Relationships

– Establishing long-term relationships with reliable suppliers can lead to better quality assurance over time. Regular communication and collaboration on quality improvements can enhance product reliability and reduce the risks associated with sourcing.

By understanding these manufacturing processes and quality assurance protocols, B2B buyers can make informed decisions when sourcing torsional springs, ensuring they receive high-quality products that meet their specific application needs.

Related Video: The Process of Manufacturing Giant Springs A Spring Factory in China

Comprehensive Cost and Pricing Analysis for torsional spring Sourcing

When sourcing torsional springs, understanding the comprehensive cost structure is essential for making informed purchasing decisions. The costs associated with torsional spring manufacturing can be broken down into several key components:

Cost Components

-

Materials: The choice of material significantly impacts the overall cost. Common materials include music wire, stainless steel, and specialty alloys. High-performance materials typically incur higher costs but may offer better durability and performance, especially in demanding applications.

-

Labor: Labor costs vary by region and can be influenced by the complexity of the torsion spring design. Skilled labor is required for custom springs, which can increase costs. Automation in manufacturing processes can help reduce labor costs, but initial investments in technology may be substantial.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Overhead can vary significantly depending on the manufacturer’s operational efficiency and geographic location.

-

Tooling: Custom tooling is often necessary for unique torsion spring designs. While these costs are amortized over production runs, they can be substantial for low-volume orders, impacting the price per unit.

-

Quality Control (QC): Ensuring the reliability and performance of torsion springs necessitates rigorous quality control measures. The costs associated with QC processes, including testing and certification, should be factored into the overall pricing.

-

Logistics: Transportation and shipping costs can vary widely, especially for international orders. Factors such as distance, shipping method, and customs duties can influence logistics costs.

-

Margin: Suppliers will apply a profit margin on top of their costs. This margin can vary based on competition, market demand, and the supplier’s positioning in the market.

Price Influencers

Several factors can affect the pricing of torsional springs:

-

Volume/MOQ: Higher order quantities typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) to optimize costs.

-

Specifications/Customization: Custom designs or specific material requirements may lead to higher prices. Buyers should clearly define specifications to avoid unexpected costs.

-

Materials: The choice of material not only affects the cost but also the performance and longevity of the spring. Buyers should assess the Total Cost of Ownership (TCO) when selecting materials.

-

Quality/Certifications: Springs that require specific certifications (e.g., ISO) may cost more due to the additional compliance and testing procedures.

-

Supplier Factors: Relationships with suppliers can influence pricing. Established suppliers may offer better terms based on historical purchases or loyalty.

-

Incoterms: Understanding Incoterms is crucial for international transactions, as they define the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs, which can significantly impact costs.

Buyer Tips

-

Negotiation: Leverage volume orders and long-term partnerships to negotiate better pricing. Be prepared to discuss specifications and potential adjustments to reduce costs.

-

Cost-Efficiency: Focus on the TCO rather than just the upfront price. Consider factors like durability and maintenance, which can lead to savings over time.

-

Pricing Nuances for International Buyers: International buyers should account for currency fluctuations, tariffs, and import duties when evaluating costs. Engage with suppliers familiar with the specific regulations in your region.

-

Request Multiple Quotes: Obtaining quotes from multiple suppliers can provide insights into market pricing and help identify cost-effective options.

-

Understand Local Market Dynamics: Buyers from Africa, South America, the Middle East, and Europe should familiarize themselves with local manufacturing capabilities and import conditions, which can affect pricing and availability.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific project requirements. Buyers are encouraged to conduct thorough market research and consult multiple suppliers to ensure competitive pricing.

Spotlight on Potential torsional spring Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘torsional spring’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for torsional spring

When sourcing torsional springs for various applications, understanding the essential technical properties and trade terminology is crucial for making informed purchasing decisions. This guide outlines the critical specifications and jargon that B2B buyers should be familiar with.

Key Technical Properties

-

Material Grade

– Definition: The type of material used to manufacture the torsional spring, which affects its strength, elasticity, and durability.

– Importance: Selecting the appropriate material (e.g., stainless steel, music wire, or phosphor bronze) ensures the spring can withstand operational stresses and environmental conditions. For instance, stainless steel is often chosen for applications requiring corrosion resistance. -

Wire Diameter

– Definition: The thickness of the wire used in the torsion spring, typically measured in inches or millimeters.

– Importance: The wire diameter influences the spring’s load-bearing capacity and flexibility. A thicker wire can support heavier loads but may reduce the spring’s ability to flex, making it essential to match the diameter with the application requirements. -

Load and Deflection

– Definition: The amount of force the spring can exert (load) and the distance it can be compressed or twisted (deflection).

– Importance: Understanding the load and deflection characteristics is critical for ensuring that the spring performs as intended within its application. Buyers should specify their load requirements to avoid spring failure during operation. -

Tolerance

– Definition: The allowable deviation from specified dimensions, which can affect the spring’s fit and performance.

– Importance: Tight tolerances are essential in applications where precision is crucial, such as in automotive or aerospace industries. Ensuring the correct tolerances minimizes the risk of malfunction and enhances product reliability. -

Spring Orientation

– Definition: The direction in which the spring is wound (left-hand or right-hand).

– Importance: The orientation must be specified to ensure compatibility with the assembly process and to prevent operational issues. This is especially critical in applications where multiple springs are used in concert.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEMs is vital for buyers looking for specific parts that fit into larger systems, as they often have unique specifications and quality requirements. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers assess whether a supplier is a viable option based on their purchasing needs. For international buyers, MOQs can affect inventory management and cash flow. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and terms for a specific quantity of goods.

– Importance: Submitting an RFQ is essential for obtaining competitive pricing and ensuring that potential suppliers can meet specific requirements, including lead times and compliance with standards. -

Incoterms (International Commercial Terms)

– Definition: A set of rules that define the responsibilities of sellers and buyers in international transactions.

– Importance: Familiarity with Incoterms helps buyers understand shipping responsibilities, risk management, and costs, which is crucial for effective international trade negotiations. -

Lead Time

– Definition: The time it takes from placing an order until the goods are delivered.

– Importance: Understanding lead times is essential for planning and maintaining supply chain efficiency. Buyers should consider lead times in relation to project timelines and inventory levels.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing torsional springs, ultimately leading to better product performance and supplier relationships.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the torsional spring Sector

Market Overview & Key Trends

The torsional spring market is experiencing dynamic growth, driven primarily by advancements in manufacturing technologies and increasing demand across various sectors, such as automotive, electronics, and renewable energy. Global supply chain challenges, particularly in the wake of the COVID-19 pandemic, have prompted B2B buyers to rethink their sourcing strategies. International buyers from Africa, South America, the Middle East, and Europe are increasingly favoring suppliers who can demonstrate agility and reliability in their operations.

Emerging trends include the integration of Industry 4.0 technologies, such as IoT and AI, into manufacturing processes. These innovations facilitate real-time monitoring and predictive maintenance, enhancing product quality and reducing lead times. Furthermore, the rise of custom torsional springs tailored to specific applications is becoming a significant differentiator among suppliers. Buyers are encouraged to engage with manufacturers that offer advanced design capabilities, allowing for optimization based on load and deflection requirements.

Sourcing strategies are also evolving, with a focus on regional suppliers to mitigate risks associated with global shipping delays. For example, European buyers may prioritize local manufacturers to ensure shorter lead times and better communication. Additionally, companies are increasingly looking for suppliers that can provide not just products but also technical support and design assistance, making partnerships more valuable in the long run.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration in the torsional spring sector, particularly as environmental regulations tighten globally. B2B buyers are increasingly evaluating the environmental impact of their suppliers, focusing on those who employ sustainable practices in their manufacturing processes. This includes the use of recycled materials and energy-efficient production methods, which can significantly reduce the carbon footprint associated with torsional spring production.

Illustrative Image (Source: Google Search)

Ethical sourcing is also gaining prominence. Buyers are urged to seek suppliers who demonstrate transparency in their supply chains and adhere to fair labor practices. Certifications such as ISO 14001, which focuses on effective environmental management systems, can be indicators of a supplier’s commitment to sustainability. Additionally, the use of ‘green’ materials, such as eco-friendly alloys or coatings, is becoming a standard expectation in procurement decisions.

For buyers in regions like Africa and South America, where sustainable practices may be less established, partnering with suppliers that prioritize ethical sourcing can enhance brand reputation and customer loyalty. As sustainability becomes a competitive advantage, suppliers that can provide evidence of their green practices will likely gain favor among discerning international buyers.

Brief Evolution/History

The evolution of torsional springs dates back to the industrial revolution, where the need for mechanical energy storage and motion control became paramount in machinery. Initially, these springs were crafted using basic materials and rudimentary techniques, limiting their application to simple machinery. Over time, advancements in metallurgy and manufacturing processes, such as CNC machining, have enabled the production of highly specialized torsional springs.

Today, torsional springs are integral components in various high-tech applications, from automotive systems to renewable energy devices. The transition from basic to complex designs reflects the broader trends in manufacturing, where customization and precision have become essential. As technology continues to evolve, the torsional spring sector is poised to further innovate, offering solutions that meet the diverse needs of international B2B buyers.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of torsional spring

-

What should I consider when vetting a torsional spring supplier?

When vetting a torsional spring supplier, focus on their experience and expertise in your industry. Check for certifications such as ISO 9001, which indicates a commitment to quality management. Look at their portfolio of past projects to ensure they can handle custom requirements. Additionally, request references from previous clients to gauge reliability and customer service. Lastly, consider their production capabilities, including technology used and material sourcing, to ensure they can meet your specifications. -

Can torsional springs be customized to fit specific applications?

Yes, torsional springs can be highly customized to meet specific application needs. Suppliers typically offer various wire materials, diameters, and body shapes. Discuss your design requirements, including load and deflection specifications, with the supplier to determine the best solution. Many manufacturers use advanced design software to assist in developing custom springs, so inquire about their capabilities in this area. Ensure that you communicate any unique requirements early in the process to avoid delays. -

What is the minimum order quantity (MOQ) for torsional springs, and how does it affect pricing?

The MOQ for torsional springs can vary significantly among suppliers, often starting at around 100 pieces. A higher MOQ may lead to lower unit costs due to economies of scale. However, smaller orders may incur higher per-unit prices. When negotiating, clarify whether the MOQ includes all customizations or if each variant requires a separate MOQ. Consider your inventory needs and budget constraints when deciding on order size, and discuss flexibility with suppliers. -

What are typical lead times for custom torsional springs?

Lead times for custom torsional springs generally range from 2 to 6 weeks, depending on the complexity of the design and the supplier’s workload. Factors influencing lead times include material availability, manufacturing capacity, and any required certifications. To expedite the process, provide clear specifications and timely feedback during the design phase. For urgent needs, some suppliers offer rush services, but this may come with additional costs. Always confirm lead times in writing to align expectations. -

How do suppliers ensure quality and compliance with international standards?

Suppliers typically implement stringent quality assurance processes, including raw material inspection, in-process testing, and final product evaluation. Look for suppliers with ISO certifications, which demonstrate adherence to international quality standards. Request documentation for compliance with industry-specific regulations. Many suppliers also offer material certification and test reports to validate the performance of their torsional springs. Establishing a clear QA process with your supplier can help ensure that the products meet your specifications. -

What payment terms are commonly offered by torsional spring suppliers?

Payment terms can vary widely among suppliers, but common options include net 30 or net 60 days after delivery, requiring an initial deposit before production. International buyers should clarify terms to account for currency exchange rates and potential transaction fees. Some suppliers may accept letters of credit or other secure payment methods to mitigate risk. Always negotiate terms that align with your cash flow and project timelines, and ensure that you have a clear invoice and payment process established. -

What logistics considerations should I keep in mind when sourcing torsional springs internationally?

When sourcing torsional springs internationally, consider shipping methods, customs regulations, and potential tariffs. Discuss with your supplier whether they handle logistics or if you need to arrange shipping. Evaluate the total landed cost, including shipping, customs duties, and insurance. Ensure that the supplier can provide necessary documentation for customs clearance. Additionally, consider lead times for shipping and potential delays to ensure that your production schedule remains on track. -

How should I handle disputes or issues with my torsional spring supplier?

In the event of a dispute, maintain clear and open communication with your supplier to resolve issues amicably. Document all correspondence and agreements to support your position. Review your contract for terms related to quality disputes, returns, and refunds. If necessary, escalate the issue within the supplier’s organization. For persistent problems, consider mediation or arbitration as outlined in your contract. Building a solid relationship with your supplier can help prevent disputes and facilitate smoother resolutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for torsional spring

In conclusion, the strategic sourcing of torsional springs is pivotal for international B2B buyers seeking quality, reliability, and cost-effectiveness. Key takeaways include the importance of understanding the technical specifications of torsion springs, such as load requirements, wire diameter, and materials used. These factors not only affect the performance but also influence the overall costs and lead times.

Illustrative Image (Source: Google Search)

Investing in long-term partnerships with reputable manufacturers can lead to enhanced customization options and improved supply chain efficiency. By leveraging advanced manufacturing technologies and design capabilities, buyers can ensure that their specific application needs are met, leading to better product performance and customer satisfaction.

As the global market continues to evolve, it is essential for buyers from Africa, South America, the Middle East, and Europe to remain proactive in sourcing strategies. Embrace innovation and sustainability in your procurement processes to stay competitive. Now is the time to explore opportunities and build relationships with manufacturers that align with your business goals. Take the next step in your sourcing journey and unlock the potential of high-quality torsional springs for your operations.