Your Ultimate Guide to Sourcing Differential Pressure Switch

Introduction: Navigating the Global Market for differential pressure switch

In the evolving landscape of industrial automation and control systems, the differential pressure switch stands as a critical component that ensures operational efficiency and safety. These devices play a pivotal role in monitoring and controlling pressure differentials within various systems, from HVAC applications to industrial machinery. For B2B buyers across regions like Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing high-quality differential pressure switches is essential for optimizing performance and minimizing downtime.

This comprehensive guide delves into the intricacies of the differential pressure switch market, offering valuable insights into various types, materials, and manufacturing quality control standards. B2B buyers will find actionable strategies for evaluating suppliers, assessing costs, and navigating market trends that influence purchasing decisions. Key topics include:

- Types of Differential Pressure Switches: Understanding the various applications and specifications.

- Materials and Quality Control: Ensuring product durability and reliability.

- Supplier Evaluation: Criteria for selecting trustworthy manufacturers.

- Cost Considerations: Strategies for negotiating favorable pricing.

- Market Dynamics: Trends impacting the global supply chain.

By leveraging this guide, international buyers will be empowered to make informed sourcing decisions, ensuring that they procure reliable products that meet their specific operational needs. Engage with the content to enhance your procurement strategy and strengthen your competitive edge in the global market.

Understanding differential pressure switch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mechanical Differential Switch | Uses mechanical movement to detect pressure changes | HVAC systems, industrial machinery | Pros: Simple design, cost-effective. Cons: Less precise, limited lifespan. |

| Electronic Differential Switch | Utilizes electronic sensors for precise measurement | Medical devices, aerospace, automation | Pros: High accuracy, real-time monitoring. Cons: Higher cost, complex installation. |

| Digital Differential Switch | Provides digital readouts and can connect to networks | Smart buildings, process control | Pros: User-friendly, remote monitoring. Cons: Expensive, requires power source. |

| Adjustable Differential Switch | Allows users to set specific pressure thresholds | Water treatment, oil & gas industries | Pros: Versatile, customizable settings. Cons: More complicated setup, potential for user error. |

| Low-Pressure Differential Switch | Specifically designed for low-pressure applications | Food processing, pharmaceuticals | Pros: Tailored for low pressure, reliable. Cons: Limited use cases, may not handle high pressure. |

Mechanical Differential Switch

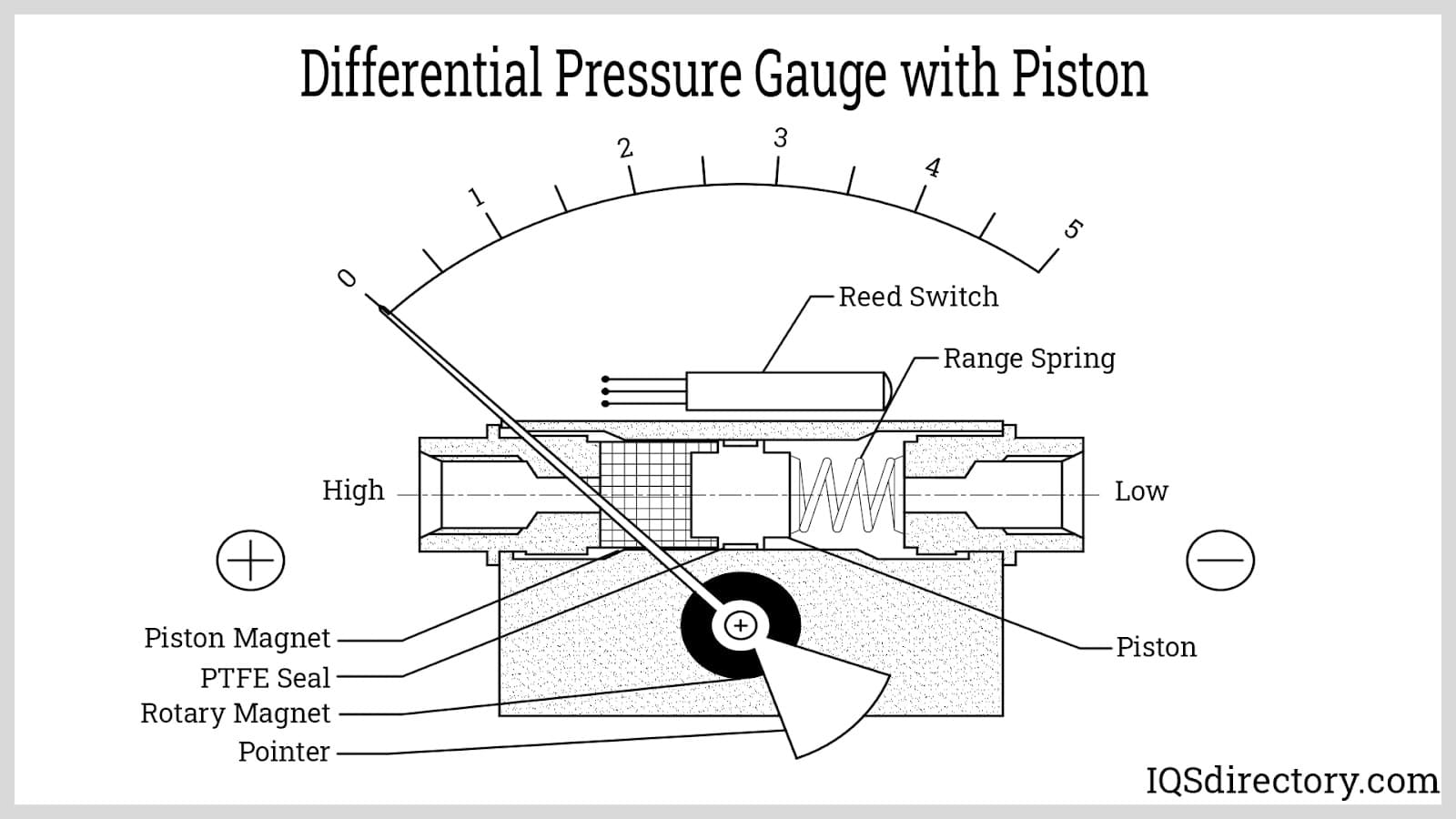

Mechanical differential switches rely on physical components, such as diaphragms or bellows, to detect pressure changes. They are widely used in HVAC systems and industrial machinery due to their straightforward design and cost-effectiveness. While they are generally reliable, their mechanical nature can lead to less precision and a shorter lifespan compared to electronic variants. Buyers should consider the operational environment and expected accuracy requirements when selecting these switches.

Electronic Differential Switch

Electronic differential switches leverage advanced sensor technology to provide precise pressure measurements. Commonly utilized in medical devices, aerospace applications, and automation systems, these switches offer real-time monitoring capabilities. Although they come at a higher price point, their accuracy and reliability make them a valuable investment for businesses prioritizing performance. Buyers must assess their specific measurement needs and installation complexity when considering this option.

Digital Differential Switch

Digital differential switches feature digital displays and often integrate with building management systems for enhanced control. They are particularly well-suited for smart buildings and process control applications. These switches provide user-friendly interfaces and remote monitoring capabilities, improving operational efficiency. However, the need for a power source and a higher initial cost may deter some buyers. Ensuring compatibility with existing systems is crucial for a successful implementation.

Adjustable Differential Switch

Adjustable differential switches allow users to set specific pressure thresholds, making them versatile for various applications, including water treatment and oil & gas industries. Their customizable settings enable businesses to tailor operations to specific needs. However, the complexity of setup and potential for user error can be drawbacks. Buyers should weigh the advantages of customization against the need for careful calibration and maintenance.

Low-Pressure Differential Switch

Low-pressure differential switches are specifically designed for applications requiring precise monitoring of low-pressure environments, such as food processing and pharmaceuticals. Their reliability in low-pressure scenarios makes them ideal for sensitive applications. However, their limited use cases and inability to handle high pressures should be considered. Buyers must evaluate their operational requirements to ensure they choose the right switch for their specific applications.

Related Video: Pressure Switch Explained | Types of Pressure Switches

Key Industrial Applications of differential pressure switch

| Industry/Sector | Specific Application of Differential Pressure Switch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| HVAC Systems | Monitoring air filters and duct pressure | Ensures optimal airflow, reduces energy costs | Look for switches with high durability and accuracy |

| Water Treatment | Managing pressure in filtration systems | Enhances system efficiency and prolongs equipment life | Ensure compliance with local standards and certifications |

| Pharmaceuticals | Monitoring pressure in cleanrooms and production lines | Maintains sterile conditions, prevents contamination | Require switches that meet stringent hygiene standards |

| Oil & Gas | Monitoring pipeline pressure differentials | Prevents leaks and enhances safety | Focus on robust materials that withstand harsh environments |

| Food & Beverage | Ensuring proper pressure in processing equipment | Improves product quality and consistency | Look for switches that are easy to clean and maintain |

HVAC Systems

In HVAC applications, differential pressure switches are crucial for monitoring the pressure in air filters and ducts. By detecting changes in pressure, these switches ensure optimal airflow and system efficiency. This not only enhances comfort but also reduces energy costs, making it a vital component for HVAC contractors and facility managers. Buyers should prioritize switches that offer high durability and precise measurement capabilities, particularly in regions with fluctuating environmental conditions.

Water Treatment

In the water treatment sector, differential pressure switches are employed to manage pressure in filtration systems. They help in detecting blockages or filter saturation, which can significantly affect system performance. By ensuring that pressure levels are maintained, these switches enhance the overall efficiency of treatment processes and prolong the life of equipment. International buyers should ensure that the switches comply with local regulations and certifications, particularly in regions where water quality standards are stringent.

Pharmaceuticals

In the pharmaceutical industry, maintaining sterile conditions is paramount, and differential pressure switches play a critical role in monitoring pressure in cleanrooms and production lines. By providing real-time data on pressure differentials, these switches help prevent contamination and ensure compliance with health and safety regulations. Buyers in this sector must prioritize switches that meet strict hygiene standards and offer reliable performance under various conditions, particularly in regions with varying regulatory frameworks.

Oil & Gas

Differential pressure switches are essential in the oil and gas industry for monitoring pressure differentials in pipelines. These switches help in identifying leaks and maintaining safe operational conditions, which is crucial for preventing environmental disasters and ensuring worker safety. Buyers should focus on sourcing robust materials that can withstand harsh environments, including extreme temperatures and corrosive substances, common in oil and gas operations.

Food & Beverage

In the food and beverage sector, differential pressure switches are used to ensure proper pressure in processing equipment, which is vital for maintaining product quality and consistency. These switches help in monitoring and controlling processes such as pasteurization and packaging. Buyers should look for switches that are easy to clean and maintain, as hygiene is critical in food production. Additionally, sourcing from suppliers with food safety certifications can enhance compliance with local health regulations.

Related Video: How to set up a Danfoss differential pressure switch | Walkthrough

Strategic Material Selection Guide for differential pressure switch

When selecting materials for differential pressure switches, it is essential to consider the specific properties and applications that will affect performance and durability. Here are four common materials used in the construction of differential pressure switches, along with their key properties, advantages, disadvantages, and considerations for international B2B buyers.

Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures and pressures. It typically has a temperature rating of up to 400°C (752°F) and can handle pressures exceeding 3000 psi, making it suitable for various industrial applications.

Pros & Cons:

The primary advantage of stainless steel is its durability and resistance to corrosion, which extends the lifespan of the pressure switch. However, it is more expensive than other materials, and its manufacturing processes can be complex, requiring advanced machining techniques.

Impact on Application:

Stainless steel is ideal for applications involving aggressive media such as chemicals and high-pressure gases. Its compatibility with a wide range of fluids makes it a versatile choice for industries like oil and gas, pharmaceuticals, and food processing.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM A240 for stainless steel grades. In regions like Europe and the Middle East, certifications like ISO 9001 for quality management systems are also essential.

Brass

Key Properties:

Brass offers good corrosion resistance and is suitable for moderate temperature and pressure applications, typically rated up to 200°C (392°F) and 1500 psi. Its excellent machinability makes it a popular choice for precision components.

Pros & Cons:

Brass is less expensive than stainless steel and easier to machine, which can lower manufacturing costs. However, it is less durable in harsh environments and may corrode when exposed to certain chemicals, limiting its application range.

Impact on Application:

Brass is commonly used in applications involving water, air, and non-corrosive gases. Its suitability for lower-pressure applications makes it ideal for residential and light commercial systems.

Considerations for International Buyers:

Buyers should be aware of local regulations regarding the use of brass, especially in potable water systems. Compliance with standards such as ASTM B36 for brass fittings can also be crucial.

Plastic (Polymer)

Key Properties:

Plastics, particularly high-performance polymers like polycarbonate or PEEK, offer lightweight, corrosion-resistant properties. They can typically withstand temperatures up to 120°C (248°F) and pressures around 1000 psi.

Pros & Cons:

The main advantage of plastic is its low weight and cost-effectiveness, making it suitable for applications where weight is a critical factor. However, plastics may not be suitable for high-temperature or high-pressure environments and can degrade over time when exposed to UV light or certain chemicals.

Impact on Application:

Plastic differential pressure switches are often used in HVAC systems and applications involving non-corrosive fluids. Their lightweight nature makes them ideal for portable devices.

Considerations for International Buyers:

Buyers should ensure that the selected plastic meets relevant safety and performance standards, such as UL 94 for flammability. Additionally, checking for certifications like RoHS compliance can be important in European markets.

Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance, with a temperature rating of up to 150°C (302°F) and pressure ratings around 2000 psi. It is also known for its excellent thermal conductivity.

Pros & Cons:

Aluminum offers a good balance between weight and strength, making it suitable for various applications. However, it is less durable than stainless steel and may require protective coatings to enhance its corrosion resistance in aggressive environments.

Impact on Application:

Aluminum is often used in applications where weight savings are essential, such as in aerospace or automotive industries. It is suitable for air and water applications but may not be ideal for harsh chemical environments.

Considerations for International Buyers:

Buyers should consider the environmental impact of aluminum production and ensure compliance with local recycling regulations. Standards such as ASTM B221 for aluminum extrusions may also be relevant.

Summary Table

| Material | Typical Use Case for differential pressure switch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Oil & gas, pharmaceuticals, food processing | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Brass | Residential and light commercial systems | Cost-effective, easy to machine | Limited durability in harsh environments | Medium |

| Plastic | HVAC systems, portable devices | Lightweight, cost-effective | Not suitable for high temperature/pressure | Low |

| Aluminum | Aerospace, automotive applications | Good weight-to-strength ratio | Less durable, requires protective coatings | Medium |

This material selection guide provides a thorough understanding of the different materials available for differential pressure switches, helping international B2B buyers make informed decisions based on their specific requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for differential pressure switch

Differential pressure switches are crucial components in various industrial applications, ensuring safety and efficiency in systems that rely on pressure management. Understanding the manufacturing processes and quality assurance (QA) measures behind these devices is essential for B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe. This section outlines the typical manufacturing stages, key techniques, and quality control protocols that can guide international buyers in sourcing reliable differential pressure switches.

Manufacturing Processes

1. Material Preparation

The first stage in manufacturing differential pressure switches involves selecting and preparing high-quality materials. Commonly used materials include:

- Stainless Steel: Offers corrosion resistance and durability, making it ideal for harsh environments.

- Brass: Provides excellent conductivity and is often used in electronic components.

- Plastic Composites: Used for lightweight applications and cost-effective solutions.

Material preparation includes cutting, machining, and surface treatment to enhance material properties such as strength and resistance to wear. This stage is critical as the quality of raw materials directly impacts the performance of the final product.

2. Forming

In this stage, the prepared materials are shaped into specific components of the differential pressure switch. Key techniques include:

- CNC Machining: Utilizes computer-controlled tools to achieve precise dimensions and intricate designs, ensuring that each part fits perfectly.

- Stamping and Forging: Commonly used for metal components, these techniques provide strength and durability while reducing waste.

Forming is essential for achieving the specifications required for accurate pressure sensing and switching mechanisms.

3. Assembly

Assembly involves the integration of various components, such as sensors, switches, and electronic circuits, into a cohesive unit. This stage typically includes:

- Manual and Automated Assembly: Skilled workers and robotic systems work together to ensure efficiency and precision.

- Integration of Electronic Components: Advanced pressure switches may incorporate microcontrollers for enhanced functionality.

During assembly, attention to detail is crucial as any misalignment can lead to operational failures.

4. Finishing

The finishing stage enhances the product’s durability and aesthetic appeal. Techniques used include:

- Surface Coating: Protective coatings are applied to prevent corrosion and wear.

- Quality Testing: Each unit undergoes rigorous testing to ensure it meets operational standards.

Finishing processes not only improve the product’s lifespan but also provide a competitive edge in terms of appearance and performance.

Quality Assurance

Quality assurance is a critical aspect of manufacturing differential pressure switches, ensuring that products meet both international and industry-specific standards. Key elements include:

International Standards

B2B buyers should look for suppliers that comply with recognized international standards, such as:

- ISO 9001: Ensures a consistent quality management system, focusing on customer satisfaction and continuous improvement.

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

Industry-Specific Certifications

Certain industries may require additional certifications:

- API (American Petroleum Institute): Relevant for products used in the oil and gas sector, ensuring adherence to safety and performance standards.

- ATEX Certification: Necessary for equipment intended for use in explosive atmospheres.

These certifications provide assurance of quality and reliability, making them essential for international buyers.

Quality Control Checkpoints

Quality control is typically structured around several checkpoints during the manufacturing process:

- Incoming Quality Control (IQC): Inspects raw materials upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitors production processes to identify defects early, ensuring consistency and quality.

- Final Quality Control (FQC): Conducts comprehensive testing of finished products before shipment.

Each checkpoint plays a vital role in maintaining product integrity throughout the manufacturing cycle.

Common Testing Methods

To verify product functionality and reliability, several testing methods are employed:

- Pressure Testing: Assesses the switch’s ability to operate under specified pressure conditions.

- Electrical Testing: Ensures that electronic components function correctly and safely.

- Environmental Testing: Evaluates performance under various environmental conditions, such as temperature and humidity extremes.

B2B buyers should inquire about the specific testing methods used by suppliers to ensure compliance with their operational requirements.

Verifying Supplier Quality Control

International buyers can take several steps to verify the quality control processes of potential suppliers:

- Conduct Audits: Regular audits can reveal the supplier’s adherence to quality standards and manufacturing practices.

- Request Quality Reports: Suppliers should provide documentation detailing their QA processes, including test results and compliance certifications.

- Engage Third-Party Inspectors: Employing independent inspectors can provide an unbiased assessment of product quality and supplier reliability.

Quality Control Nuances for International Buyers

When sourcing differential pressure switches, international buyers from Africa, South America, the Middle East, and Europe must be aware of specific nuances:

- Local Regulations: Familiarize yourself with local regulations and standards that may differ from international norms, particularly in safety and environmental impact.

- Cultural Differences: Understand cultural nuances in business practices and communication styles, which may affect negotiations and relationship building.

- Supply Chain Considerations: Evaluate the stability of the supplier’s supply chain to mitigate risks associated with delays or shortages.

By understanding these nuances and implementing thorough verification processes, international B2B buyers can secure high-quality differential pressure switches that meet their operational needs while fostering long-term supplier relationships.

Related Video: Siemens Differential Pressure Switch for HVAC

Comprehensive Cost and Pricing Analysis for differential pressure switch Sourcing

When sourcing differential pressure switches, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. This analysis focuses on the various cost components and factors influencing pricing, along with actionable tips for negotiation and cost-efficiency.

Cost Components

-

Materials

The primary materials used in manufacturing differential pressure switches, such as metals (e.g., stainless steel), plastics, and electronic components, significantly influence costs. The quality and sourcing of these materials can vary by region, affecting price points. For instance, sourcing materials locally in Africa or South America might reduce logistics costs but could increase material costs if local suppliers lack scale. -

Labor

Labor costs depend on the manufacturing location. Regions with lower wage rates can offer competitive pricing. However, it’s essential to balance labor cost advantages with the skill level of the workforce, as this impacts the quality of the final product.

Illustrative Image (Source: Google Search)

-

Manufacturing Overhead

This includes costs related to facilities, utilities, and administrative expenses. Efficient manufacturing processes can lower overhead costs, which can be an important factor when negotiating prices with suppliers. -

Tooling

Initial tooling costs for custom designs can be substantial. Buyers should consider whether the tooling costs are amortized over a large production run, as high volume can lead to lower per-unit costs. -

Quality Control (QC)

Investing in robust QC processes ensures product reliability and compliance with industry standards. Suppliers with strong QC protocols may charge higher prices, but this investment can reduce long-term costs associated with defects and returns. -

Logistics

Shipping costs can vary based on the supplier’s location and the chosen Incoterms. For international buyers, understanding the total logistics cost, including customs duties and freight charges, is essential to accurately assess the overall expense. -

Margin

Supplier margins can fluctuate based on market demand and competition. Buyers should be aware that specialized or high-quality switches may carry a premium due to their unique specifications or certifications.

Price Influencers

Several factors influence the pricing of differential pressure switches:

-

Volume/MOQ: Higher order volumes often lead to better pricing. Suppliers may offer discounts for larger quantities, making it advantageous for buyers to consolidate orders.

-

Specifications/Customization: Customized products often incur additional costs due to unique design requirements. Buyers should weigh the benefits of customization against potential price increases.

-

Materials and Quality/Certifications: High-quality materials and certifications (like ISO standards) can enhance product reliability but may also raise costs. It’s crucial for buyers to determine the necessary quality level for their specific applications.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their perceived value, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is vital as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Choosing the right Incoterm can optimize shipping costs and mitigate risk.

Buyer Tips

-

Negotiation: Leverage your position by negotiating based on volume, long-term contracts, or multi-product purchases. Suppliers may be willing to offer better terms for guaranteed business.

-

Cost-Efficiency: Assess the Total Cost of Ownership (TCO) rather than just the initial price. Consider factors such as reliability, maintenance, and the potential for future orders when evaluating suppliers.

-

Pricing Nuances: Be aware of regional pricing differences. For example, suppliers in Europe may have higher base prices due to labor and regulatory costs. In contrast, manufacturers in Asia may offer lower prices but require careful vetting for quality assurance.

-

Disclaimer for Indicative Prices: Always request formal quotes and be cautious of indicative pricing as costs can fluctuate due to market conditions, material availability, and other external factors.

By understanding these cost components and pricing influencers, international B2B buyers can make informed decisions when sourcing differential pressure switches, ensuring they achieve the best balance between quality and cost.

Spotlight on Potential differential pressure switch Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘differential pressure switch’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for differential pressure switch

Differential pressure switches are critical components in various industrial applications, ensuring optimal operation by monitoring pressure differences. Understanding their essential technical properties and common trade terminology is vital for B2B buyers looking to make informed purchasing decisions.

Essential Technical Properties

-

Pressure Range

– Definition: The range of pressure that the switch can accurately measure, typically expressed in psi (pounds per square inch) or bar.

– Importance: Selecting a differential pressure switch with an appropriate pressure range is crucial for your application. An incorrect range can lead to system failures or inefficiencies, impacting operational performance and safety. -

Switch Type

– Definition: Refers to the mechanism used to activate the switch, such as mechanical, electronic, or solid-state.

– Importance: Different switch types offer varying levels of reliability, response times, and durability. For example, electronic switches provide faster response times and higher accuracy, which can be critical in sensitive applications. -

Material Grade

– Definition: The quality and type of materials used in the construction of the switch, often including stainless steel or plastic.

– Importance: Material selection affects the switch’s durability, resistance to environmental factors, and overall longevity. For example, stainless steel switches are better suited for corrosive environments, making them ideal for specific industries like oil and gas. -

Tolerance

– Definition: The allowable deviation from the specified measurement, typically expressed as a percentage.

– Importance: Tolerance affects the accuracy and reliability of the switch. Tight tolerances are essential in critical applications where precision is paramount, while looser tolerances might be acceptable in less critical settings. -

Operating Temperature

– Definition: The temperature range within which the switch can function effectively.

– Importance: Ensuring that the differential pressure switch can operate within the expected temperature range of your environment is crucial. Operating outside this range can lead to malfunctions or premature failure.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding whether to source OEM components or aftermarket parts can significantly influence the quality, performance, and cost of your purchases. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers plan their inventory and budget effectively. Suppliers with lower MOQs may be beneficial for smaller businesses or pilot projects. -

RFQ (Request for Quotation)

– Definition: A document used to invite suppliers to submit price quotes for specific products or services.

– Importance: Issuing an RFQ is a strategic way to compare pricing and terms from multiple suppliers, ensuring that you secure the best deal for your needs. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms that clarify the responsibilities of buyers and sellers.

– Importance: Familiarity with Incoterms is crucial for international transactions, as they define who pays for shipping, insurance, and tariffs, thus helping to avoid misunderstandings and disputes. -

Lead Time

– Definition: The amount of time from the placement of an order until it is fulfilled and delivered.

– Importance: Understanding lead times is essential for supply chain planning. Longer lead times can impact project timelines and inventory management, making it critical to negotiate favorable terms with suppliers.

By grasping these technical properties and trade terms, international B2B buyers can enhance their procurement strategies, ensuring they select the right differential pressure switches that meet their specific operational needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the differential pressure switch Sector

Market Overview & Key Trends

The differential pressure switch market is witnessing significant growth driven by increasing demand across various sectors, including HVAC systems, automotive, and industrial automation. Global initiatives aimed at improving energy efficiency and reducing emissions are propelling the adoption of advanced pressure management solutions. In regions such as Africa and South America, the push for infrastructure development and modernization of industrial facilities is creating ample opportunities for sourcing high-quality differential pressure switches.

Emerging technologies, such as IoT-enabled pressure switches, are enhancing the functionality and efficiency of these devices. These smart systems offer real-time monitoring and data analytics capabilities, allowing businesses to optimize their operations and reduce downtime. As a result, international B2B buyers should prioritize suppliers who integrate these technologies into their product offerings.

Illustrative Image (Source: Google Search)

Furthermore, sourcing trends indicate a shift towards localized supply chains to mitigate risks associated with global disruptions. Buyers are increasingly looking for suppliers within their regions, especially in Europe and the Middle East, to enhance responsiveness and reduce lead times. This trend is complemented by a growing focus on supplier reliability and quality assurance, with buyers keen to establish long-term partnerships with manufacturers that demonstrate consistency in product performance.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone of procurement strategies in the differential pressure switch sector. The environmental impact of manufacturing processes and materials used in these devices is under scrutiny, prompting buyers to seek eco-friendly alternatives. B2B buyers should prioritize suppliers who utilize sustainable materials and practices, such as recycled metals and energy-efficient production methods.

Ethical sourcing is equally critical. Buyers need to ensure that their supply chains adhere to ethical labor practices and environmental regulations. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) can serve as benchmarks for assessing supplier compliance. Additionally, the use of “green” certifications, such as Energy Star or CE Marking, can help buyers identify products that meet stringent environmental standards.

Investing in sustainable products not only aligns with corporate social responsibility goals but can also enhance brand reputation among environmentally conscious customers. As the demand for transparency in supply chains continues to rise, B2B buyers should actively engage with suppliers about their sustainability initiatives and certifications to make informed sourcing decisions.

Brief Evolution/History

The differential pressure switch has evolved significantly since its inception, transitioning from simple mechanical devices to sophisticated electronic systems. Initially, these switches were primarily used in industrial applications for basic pressure monitoring. However, advancements in technology have led to the development of digital pressure switches that offer enhanced accuracy and reliability.

In recent years, the integration of IoT capabilities has revolutionized the market, allowing for remote monitoring and control of pressure systems. This evolution reflects a broader trend in industrial automation where smart technologies are increasingly being adopted to optimize operational efficiency and reduce costs. For B2B buyers, understanding this evolution is crucial in sourcing products that not only meet current demands but are also future-ready.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of differential pressure switch

-

What key factors should I consider when vetting suppliers for differential pressure switches?

When vetting suppliers, prioritize their certifications (e.g., ISO 9001), manufacturing capabilities, and track record in the industry. Request references and customer feedback to assess their reliability and quality. Additionally, consider their technical support and communication skills, especially if you require assistance with customization or installation. Look for suppliers that can provide testing data and performance specifications to ensure their products meet your standards. -

Can I customize differential pressure switches to meet specific application needs?

Yes, many suppliers offer customization options for differential pressure switches, including pressure ranges, switching points, and connection types. When discussing customization, provide detailed specifications of your application to ensure the supplier understands your requirements. It’s beneficial to inquire about their design process and lead times for custom orders, as these can vary significantly between manufacturers. -

What are the typical lead times and minimum order quantities (MOQ) for differential pressure switches?

Lead times for differential pressure switches can range from 2 to 12 weeks, depending on the supplier’s inventory, customization requirements, and geographic location. MOQs can also vary; some suppliers may require a minimum of 50 to 100 units, while others might accommodate smaller orders. Always clarify these details upfront to avoid unexpected delays or costs in your procurement process. -

How can I ensure the quality of differential pressure switches I source?

To ensure quality, request certifications such as CE, UL, or RoHS compliance, which indicate adherence to safety and performance standards. Ask for samples to evaluate their performance before placing a bulk order. Additionally, inquire about the supplier’s quality control processes, including any testing they conduct on their products to verify their reliability and durability. -

What payment methods are typically accepted when sourcing differential pressure switches internationally?

Most suppliers accept various payment methods, including bank transfers, letters of credit, and PayPal. For large orders, a letter of credit may provide additional security. It’s advisable to discuss payment terms early in negotiations to align expectations. Consider using escrow services for high-value transactions to mitigate risks related to payment and product quality. -

What logistics considerations should I keep in mind when importing differential pressure switches?

When importing, consider shipping costs, customs duties, and import regulations in your country. Work with suppliers who have experience with international shipping to ensure compliance with all legal requirements. Additionally, ensure that the supplier provides adequate packaging to prevent damage during transit. Establish clear communication regarding delivery timelines and tracking to manage expectations effectively. -

How should I handle disputes with suppliers over quality or delivery issues?

Establish clear terms in your purchase agreements regarding quality expectations, delivery timelines, and dispute resolution processes. If a dispute arises, maintain open communication with the supplier to address issues directly. Document all correspondence and agreements. If necessary, consider mediation or arbitration as a resolution method. Having a legal framework in place can also protect your interests in the event of severe disputes. -

What are the common certifications I should look for in differential pressure switches?

Common certifications include ISO 9001 for quality management, CE marking for compliance with European safety standards, and UL certification for safety in North America. Additionally, look for RoHS compliance, which indicates that the product is free from hazardous substances. These certifications not only validate product quality but also enhance your credibility when reselling or using these components in larger systems.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for differential pressure switch

In the realm of sourcing differential pressure switches, strategic planning and thorough supplier evaluation are paramount. International B2B buyers should prioritize understanding technical specifications, distinguishing between OEM and aftermarket options, and assessing suppliers based on quality, certifications, and support capabilities. This diligence not only enhances product reliability but also fosters long-term supplier relationships that can yield competitive advantages.

Moreover, leveraging digital platforms can streamline the sourcing process, enabling buyers to connect with verified suppliers and remain abreast of industry trends, such as advancements in smart sensor technologies. Investing in quality over mere cost savings will ultimately lead to reduced warranty claims and increased customer satisfaction.

As we look to the future, the demand for differential pressure switches is expected to grow, particularly in sectors such as HVAC, industrial automation, and renewable energy. By adopting a proactive and informed approach to sourcing, buyers from Africa, South America, the Middle East, and Europe can position themselves to capitalize on these opportunities. Engage with suppliers who align with your strategic goals and embrace innovation to ensure your operations remain at the forefront of this evolving market.