Your Ultimate Guide to Sourcing Nema Power Plug

Introduction: Navigating the Global Market for nema power plug

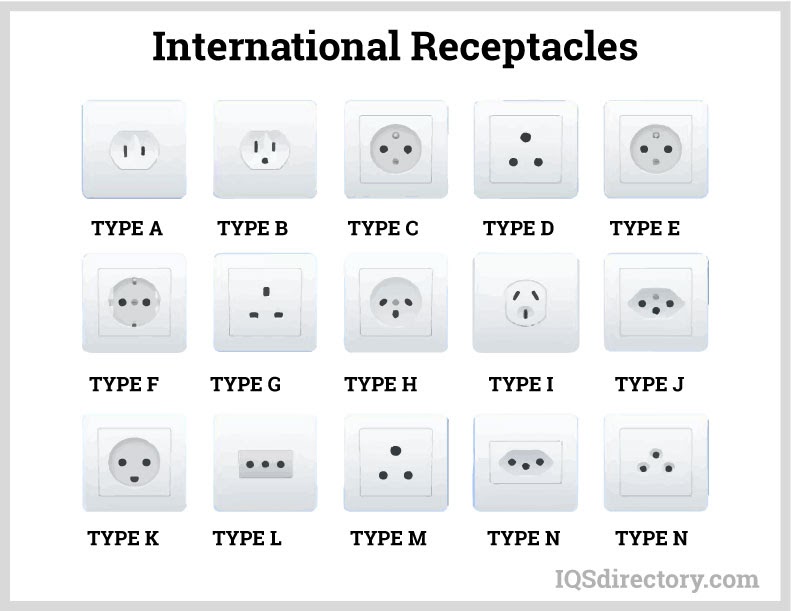

In today’s interconnected global marketplace, the NEMA power plug stands as a critical component for industries ranging from manufacturing to construction. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding the nuances of NEMA plugs is vital for ensuring operational efficiency and safety. These plugs not only facilitate reliable electrical connections but also adhere to strict industry standards, making them indispensable in various applications.

This guide provides a comprehensive overview of the NEMA power plug, covering essential aspects such as types, materials, manufacturing processes, and quality control measures. It highlights key suppliers and offers insights into pricing structures, enabling buyers to navigate the complexities of sourcing effectively. Additionally, the guide addresses frequently asked questions, ensuring that all critical considerations are met.

By leveraging this resource, international buyers can make informed decisions that align with their specific needs. Whether you are sourcing for large-scale projects in Saudi Arabia or looking to optimize supply chains in Europe, understanding the specifications and applications of NEMA plugs will empower you to choose the right products. This guide is designed to streamline your procurement process, enhance your competitive edge, and ultimately support your business growth in a rapidly evolving market.

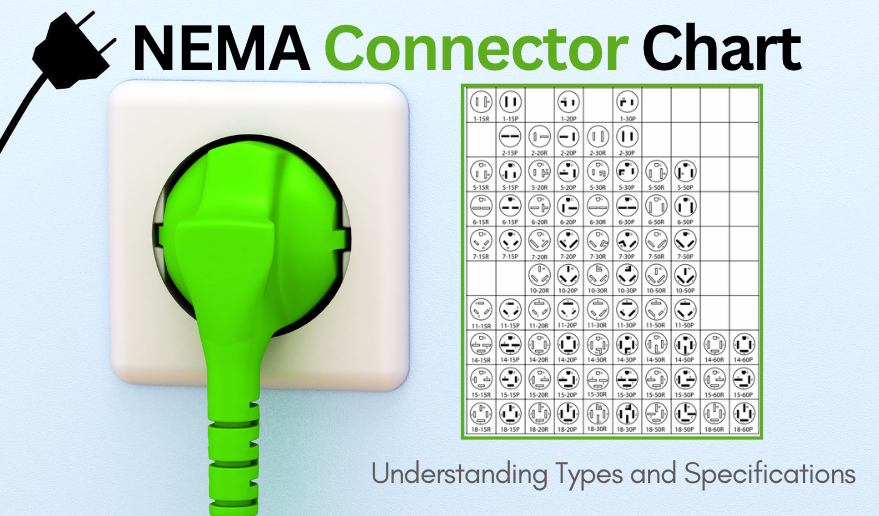

Understanding nema power plug Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| NEMA 5-15 | Standard 3-prong design, rated for 15A, 125V | General purpose, office equipment | Pros: Widely available, low cost. Cons: Not suitable for high-power applications. |

| NEMA L6-30 | Twist-lock design, rated for 30A, 250V | Industrial machinery, HVAC systems | Pros: Secure connection, suitable for high loads. Cons: Requires compatible receptacles. |

| NEMA 14-50 | 4-prong design, rated for 50A, 250V | Electric vehicle charging, heavy machinery | Pros: High power capacity, versatile. Cons: Bulkier, may require specialized installation. |

| NEMA 6-15 | Similar to NEMA 5-15 but rated for 15A, 250V | Commercial appliances, lighting | Pros: Higher voltage tolerance. Cons: Less common than NEMA 5-15, may need adapters. |

| NEMA L5-20 | Twist-lock design, rated for 20A, 125V | Temporary power setups, events | Pros: Secure connection, prevents accidental disconnection. Cons: More expensive than standard plugs. |

NEMA 5-15

The NEMA 5-15 plug is the most common type, featuring a standard three-prong design that supports devices up to 15A and 125V. Its widespread usage in commercial and office environments makes it a go-to choice for general-purpose applications. When purchasing, consider the availability and compatibility of receptacles; while it’s cost-effective, it may not meet the demands of high-power equipment.

NEMA L6-30

With a twist-lock mechanism, the NEMA L6-30 plug is designed for heavy-duty applications, rated for 30A at 250V. This type is prevalent in industrial settings, particularly for machinery and HVAC systems, where secure connections are critical. Buyers should ensure their infrastructure can accommodate this plug type, as its unique design requires compatible receptacles.

NEMA 14-50

The NEMA 14-50 plug is a robust four-prong connector rated for 50A and 250V, commonly used in electric vehicle charging stations and heavy machinery. Its high power capacity makes it versatile for various applications. However, due to its bulkiness, buyers must consider installation requirements and space constraints in their facilities.

NEMA 6-15

The NEMA 6-15 plug is similar in appearance to the NEMA 5-15 but is designed for 15A at 250V applications, making it suitable for commercial appliances and lighting. While it offers higher voltage tolerance, it is less common than the 5-15, which may necessitate the use of adapters. B2B buyers should evaluate their equipment compatibility before making a purchase.

NEMA L5-20

The NEMA L5-20 plug features a twist-lock design and is rated for 20A at 125V, making it ideal for temporary power setups and events where secure connections are necessary. Although it is more expensive than standard plugs, its reliability and safety features make it a worthwhile investment for businesses that require frequent setups and breakdowns. Buyers should consider their specific power needs and the availability of compatible receptacles when selecting this plug type.

Related Video: How to Install ChargePoint Home Flex (CPH50) Plug-in with NEMA 6-50 or 14-50 outlet

Key Industrial Applications of nema power plug

| Industry/Sector | Specific Application of NEMA Power Plug | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Temporary power distribution for tools and equipment | Ensures reliable power supply on job sites, enhancing productivity | Durability, compatibility with local electrical codes, and weather resistance |

| Events and Entertainment | Power supply for lighting and sound equipment | Enables seamless operation of events, improving audience experience | Portability, ease of setup, and safety certifications |

| Manufacturing | Connection for heavy machinery and industrial equipment | Supports efficient operation and minimizes downtime | Amperage ratings, environmental ratings, and compliance with industry standards |

| Military Applications | Powering mobile command centers and equipment | Provides robust and secure power solutions in diverse environments | Ruggedness, reliability under extreme conditions, and compliance with military specifications |

| Telecommunications | Powering communication infrastructure | Ensures uninterrupted service and connectivity | Voltage specifications, compatibility with existing systems, and availability of support services |

Detailed Application Scenarios

Construction

In the construction industry, NEMA power plugs are essential for temporary power distribution. They connect various tools and equipment, ensuring a reliable power supply on job sites. This application significantly enhances productivity by minimizing downtime caused by power interruptions. International buyers should consider sourcing plugs that are durable and compatible with local electrical codes, particularly in regions like Africa and South America where construction sites may face environmental challenges.

Events and Entertainment

For events and entertainment, NEMA power plugs are commonly used to supply power to lighting and sound equipment. This application is crucial for ensuring that events run smoothly, thereby enhancing the overall audience experience. Buyers in this sector should prioritize portability and ease of setup, as well as safety certifications to comply with local regulations, especially in the Middle East and Europe where event standards can vary.

Illustrative Image (Source: Google Search)

Manufacturing

In the manufacturing sector, NEMA power plugs are utilized to connect heavy machinery and industrial equipment. This application is vital for supporting efficient operations and minimizing downtime. Buyers in this field should focus on plugs that meet specific amperage ratings and environmental ratings, ensuring compliance with industry standards. This is particularly important for manufacturers in Europe, where stringent safety regulations are enforced.

Military Applications

NEMA power plugs are critical in military applications for powering mobile command centers and various equipment. The robust and secure power solutions provided by these plugs are essential in diverse environments, from desert conditions in the Middle East to more temperate climates in Europe. Buyers must ensure that the plugs sourced are rugged and reliable under extreme conditions, in addition to meeting military specifications for safety and performance.

Telecommunications

In the telecommunications industry, NEMA power plugs are used to power communication infrastructure. This application is vital for ensuring uninterrupted service and connectivity, particularly in regions with developing infrastructure. When sourcing these plugs, buyers should pay attention to voltage specifications and compatibility with existing systems, along with the availability of support services to ensure seamless integration and operation.

Related Video: 3 Prong 4 Prong Dryer Outlet Receptacle Plug Nema 10-30R Nema 14-30R install wiring

Strategic Material Selection Guide for nema power plug

When selecting materials for NEMA power plugs, international B2B buyers must consider a range of factors that influence performance, durability, and compliance with local standards. Here, we analyze four common materials used in NEMA power plugs, focusing on their key properties, advantages and disadvantages, and implications for various applications.

1. Thermoplastic Elastomers (TPE)

Key Properties: TPEs are known for their excellent flexibility and resilience, with a temperature rating typically ranging from -40°C to 120°C. They also exhibit good electrical insulation properties.

Pros & Cons: TPEs are lightweight and resistant to UV radiation and chemicals, making them suitable for outdoor applications. However, they may have lower mechanical strength compared to other materials, which can affect durability in high-stress environments. The manufacturing complexity is moderate, often requiring specialized molding techniques.

Impact on Application: TPEs are ideal for applications requiring flexibility and resistance to environmental factors, such as construction sites or outdoor events. Their compatibility with various media, including water and oils, enhances their utility.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and IEC for electrical safety. In regions like Europe and Australia, certifications for environmental impact may also be relevant.

2. Polycarbonate (PC)

Key Properties: Polycarbonate is known for its high impact resistance and a temperature rating between -40°C and 125°C. It also has good dimensional stability and transparency.

Pros & Cons: The primary advantage of polycarbonate is its toughness, which makes it suitable for harsh environments. However, it can be more expensive than alternatives like PVC and may require specific processing techniques, increasing manufacturing complexity.

Impact on Application: Polycarbonate is commonly used in industrial settings where durability is crucial, such as manufacturing plants and heavy machinery applications. Its clarity allows for visual inspection of internal components, which can be beneficial in maintenance scenarios.

Considerations for International Buyers: Compliance with safety standards is critical, especially in regions with stringent regulations. Buyers in Africa and the Middle East should be aware of local standards that may differ from European norms.

3. Nylon

Key Properties: Nylon offers excellent strength and abrasion resistance, with a temperature rating typically ranging from -40°C to 120°C. It is also resistant to many chemicals and has good electrical insulating properties.

Pros & Cons: The durability of nylon makes it suitable for high-stress applications, but it can be prone to moisture absorption, which may affect its dimensional stability over time. The cost is generally moderate, and manufacturing processes are well-established.

Impact on Application: Nylon is often used in applications where mechanical strength is essential, such as in industrial machinery and automotive components. Its chemical resistance makes it suitable for environments where exposure to oils and solvents is common.

Considerations for International Buyers: Buyers should check for compliance with both international and local standards, particularly in regions with specific regulations regarding materials used in electrical components.

4. Polyvinyl Chloride (PVC)

Key Properties: PVC is a versatile material with a temperature rating of approximately -15°C to 60°C. It is known for its good chemical resistance and electrical insulating properties.

Pros & Cons: PVC is cost-effective and easy to process, making it a popular choice for many applications. However, it has lower temperature resistance compared to other materials and can become brittle over time when exposed to UV light.

Impact on Application: PVC is often used in residential and light commercial applications where cost is a significant factor. It is suitable for environments with minimal exposure to extreme temperatures or harsh chemicals.

Considerations for International Buyers: Compliance with environmental regulations is crucial, especially in Europe where restrictions on certain materials are in place. Buyers should also consider the impact of PVC on sustainability initiatives.

Summary Table

| Material | Typical Use Case for nema power plug | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic Elastomers (TPE) | Outdoor applications, construction sites | Excellent flexibility and UV resistance | Lower mechanical strength | Medium |

| Polycarbonate (PC) | Industrial settings, heavy machinery | High impact resistance | Higher cost and processing complexity | High |

| Nylon | Industrial machinery, automotive components | Excellent strength and abrasion resistance | Moisture absorption affects stability | Medium |

| Polyvinyl Chloride (PVC) | Residential and light commercial applications | Cost-effective and easy to process | Lower temperature resistance | Low |

This guide provides actionable insights for B2B buyers in diverse regions, helping them make informed decisions on material selection for NEMA power plugs based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for nema power plug

The manufacturing of NEMA power plugs involves a series of well-defined processes and stringent quality assurance measures. This section provides an in-depth look at the typical stages of manufacturing, the quality control standards applied, and actionable insights for B2B buyers, particularly those from Africa, South America, the Middle East, and Europe.

Manufacturing Processes

-

Material Preparation

– The initial step in manufacturing NEMA power plugs is the selection and preparation of materials. Common materials include high-grade thermoplastics for the housing and conductive metals such as copper or brass for the pins.

– Key Techniques:- Material Testing: Before production, materials undergo rigorous testing for electrical conductivity, thermal resistance, and mechanical strength.

- Sourcing: Buyers should ensure that materials are sourced from certified suppliers to avoid quality issues.

-

Forming

– This stage involves shaping the prepared materials into the desired forms. For instance, the metal pins are often stamped or extruded to achieve precision dimensions.

– Key Techniques:- Stamping Machines: These machines are used to cut and shape the metal into pins with high accuracy.

- Injection Molding: Thermoplastic components are produced through this process, ensuring uniformity and strength in the plug housing.

-

Assembly

– Once individual components are formed, the assembly process commences. This stage can be manual or automated depending on the production scale.

– Key Techniques:- Soldering and Welding: Electrical connections are established through soldering or ultrasonic welding, ensuring a strong bond that can withstand high currents.

- Quality Checks: Each assembly line should incorporate checkpoints where components are inspected for correct alignment and secure connections.

-

Finishing

– The final stage involves surface treatment and finishing touches to enhance durability and aesthetics. This may include coating, polishing, or applying labels.

– Key Techniques:- Surface Coating: Application of protective coatings to prevent corrosion and wear.

- Final Inspection: Each plug undergoes a visual inspection to check for defects before packaging.

Quality Assurance

International Standards

- ISO 9001: This standard ensures that manufacturers maintain a quality management system. It is crucial for ensuring consistency and quality in production processes.

- CE Marking: For products sold in Europe, compliance with CE standards is mandatory, indicating that the product meets EU safety and environmental requirements.

- API Standards: For specific industrial applications, adherence to American Petroleum Institute (API) standards may also be required.

Quality Control Checkpoints

- Incoming Quality Control (IQC)

– At this stage, raw materials are inspected for compliance with specifications. This includes checking material certifications and conducting random sampling tests.

Illustrative Image (Source: Google Search)

-

In-Process Quality Control (IPQC)

– During manufacturing, various checkpoints are established to monitor the processes. This includes measuring dimensions of formed components and conducting electrical tests on assembled plugs. -

Final Quality Control (FQC)

– After assembly, the final products are subjected to comprehensive testing. This includes:- Dielectric Testing: To ensure insulation integrity.

- Load Testing: To verify that the plugs can handle their rated current without overheating.

- Visual Inspection: For cosmetic defects and labeling accuracy.

Verifying Supplier Quality Control

B2B buyers can take several steps to verify the quality control processes of their suppliers:

- Supplier Audits: Conducting on-site audits can provide insights into the manufacturing and quality assurance processes. This includes reviewing documentation and inspecting the production facility.

- Quality Reports: Requesting detailed quality reports and certifications can help assess the supplier’s commitment to quality.

- Third-party Inspections: Utilizing independent inspectors can provide an unbiased assessment of product quality and adherence to standards.

Quality Control and Certification Nuances for International Buyers

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is crucial:

- Regional Compliance: Each region may have specific regulations and compliance requirements. For instance, products intended for the EU market must comply with CE marking, while products sold in the Middle East may require GCC certification.

- Cultural Considerations: Understanding local business practices and cultural nuances can aid in building trust with suppliers. This is particularly relevant in regions where face-to-face relationships are valued.

- Language Barriers: Ensure that all documentation is available in the buyer’s preferred language to avoid miscommunication regarding quality standards and requirements.

Conclusion

In conclusion, the manufacturing processes and quality assurance measures for NEMA power plugs are critical components that B2B buyers must consider. By understanding these processes and implementing thorough verification practices, buyers can ensure they source high-quality products that meet international standards, ultimately supporting their operational needs in diverse markets.

Related Video: 18650 Cell Manufacturing Process, Automatic Production Line

Comprehensive Cost and Pricing Analysis for nema power plug Sourcing

In the procurement of NEMA power plugs, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. This analysis covers the key cost components, price influencers, and actionable buyer tips to optimize sourcing strategies.

Cost Components

-

Materials: The primary raw materials for NEMA plugs include high-quality plastics and metals, which contribute significantly to the overall cost. The prices of these materials can fluctuate based on global market trends and regional availability, impacting the total cost of the product.

-

Labor: Labor costs vary by region, affecting both manufacturing and assembly processes. Countries with higher labor costs may yield higher-priced products, while regions with lower labor costs can provide more competitive pricing.

-

Manufacturing Overhead: This encompasses indirect costs related to production, including utilities, rent, and equipment maintenance. Efficient manufacturing processes and economies of scale can help mitigate these overhead costs.

-

Tooling: The initial investment in tooling for NEMA plug production can be substantial, especially for custom designs. Tooling costs are typically amortized over production runs, influencing pricing for lower volume orders.

-

Quality Control (QC): Ensuring that products meet industry standards and certifications requires investment in quality control processes. This can add to the cost but is essential for maintaining product reliability and safety.

-

Logistics: Shipping costs are a significant factor, especially for international transactions. These costs can vary based on the mode of transport, distance, and Incoterms agreed upon in the contract.

-

Margin: Suppliers typically mark up prices to achieve a profit margin. The margin can vary based on competition, perceived value, and the supplier’s market positioning.

Price Influencers

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) to optimize pricing.

-

Specifications/Customization: Custom designs or specific specifications can increase costs. Buyers should evaluate whether standard products meet their needs to avoid unnecessary expenses.

-

Materials and Quality/Certifications: Higher-quality materials and certified products usually command premium prices. Buyers should assess their quality requirements to balance cost and performance.

-

Supplier Factors: The supplier’s reputation, reliability, and production capacity can influence pricing. Building strong relationships with suppliers may lead to better pricing and terms.

-

Incoterms: Understanding the chosen Incoterms (e.g., FOB, CIF) is vital, as they dictate the responsibilities of buyers and sellers regarding shipping costs and risk.

Buyer Tips

-

Negotiation: Leverage the purchasing power of volume orders to negotiate better pricing. Establishing long-term relationships with suppliers can also yield favorable terms.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not only the purchase price but also shipping, handling, and potential maintenance costs. This holistic view can guide better purchasing decisions.

-

Pricing Nuances: International buyers should be aware of currency fluctuations, import duties, and local taxes that can affect the final cost. Engage with local experts to navigate these complexities.

-

Market Research: Conduct thorough market research to understand regional pricing trends and supplier capabilities. This knowledge can empower buyers to make informed decisions and identify the best sourcing options.

Disclaimer

Prices for NEMA power plugs can vary widely based on the aforementioned factors, and the information provided is indicative. Buyers should conduct due diligence and obtain quotes from multiple suppliers to ensure competitive pricing.

Spotlight on Potential nema power plug Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘nema power plug’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for nema power plug

Key Technical Properties of NEMA Power Plugs

-

Material Grade

– NEMA power plugs are commonly made from materials such as thermoplastic or thermoset polymers, which provide durability and electrical insulation. The choice of material affects the plug’s resistance to heat, impact, and chemicals. For B2B buyers, understanding the material grade is crucial for ensuring that the plugs can withstand specific environmental conditions in their applications. -

Current Rating

– This specification indicates the maximum amount of electrical current the plug can handle safely, typically measured in amperes (A). Common ratings include 15A, 20A, and 30A. Selecting the correct current rating is essential for preventing overheating and ensuring the safety of electrical systems, particularly in heavy industrial settings. -

Voltage Rating

– Voltage rating defines the maximum voltage the plug can safely handle, usually expressed in volts (V). NEMA plugs are available for different voltage classes, such as 120V, 240V, and 480V. For international buyers, knowing the voltage requirements of their equipment and aligning them with the NEMA plug specifications ensures compatibility and operational safety. -

Pin Configuration

– The arrangement and shape of the pins in a NEMA plug dictate its compatibility with receptacles. Different configurations (e.g., NEMA L5-30, NEMA L6-30) are designed for specific applications and power requirements. Understanding the pin configuration is vital for B2B buyers to avoid mismatches that could lead to equipment failure or safety hazards. -

Tolerance and Specifications

– Tolerances refer to the permissible limits of variation in the dimensions and performance of the plug. This includes size, electrical resistance, and heat dissipation. High-quality NEMA plugs will have precise tolerances to ensure optimal performance. For manufacturers and buyers, ensuring that plugs meet stringent tolerance levels is essential for maintaining the integrity of their electrical systems. -

Ingress Protection (IP) Rating

– The IP rating indicates the level of protection against dust and moisture. For example, an IP67 rating means the plug is dust-tight and can withstand immersion in water up to 1 meter. This is particularly important for applications in harsh environments, making it a critical consideration for buyers in sectors like construction and marine operations.

Common Trade Terminology in NEMA Power Plug Transactions

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of NEMA plugs, knowing the OEM can help buyers ensure they are sourcing high-quality components that meet industry standards. -

MOQ (Minimum Order Quantity)

– This term indicates the smallest number of units that a supplier is willing to sell. Understanding the MOQ is crucial for B2B buyers to align their purchasing strategies with inventory management and budget constraints. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to request pricing and terms for a specific quantity of goods. For buyers, issuing an RFQ for NEMA plugs helps in comparing prices and terms from various suppliers, facilitating better procurement decisions. -

Incoterms (International Commercial Terms)

– Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is essential for buyers to understand shipping costs, risk allocation, and delivery responsibilities. -

Lead Time

– Lead time refers to the amount of time it takes from placing an order to receiving the goods. For B2B buyers, knowing the lead time for NEMA plugs is critical for project planning and ensuring that equipment is available when needed. -

Certification Standards

– Many NEMA plugs must meet specific certification standards (e.g., UL, CE) to ensure safety and reliability. Buyers should verify that the plugs comply with relevant standards for their region to avoid legal issues and ensure operational safety.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing NEMA power plugs, ensuring compatibility, safety, and performance in their electrical systems.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the nema power plug Sector

Market Overview & Key Trends

The global market for NEMA power plugs is experiencing notable growth, driven by increasing demand for reliable electrical connections across various industries, including manufacturing, construction, and entertainment. The rise of renewable energy and electric vehicles is propelling the need for efficient power distribution systems, further enhancing the significance of NEMA plugs. International B2B buyers, especially from Africa, South America, the Middle East, and Europe, should be aware of the following key trends:

-

Technological Advancements: The integration of smart technology into power distribution is gaining traction. Buyers are increasingly looking for NEMA plugs that offer features like remote monitoring and diagnostics, which improve operational efficiency.

-

Customization and Versatility: As businesses seek to optimize their operations, there is a growing demand for customizable NEMA plugs that can cater to specific voltage and amperage requirements. Suppliers that offer tailored solutions will likely capture more market share.

-

Cross-Regional Sourcing: With the rise of global supply chains, international buyers are exploring sourcing options beyond local markets. This trend is particularly pronounced in Europe, where companies are looking to diversify their suppliers to mitigate risks associated with geopolitical tensions and trade policies.

-

Regulatory Compliance: Adherence to international safety standards is paramount. Buyers must ensure that the NEMA plugs they procure meet relevant certifications, such as UL and IEC, to avoid potential legal and operational challenges.

Sustainability & Ethical Sourcing in B2B

Sustainability has emerged as a critical consideration in the procurement of NEMA power plugs. The environmental impact of electrical components extends beyond their lifespan; it includes the materials used in their production and the processes employed. International B2B buyers should focus on the following aspects to promote sustainability:

-

Ethical Supply Chains: It is essential to partner with manufacturers that prioritize ethical sourcing practices. This includes ensuring fair labor practices, transparency in sourcing materials, and minimizing environmental degradation.

-

Green Certifications: Look for NEMA plugs that come with certifications like RoHS (Restriction of Hazardous Substances) and Energy Star. These certifications indicate that the products meet rigorous environmental standards and contribute to energy efficiency.

-

Material Selection: Opt for NEMA plugs made from recyclable or sustainably sourced materials. Manufacturers that utilize eco-friendly materials not only reduce their carbon footprint but also appeal to a growing segment of environmentally conscious consumers.

By aligning procurement strategies with sustainability goals, B2B buyers can enhance their corporate social responsibility (CSR) initiatives while simultaneously meeting market demand for eco-friendly products.

Brief Evolution/History

NEMA (National Electrical Manufacturers Association) power plugs have a rich history, evolving alongside advancements in electrical engineering and safety standards. Initially developed in the early 20th century, these plugs were designed to standardize electrical connections in North America. Over the decades, the adoption of NEMA standards expanded globally, driven by the need for safe and reliable electrical connections across various applications.

Today, NEMA power plugs are integral to diverse sectors, including industrial, commercial, and residential applications. The ongoing evolution of these plugs reflects technological advancements and the increasing emphasis on safety, efficiency, and sustainability in electrical systems. Understanding this history equips international buyers with the context necessary for making informed sourcing decisions in an ever-evolving market landscape.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of nema power plug

-

What should I consider when vetting suppliers for NEMA power plugs?

When vetting suppliers, prioritize their industry experience, product quality certifications, and compliance with international standards. Request references from previous clients and investigate their reputation in the market. Verify if they have the capacity to meet your specific needs, including volume and customization. Additionally, assess their production capabilities and supply chain reliability to ensure they can deliver on time and at the agreed quality. -

Can NEMA power plugs be customized to meet specific requirements?

Yes, many manufacturers offer customization options for NEMA power plugs. This can include variations in voltage, amperage, and even design features like color coding or housing materials. When discussing customization, provide detailed specifications to ensure the supplier understands your requirements. Also, confirm any additional costs or lead times associated with custom orders. -

What are the typical minimum order quantities (MOQ) and lead times for NEMA power plugs?

Minimum order quantities (MOQ) can vary widely among suppliers, often ranging from 100 to 1,000 units. Lead times typically depend on the complexity of the order and the supplier’s production capacity, usually ranging from 2 to 8 weeks. It’s essential to discuss these aspects upfront to align with your project timelines and inventory needs, especially if you operate in regions with fluctuating demand. -

What payment options are usually available when sourcing NEMA power plugs?

Payment options can include bank transfers, letters of credit, and payment platforms like PayPal or Alibaba Trade Assurance. Discuss payment terms during negotiations, including deposits and full payment timelines. Some suppliers may offer financing options for larger orders. Ensure that the payment method you choose provides sufficient security and meets your financial management practices. -

How can I ensure quality assurance and certification for NEMA power plugs?

Request documentation regarding quality assurance processes and certifications such as ISO 9001 or UL listing. Suppliers should provide test reports and compliance certificates that demonstrate adherence to safety and performance standards. Regular audits and quality checks are also advisable to ensure ongoing compliance, especially for high-volume orders or critical applications. -

What logistics considerations should I keep in mind when importing NEMA power plugs?

Logistics involve several components, including shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder experienced in handling electrical components. Understand the customs regulations in your country to avoid delays, and ensure your supplier provides necessary documentation like invoices and certificates of origin to facilitate smooth customs processing. -

How should I handle disputes or issues with suppliers?

Establish clear communication channels and document all agreements to mitigate disputes. If issues arise, address them promptly with the supplier, providing evidence of the problem. Many suppliers have dispute resolution processes, such as mediation or arbitration. If a satisfactory resolution cannot be reached, consider involving a legal advisor familiar with international trade law to explore your options. -

What are the common applications for NEMA power plugs in different industries?

NEMA power plugs are widely used in various sectors, including manufacturing, construction, entertainment, and military applications. They are ideal for connecting heavy machinery, power distribution systems, and temporary power setups for events. Understanding the specific needs of your industry can help guide your sourcing decisions, ensuring you select the right type of NEMA plug for your applications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for nema power plug

As international B2B buyers navigate the complexities of sourcing NEMA power plugs, strategic sourcing emerges as a vital component for ensuring reliability and efficiency in operations. Key takeaways include the importance of understanding regional standards, such as voltage and amperage specifications, which vary across Africa, South America, the Middle East, and Europe. Buyers should prioritize partnerships with reputable manufacturers and suppliers who demonstrate compliance with international safety and quality standards.

Moreover, leveraging technology and data analytics can streamline procurement processes, allowing for better inventory management and cost control. Establishing strong relationships with suppliers not only enhances negotiation power but also fosters innovation and adaptability in response to changing market demands.

Looking ahead, the demand for NEMA power plugs is expected to grow, driven by increased industrialization and infrastructure development. International buyers are encouraged to stay informed about emerging trends and technologies in the electrical components sector. By adopting a proactive sourcing strategy, businesses can position themselves to capitalize on future opportunities, ensuring their operations remain competitive and sustainable in a dynamic global market. Engage with trusted suppliers today to secure your supply chain and enhance operational resilience.