Master Sourcing High-Quality Magnetic Coils for Global

Introduction: Navigating the Global Market for magnetic coil

In today’s technologically driven landscape, magnetic coils are integral components that enhance the functionality of numerous industrial applications, from automotive systems and medical devices to renewable energy solutions. As B2B buyers from Africa, South America, the Middle East, and Europe seek to innovate and optimize their operations, understanding the nuances of magnetic coil sourcing becomes crucial. The demand for high-quality, efficient coils is not just a trend; it reflects a fundamental shift towards advanced manufacturing and automation.

This comprehensive guide serves as a vital resource for procurement professionals navigating the complexities of the global magnetic coil market. It covers a wide spectrum of critical topics, including:

- Types and Materials: An exploration of various magnetic coils, such as those made from copper, aluminum, and specialized alloys, tailored for specific applications.

- Manufacturing and Quality Control: Insights into production processes and quality assurance measures that ensure reliability and performance.

- Supplier Selection: Detailed profiles of reputable manufacturers, including their strengths and market positions across different regions.

- Cost Analysis: A breakdown of pricing structures and factors influencing the cost of magnetic coils.

- Market Trends: Up-to-date information on industry developments and regional sourcing dynamics.

- FAQs: Answers to common questions that arise during the sourcing process.

By leveraging this guide, international B2B buyers can make informed decisions that not only reduce sourcing risks but also enhance product quality and operational efficiency. Embrace the magnetic advantage and transform your procurement strategy to meet the demands of tomorrow’s market.

Understanding magnetic coil Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Air Core Coils | Lightweight, no magnetic core, low inductance | RF applications, antennas, inductors | Pros: Cost-effective, lightweight. Cons: Lower efficiency, limited applications. |

| Iron Core Coils | Utilizes iron or ferromagnetic core for enhanced inductance | Transformers, relays, solenoids | Pros: High efficiency, increased magnetic field. Cons: Heavier, potential core saturation. |

| Ferrite Core Coils | Made with ferrite material, excellent high-frequency performance | Telecommunications, power supplies | Pros: Lightweight, good for high frequencies. Cons: Brittle, limited mechanical strength. |

| Toroidal Coils | Ring-shaped, minimal electromagnetic interference | Power supplies, inductors, audio applications | Pros: Compact, reduced EMI. Cons: More complex to manufacture. |

| Litz Wire Coils | Composed of multiple thin wire strands, reduces skin effect | High-frequency applications, motors, transformers | Pros: Improved efficiency at high frequencies. Cons: Higher cost, complex manufacturing. |

Air Core Coils

Air core coils are notable for their simplicity, as they do not utilize a magnetic core. This feature makes them lightweight and cost-effective, which is particularly beneficial in applications like radio frequency (RF) systems and antennas. However, air core coils generally have lower inductance and efficiency compared to other types, limiting their use in high-power applications. Buyers should consider the specific inductance requirements of their projects and the potential trade-offs in efficiency.

Iron Core Coils

Iron core coils are characterized by their use of ferromagnetic materials, which significantly enhance their inductance. This makes them ideal for applications that require high efficiency, such as transformers and solenoids. While their increased inductance is a significant advantage, buyers must also consider the added weight and the risk of core saturation under high currents. It’s essential to assess the operational environment and load conditions to ensure optimal performance.

Illustrative Image (Source: Google Search)

Ferrite Core Coils

Ferrite core coils are composed of ferrite materials, known for their excellent performance at high frequencies. They are commonly used in telecommunications and power supply applications. The lightweight nature of ferrite cores allows for compact designs, but their brittleness can pose challenges during handling and installation. B2B buyers should evaluate the mechanical strength and thermal stability of ferrite coils, especially in applications subjected to vibration or thermal cycling.

Toroidal Coils

Toroidal coils, which are ring-shaped, are designed to minimize electromagnetic interference (EMI) while providing a compact solution for various applications, including power supplies and audio devices. The toroidal shape allows for efficient magnetic field containment, enhancing performance. However, the complexity of manufacturing toroidal coils can lead to higher costs. Buyers should weigh the benefits of reduced EMI against the investment in manufacturing when selecting this type of coil.

Litz Wire Coils

Litz wire coils are made from multiple strands of thin wire, which helps to reduce the skin effect and improve efficiency in high-frequency applications. They are particularly useful in motors and transformers where high efficiency is critical. While Litz wire coils offer significant advantages in performance, they tend to be more expensive and complex to manufacture. B2B buyers should ensure that the cost aligns with the performance benefits required for their specific applications.

Related Video: What Are The Different Atomic Models? Dalton, Rutherford, Bohr and Heisenberg Models Explained

Key Industrial Applications of magnetic coil

| Industry/Sector | Specific Application of Magnetic Coil | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Electric Vehicle (EV) Motors | Enhanced efficiency and performance in electric drivetrains | Look for suppliers with expertise in automotive-grade coils and certifications for safety and performance. |

| Healthcare | MRI Machines | High-precision imaging capabilities for better diagnostics | Ensure manufacturers comply with medical standards and provide reliable testing data. |

| Renewable Energy | Wind Turbine Generators | Improved energy conversion efficiency | Source from suppliers offering durable coils that withstand harsh environmental conditions. |

| Consumer Electronics | Audio Equipment (Speakers) | Superior sound quality and energy efficiency | Evaluate suppliers for miniaturization capabilities and high-quality materials. |

| Industrial Automation | Robotics and Automation Systems | Increased reliability and operational efficiency | Seek manufacturers with customization options to meet specific automation needs. |

Automotive: Electric Vehicle (EV) Motors

In the automotive sector, magnetic coils are crucial components in electric vehicle (EV) motors. These coils enhance the efficiency and performance of electric drivetrains by generating strong magnetic fields that drive the motor’s rotation. For international buyers, particularly in Africa and South America, the focus should be on sourcing from suppliers with proven expertise in automotive-grade coils, as these components must meet stringent safety and performance standards. Additionally, certifications such as ISO can help ensure reliability and compliance with regional regulations.

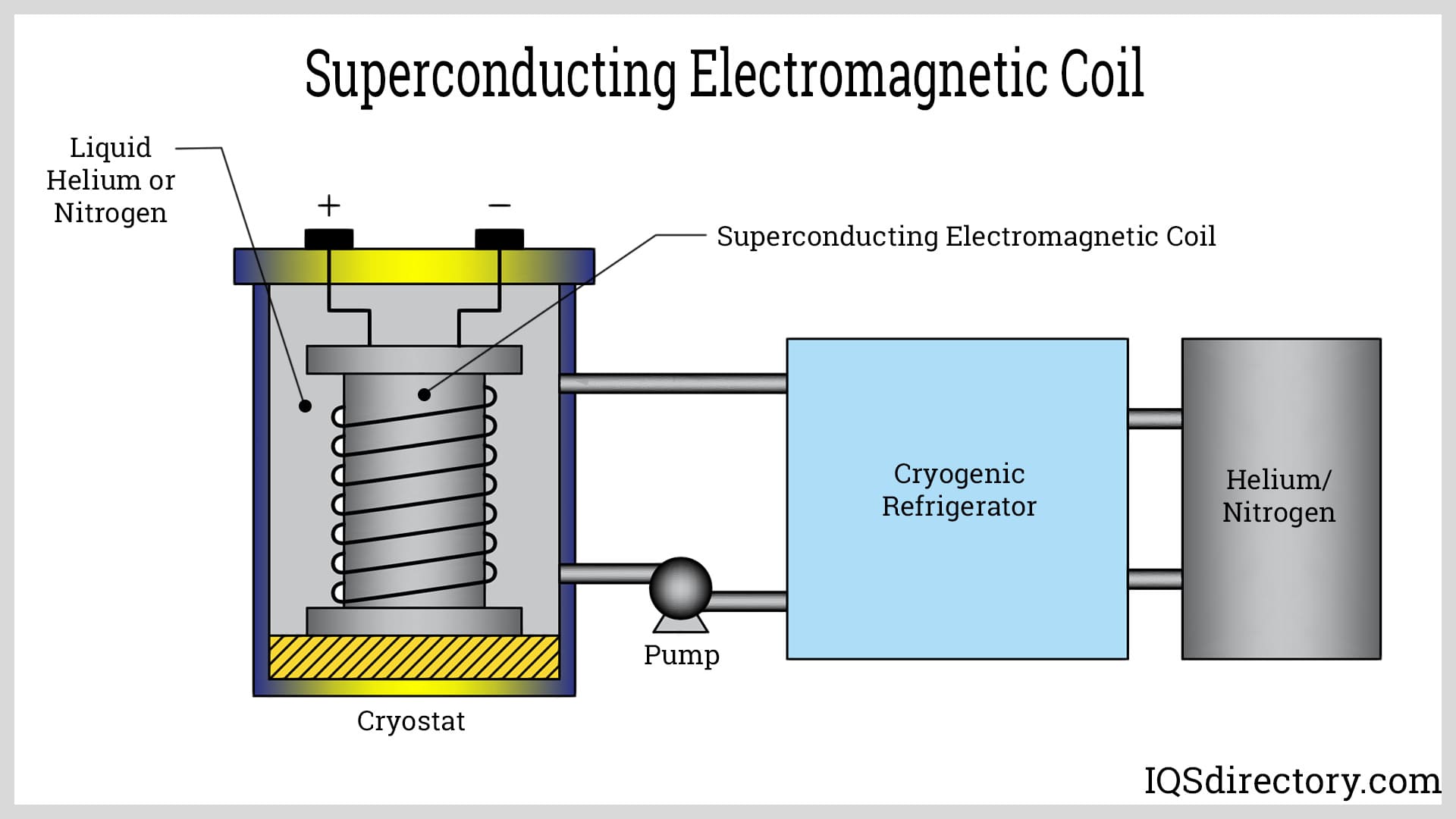

Healthcare: MRI Machines

Magnetic coils are integral to the operation of MRI machines, providing the necessary magnetic fields for high-precision imaging. This application is vital for accurate diagnostics in healthcare. Buyers in the Middle East and Europe should prioritize manufacturers that specialize in medical-grade components, ensuring compliance with health regulations and robust testing protocols. Reliability and consistency in performance are critical, making it essential to verify a supplier’s track record in the medical sector.

Renewable Energy: Wind Turbine Generators

In the renewable energy industry, magnetic coils are utilized in wind turbine generators to convert mechanical energy into electrical energy. High-quality coils significantly improve energy conversion efficiency, which is crucial for maximizing output in renewable installations. B2B buyers in regions such as Africa, where renewable energy projects are expanding, should focus on sourcing durable coils capable of withstanding harsh environmental conditions. Suppliers that offer robust warranties and proven performance metrics will be beneficial.

Consumer Electronics: Audio Equipment (Speakers)

Magnetic coils are pivotal in audio equipment, specifically in speakers, where they help produce superior sound quality by converting electrical signals into sound waves. The demand for energy-efficient and high-fidelity audio devices is growing, particularly in Europe and South America. Buyers should evaluate suppliers based on their ability to provide miniaturized coils that do not compromise on quality. The material used in coil construction can also affect sound performance, making it essential to source from reputable manufacturers.

Industrial Automation: Robotics and Automation Systems

In industrial automation, magnetic coils are employed in various robotic systems to enhance reliability and operational efficiency. These coils help control the movement of robotic arms and components, making them essential for precision tasks in manufacturing. International buyers, especially those in rapidly developing markets like South Africa, should seek manufacturers that offer customization options tailored to specific automation needs. Additionally, the supplier’s ability to provide quick turnaround times can be a significant advantage in this fast-paced industry.

Related Video: Eddy currents & their applications (& how to reduce them) | Electromagnetic induction | Khan Academy

Strategic Material Selection Guide for magnetic coil

When selecting materials for magnetic coils, international B2B buyers must consider various factors that influence performance, durability, and overall suitability for specific applications. Below is an analysis of four common materials used in magnetic coils, highlighting their key properties, advantages, disadvantages, and specific considerations for buyers, particularly from Africa, South America, the Middle East, and Europe.

Copper

Key Properties:

Copper is widely recognized for its excellent electrical conductivity, making it the most common choice for winding magnetic coils. It typically operates effectively at temperatures up to 200°C and has good corrosion resistance when properly coated.

Pros & Cons:

Copper’s high conductivity translates to efficient energy transfer, which is crucial for applications requiring rapid response times, such as in electric motors and transformers. However, it is relatively expensive compared to alternatives like aluminum, and its susceptibility to corrosion can be a concern in harsh environments.

Impact on Application:

Copper coils are ideal for high-performance applications, particularly in consumer electronics and automotive sectors, where efficiency and reliability are paramount. However, they may not be suitable for outdoor applications without protective coatings.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM B170 for copper wire. In regions like Africa and South America, where environmental conditions can vary significantly, it’s essential to consider the need for additional protective coatings to enhance durability.

Aluminum

Key Properties:

Aluminum offers good electrical conductivity, though not as high as copper, and is lightweight, making it easier to handle and install. It typically has a temperature rating of up to 150°C and exhibits decent corrosion resistance.

Pros & Cons:

The primary advantage of aluminum is its lower cost and reduced weight, which can lead to lower shipping costs and easier installation. However, its lower conductivity means that aluminum coils may require more turns to achieve the same magnetic field strength as copper, potentially increasing manufacturing complexity.

Impact on Application:

Aluminum is often used in applications where weight is a critical factor, such as in aerospace and portable electronic devices. However, its lower performance in high-temperature environments may limit its use in industrial applications.

Considerations for International Buyers:

Buyers should be aware of the specific grades of aluminum that meet their application needs, as well as compliance with standards like ASTM B221. In Europe, buyers might prefer suppliers who adhere to the REACH regulations regarding material safety.

Ferrite

Key Properties:

Ferrite materials are ceramic compounds that provide moderate magnetic strength and high resistance to corrosion. They can operate effectively at temperatures up to 250°C, making them suitable for a range of industrial applications.

Pros & Cons:

Ferrite coils are cost-effective and robust, making them ideal for high-volume applications such as loudspeakers and magnetic separators. However, they have lower conductivity compared to metal coils, which can limit their efficiency in high-frequency applications.

Impact on Application:

Ferrite is commonly used in consumer electronics and low-frequency applications. Its durability and cost-effectiveness make it a preferred choice in industries where performance requirements are moderate.

Considerations for International Buyers:

Buyers should verify that ferrite materials comply with international standards such as JIS C 2550 for magnetic materials. In regions like the Middle East, where high humidity is common, ensuring proper sealing and protection against moisture is crucial.

Samarium Cobalt (SmCo)

Key Properties:

Samarium cobalt magnets are known for their high magnetic strength and excellent thermal stability, operating effectively at temperatures up to 350°C. They are also highly resistant to corrosion.

Pros & Cons:

The key advantage of SmCo is its ability to maintain performance in extreme conditions, making it ideal for aerospace and military applications. However, it is significantly more expensive than other materials, which can be a barrier for some buyers.

Impact on Application:

SmCo is often used in high-performance applications where reliability and durability are critical, such as in medical devices and high-temperature motors. Its high cost can limit its use in consumer products.

Considerations for International Buyers:

Buyers should ensure that suppliers provide certification for the material’s performance and compliance with standards such as ISO 9001. In regions like South America, where budget constraints may exist, the higher initial investment must be justified by the long-term benefits of durability and performance.

Summary Table

| Material | Typical Use Case for magnetic coil | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electric motors, transformers | Excellent conductivity and performance | Higher cost and corrosion susceptibility | High |

| Aluminum | Aerospace, portable electronics | Lightweight and cost-effective | Lower conductivity and increased manufacturing complexity | Medium |

| Ferrite | Loudspeakers, magnetic separators | Cost-effective and robust | Lower efficiency in high-frequency applications | Low |

| Samarium Cobalt (SmCo) | Aerospace, military applications | High strength and thermal stability | High cost and limited availability | High |

This guide provides essential insights into material selection for magnetic coils, enabling international B2B buyers to make informed decisions that align with their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for magnetic coil

In the manufacturing of magnetic coils, understanding the processes involved and the quality assurance measures in place is crucial for B2B buyers. This knowledge allows buyers to make informed decisions when selecting suppliers, ensuring they receive high-quality products that meet their specific needs.

Manufacturing Processes for Magnetic Coils

The production of magnetic coils involves several key stages, each critical to the overall quality and performance of the final product.

1. Material Preparation

The first step in the manufacturing process is material selection and preparation. Typically, copper, aluminum, or silver are used for the wire, with copper being the most common due to its excellent conductivity. The materials must be sourced from reliable suppliers to ensure quality.

Illustrative Image (Source: Google Search)

- Material Testing: Before use, materials should undergo testing to verify their electrical and mechanical properties. This might include checks for resistivity, tensile strength, and purity levels.

- Quality Assurance: B2B buyers should inquire about suppliers’ material certifications, such as ASTM or ISO standards, to ensure compliance with international quality benchmarks.

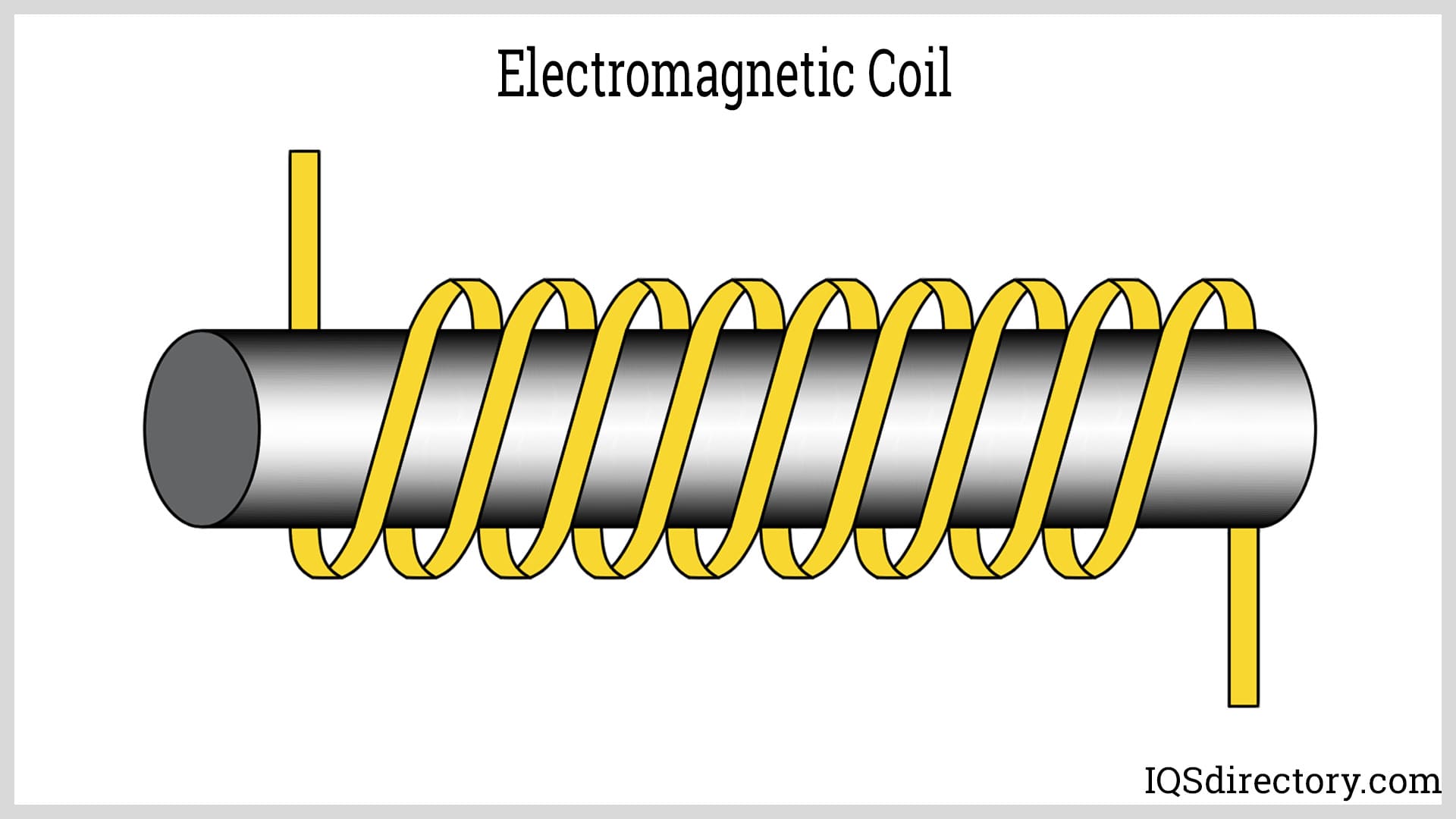

2. Forming

Once the materials are prepared, the next stage is the forming of the coil. This involves winding the conductive wire around a core, which can be made of air, plastic, or a magnetic material, depending on the application.

- Winding Techniques: Advanced winding techniques, such as CNC winding or automatic winding machines, are employed to enhance precision. These methods ensure consistent coil dimensions and tight tolerances.

- Core Selection: The choice of core material significantly affects the coil’s performance. For instance, using a ferromagnetic core can enhance the magnetic field produced by the coil.

3. Assembly

After winding, the coils undergo assembly, which may include integrating additional components such as connectors, insulation, and protective coatings.

- Insulation Methods: Insulation is critical for preventing short circuits and ensuring safety. Options include varnish, epoxy, or heat-shrink tubing.

- Integration: In some cases, coils may need to be integrated into larger systems or devices, which necessitates careful handling and assembly techniques to avoid damage.

4. Finishing

The final stage is finishing, which may involve various treatments to enhance durability and performance.

- Coating and Finishing: Coatings can provide environmental protection and improve the coil’s longevity. Processes such as electroplating or powder coating are commonly used.

- Final Inspection: A thorough inspection is conducted at this stage to ensure the coil meets all specifications before shipment.

Quality Assurance for Magnetic Coils

Quality assurance is a fundamental aspect of the magnetic coil manufacturing process, ensuring that products meet both international standards and specific client requirements.

Relevant International Standards

B2B buyers should be aware of the key international standards that govern the quality of magnetic coils:

- ISO 9001: This standard focuses on quality management systems and is critical for suppliers aiming to ensure consistent quality in their products.

- CE Marking: Particularly relevant for products sold in Europe, CE marking indicates compliance with EU safety, health, and environmental protection standards.

- API Standards: For coils used in the oil and gas industry, compliance with API standards is essential to ensure reliability under demanding conditions.

Quality Control Checkpoints

Quality control (QC) checkpoints are integral to the manufacturing process, ensuring that products meet the required specifications at various stages:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet predefined standards before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify any deviations from specifications, allowing for immediate corrective actions.

- Final Quality Control (FQC): Before shipment, each finished coil undergoes a final inspection to verify that it meets all technical and aesthetic specifications.

Common Testing Methods

Several testing methods are commonly used to assess the performance and quality of magnetic coils:

- Electrical Testing: Includes measuring resistance, inductance, and insulation resistance to ensure the coils perform as expected under operational conditions.

- Mechanical Testing: Involves assessing the physical properties of the coils, such as tensile strength and flexibility.

- Environmental Testing: Coils may be subjected to temperature and humidity tests to determine their performance under extreme conditions.

Verifying Supplier Quality Assurance

B2B buyers should take proactive steps to verify the quality assurance measures employed by potential suppliers:

- Audits: Conducting supplier audits can provide insights into their manufacturing processes, quality control practices, and overall operational efficiency.

- Quality Reports: Requesting detailed quality reports and compliance documentation can help assess a supplier’s commitment to maintaining high standards.

- Third-Party Inspections: Engaging third-party inspection services can provide unbiased assessments of a supplier’s products and processes, ensuring they meet required specifications.

Considerations for International Buyers

International B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances when sourcing magnetic coils:

- Regulatory Compliance: Understanding local regulations and compliance requirements is essential to avoid costly delays or penalties.

- Cultural Differences: Building strong relationships with suppliers may require an understanding of cultural nuances and communication styles, which can impact negotiations and project timelines.

- Supply Chain Dynamics: Buyers should consider logistics and supply chain factors, particularly in regions with less developed infrastructure, as these can affect lead times and costs.

By understanding the manufacturing processes and quality assurance measures associated with magnetic coils, B2B buyers can confidently select suppliers that meet their operational needs and uphold the highest standards of quality. This knowledge not only enhances procurement strategies but also contributes to the overall success of their projects.

Related Video: Magnetic Particle Inspection

Comprehensive Cost and Pricing Analysis for magnetic coil Sourcing

Understanding the cost structure and pricing dynamics of magnetic coil sourcing is crucial for international B2B buyers, especially those operating in regions such as Africa, South America, the Middle East, and Europe. This analysis will highlight key cost components, price influencers, and provide actionable tips for buyers to optimize their procurement strategies.

Cost Components

The total cost of magnetic coils encompasses several components:

-

Materials: The primary material used in magnetic coils is copper, although aluminum and silver may also be utilized. The choice of material significantly influences cost, with copper being the most common due to its excellent conductivity and cost-effectiveness. The price of raw materials can fluctuate based on market conditions, impacting overall costs.

-

Labor: Labor costs vary by region and depend on the complexity of the manufacturing process. Skilled labor is often required for high-precision coils, especially in specialized applications such as medical devices or aerospace.

-

Manufacturing Overhead: This includes expenses related to utilities, maintenance, and factory management. Efficient manufacturing processes can help minimize these costs, thus impacting the final price.

-

Tooling: Investment in tooling is necessary for custom coils. The initial setup costs can be significant, especially for complex designs, but can be amortized over larger production runs.

-

Quality Control (QC): Stringent QC processes are vital, particularly in sectors where reliability is critical. Costs associated with testing and certification (e.g., ISO standards) should be factored into the overall pricing.

-

Logistics: Shipping costs can vary dramatically depending on the supplier’s location and the destination. International buyers must consider freight charges, insurance, and customs duties.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market competition and the uniqueness of their offerings.

Price Influencers

Several factors can influence the pricing of magnetic coils:

-

Volume/MOQ (Minimum Order Quantity): Higher volumes often lead to lower per-unit costs. Suppliers may offer discounts for bulk purchases, making it advantageous for buyers with larger needs.

-

Specifications/Customization: Custom designs or specific performance requirements can increase costs. Understanding the trade-off between standard products and tailored solutions is essential for cost management.

-

Material Quality/Certifications: Higher-quality materials and certifications can raise costs but may provide long-term savings through enhanced performance and reliability.

-

Supplier Factors: The reputation, location, and capabilities of the supplier can affect pricing. Established suppliers may charge a premium for their reliability and service.

-

Incoterms: The choice of Incoterms impacts the total cost. Understanding the responsibilities associated with shipping terms can help in budgeting logistics expenses accurately.

Buyer Tips

To navigate the complexities of magnetic coil pricing, consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Leverage volume commitments to negotiate better terms.

-

Cost Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the upfront price. Consider factors such as durability, maintenance, and operational efficiency.

-

Pricing Nuances: Be aware of regional pricing differences. For example, suppliers in Asia may offer more competitive rates compared to those in Europe or North America due to lower labor and overhead costs.

-

Local Market Conditions: Stay informed about local market dynamics, including currency fluctuations and trade regulations, which can impact pricing.

-

Supplier Relationships: Build strong relationships with suppliers to enhance trust and potentially secure better pricing and service terms.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific order requirements. Buyers are encouraged to conduct thorough market research and supplier assessments before finalizing contracts.

Spotlight on Potential magnetic coil Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘magnetic coil’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for magnetic coil

Key Technical Properties of Magnetic Coils

Understanding the critical technical properties of magnetic coils is essential for B2B buyers aiming to source the right components for their applications. Below are several key specifications that influence performance and suitability:

1. Material Grade

The material used in magnetic coils significantly affects their efficiency and durability. Common materials include copper, aluminum, and occasionally silver. Copper is preferred for its excellent conductivity, while aluminum is lighter and more cost-effective. For B2B buyers, selecting the right material grade is crucial to ensuring optimal performance and longevity of the coils in their specific applications.

2. Inductance

Inductance is a measure of a coil’s ability to store energy in a magnetic field. It is typically expressed in henries (H). Higher inductance values can indicate greater energy storage capacity, which is vital for applications like transformers and inductors. For B2B buyers, understanding inductance helps in selecting coils that meet the energy demands of their systems.

3. Tolerance

Tolerance refers to the allowable variation in a coil’s dimensions and electrical properties. High precision is often required in applications such as medical devices or consumer electronics. For buyers, knowing the tolerance specifications ensures that the coils will fit properly within their designs and function as intended without performance issues.

4. Temperature Rating

Temperature rating indicates the maximum operating temperature of a magnetic coil. This property is crucial for applications exposed to varying thermal environments, such as automotive or industrial machinery. Selecting coils with appropriate temperature ratings can prevent failures and extend the product life, making it a significant consideration for international buyers.

5. Winding Type

The winding type (e.g., single-layer, multi-layer, bifilar) affects the performance characteristics of the coil, including its inductance and resistance. The choice of winding type can influence the efficiency and effectiveness of the coil in its application. Buyers should consider how the winding type aligns with their project requirements to ensure compatibility.

6. Core Material

The core material, often made of iron or ferrite, enhances the magnetic field produced by the coil. The choice of core material can significantly impact the coil’s performance in terms of efficiency and saturation levels. B2B buyers must evaluate the core material to ensure it meets the operational demands of their applications.

Common Trade Terminology

Familiarity with key industry terms enhances communication and negotiation for B2B buyers. Here are some essential terms related to magnetic coils:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products that are sold under another company’s brand name. Understanding OEM relationships can help buyers identify reliable suppliers who can meet their specific needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is vital for B2B buyers as it affects budgeting and inventory management. Knowing the MOQ helps in planning purchases and managing cash flow effectively.

3. RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers to obtain pricing information for specific quantities of products. For buyers, issuing an RFQ can streamline the procurement process and facilitate comparisons among suppliers.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in the shipping process. Understanding Incoterms is crucial for B2B buyers to clarify shipping costs, risk transfer, and delivery obligations, ensuring a smooth transaction.

5. Lead Time

Lead time is the period between placing an order and receiving the product. This term is essential for buyers to anticipate when they will have the necessary components for their projects, aiding in production scheduling and inventory management.

6. Certification

Certification refers to the validation of products against industry standards (e.g., ISO). For B2B buyers, ensuring that their suppliers have the necessary certifications is critical to guarantee product quality and compliance with regulatory requirements.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions, optimize their sourcing strategies, and enhance their operational efficiency in the magnetic coil market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the magnetic coil Sector

In the rapidly evolving landscape of magnetic coils, international B2B buyers must stay attuned to market dynamics that influence sourcing strategies. The global market is driven by an increasing demand for efficient energy solutions, with magnetic coils being integral to applications in electric vehicles, renewable energy systems, and advanced electronics. Countries across Africa, South America, the Middle East, and Europe are experiencing growth in these sectors, highlighting a need for high-performance magnetic coils tailored to specific industrial applications.

Current sourcing trends indicate a shift towards digital procurement technologies, enabling buyers to streamline the purchasing process and enhance supply chain visibility. Buyers are increasingly leveraging platforms that provide comprehensive supplier databases and market insights, allowing for data-driven decision-making. Additionally, a growing emphasis on customization is evident as industries seek magnetic coils that meet unique specifications, particularly in sectors like automotive and medical devices.

Emerging technologies such as automation and IoT are shaping the future of magnetic coil manufacturing, pushing for more precise and efficient production processes. B2B buyers should consider suppliers who are investing in these technologies to ensure they receive high-quality products that adhere to stringent performance standards.

Sustainability & Ethical Sourcing in B2B

As environmental concerns rise, the importance of sustainability in the magnetic coil sector cannot be overstated. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and sustainable practices. This includes the use of eco-friendly materials and manufacturing processes that minimize waste and reduce carbon footprints.

Buyers should look for suppliers that have obtained green certifications, such as ISO 14001 for environmental management or RoHS compliance for hazardous materials. These certifications not only indicate a supplier’s commitment to sustainability but also enhance the overall credibility of the products. Additionally, sourcing from manufacturers who utilize recycled materials in their coils can significantly reduce environmental impact, appealing to buyers who aim to align their purchasing decisions with corporate social responsibility goals.

Moreover, fostering transparent supply chains is essential. Buyers should engage with suppliers who provide visibility into their sourcing practices, ensuring that materials are obtained from responsible sources that do not exploit labor or degrade the environment.

Brief Evolution/History

The evolution of magnetic coils has been closely tied to advancements in electrical engineering and technology. Initially used in simple electromagnetic applications, the development of more sophisticated materials and manufacturing techniques has expanded the utility of magnetic coils across various industries. The introduction of high-performance materials, such as copper and aluminum, along with innovative winding techniques, has significantly enhanced the efficiency and reliability of these components.

Over the decades, as industries have advanced, so too have the applications for magnetic coils, ranging from traditional uses in motors and transformers to modern applications in renewable energy and medical devices. This evolution underscores the importance for B2B buyers to stay informed about technological advancements and emerging trends to ensure they are sourcing the most effective and sustainable solutions available.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of magnetic coil

-

How can I effectively vet suppliers for magnetic coils?

Vetting suppliers is crucial for ensuring quality and reliability. Start by researching potential suppliers through industry directories and reviews. Assess their manufacturing capabilities, certifications (such as ISO), and experience in your specific application area. Request samples to evaluate product quality, and inquire about their production processes and technology. Additionally, consider visiting their facility if feasible, or arranging virtual tours to better understand their operations. Building relationships with suppliers who communicate transparently can also help mitigate risks. -

What customization options are available for magnetic coils?

Many suppliers offer customization to meet specific application requirements. Customization may include varying the coil size, shape, and number of turns, as well as selecting different materials for the wire and core. Some manufacturers can also provide specialized coatings or insulation to enhance performance in unique environments. When discussing your needs, be clear about the application and environmental conditions to ensure the supplier can deliver a product tailored to your specifications. -

What are the typical minimum order quantities (MOQs) and lead times for magnetic coils?

Minimum order quantities can vary widely depending on the supplier and the complexity of the coil. Typically, MOQs may range from a few dozen to several hundred units. Lead times also vary based on the supplier’s production capacity and the complexity of the order, often ranging from 2 to 12 weeks. It’s advisable to discuss these parameters early in the negotiation process to align expectations. Suppliers may offer flexibility for larger orders or long-term contracts, so consider your future needs when placing initial orders. -

What payment terms are standard when sourcing magnetic coils internationally?

Payment terms often depend on the relationship with the supplier and the order size. Common terms include advance payment, partial payment upon order confirmation, and balance upon delivery. For international transactions, consider using secure payment methods such as letters of credit or escrow services to protect both parties. It is also beneficial to discuss currency exchange rates and potential fees upfront to avoid unexpected costs during the transaction. -

What quality assurance practices should I look for in magnetic coil suppliers?

Quality assurance is vital for ensuring that the coils meet performance standards. Look for suppliers that implement rigorous QA protocols, such as testing for electrical performance, insulation resistance, and mechanical durability. Certifications like ISO 9001 can indicate a commitment to quality management systems. Additionally, inquire about their testing methods and whether they offer third-party verification for quality assurance. A reliable supplier should be willing to share their QA documentation and testing results. -

How do logistics and shipping considerations impact the sourcing of magnetic coils?

Logistics play a significant role in the overall sourcing strategy. Consider the supplier’s location, shipping options, and costs when selecting a partner. Assess the supplier’s experience with international shipping and customs regulations, as these can affect delivery timelines and additional costs. It’s also wise to discuss responsibilities regarding freight insurance and potential duties or tariffs. Establishing clear logistics protocols upfront can help prevent delays and ensure smooth delivery. -

What should I do if there is a dispute with my magnetic coil supplier?

If a dispute arises, first try to resolve the issue through direct communication. Clearly outline your concerns and seek to understand the supplier’s perspective. If resolution is not achieved, refer to the contract for dispute resolution procedures, which may include mediation or arbitration. Keeping records of all communications and agreements will be helpful. If necessary, consider involving legal counsel, especially if significant financial implications are involved. -

Are there specific certifications that magnetic coils should have for international markets?

Certifications can greatly influence the acceptance of magnetic coils in various markets. Key certifications include ISO standards, which indicate adherence to quality management practices, and CE marking for compliance with European health and safety regulations. For specific industries, such as medical or automotive, additional certifications may be required, such as RoHS or UL certification. Always verify the certifications relevant to your target market and application to ensure compliance and enhance marketability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for magnetic coil

In conclusion, the strategic sourcing of magnetic coils is essential for B2B buyers aiming to enhance their operational efficiency and product performance across various industries. Understanding the diverse types of magnetic coils, their applications, and the importance of selecting the right supplier can significantly impact your procurement strategy. Key takeaways include:

- Material Quality: Prioritize manufacturers that use high-grade materials to ensure durability and performance.

- Customization: Seek suppliers who can tailor their products to meet specific application requirements, enhancing your competitive edge.

- Technological Capability: Choose manufacturers that leverage advanced production technologies to ensure precision and consistency.

As the global market continues to evolve, particularly in emerging regions such as Africa, South America, the Middle East, and Europe, staying informed about market trends and supplier capabilities is crucial. Investing in strategic sourcing not only mitigates risks but also fosters innovation and sustainability in your supply chain.

Looking ahead, engage with reputable suppliers who align with your business goals and values. By doing so, you can unlock new opportunities, drive growth, and secure a successful future in the dynamic landscape of magnetic coil applications.