Top 30 Vibratory Tumbler Manufacturers You Should Know

Top 30 Vibratory Tumbler Manufacturers

Penn Tool Co. – Vibratory Tumblers for Metal Finishing

Domain: penntoolco.com

Registered: 1997 ( 28 years )

Introduction: Penn Tool Co. offers a range of vibratory tumblers designed for finishing and polishing metal parts.

Kramer Industries – Vibratory Finishing Systems

Domain: kramerindustriesonline.com

Registered: 2001 ( 24 years )

Introduction: Kramer Industries offers a range of vibratory finishing systems, including vibratory tumblers and bowls designed for industrial applications. Their products are used for surface finishing, deburring, and polishing various materials.

McMaster – Vibratory Tumblers for Metal Finishing

Domain: mcmaster.com

Registered: 1994 ( 31 years )

Introduction: Vibratory tumblers designed for polishing and finishing metal parts.

Raytech Ind – Vibratory Finishing Solutions

Domain: raytech-ind.com

Registration year: Not available

Introduction: Tumble Vibe 10 is a vibratory finishing machine designed for efficient surface finishing and deburring of various materials.

Rockhound Resource – Rock Tumblers and Polishing Solutions

Domain: rockhoundresource.com

Registered: 2020 ( 5 years )

Introduction: The company offers rotary and vibratory rock tumblers for polishing rocks, with a focus on the differences in their operation and results.

Eastwood – Tumbler Media Cleaning Solutions

Domain: eastwood.com

Registered: 1995 ( 30 years )

Introduction: Eastwood 5 lb Tumbler with Media is designed for cleaning and polishing small parts and components.

Harbor Freight – Metal Vibratory Bowl Solutions

Inovatec Machinery – Vibratory and Rock Tumblers

Domain: inovatecmachinery.com

Registered: 2018 ( 7 years )

Introduction: Vibratory Tumbler and Rock Tumbler for mass finishing applications.

Mscdirect – Products

Practical Machinist – Vibratory Deburring Solutions

Domain: practicalmachinist.com

Registered: 2000 ( 25 years )

Introduction: Vibratory deburring machines and tumbling media for surface finishing.

Grainger – Vibratory Tumblers for Metal Finishing

Domain: grainger.com

Registered: 1994 ( 31 years )

Introduction: Vibratory tumblers designed for finishing and polishing metal parts and components.

Kingsleynorth – Products

Domain: kingsleynorth.com

Registered: 1997 ( 28 years )

Introduction: Vibratory tumblers for polishing rocks and stones.

Treasure Pursuits – Vibratory Tumblers for Gun Reloaders

Domain: treasurepursuits.com

Registered: 2016 ( 9 years )

Introduction: The company offers a selection of vibratory tumblers designed for cleaning and polishing metal casings, primarily used by gun reloaders.

Arrowhead Lapidary Supply – Vibra-Sonic Tumblers

Domain: arrowheadlapidarysupply.com

Registered: 2003 ( 22 years )

Introduction: The VT models of the Vibra-Sonic tumblers are designed for grinding and polishing operations, featuring both vibratory and rotary tumbling action. They are available in various hopper sizes and are built for durability and efficiency.

Thumler’s Tumblers – Rock Tumblers for All Levels

Domain: rocktumbler.com

Registered: 2000 ( 25 years )

Introduction: Thumler’s Tumblers offers a range of rock tumblers designed for beginners and advanced users, including rotary and vibratory models. Their products are known for durability and ease of use.

Iqsdirectory – Vibratory Tumblers for Finishing Processes

Domain: iqsdirectory.com

Registered: 2004 ( 21 years )

Introduction: Vibratory tumblers used for vibratory finishing processes, suitable for cleaning, deburring, deflashing, descaling, and polishing various workpieces.

Thumler’s Tumbler – Rock Tumblers and Accessories

Domain: thumlerstumbler.com

Registered: 2000 ( 25 years )

Introduction: Thumler’s Tumbler offers a range of rock tumblers and related accessories, including polishing grit packs, gem mixes, and replacement parts for various tumbler models.

Rockshed – Rock Tumblers and Polishing Solutions

Domain: rockshed.com

Registered: 2001 ( 24 years )

Introduction: Lot-O-Tumbler is a single barrel rock tumbler with a capacity of 4.5 lbs, designed for polishing rocks and gemstones.

Trick Tools – Products

Domain: trick-tools.com

Registered: 2001 ( 24 years )

Introduction: Burr King Vibratory Tumbler Machines are designed for deburring, polishing, and finishing metal parts and components.

Brandon Ind Deburr – Products

Domain: brandon-ind-deburr.com

Registered: 1998 ( 27 years )

Introduction: Brandon Industries offers vibratory deburring machines and tumblers, including custom solutions for mass finishing applications.

Grafs – Industrial and Commercial Solutions

Domain: grafs.com

Registered: 1997 ( 28 years )

Introduction: The company offers a range of high-quality, durable, and versatile products designed for various applications in industrial and commercial settings.

Summit Racing – Vibratory Tumblers for Metal Finishing

Domain: summitracing.com

Registered: 1995 ( 30 years )

Introduction: Vibratory tumblers for metal finishing and surface preparation.

Royson – Industrial Coatings and Finishing Solutions

Domain: royson.com

Registered: 1997 ( 28 years )

Introduction: Royson offers a range of high-quality industrial coatings and finishing solutions, including powder coatings, liquid coatings, and specialty coatings.

Gemcuts – Rotary & Vibratory Tumblers for Polishing

Domain: gemcuts.com.au

Registration year: Not available

Introduction: Rotary and Vibratory Tumblers for polishing rocks, mass finishing small parts, and burnishing jewellery.

Diamond Pacific – Vibratory Tumblers for Lapidary Work

Domain: diamondpacific.com

Registered: 1997 ( 28 years )

Introduction: Diamond Pacific offers a range of vibratory tumblers, including the MT-4, MT-10, and MT-14 Mini Sonic Vibratory Tumblers, designed for various applications in lapidary work and other industries.

Shinysmooth – Industrial Vibratory Tumblers

Domain: shinysmooth.com

Registered: 2016 ( 9 years )

Introduction: Inovatec offers high-quality industrial vibratory tumblers with capacities ranging from 100L to 780L, designed for deburring and polishing applications. The machines feature a German design, a rigid structure with an inclined processing channel, and come with a media separation table.

Burrking – Products

Domain: burrking.com

Registered: 1999 ( 26 years )

Introduction: Models 110, 150 & 200 Vibra KING Bench Top Bowls are designed for efficient vibratory finishing and deburring of parts.

Kabrasives – Vibratory Tumblers for Surface Finishing

Domain: kabrasives.com

Registered: 2023 ( 2 years )

Introduction: Vibratory tumblers for polishing, deburring, cleaning, and improving the surface finish of parts.

MidwayUSA – Shooting Supplies and Equipment

Domain: midwayusa.com

Registration year: Not available

Introduction: Berry’s QD-500 Vibratory Tumbler

Cabela’s – Brass Cleaning and Polishing Equipment

Domain: cabelas.com

Registered: 1995 ( 30 years )

Introduction: Cabela’s Vibratory Tumbler with Detachable Bowl is designed for cleaning and polishing brass casings and other small metal parts.

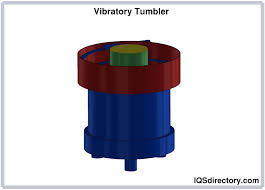

Category Information

A vibratory tumbler is a mechanical device used primarily for finishing and polishing metal parts and other materials. It operates by creating a controlled vibration that causes the contents within the tumbler to move in a tumbling motion. This action facilitates processes such as deburring, cleaning, and surface smoothing, making vibratory tumblers essential in various manufacturing and metalworking industries. The significance of vibratory tumblers lies in their efficiency and effectiveness in improving the surface quality of components.

By reducing rough edges and enhancing finishes, they help in increasing the longevity and aesthetic appeal of parts. Additionally, vibratory tumblers can accommodate a wide range of materials, including metals, ceramics, and plastics, making them versatile tools for businesses focused on quality and precision in production.

Application Information

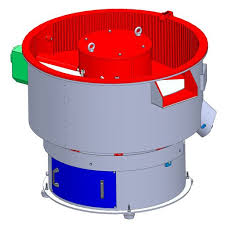

Vibratory tumblers are widely used across various industries for surface finishing, deburring, and polishing of metal and non-metal parts. In the manufacturing sector, they are essential for cleaning and smoothing edges of machined components, helping to enhance the overall quality and aesthetic of the products. This process is crucial in industries such as aerospace, automotive, and electronics, where precision and surface integrity are paramount.

In the jewelry industry, vibratory tumblers are employed for polishing and finishing precious metals and gemstones, ensuring a high-quality shine and reducing rough edges. Additionally, they find applications in the woodworking industry for smoothing wooden surfaces and preparing them for finishing. Overall, vibratory tumblers streamline production processes, improve product quality, and reduce manual labor, making them invaluable across these sectors.

Production Process Information

Manufacturing vibratory tumblers involves several key steps to ensure high-quality products that effectively smooth and polish materials. The process typically begins with design and engineering, where specifications are developed based on the intended use of the tumbler, whether for industrial or hobbyist applications. Next, raw materials are sourced, including durable metals and components like motors and bowls. These materials are then fabricated, which involves cutting, shaping, and assembling the parts.

Once assembled, the tumblers undergo rigorous testing to ensure they function correctly and meet safety standards. Finally, the products are finished, often with protective coatings, and packaged for distribution. Throughout the process, quality control is crucial to maintain performance and reliability, ensuring customers receive a product that meets their expectations.

Related Video

Frequently Asked Questions (FAQs)

How do I find reliable vibratory tumbler manufacturers?

Start by searching online directories, industry trade shows, and business networks. Websites like Alibaba and ThomasNet can help you connect with reputable suppliers. Additionally, consider joining industry forums or groups on social media to gather recommendations from peers.

What should I consider when choosing a vibratory tumbler factory?

Look for factors such as the factory’s experience, production capacity, quality control measures, and customer reviews. It’s also important to assess their certifications and whether they can meet your specific customization needs.

How can I ensure the quality of the vibratory tumblers?

Request samples before placing a bulk order to evaluate quality firsthand. Additionally, inquire about their quality assurance processes, such as inspections and testing methods, to ensure they meet your standards.

What are the typical lead times for vibratory tumbler orders?

Lead times can vary based on the manufacturer and order size, but generally, you can expect anywhere from 2 to 8 weeks. Always confirm the timeline with the supplier and factor in shipping times for your planning.

Are there minimum order quantities (MOQs) for vibratory tumblers?

Yes, many manufacturers have MOQs that can range from a few units to several hundred, depending on the factory. Be sure to discuss MOQs upfront to avoid any surprises and to ensure it aligns with your budget and needs.