Master Sourcing Strategies for Planetary Gear Sets: A B2B

Introduction: Navigating the Global Market for planetary gear set

In an increasingly interconnected world, the demand for planetary gear sets is surging, driven by their critical role in various industries such as automotive, aerospace, and robotics. These sophisticated mechanical components are essential for applications requiring high torque, compact design, and efficient power transmission. As international B2B buyers from diverse regions—including Africa, South America, the Middle East, and Europe—seek to enhance their operational efficiencies, understanding the nuances of the planetary gear set market becomes paramount.

This comprehensive guide is designed to equip B2B buyers with the insights needed to make informed sourcing decisions. It covers a broad spectrum of topics, including types of planetary gear sets, materials used in their construction, manufacturing and quality control processes, and an analysis of key suppliers in the market. Additionally, we delve into cost considerations and market trends that can impact purchasing strategies.

By leveraging the information presented in this guide, buyers can navigate the complexities of sourcing planetary gear sets effectively. Whether you are looking to optimize production capabilities or enhance product offerings, this resource aims to empower your decision-making process, ensuring you stay ahead in a competitive global landscape. With a focus on actionable insights, this guide is your essential companion for successful procurement in the planetary gear set market.

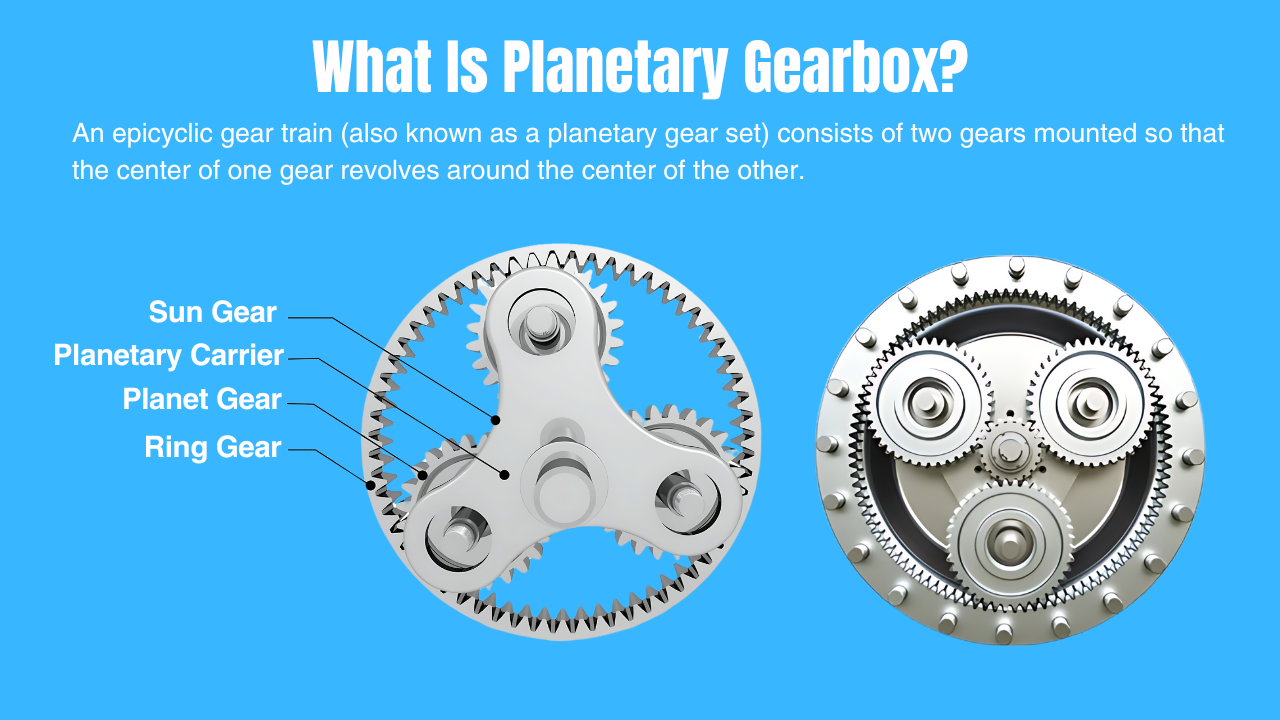

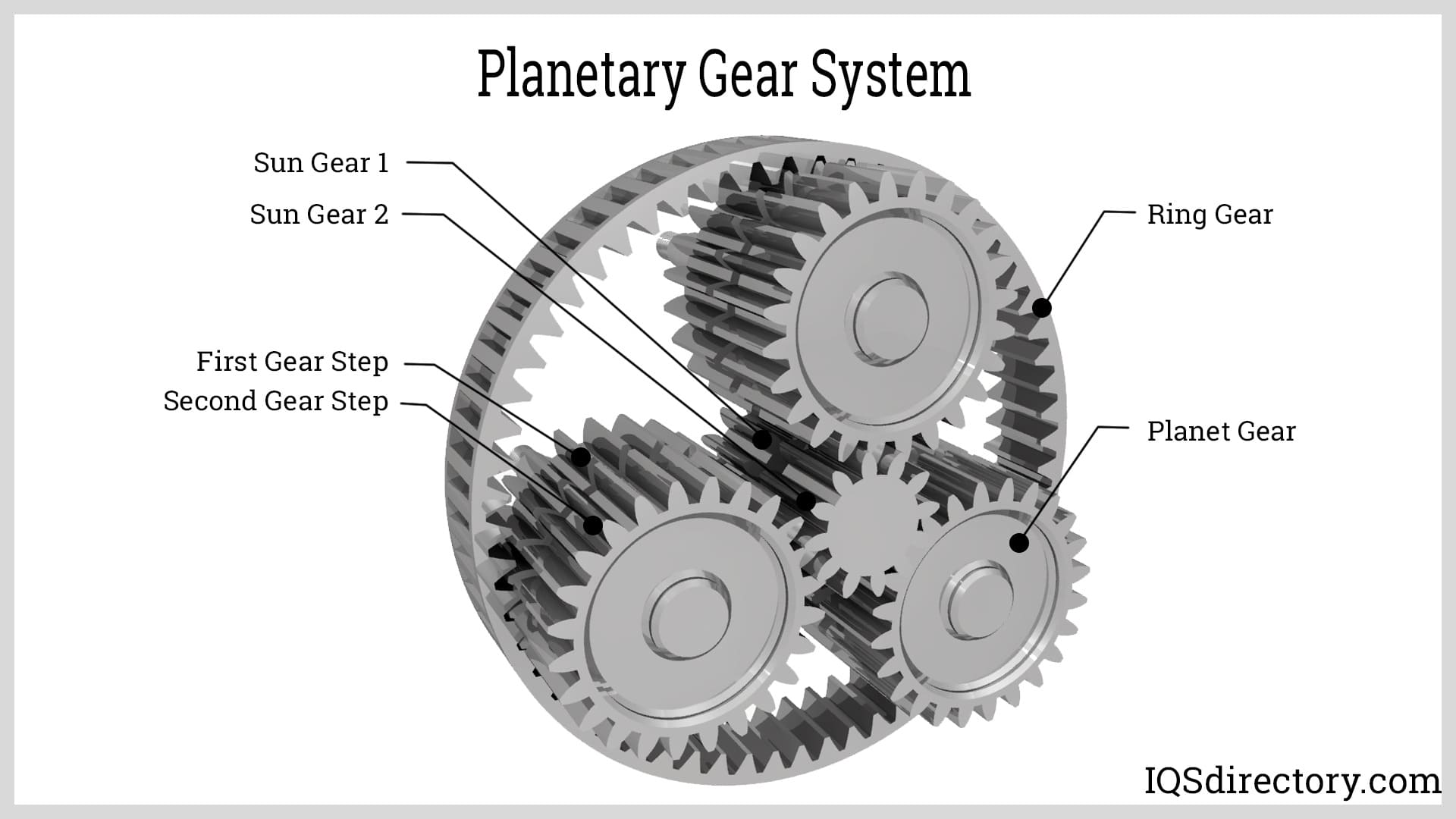

Understanding planetary gear set Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single Planetary Gear | Simple design with one sun gear and multiple planet gears. | Robotics, Automotive, Industrial Machinery | Pros: Compact, efficient, cost-effective. Cons: Limited torque handling compared to multi-stage systems. |

| Double Planetary Gear | Two sun gears, allowing for higher torque and compact design. | Aerospace, High-Performance Motors | Pros: Increased torque capacity, reduced size. Cons: More complex, potentially higher costs. |

| Epicyclic Gear Train | Gear system where gears rotate around a central sun gear. | Automotive Transmissions, Wind Turbines | Pros: High efficiency, versatile applications. Cons: Complexity can lead to higher maintenance needs. |

| Hybrid Planetary Gear Set | Combines planetary gears with other gear types for enhanced performance. | Electric Vehicles, Machinery | Pros: Tailored solutions, improved efficiency. Cons: Design complexity may increase costs. |

| Custom Planetary Gear Set | Tailored designs based on specific application requirements. | Specialized Machinery, Custom Robotics | Pros: Optimized for specific needs, high performance. Cons: Longer lead times, potentially higher costs. |

Single Planetary Gear

The Single Planetary Gear is characterized by its straightforward structure, comprising a single sun gear and multiple planet gears. This design is particularly suitable for applications requiring compactness and efficiency, such as in robotics and automotive systems. When purchasing, buyers should consider the torque requirements of their application, as this type is generally limited in torque handling compared to more complex systems.

Double Planetary Gear

The Double Planetary Gear features two sun gears, which allows for enhanced torque capacity while maintaining a compact size. This type is ideal for high-performance applications, such as aerospace and specialized motors. Buyers should evaluate the complexity of the system and potential costs, as the increased torque handling comes with a more intricate design that may affect maintenance and initial investment.

Epicyclic Gear Train

The Epicyclic Gear Train is a sophisticated system where gears revolve around a central sun gear, providing a highly efficient mechanism. Its versatility makes it suitable for applications in automotive transmissions and wind turbines. When considering this type, B2B buyers should weigh the benefits of high efficiency against the complexity and potential maintenance challenges that arise from its intricate design.

Hybrid Planetary Gear Set

A Hybrid Planetary Gear Set integrates planetary gears with other gear types, creating a highly efficient and adaptable system. This type is increasingly used in electric vehicles and advanced machinery, where performance optimization is crucial. Buyers should assess their specific needs, as the tailored solutions can lead to improved efficiency but may also introduce design complexities that could raise costs.

Custom Planetary Gear Set

The Custom Planetary Gear Set allows for a bespoke design tailored to specific application requirements, making it ideal for specialized machinery and custom robotics. This type offers the advantage of optimized performance for unique needs, but buyers must be prepared for longer lead times and potentially higher costs associated with custom manufacturing. Understanding the balance between customization and budget is key for B2B buyers in this segment.

Related Video: Understanding PLANETARY GEAR set !

Key Industrial Applications of planetary gear set

| Industry/Sector | Specific Application of Planetary Gear Set | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Electric Vehicle Drivetrains | Enhanced torque and efficiency, compact design | Supplier reliability, compliance with automotive standards, and cost-effectiveness. |

| Aerospace | Turbine Engines | High power density and reliability in extreme conditions | Certification for aerospace applications, material quality, and performance testing. |

| Industrial Automation | Robotics and Conveyor Systems | Precision control and reduced maintenance needs | Compatibility with existing systems, customization options, and support services. |

| Mining and Construction | Heavy Machinery Gearboxes | Improved durability and load handling capabilities | Supplier experience in heavy-duty applications, warranty terms, and after-sales support. |

| Renewable Energy | Wind Turbine Gearboxes | Increased energy efficiency and reduced noise levels | Performance metrics, environmental compliance, and availability of replacement parts. |

Automotive

In the automotive sector, planetary gear sets are integral to electric vehicle drivetrains, where they provide compactness and high efficiency. By allowing for significant torque multiplication, they enhance vehicle performance while optimizing energy consumption. Buyers in this sector, especially in emerging markets like South Africa and Brazil, should prioritize suppliers who comply with stringent automotive standards and offer reliable after-sales support to ensure longevity and performance.

Aerospace

Planetary gear sets are pivotal in aerospace applications, particularly in turbine engines where they must operate under extreme conditions. Their ability to deliver high power density while maintaining reliability is crucial for safety and efficiency. International B2B buyers in this sector must ensure that their suppliers have the necessary certifications and quality assurance processes in place to meet industry-specific regulations, especially in regions like Europe where compliance is strictly monitored.

Industrial Automation

In industrial automation, planetary gear sets are commonly used in robotics and conveyor systems. They allow for precise control of motion and torque, which is essential for high-speed manufacturing processes. Buyers should consider sourcing options that offer customization to fit specific operational needs, along with strong technical support to facilitate integration with existing systems. This is particularly important for businesses in regions like the Middle East, where rapid industrial growth is occurring.

Mining and Construction

Heavy machinery in the mining and construction industries relies on planetary gear sets for gearboxes that manage high loads and harsh environments. These gear sets improve durability and performance, minimizing downtime due to maintenance issues. Buyers should focus on suppliers with extensive experience in heavy-duty applications, as well as favorable warranty terms and robust after-sales support, to ensure that their machinery operates effectively in challenging conditions.

Renewable Energy

In the renewable energy sector, particularly in wind turbines, planetary gear sets enhance energy efficiency and reduce operational noise. The precise design allows for optimal energy conversion, which is crucial for maximizing output. Buyers should look for suppliers who can provide detailed performance metrics and demonstrate compliance with environmental regulations, ensuring that their gear sets contribute positively to sustainability goals while maintaining high operational standards.

Strategic Material Selection Guide for planetary gear set

When selecting materials for planetary gear sets, international B2B buyers must consider a variety of factors, including performance characteristics, manufacturing complexities, and compliance with regional standards. Here, we analyze four common materials used in the production of planetary gear sets: Steel, Aluminum, Plastic, and Composite materials. Each material presents unique advantages and disadvantages that can significantly impact the performance and suitability of the gear set for specific applications.

Steel

Key Properties: Steel is renowned for its high tensile strength and durability. It typically has excellent wear resistance, making it suitable for high-load applications. Steel can also withstand high temperatures and pressures, which is crucial in demanding environments.

Pros & Cons: The primary advantage of steel is its strength and longevity, which translates to less frequent replacements and lower maintenance costs. However, steel is heavier than other materials, which can impact the overall weight of the machinery. Additionally, it is susceptible to corrosion unless treated, which may increase manufacturing complexity and costs.

Impact on Application: Steel is ideal for applications involving high torque and heavy loads, such as in automotive and industrial machinery. Its compatibility with various lubricants and operating conditions makes it versatile.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM A36 or DIN 17100. In regions like Europe and South Africa, buyers may prefer suppliers that provide corrosion-resistant coatings, especially for outdoor applications.

Aluminum

Key Properties: Aluminum is lightweight and possesses good corrosion resistance. It has moderate strength compared to steel but can be enhanced through alloying.

Pros & Cons: The key advantage of aluminum is its low weight, which can improve the energy efficiency of machinery. However, its lower strength limits its use in high-load applications. Manufacturing processes for aluminum can be more straightforward, but the cost of high-quality aluminum alloys can be significant.

Impact on Application: Aluminum is suitable for applications where weight savings are critical, such as in aerospace or portable machinery. Its corrosion resistance makes it ideal for environments prone to moisture.

Considerations for International Buyers: Buyers should look for compliance with standards like ASTM B221 and consider the specific alloy grades that meet their application needs. In Europe, buyers may also need to consider EU regulations regarding material sourcing.

Plastic

Key Properties: Engineering plastics, such as Nylon or PEEK, offer low friction, good wear resistance, and lightweight properties. They also provide excellent chemical resistance.

Pros & Cons: Plastics can significantly reduce weight and noise in gear applications, making them suitable for consumer electronics and medical devices. However, they generally have lower strength and thermal stability compared to metals, limiting their use in high-stress environments.

Impact on Application: Plastic gears are ideal for low-load applications where noise reduction and weight are priorities. They are compatible with various chemicals, making them suitable for specific industrial applications.

Considerations for International Buyers: Compliance with standards such as ASTM D638 for tensile properties is essential. Buyers should also be aware of the thermal and chemical limits of the plastics used, especially in regions with extreme temperatures.

Composite Materials

Key Properties: Composites combine materials to enhance performance characteristics, offering high strength-to-weight ratios and excellent fatigue resistance.

Pros & Cons: The primary advantage of composites is their customizable properties, which can be tailored for specific applications. However, they can be more expensive to produce and require specialized manufacturing processes.

Impact on Application: Composites are suitable for high-performance applications, such as in aerospace and automotive sectors, where weight and strength are critical. Their resistance to fatigue makes them ideal for dynamic applications.

Considerations for International Buyers: Buyers should ensure that composites meet relevant industry standards, such as ASTM D3039 for tensile properties. Understanding the manufacturing capabilities of suppliers in regions like Africa and South America can also be crucial for sourcing.

Summary Table

| Material | Typical Use Case for planetary gear set | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery, automotive applications | High strength and durability | Heavier, susceptible to corrosion | High |

| Aluminum | Aerospace, portable machinery | Lightweight, good corrosion resistance | Lower strength than steel | Medium |

| Plastic | Consumer electronics, medical devices | Low weight, noise reduction | Lower strength, thermal limits | Low |

| Composite | Aerospace, high-performance automotive | Customizable properties | Higher cost, specialized processes | High |

This strategic material selection guide assists international B2B buyers in making informed decisions tailored to their specific applications and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for planetary gear set

Manufacturing Processes for Planetary Gear Sets

The manufacturing of planetary gear sets is a complex process that involves several critical stages. Each stage requires precision and adherence to strict quality standards to ensure that the final product meets the operational demands of various applications. The main stages of manufacturing include:

Material Preparation

Selection of Raw Materials

The first step in manufacturing planetary gear sets is selecting high-quality raw materials. Common materials include alloy steels, carbon steels, and certain composites, chosen for their strength, hardness, and wear resistance. For B2B buyers, understanding the material specifications is crucial; this information can often be found in the supplier’s documentation.

Material Treatment

Once the materials are selected, they may undergo treatments such as heat treatment or surface hardening to enhance their properties. This is particularly important for components that will experience high stress during operation.

Forming

Machining

The machining process involves various techniques such as turning, milling, and grinding to create the precise shapes and dimensions needed for each component of the gear set. CNC (Computer Numerical Control) machines are often employed to ensure high accuracy and repeatability.

Gear Tooth Formation

The formation of gear teeth is a critical process. Techniques such as hobbing, shaping, or grinding are used to create the gear profiles. For planetary gear sets, the teeth must be designed to withstand significant loads, making the choice of technique and tool critical.

Assembly

Sub-Assembly

During this stage, individual components such as sun gears, planet gears, and ring gears are assembled. Proper alignment and fitting are crucial to ensure smooth operation. Specialized jigs and fixtures are often used to maintain precision during assembly.

Final Assembly

The final assembly involves integrating all sub-assemblies into the complete planetary gear set. This stage may include the installation of bearings, seals, and lubrication systems. Ensuring that all components fit correctly is essential to minimize wear and increase lifespan.

Finishing

Surface Treatment

After assembly, surface treatments such as coating, anodizing, or polishing may be applied to reduce friction and enhance corrosion resistance. This step is particularly important for gear sets used in harsh environments.

Inspection and Testing

Finally, the finished planetary gear sets undergo rigorous inspection and testing to ensure they meet specifications. This includes dimensional checks, functional tests, and performance evaluations.

Quality Assurance in Planetary Gear Set Manufacturing

Quality assurance is paramount in the manufacturing of planetary gear sets. B2B buyers must ensure that their suppliers adhere to international and industry-specific standards to guarantee product reliability and performance.

International Standards

ISO 9001

ISO 9001 is a widely recognized international standard that outlines quality management system requirements. Suppliers certified to this standard demonstrate their commitment to quality and continuous improvement.

Other Relevant Standards

Depending on the application, suppliers may also need to comply with additional standards such as CE marking for European markets, API standards for the oil and gas industry, or specific automotive industry standards.

Quality Control Checkpoints

Incoming Quality Control (IQC)

IQC is the first checkpoint where raw materials and components are inspected upon receipt. This ensures that only materials meeting specified standards are used in manufacturing.

In-Process Quality Control (IPQC)

During the manufacturing process, IPQC involves regular inspections at various stages to catch defects early. This may include dimensional checks and functional tests of individual components.

Final Quality Control (FQC)

FQC is conducted after assembly and finishing. This stage includes comprehensive testing of the entire gear set, ensuring it meets performance and safety standards.

Common Testing Methods

- Dimensional Inspection: Using tools such as calipers and micrometers to measure component dimensions.

- Functional Testing: Assessing the performance of the gear set under simulated operational conditions.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing or magnetic particle inspection to detect internal defects without damaging the product.

Verifying Supplier Quality Control

For international B2B buyers, verifying a supplier’s quality control measures is crucial. Here are actionable steps to ensure quality assurance:

Conduct Audits

Regular audits of potential suppliers can provide insight into their manufacturing processes and quality control systems. This can be done through on-site visits or third-party audit services.

Request Quality Reports

Ask suppliers for detailed quality reports that document their quality control processes, including IQC, IPQC, and FQC results. These reports should include any corrective actions taken in response to quality issues.

Engage Third-Party Inspectors

Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These inspectors can conduct pre-shipment inspections and provide detailed reports on compliance with required standards.

Quality Control Nuances for International Buyers

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality control practices:

- Cultural Differences: Different regions may have varying approaches to quality assurance. Understanding these cultural differences can help in negotiating quality standards and expectations.

- Regulatory Compliance: Ensure that suppliers are compliant with local regulations, which may differ significantly from international standards.

- Supply Chain Transparency: Establishing transparency in the supply chain can help buyers track the quality of materials and components used in the manufacturing process.

In summary, the manufacturing processes and quality assurance practices for planetary gear sets are critical elements that B2B buyers must consider. By understanding these processes and implementing thorough verification methods, buyers can ensure that they procure high-quality products that meet their operational needs.

Related Video: Amazing Production Process with Modern Machines and Skilful Workers

Comprehensive Cost and Pricing Analysis for planetary gear set Sourcing

Understanding the Cost Structure of Planetary Gear Sets

When sourcing planetary gear sets, international B2B buyers must consider several key cost components that directly impact the pricing structure:

-

Materials: The choice of materials significantly affects the overall cost. Common materials include steel, aluminum, and specialized alloys, each with varying price points. For instance, high-strength steel may offer better performance but at a higher cost.

-

Labor: Labor costs can vary widely by region and the complexity of the manufacturing process. Skilled labor is often required for precision machining and assembly, which can increase costs.

-

Manufacturing Overhead: This includes costs related to the facilities, utilities, and indirect labor involved in production. Buyers should inquire about a manufacturer’s overhead rates, as they can significantly affect the final price.

-

Tooling: Custom tooling may be necessary for specific gear designs, impacting initial costs. While these costs can be amortized over larger production runs, they can present a barrier for smaller orders.

-

Quality Control (QC): Rigorous QC processes ensure that gear sets meet specific performance and safety standards. Costs associated with QC can add to the overall price but are critical for maintaining product integrity.

-

Logistics: Shipping and handling costs should not be overlooked. They vary based on the distance, mode of transport, and any duties or tariffs applicable to international shipments.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on market conditions and competitive pressures.

Factors Influencing Pricing

Several factors can influence the pricing of planetary gear sets, including:

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing. Larger orders often lead to volume discounts, while smaller orders might incur higher per-unit costs.

-

Specifications/Customization: Custom gear sets tailored to specific applications can lead to higher prices due to the additional engineering and production time required.

-

Materials Quality/Certifications: Higher quality materials or certifications (like ISO standards) can justify a higher price but ensure reliability and performance.

-

Supplier Factors: The supplier’s reputation, reliability, and location can influence pricing. Established suppliers with proven track records may charge a premium.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can affect the total cost. For example, “Delivered Duty Paid” (DDP) includes shipping and customs duties, impacting the final price buyers see.

Practical Tips for Buyers

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies:

-

Negotiation: Engage in discussions with suppliers to negotiate prices, especially for larger orders. Suppliers may be willing to provide discounts or better payment terms.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO) rather than just the initial purchase price. Consider factors such as maintenance, durability, and potential downtime costs.

-

Pricing Nuances: Be aware of pricing variations between suppliers. It’s beneficial to obtain quotes from multiple manufacturers to compare costs and services.

-

Cultural Sensitivity: Understanding cultural differences in business practices can enhance negotiations and foster better relationships with suppliers.

Disclaimer

Prices for planetary gear sets can vary widely based on the factors mentioned above. This analysis serves as a guide, and buyers should conduct due diligence to obtain precise quotes tailored to their specific needs and circumstances.

Spotlight on Potential planetary gear set Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘planetary gear set’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for planetary gear set

Key Technical Properties of Planetary Gear Sets

Understanding the essential technical properties of planetary gear sets is crucial for B2B buyers, especially those involved in manufacturing and engineering sectors. Here are the critical specifications to consider:

-

Material Grade

– The material used in planetary gear sets typically includes steel, aluminum, or plastic composites. High-grade steel is preferred for its strength and durability, while aluminum is lighter and offers good corrosion resistance. Selecting the appropriate material can significantly impact the performance and lifespan of the gear set. -

Gear Ratio

– This specification defines the relationship between the input speed and output speed of the gear set. A higher gear ratio allows for greater torque multiplication but may reduce speed. Understanding the required gear ratio is vital for matching the gear set to specific applications, ensuring optimal performance. -

Backlash

– Backlash refers to the amount of play between the gears when they are not under load. It is crucial for maintaining precision in applications such as robotics and aerospace. A lower backlash is often preferred, especially in high-precision environments, as it reduces the risk of mechanical errors and enhances overall efficiency. -

Load Capacity

– This property indicates the maximum load that the gear set can handle without failure. It is essential for ensuring that the gear set will perform reliably under operational stress. Buyers must assess the anticipated loads in their applications to select a gear set with adequate load capacity.

Illustrative Image (Source: Google Search)

-

Tolerance

– Tolerance refers to the permissible limits of variation in dimensions and physical properties. It is critical for ensuring compatibility between components and maintaining operational efficiency. Tighter tolerances often lead to better performance but can increase manufacturing costs. -

Efficiency

– Efficiency measures how much input energy is converted to output energy in the gear system. Higher efficiency translates to lower energy consumption and reduced heat generation, which is particularly important in energy-sensitive applications. Buyers should prioritize gear sets with high efficiency ratings to enhance operational sustainability.

Common Trade Terminology

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking for reliable suppliers that adhere to quality standards. -

MOQ (Minimum Order Quantity)

– This term refers to the smallest number of units that a supplier is willing to sell. Being aware of MOQs helps buyers manage inventory and budget constraints effectively, ensuring they do not overcommit financially. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing information for specific products or services. It is a vital step in the procurement process, enabling buyers to compare costs and terms from different suppliers. -

Incoterms (International Commercial Terms)

– These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and delivery responsibilities, which can vary significantly by term. -

Lead Time

– Lead time refers to the period between placing an order and receiving the goods. Understanding lead times is critical for planning production schedules and managing supply chain logistics, especially in industries with tight deadlines. -

Customization

– Customization involves altering standard products to meet specific customer requirements. Buyers should explore customization options to ensure that the planetary gear sets meet unique operational needs, enhancing overall efficiency and effectiveness.

In conclusion, a solid grasp of both the technical properties and trade terminology associated with planetary gear sets is essential for B2B buyers. This knowledge not only facilitates informed purchasing decisions but also enhances negotiation capabilities and supply chain management.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the planetary gear set Sector

Market Overview & Key Trends

The planetary gear set market is experiencing robust growth, fueled by advancements in industrial automation and increasing demand for energy-efficient machinery. Global drivers include the rise of electric vehicles, robotics, and renewable energy applications, particularly in regions like Europe and North America, which are leading in technological innovations. For international B2B buyers from Africa, South America, the Middle East, and Europe, understanding these dynamics is essential for effective sourcing strategies.

Emerging trends indicate a shift towards modular designs, allowing for easier integration into various applications such as gearhead motors and turbine engines. Additionally, the adoption of Industry 4.0 practices is transforming the landscape, with IoT-enabled gear sets providing real-time performance data and predictive maintenance capabilities. Buyers should prioritize suppliers that are investing in these technologies to ensure they remain competitive.

Furthermore, the market is witnessing a consolidation trend, with major players like Stork, Framo, and Mitsui Miike investing in mergers and acquisitions to enhance their product offerings and expand their geographical reach. This competitive environment offers opportunities for B2B buyers to negotiate better terms and explore innovative solutions tailored to their specific needs.

Sustainability & Ethical Sourcing in B2B

As environmental concerns escalate, sustainability is becoming a critical factor in the sourcing of planetary gear sets. The industry faces scrutiny regarding its carbon footprint and the use of non-renewable resources. Therefore, B2B buyers must prioritize suppliers who demonstrate a commitment to sustainable practices and ethical sourcing.

Buyers should look for suppliers that utilize green certifications such as ISO 14001, which indicates a commitment to environmental management, and those that offer products made from recycled materials or that employ sustainable manufacturing processes. Moreover, transparency in the supply chain is essential; suppliers should provide detailed information about their sourcing practices, including the traceability of materials used.

Integrating sustainability into procurement strategies not only helps in reducing environmental impact but also enhances brand reputation. Companies that prioritize sustainability are increasingly favored by consumers and stakeholders, thus presenting a competitive advantage in the marketplace.

Brief Evolution/History

The planetary gear set has evolved significantly since its inception in the late 19th century, originally designed for steam engines. As industries progressed, so did the technology behind these gear sets, adapting to the needs of various applications in automotive, aerospace, and manufacturing sectors. The introduction of advanced materials and manufacturing techniques has led to improvements in efficiency, compactness, and durability.

Today, the focus is on integrating smart technologies and sustainable practices, reflecting broader industry trends towards automation and environmental responsibility. This evolution not only showcases the adaptability of planetary gear sets but also highlights their critical role in modern engineering solutions, making them a valuable component for B2B buyers aiming for innovation and efficiency in their operations.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of planetary gear set

-

How should I vet suppliers for planetary gear sets?

When vetting suppliers, prioritize companies with a proven track record in manufacturing planetary gear sets. Check for industry certifications such as ISO 9001, which indicates quality management systems. Request references from previous clients to gauge reliability. Additionally, assess the supplier’s financial stability and production capacity, especially if you require large volumes. Utilize platforms like DirectIndustry or industry-specific trade shows to gather information and meet potential suppliers face-to-face. -

Can planetary gear sets be customized for specific applications?

Yes, many manufacturers offer customization options for planetary gear sets to meet specific application requirements. Customizations can include changes in size, gear ratios, and material selection. When discussing customization, provide detailed specifications and application contexts to ensure the manufacturer understands your needs. Be prepared for potential additional costs and longer lead times associated with custom designs, and ensure clear communication throughout the process. -

What are the typical minimum order quantities (MOQ) and lead times?

MOQs for planetary gear sets can vary widely depending on the supplier and the complexity of the order. Generally, expect MOQs to range from 50 to 500 units. Lead times typically range from 4 to 12 weeks, influenced by factors such as production capacity and customization requirements. To avoid delays, discuss your timelines upfront and consider placing larger orders to secure better pricing and reduced lead times. -

What payment terms should I expect when sourcing internationally?

Payment terms can vary by supplier and region. Common options include advance payment, letters of credit, or payment upon delivery. Ensure you understand the supplier’s payment preferences and negotiate terms that protect your interests. Using secure payment methods, such as escrow services, can mitigate risks. Additionally, consider currency fluctuations and potential import duties when budgeting for your purchases. -

What quality assurance processes should I look for?

A reputable supplier should have a robust quality assurance (QA) process in place. Inquire about their testing methods, including material inspections, dimensional checks, and performance testing of planetary gear sets. Request documentation of their QA procedures and any certifications they hold. Additionally, consider conducting on-site audits or requesting third-party inspections to verify compliance with your quality standards before finalizing orders. -

What certifications should I look for in suppliers?

Look for suppliers with relevant industry certifications such as ISO 9001 for quality management, ISO 14001 for environmental management, and specific certifications related to your industry (e.g., aerospace or automotive standards). Certifications not only indicate adherence to quality standards but also demonstrate a commitment to continuous improvement. Request copies of these certifications during the supplier evaluation process to ensure compliance. -

How can I manage logistics and shipping for international orders?

Effective logistics management is crucial for international orders. Collaborate with suppliers to determine the best shipping methods based on your budget and timeline. Consider working with a freight forwarder experienced in handling industrial equipment to navigate customs regulations and minimize delays. Ensure that shipping terms (Incoterms) are clearly defined in your contract to avoid misunderstandings regarding responsibilities for shipping costs and risks. -

What steps can I take if a dispute arises with a supplier?

In case of a dispute, first attempt to resolve the issue through direct communication with the supplier. Document all correspondence and agreements to support your position. If the dispute escalates, refer to the terms outlined in your contract regarding dispute resolution methods, such as mediation or arbitration. Engaging a legal professional experienced in international trade can provide guidance on your rights and obligations, ensuring that you take the appropriate steps to protect your interests.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for planetary gear set

In conclusion, the landscape for planetary gear sets is poised for significant growth, driven by advancements in technology and increasing demand across various sectors such as automotive, aerospace, and industrial machinery. For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, strategic sourcing is not merely a procurement tactic but a vital component of long-term business success.

Illustrative Image (Source: Google Search)

By prioritizing comprehensive market research, understanding regional dynamics, and fostering strong relationships with key suppliers, buyers can effectively navigate the complexities of the planetary gear set market. Key takeaways include the importance of continuous monitoring of market trends, evaluating supplier capabilities, and leveraging competitive analysis to make informed decisions.

As we look towards 2032, it is imperative for businesses to remain agile and innovative in their sourcing strategies. This proactive approach will not only mitigate risks but also unlock new opportunities for growth and collaboration. Embrace the future of planetary gear sets by investing in strategic partnerships and staying ahead of industry trends to secure a competitive advantage in your respective markets.