Your Ultimate Guide to Sourcing Power Press

Introduction: Navigating the Global Market for power press

In the ever-evolving landscape of global manufacturing, Power Press technology stands as a cornerstone for efficiency and precision across various industries. As a pivotal tool in the production process, power presses facilitate the shaping, cutting, and forming of materials, making them indispensable in sectors such as automotive, aerospace, and consumer electronics. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of power presses can significantly enhance sourcing strategies and operational efficiencies.

This comprehensive guide delves into the multifaceted world of power presses, covering essential topics such as the types of machines available, the materials used, and the manufacturing and quality control processes that ensure reliability and performance. Buyers will also gain insights into evaluating suppliers, understanding cost structures, and navigating the market dynamics that influence purchasing decisions. Additionally, a dedicated FAQ section addresses common queries, empowering buyers with the knowledge necessary to make informed decisions.

By arming B2B buyers with actionable insights and detailed information, this guide not only simplifies the sourcing process but also enhances the strategic alignment of procurement efforts with organizational goals. In a competitive global market, leveraging the right power press can lead to increased productivity, reduced operational costs, and a stronger foothold in the industry.

Understanding power press Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mechanical Press | Uses a motor-driven crank mechanism; high-speed operation | Automotive parts, electronics | Pros: Fast production, high precision. Cons: Limited flexibility for complex shapes. |

| Hydraulic Press | Utilizes hydraulic fluid for power; offers adjustable force | Aerospace components, heavy machinery | Pros: Excellent control, suitable for intricate designs. Cons: Slower operation, higher maintenance. |

| Pneumatic Press | Operated by compressed air; lightweight and portable | Sheet metal forming, packaging | Pros: Quick setup, ideal for light materials. Cons: Less power compared to hydraulic presses. |

| Servo Press | Incorporates servo motors for precise control | High-volume production, automotive | Pros: Energy-efficient, programmable for various tasks. Cons: Higher initial investment. |

| Toggle Press | Employs a toggle mechanism for increased force | Stamping, metal forming | Pros: High force output, compact design. Cons: Limited stroke length, can be slower. |

Mechanical Press

Mechanical presses are characterized by their motor-driven crank mechanism, which allows for high-speed operation. They are particularly well-suited for mass production in industries such as automotive and electronics, where high precision and rapid output are critical. When purchasing, buyers should consider the press’s speed, tonnage, and the specific types of materials it will process, as mechanical presses may have limitations when it comes to flexibility for complex shapes.

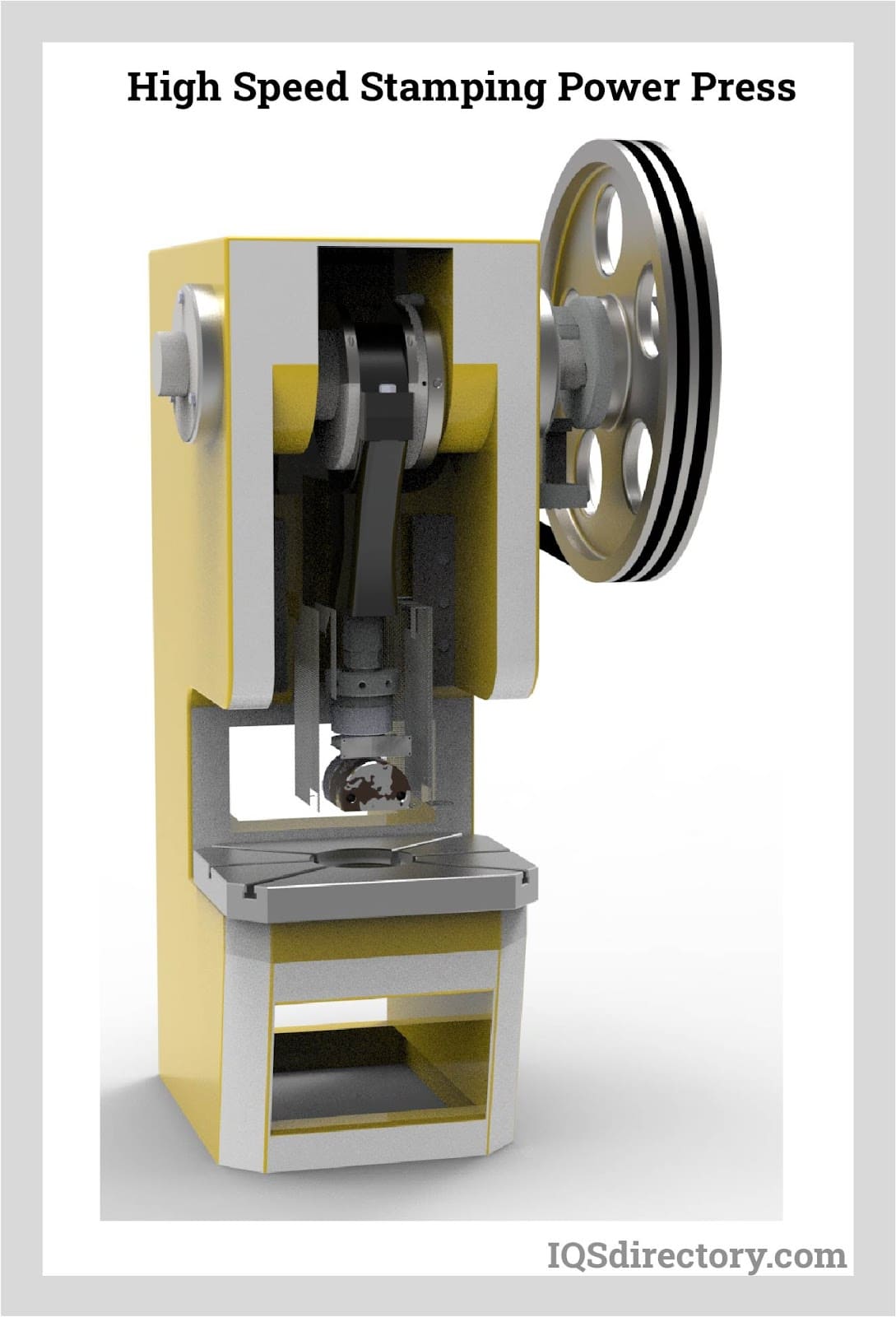

Illustrative Image (Source: Google Search)

Hydraulic Press

Hydraulic presses utilize hydraulic fluid to generate force, making them ideal for applications requiring adjustable pressure. Commonly used in aerospace and heavy machinery sectors, they excel in producing intricate components. Buyers should focus on the press’s capacity, control features, and maintenance requirements, as hydraulic systems can be slower and may require more upkeep compared to mechanical counterparts.

Pneumatic Press

Pneumatic presses operate using compressed air, making them lightweight and portable. They are often employed in sheet metal forming and packaging applications. These presses are advantageous for quick setups and are suitable for lighter materials. However, buyers should be aware that pneumatic presses may lack the power required for heavier tasks and have limitations in terms of force output.

Servo Press

Servo presses integrate servo motors for precise control, which enables programmable operations that can be tailored to various tasks. They are particularly beneficial in high-volume production environments, such as automotive manufacturing. When considering a servo press, buyers should evaluate energy efficiency, programming capabilities, and the initial investment, as these systems typically have a higher upfront cost but can lead to long-term savings.

Toggle Press

Toggle presses use a toggle mechanism to amplify force output, making them compact yet powerful. They are commonly used for stamping and metal forming applications. Buyers should consider the specific requirements of their production needs, including the desired stroke length and operational speed. While toggle presses can deliver high force, they may be slower and have limitations in stroke length compared to other press types.

Related Video: Crank type mechanical power press machine simulation

Key Industrial Applications of power press

| Industry/Sector | Specific Application of Power Press | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Stamping body panels and components | Enhances production speed and reduces labor costs | Look for presses with high tonnage capacity and precision engineering features. |

| Aerospace | Forming intricate structural parts | Ensures high precision and lightweight components | Consider presses with advanced control systems for accuracy and repeatability. |

| Electronics | Manufacturing connectors and housings | Increases efficiency and reduces material waste | Choose presses that offer flexibility in tooling and quick changeover capabilities. |

| Construction | Bending and shaping metal sheets | Improves structural integrity and durability | Evaluate presses that can handle various material types and thicknesses. |

| Consumer Goods | Producing packaging and containers | Streamlines production and enhances product quality | Look for energy-efficient models with integrated safety features. |

In the automotive industry, power presses are primarily used for stamping body panels and various components. These machines enable manufacturers to produce complex shapes at high speeds, significantly reducing labor costs and increasing throughput. Buyers should prioritize presses with high tonnage capacities and precision engineering features to ensure consistent quality and performance in high-volume production settings.

In the aerospace sector, power presses play a crucial role in forming intricate structural parts that require exceptional precision. The lightweight nature of these components is vital for aircraft performance, and the use of power presses ensures that specifications are met consistently. International buyers should consider sourcing presses with advanced control systems that provide accuracy and repeatability, essential for meeting stringent aerospace standards.

The electronics industry utilizes power presses for the manufacturing of connectors, housings, and other small components. These applications benefit from the efficiency of power presses, which can significantly reduce material waste and enhance production rates. Buyers in this sector should focus on presses that offer flexibility in tooling and quick changeover capabilities, allowing for rapid adaptation to changing production needs.

In the construction industry, power presses are essential for bending and shaping metal sheets used in various structural applications. The ability to create precise bends improves the structural integrity and durability of construction materials. Buyers should evaluate presses that can handle a variety of material types and thicknesses, ensuring they can meet diverse project requirements.

Lastly, in the consumer goods sector, power presses are utilized for producing packaging and containers. These applications benefit from streamlined production processes that enhance product quality while reducing costs. Buyers should look for energy-efficient models equipped with integrated safety features to ensure compliance with safety regulations and sustainable operations in their manufacturing facilities.

Related Video: Rajesh 20 Ton Mechanical Power Press

Strategic Material Selection Guide for power press

When selecting materials for power presses, understanding the properties, advantages, disadvantages, and implications for specific applications is crucial for B2B buyers. Here, we analyze four common materials used in the construction of power presses: Steel, Aluminum, Cast Iron, and Composite Materials. Each material has unique characteristics that influence performance, cost, and suitability for various applications.

Steel

Key Properties:

Steel is renowned for its strength and durability, with excellent temperature and pressure ratings. It can withstand high stress and is resistant to deformation under load, making it ideal for heavy-duty applications.

Pros & Cons:

Steel’s primary advantage is its high tensile strength, which allows for the production of robust and long-lasting power presses. However, it is relatively heavy and can be more expensive than other materials. Additionally, steel is prone to corrosion if not properly treated, which can affect its longevity.

Impact on Application:

Steel’s compatibility with high-pressure applications makes it suitable for industries like automotive and aerospace, where precision and reliability are paramount.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM and DIN. In regions like Africa and South America, where corrosion may be a concern due to environmental factors, selecting galvanized or stainless steel can enhance durability.

Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance, making it ideal for applications where weight is a critical factor. It also has decent thermal and electrical conductivity.

Pros & Cons:

The key advantage of aluminum is its low weight, which can lead to reduced energy costs in transportation and operation. However, it has lower tensile strength compared to steel, which may limit its use in high-load applications. Additionally, aluminum can be more expensive than steel, depending on the market.

Impact on Application:

Aluminum is particularly effective in applications requiring high-speed operations due to its lightweight nature, making it suitable for the electronics and consumer goods industries.

Considerations for International Buyers:

Buyers should be aware of the varying grades of aluminum and their corresponding properties. Compliance with JIS standards is crucial, especially in Asian markets like Vietnam and Thailand, where specific grades are preferred for manufacturing.

Cast Iron

Key Properties:

Cast iron is known for its excellent wear resistance and ability to dampen vibrations, making it suitable for heavy machinery. It has good compressive strength but is brittle under tensile stress.

Pros & Cons:

The primary advantage of cast iron is its durability and ability to withstand high temperatures, making it ideal for heavy-duty applications. However, its brittleness can be a significant drawback, as it may fracture under sudden impacts or stress.

Impact on Application:

Cast iron is often used in applications where vibration damping is essential, such as in the manufacturing of automotive parts.

Considerations for International Buyers:

Buyers should consider the weight and handling of cast iron components, especially in regions with logistical challenges. Compliance with ASTM standards is important for ensuring quality and consistency.

Composite Materials

Key Properties:

Composite materials, often made from a combination of resins and fibers, offer excellent strength-to-weight ratios and corrosion resistance. They can be engineered for specific performance characteristics.

Pros & Cons:

The main advantage of composites is their versatility and ability to be tailored for specific applications. However, they can be more expensive to manufacture and may require specialized processes for handling and repair.

Impact on Application:

Composites are increasingly used in applications where weight reduction is critical, such as in aerospace and high-performance automotive sectors.

Considerations for International Buyers:

International buyers should be aware of the certifications required for composite materials, as they may vary significantly by region. Understanding local regulations and standards is essential for compliance and successful integration into existing systems.

Summary Table

| Material | Typical Use Case for power press | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty manufacturing | High tensile strength | Prone to corrosion | High |

| Aluminum | High-speed operations | Lightweight | Lower tensile strength | Medium |

| Cast Iron | Automotive parts manufacturing | Excellent wear resistance | Brittle under tensile stress | Medium |

| Composite Materials | Aerospace and high-performance automotive | Tailored performance characteristics | Higher manufacturing complexity | High |

This guide provides a comprehensive overview of the materials commonly used in power presses, allowing international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for power press

Manufacturing Processes for Power Press

Understanding the manufacturing processes for power presses is critical for international B2B buyers seeking to ensure quality, efficiency, and reliability in their supply chains. The production of a power press typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage employs specific techniques that contribute to the overall performance and durability of the machine.

Material Preparation

The first step in manufacturing a power press is material preparation, which involves selecting high-quality raw materials, often steel or cast iron, known for their strength and durability. Key processes include:

- Cutting and Shaping: Materials are cut into required shapes and sizes using CNC machines, ensuring precision.

- Heat Treatment: This process enhances the mechanical properties of the material, improving hardness and toughness, which are crucial for the longevity of the press.

Forming

Once the materials are prepared, the next stage is forming, which involves shaping the materials into the desired components of the power press. Techniques used in this stage include:

- Stamping: This method uses a die to cut or shape the material under high pressure, creating components like the frame and ram.

- Bending: Components may also be bent to achieve specific angles or shapes, which is essential for parts that require precise fits.

Assembly

The assembly stage brings together all the formed components into a functioning unit. This stage is critical, as the accuracy of assembly affects the overall performance of the power press. Key techniques include:

- Welding: Components are often welded together to create a robust structure. Advanced welding techniques, such as robotic welding, may be employed for precision and efficiency.

- Mechanical Fastening: Bolts and screws are used to secure parts, ensuring that the assembly can withstand operational stresses.

Finishing

The final manufacturing stage is finishing, which enhances the durability and appearance of the power press. This stage may involve:

- Painting and Coating: Protective coatings are applied to prevent rust and wear, extending the lifespan of the machine.

- Surface Treatment: Techniques like anodizing or polishing improve surface quality, reducing friction and wear during operation.

Quality Assurance in Power Press Manufacturing

Quality assurance is paramount in the manufacturing of power presses, ensuring that each machine meets international standards and operates reliably under demanding conditions. B2B buyers should be aware of relevant quality standards and checkpoints throughout the manufacturing process.

International and Industry-Specific Standards

For power press manufacturers, adherence to quality standards is essential. Some key standards include:

- ISO 9001: This international standard outlines the criteria for a quality management system, ensuring consistent quality in products and services.

- CE Marking: In Europe, CE marking indicates compliance with health, safety, and environmental protection standards for products.

- API Standards: For manufacturers supplying to the oil and gas industry, compliance with American Petroleum Institute (API) standards is crucial.

Quality Control Checkpoints

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that each stage meets specified criteria. Common QC checkpoints include:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet quality specifications.

- In-Process Quality Control (IPQC): During the manufacturing process, various inspections are conducted to monitor compliance with quality standards. This may include measurements of dimensions and tolerances.

- Final Quality Control (FQC): Before the power press is shipped, a final inspection is conducted to verify that the machine meets all specifications and performance standards.

Common Testing Methods

To ensure the reliability and performance of power presses, several testing methods are commonly employed:

- Functional Testing: This assesses the operational performance of the power press under various loads and conditions.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing and magnetic particle testing are used to identify internal defects without damaging the components.

- Fatigue Testing: This evaluates how the power press will perform under repeated stress and load, providing insights into its durability.

Verifying Supplier Quality Control

For international B2B buyers, verifying a supplier’s quality control processes is essential for ensuring that the power presses meet the required standards. Here are actionable strategies:

- Audits: Conducting regular audits of the supplier’s manufacturing facilities can provide insights into their quality control processes and adherence to standards.

- Quality Reports: Request detailed quality reports that outline testing results and compliance with international standards. This transparency can help build trust.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the manufacturer’s quality control practices and product quality.

Quality Control Nuances for International Buyers

International buyers, especially those from Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

- Cultural Differences: Different regions may have varying approaches to quality assurance. Understanding these cultural differences can help in negotiations and establishing quality expectations.

- Regulatory Compliance: Different countries have unique regulatory requirements that must be adhered to. Buyers should ensure that suppliers are compliant with the regulations specific to their market.

- Supply Chain Integrity: Establishing a robust supply chain with reliable partners can minimize risks associated with quality issues. Consideration of geographical challenges and logistics is essential.

In conclusion, the manufacturing processes and quality assurance practices for power presses are integral to ensuring that international B2B buyers receive reliable, high-quality machinery. By understanding the stages of production, relevant standards, and effective verification methods, buyers can make informed decisions and strengthen their supply chain.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for power press Sourcing

In the world of power press sourcing, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis will guide buyers from Africa, South America, the Middle East, and Europe through the key cost components, price influencers, and strategic negotiation tips to optimize their purchasing decisions.

Cost Components

-

Materials

The type of materials used in manufacturing power presses significantly impacts the overall cost. Common materials include high-strength steel and specialized alloys, which can vary in price based on market demand and availability. Buyers should consider the long-term durability and performance characteristics of materials when evaluating costs. -

Labor

Labor costs encompass wages for skilled workers involved in the assembly and quality assurance of power presses. These costs can fluctuate based on geographic location and labor market conditions. In regions with high labor costs, such as parts of Europe, manufacturers may charge more, while lower-cost labor markets may offer more competitive pricing. -

Manufacturing Overhead

This includes costs related to factory maintenance, utilities, and administrative expenses. Manufacturers often distribute these overhead costs across their product lines, affecting the final price of power presses. Buyers should inquire about the production capacity and operational efficiencies of suppliers to assess how these factors influence pricing. -

Tooling

Tooling costs are associated with the specific molds and dies required for producing custom power presses. These costs can be substantial for custom designs, so buyers should assess whether standard models meet their needs to avoid unnecessary expenditures. -

Quality Control (QC)

Implementing stringent QC measures ensures that the power presses meet specified standards and certifications. While this can increase initial costs, it often leads to reduced long-term expenses related to maintenance and failures. Buyers should prioritize suppliers with robust QC processes to ensure reliability. -

Logistics

Shipping and handling costs can vary widely based on location and the chosen Incoterms. International buyers must consider freight charges, insurance, and customs duties, which can significantly impact the total cost. It’s advisable to work closely with logistics providers to find the most cost-effective shipping solutions. -

Margin

Supplier margins can vary based on their market positioning, brand reputation, and service offerings. Understanding a supplier’s pricing strategy can help buyers negotiate better terms and potentially lower prices.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Purchasing in larger quantities can lead to reduced per-unit costs, making it vital for buyers to assess their production needs and negotiate favorable terms based on anticipated demand.

-

Specifications/Customization: Custom power presses will incur higher costs due to additional design and tooling requirements. Buyers should evaluate whether standard models meet their specifications to optimize costs.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., ISO standards) can increase costs but also enhance performance and longevity. Buyers must weigh the benefits against the costs.

-

Supplier Factors: The reputation, experience, and financial stability of suppliers can influence pricing. Engaging with established suppliers may provide better assurance of product quality and service.

-

Incoterms: The choice of Incoterms affects the allocation of costs and responsibilities in international shipping. Buyers should carefully select terms that align with their logistical capabilities and cost structures.

Buyer Tips

-

Negotiation: Engage suppliers in discussions about pricing structures, volume discounts, and payment terms. Establishing a good rapport can lead to better pricing and service conditions.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, maintenance, operational costs, and potential downtime. A slightly higher initial investment may yield lower long-term costs.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and local taxes that can affect the final price. It is advisable to seek quotes in your local currency and clarify all associated costs upfront.

Disclaimer

Prices for power presses can vary significantly based on the factors outlined above. This analysis provides indicative insights, and buyers are encouraged to conduct thorough market research and supplier evaluations to obtain accurate pricing tailored to their specific needs.

Spotlight on Potential power press Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘power press’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for power press

When considering the procurement of power presses, understanding their essential technical properties and industry-specific terminology is crucial for making informed decisions. Below is a detailed overview that provides actionable insights for B2B buyers, particularly in international markets.

Key Technical Properties of Power Presses

-

Material Grade

– The construction material of a power press significantly affects its durability and performance. Common materials include high-strength steel and cast iron, which offer robustness and stability. Buyers should ensure that the material grade aligns with the operational environment and the specific applications of the press. -

Tonnage Capacity

– Tonnage refers to the maximum force the press can exert, typically measured in tons. This specification is critical as it determines the types of materials and thicknesses the press can handle. B2B buyers must assess their production requirements to select a press with adequate tonnage capacity. -

Stroke Length

– The stroke length is the distance the ram travels during each cycle of operation. A longer stroke length allows for processing larger workpieces, while shorter strokes are suitable for precision tasks. Understanding stroke length helps buyers match the press to their specific manufacturing processes. -

Speed (SPM – Strokes Per Minute)

– This metric indicates how many cycles the press can complete in a minute. Higher SPM rates lead to increased productivity but may require more sophisticated control systems. Buyers should consider their production volume and efficiency goals when evaluating this property. -

Control Systems

– Modern power presses are equipped with advanced control systems that enhance operational precision and safety. Features may include programmable logic controllers (PLCs) and touch screen interfaces. Buyers should prioritize presses with user-friendly controls that facilitate training and minimize operational errors. -

Safety Features

– Safety is paramount when operating power presses. Key safety features include emergency stop buttons, light curtains, and two-hand controls, which prevent accidental activation. B2B buyers must ensure that the presses they consider comply with local safety regulations and industry standards to protect operators.

Common Trade Terminology in Power Press Procurement

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In power press procurement, understanding whether a press is sourced from an OEM can influence quality assurance and warranty considerations. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is vital for buyers who need to understand the implications of bulk purchasing and inventory management, especially in regions with fluctuating demand. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and other relevant details for specific products or services. Buyers should prepare detailed RFQs to ensure they receive accurate quotes that align with their requirements. -

Incoterms (International Commercial Terms)

– These are standardized terms used in international trade to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for navigating international transactions and ensuring compliance with trade regulations. -

Lead Time

– Lead time refers to the duration from placing an order to receiving the product. Understanding lead times is crucial for planning production schedules and managing supply chain efficiency, especially in global sourcing scenarios. -

Calibration

– Calibration involves adjusting the power press to ensure it operates within specified tolerances. Regular calibration is necessary for maintaining precision and quality in manufacturing processes. Buyers should inquire about calibration services offered by suppliers to sustain operational effectiveness.

By grasping these technical properties and trade terms, B2B buyers can enhance their procurement strategies, ensuring they select the right power press for their manufacturing needs while navigating the complexities of international trade.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the power press Sector

Global drivers and trends in the power press sector are shaped by a combination of technological advancements, economic shifts, and evolving consumer demands. As industries strive for greater efficiency and precision, the adoption of automation and smart technologies has surged. Manufacturers are increasingly investing in Industry 4.0 solutions, integrating IoT devices and AI analytics to enhance operational performance. This trend is particularly significant for international B2B buyers in regions like Africa and South America, where there is a growing emphasis on modernizing production processes to compete on a global scale.

Additionally, the demand for customized solutions is rising, with buyers seeking power presses that can accommodate specific applications across diverse sectors, including automotive, aerospace, and electronics. The shift towards sustainability is also influencing sourcing trends, as companies are pressured to adopt greener practices. Buyers should be aware of suppliers who prioritize energy-efficient machines and sustainable materials, as these factors are becoming increasingly critical in procurement decisions.

In terms of market dynamics, the power press sector is witnessing a consolidation of suppliers, especially in Europe and the Middle East. This consolidation allows for better resource allocation and innovation sharing, but it also means that international buyers need to conduct thorough due diligence when selecting suppliers to ensure they meet quality and sustainability standards. Furthermore, fluctuations in raw material prices and geopolitical factors can impact sourcing strategies, making it essential for buyers to stay informed about market conditions.

Sustainability & Ethical Sourcing in B2B

The environmental impact of manufacturing processes, particularly in the power press sector, cannot be overlooked. As industries face increasing scrutiny regarding their carbon footprints, the importance of ethical sourcing and sustainable practices is paramount. Buyers should prioritize suppliers that are committed to reducing waste and energy consumption, as well as those that implement recycling initiatives for their products.

Green certifications, such as ISO 14001, demonstrate a supplier’s commitment to environmental management systems. Additionally, sourcing materials that are recyclable or derived from sustainable sources can significantly enhance a company’s sustainability profile. For instance, choosing power presses made from recycled metals or that incorporate biodegradable components can mitigate the overall environmental impact.

Moreover, ethical supply chains are crucial for ensuring that the materials used in power presses are sourced responsibly, free from conflict minerals and labor exploitation. B2B buyers should engage with suppliers who provide transparency in their sourcing practices, fostering a responsible supply chain that aligns with global sustainability goals.

Brief Evolution/History

The evolution of power press technology has been marked by significant milestones that have shaped its current form. Originally developed in the 19th century, power presses were primarily mechanical, relying on manual operation. As industrial needs expanded, the introduction of hydraulic presses in the mid-20th century revolutionized the sector, allowing for greater control over pressure application and versatility in manufacturing processes.

The late 20th and early 21st centuries saw further advancements with the integration of automation and computerization, enabling real-time monitoring and adjustments during production. Today, the focus is on smart manufacturing, where power presses are part of interconnected systems that optimize efficiency and sustainability. This evolution not only reflects technological progress but also highlights the need for B2B buyers to remain adaptable and forward-thinking in their sourcing strategies.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of power press

-

What key factors should I consider when vetting suppliers for power presses?

When vetting suppliers for power presses, focus on their industry reputation, experience, and certifications. Verify their production capabilities, quality control processes, and adherence to international standards. Request references from previous clients, particularly those in your region, to gauge reliability. Additionally, assess their after-sales support and service options, as these can significantly impact your operational efficiency. A supplier’s ability to communicate effectively and provide timely updates is also crucial in maintaining a strong business relationship. -

Can I customize my power press order to meet specific manufacturing needs?

Yes, many suppliers offer customization options for power presses to suit specific manufacturing applications. When discussing customization, clarify your requirements regarding size, capacity, and features such as automation or safety mechanisms. Ensure that the supplier has a proven track record of delivering customized solutions and can provide examples of past projects. Be prepared to discuss technical specifications in detail, as this will help the supplier understand your needs and propose suitable modifications. -

What are the typical minimum order quantities (MOQs) and lead times for power presses?

Minimum order quantities (MOQs) for power presses can vary widely depending on the supplier and the type of machine. Generally, MOQs may range from one unit for standard models to several units for customized designs. Lead times also differ based on production schedules, customization complexity, and shipping logistics. It’s essential to discuss these factors upfront with potential suppliers to establish realistic timelines and ensure your production schedules align with their capabilities. -

What payment terms are commonly offered by suppliers of power presses?

Payment terms for power presses typically vary by supplier and are influenced by factors such as order size and customer relationship. Common arrangements include advance payment, partial payment upon order confirmation, and the balance upon delivery. Some suppliers may also accept letters of credit or installment payments, particularly for larger orders. Always negotiate terms that provide you with financial security while accommodating the supplier’s needs, and ensure all terms are documented in the contract. -

How can I ensure quality assurance and certifications for the power presses I purchase?

To ensure quality assurance, request documentation of the supplier’s certifications, such as ISO 9001 or other relevant industry standards. Verify that their manufacturing processes comply with international quality control regulations. Conducting an on-site inspection of the production facility can provide further assurance of their quality practices. Additionally, consider asking for test reports or samples before full production, and establish clear criteria for quality checks in your contract to protect your interests. -

What logistics considerations should I keep in mind when importing power presses?

Logistics play a critical role in the successful importation of power presses. Consider factors such as shipping methods, customs regulations, and potential tariffs or duties in your country. Choose a reliable freight forwarder experienced in handling heavy machinery to ensure safe and timely delivery. Additionally, clarify the supplier’s responsibilities regarding shipping and insurance, and establish a clear timeline for delivery to avoid disruptions in your production schedule. -

How should I handle disputes with suppliers regarding power press orders?

Handling disputes with suppliers requires a proactive approach. Start by clearly documenting all communications and agreements related to the order. If a dispute arises, initiate a discussion with the supplier to seek a resolution amicably. If necessary, refer to the contract for guidance on dispute resolution processes, including mediation or arbitration. Establishing a strong relationship with suppliers can often help mitigate conflicts before they escalate, emphasizing open communication and mutual understanding. -

What are the best practices for ongoing maintenance of power presses?

Regular maintenance is essential for the longevity and performance of power presses. Establish a maintenance schedule based on the manufacturer’s recommendations and operational usage. Key practices include routine inspections, lubrication of moving parts, and timely replacement of worn components. Training your operators on proper usage and maintenance protocols can prevent costly downtime. Additionally, consider partnering with the supplier for ongoing support and training to ensure optimal machine performance throughout its lifecycle.

Illustrative Image (Source: Google Search)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for power press

In conclusion, the strategic sourcing of Power Press technology is integral for businesses aiming to enhance operational efficiency and product quality. By understanding the various types of Power Presses—mechanical and hydraulic—and their specific applications, buyers can make informed decisions that align with their production needs. The emphasis on safety features and automation not only mitigates risks but also boosts productivity, making these machines invaluable assets in manufacturing.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, the opportunity to leverage advanced Power Press technology is significant. Establishing partnerships with reliable suppliers and investing in modern machinery can lead to sustainable growth and competitive advantage in global markets.

As we look to the future, the ongoing innovations in Power Press design and functionality promise even greater efficiencies and capabilities. Now is the time to engage with suppliers, explore the latest technologies, and position your business for success in an ever-evolving industrial landscape. Embrace the power of strategic sourcing to transform your manufacturing processes and drive your business forward.