Your Ultimate Guide to Sourcing Gear Reducer

Introduction: Navigating the Global Market for gear reducer

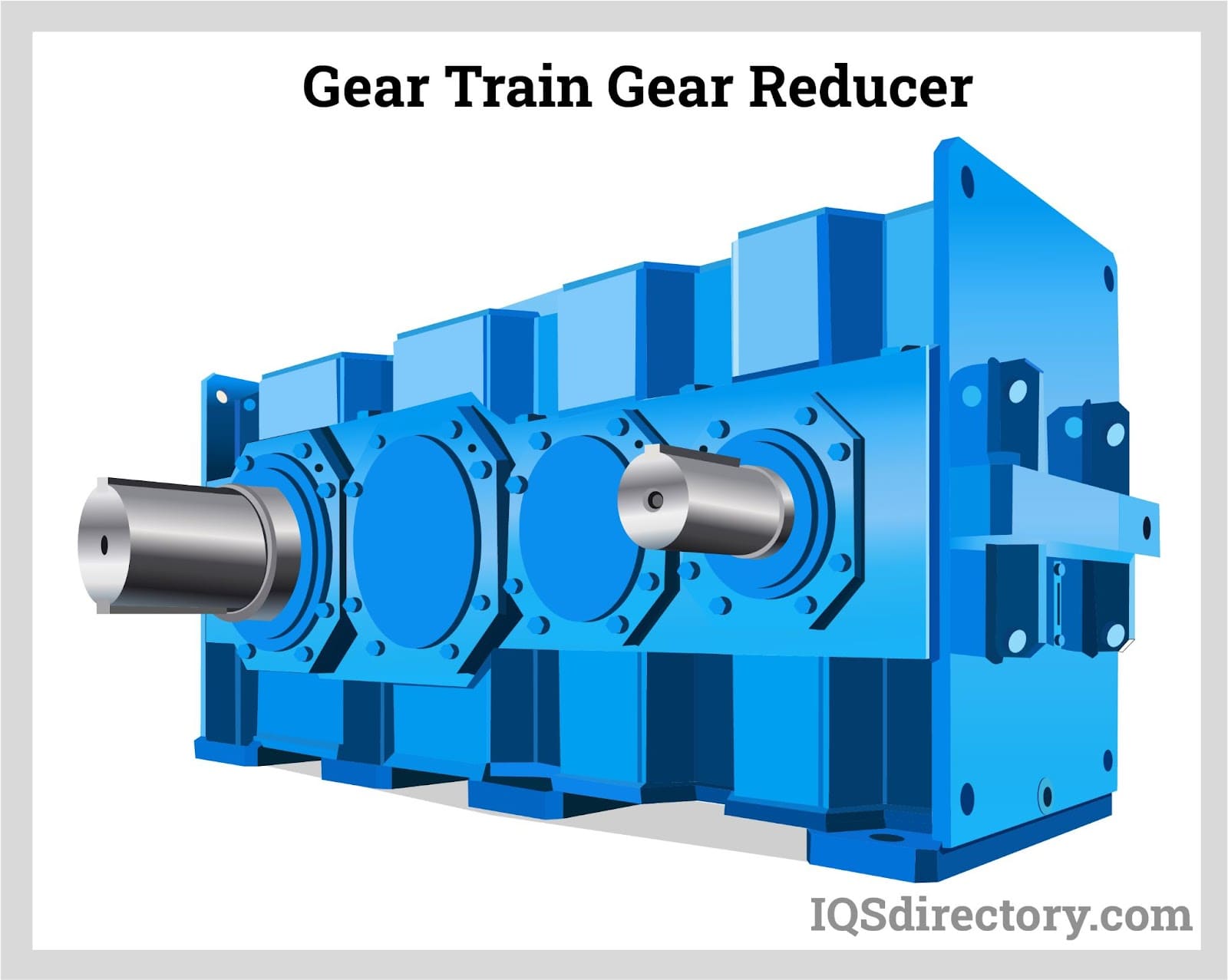

In the dynamic landscape of industrial machinery, gear reducers are indispensable components that enhance the efficiency and performance of various applications. These devices are crucial for managing speed and torque, making them vital for sectors such as automotive, manufacturing, agriculture, and energy. As global industrialization accelerates, the demand for high-quality gear reducers continues to rise, presenting lucrative opportunities for international B2B buyers.

This guide aims to empower B2B buyers from Africa, South America, the Middle East, and Europe by providing a comprehensive overview of the gear reducer market. Key topics include the various types of gear reducers—such as single and double reduction gears—an analysis of materials used in production, and insights into manufacturing and quality control processes. Additionally, we will explore the landscape of suppliers, cost factors, and market trends, along with frequently asked questions to address common concerns.

By delving into these areas, this guide equips buyers with the knowledge needed to make informed sourcing decisions, facilitating the selection of reliable suppliers and innovative products. With actionable insights tailored to diverse regional needs, B2B buyers will be better positioned to navigate the complexities of the global gear reducer market, ensuring optimal investment and operational efficiency.

Understanding gear reducer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Worm Gear Reducer | High torque output, compact design, self-locking | Conveyors, packaging machines | Pros: Space-saving, high reduction ratios. Cons: Limited efficiency, heat generation. |

| Helical Gear Reducer | Smooth operation, high efficiency, low noise levels | Robotics, automotive, industrial machinery | Pros: High load capacity, efficient. Cons: More expensive, requires precise alignment. |

| Bevel Gear Reducer | Angular drive, versatile configurations | Automotive, aerospace, power tools | Pros: Space-efficient, adaptable. Cons: Complex design, higher manufacturing cost. |

| Planetary Gear Reducer | Multiple gears, compact, high torque density | Electric vehicles, robotics, aerospace | Pros: High efficiency, low backlash. Cons: More complex, potential for higher maintenance. |

| Spur Gear Reducer | Simple design, high reliability | Manufacturing, conveyor systems | Pros: Cost-effective, straightforward design. Cons: Noisy operation, limited torque capability. |

Worm Gear Reducer

Worm gear reducers are characterized by their ability to provide high torque output in a compact design. Their self-locking feature prevents back-driving, making them ideal for applications that require secure positioning, such as conveyors and packaging machines. When purchasing, buyers should consider the efficiency, as worm gears can generate significant heat, potentially leading to performance issues. Additionally, while they are space-saving, the limited efficiency compared to other types may necessitate a careful evaluation of operational needs.

Helical Gear Reducer

Helical gear reducers are known for their smooth operation and high efficiency, featuring teeth that are cut at an angle to the gear axis. This design results in lower noise levels and higher load capacities, making them suitable for applications in robotics, automotive, and industrial machinery. Buyers should focus on the precision required during installation, as misalignment can lead to increased wear and reduced lifespan. While they are generally more expensive than other options, their efficiency and durability often justify the investment.

Bevel Gear Reducer

Bevel gear reducers enable angular drives and come in various configurations, making them versatile for different applications, including automotive and aerospace. Their design allows for changes in the axis of rotation, which can be beneficial in compact spaces. However, the complexity of their design can lead to higher manufacturing costs. Buyers should weigh the benefits of adaptability against the potential challenges in installation and maintenance, ensuring that the application justifies the investment.

Planetary Gear Reducer

Planetary gear reducers consist of multiple gears that distribute load evenly, leading to high torque density and compact size. They are particularly favored in electric vehicles, robotics, and aerospace applications due to their efficiency and low backlash. When considering a planetary gear reducer, buyers should be aware of the complexity of the system, which may require specialized maintenance. However, the benefits of reduced size and increased torque make them a compelling choice for high-performance applications.

Spur Gear Reducer

Spur gear reducers are the simplest and most reliable type, characterized by their straight teeth and straightforward design. They are commonly used in manufacturing and conveyor systems due to their cost-effectiveness and ease of maintenance. However, spur gear reducers can be noisy and have limitations in torque capability. Buyers should assess the operational environment and noise tolerance when selecting spur gear reducers, as these factors can significantly impact performance and user satisfaction.

Related Video: How Gear Reducers Work – Animation

Key Industrial Applications of gear reducer

| Industry/Sector | Specific Application of gear reducer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Transmission systems in electric vehicles | Enhances energy efficiency and performance | Compliance with automotive standards and certifications |

| Industrial Machinery | Conveyor systems in manufacturing plants | Increases operational efficiency and reduces downtime | Customization options for torque and speed settings |

| Agriculture | Tractors and harvesting equipment | Improves power transmission and reduces fuel consumption | Durability and resistance to harsh environments |

| Renewable Energy | Wind turbine gearboxes | Maximizes energy output and operational reliability | Sourcing of high-quality materials for longevity |

| Food & Beverage | Mixing and processing equipment | Ensures consistent product quality and efficiency | Hygiene compliance and material safety standards |

Automotive Sector

In the automotive industry, gear reducers are integral to the transmission systems of electric vehicles (EVs). They allow for the efficient conversion of motor speed to wheel speed, enhancing overall energy efficiency and performance. For international buyers, particularly in regions like Europe and South America, sourcing gear reducers that meet stringent automotive standards and certifications is crucial. This ensures not only compliance but also the reliability of the vehicle’s performance over time.

Industrial Machinery

Gear reducers are widely used in conveyor systems within manufacturing plants. They help control the speed and torque of motors, leading to increased operational efficiency and reduced downtime. For buyers in Africa and the Middle East, it is essential to consider customization options that can cater to specific torque and speed requirements, ensuring the gear reducers can handle the unique demands of their operations. Additionally, buyers should evaluate suppliers based on their ability to deliver quality products that can withstand heavy usage.

Illustrative Image (Source: Google Search)

Agriculture

In the agricultural sector, gear reducers are employed in tractors and harvesting equipment to enhance power transmission. This application leads to improved fuel efficiency and operational effectiveness, which are critical for maximizing productivity in farming operations. Buyers from South America, where agriculture is a significant industry, should prioritize sourcing gear reducers that are durable and resistant to harsh environmental conditions, ensuring longevity and reliability in the field.

Renewable Energy

Gear reducers play a vital role in wind turbine gearboxes, where they convert the low-speed rotation of the turbine blades into a higher speed suitable for electricity generation. This maximizes energy output and ensures operational reliability. International buyers, especially from regions investing in renewable energy, must focus on sourcing high-quality gear reducers made from durable materials to withstand extreme weather conditions and prolonged operational demands.

Food & Beverage

In the food and beverage industry, gear reducers are used in mixing and processing equipment to ensure consistent product quality and operational efficiency. The specific requirements for buyers in this sector include compliance with hygiene standards and the use of safe materials. Buyers should look for suppliers that can guarantee not only the performance of the gear reducers but also their adherence to food safety regulations, ensuring that the equipment meets industry standards.

Strategic Material Selection Guide for gear reducer

When selecting materials for gear reducers, international B2B buyers must consider various factors that influence performance, durability, and cost. Here’s an analysis of four common materials used in gear reducer manufacturing, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Steel

Key Properties:

Steel is known for its high strength, toughness, and wear resistance. It typically has a temperature rating up to 300°C and can withstand significant pressure, making it suitable for heavy-duty applications.

Pros & Cons:

Steel gear reducers are durable and can handle high torque loads, which is essential in industrial applications. However, they can be prone to corrosion if not treated, leading to potential maintenance issues. The manufacturing complexity is moderate, as steel requires precise machining.

Impact on Application:

Steel is compatible with various media, including oils and greases, which are commonly used in gear reducer applications.

Considerations for Buyers:

Buyers should ensure compliance with international standards such as ASTM and DIN for steel grades. In regions like Africa and South America, sourcing local steel can reduce costs but may require careful evaluation of quality standards.

Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance, with temperature ratings around 150°C. It is less dense than steel, which can be beneficial for applications where weight is a concern.

Pros & Cons:

The primary advantage of aluminum is its resistance to corrosion, making it ideal for outdoor or humid environments. However, it has lower strength compared to steel, which may limit its use in high-torque applications. Manufacturing processes for aluminum can be more complex due to its softer nature.

Impact on Application:

Aluminum gear reducers are suitable for applications where weight savings are critical, such as in automotive and aerospace industries.

Considerations for Buyers:

International buyers should look for aluminum that meets JIS standards, especially in regions like Japan and South Korea, where quality is paramount. In the Middle East, where high temperatures are common, ensuring the aluminum alloy can withstand local conditions is crucial.

Cast Iron

Key Properties:

Cast iron is known for its excellent wear resistance and vibration dampening properties. It can handle temperatures up to 400°C and is often used in heavy machinery applications.

Pros & Cons:

The durability and ability to absorb vibrations make cast iron a preferred choice for many industrial applications. However, it is heavier than steel and aluminum, which can be a disadvantage in weight-sensitive designs. The manufacturing process can be more complex and costly due to the need for casting.

Impact on Application:

Cast iron gear reducers are particularly effective in environments that involve high loads and shock loads, such as in mining and construction.

Considerations for Buyers:

Buyers in Europe should ensure compliance with EN standards for cast iron products. In South America, understanding local sourcing options can help mitigate costs associated with importing heavy materials.

Plastic Composites

Key Properties:

Plastic composites offer low weight and good chemical resistance, with operating temperatures typically up to 100°C. They are non-corrosive and can be designed for specific applications.

Pros & Cons:

The main advantage of plastic composites is their lightweight and resistance to corrosion, making them suitable for various environments. However, they are not as strong as metals, limiting their use in high-load applications. Manufacturing is often simpler and less expensive.

Impact on Application:

Plastic gear reducers are often used in light-duty applications, such as in consumer products and small machinery.

Considerations for Buyers:

International buyers should ensure that the plastic materials comply with relevant standards, such as ISO, to ensure quality. In regions like Africa, where certain plastics may be less available, sourcing from established manufacturers is advisable.

| Material | Typical Use Case for gear reducer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial applications | High strength and durability | Prone to corrosion without treatment | Medium |

| Aluminum | Automotive and aerospace | Lightweight and corrosion-resistant | Lower strength than steel | Medium |

| Cast Iron | Mining and construction | Excellent wear resistance | Heavier and more costly to manufacture | High |

| Plastic Composites | Consumer products and small machinery | Lightweight and non-corrosive | Limited strength for heavy loads | Low |

This material selection guide provides essential insights for international B2B buyers to make informed decisions when sourcing gear reducers tailored to their specific industrial applications.

In-depth Look: Manufacturing Processes and Quality Assurance for gear reducer

In the competitive landscape of gear reducer manufacturing, understanding the intricacies of production processes and quality assurance is paramount for international B2B buyers. This knowledge not only aids in selecting reliable suppliers but also ensures that the gear reducers meet the operational demands of various industries. Below is a detailed exploration of typical manufacturing processes, quality assurance measures, and actionable insights for buyers, particularly from Africa, South America, the Middle East, and Europe.

Manufacturing Processes for Gear Reducers

The manufacturing process of gear reducers can be divided into several key stages:

1. Material Preparation

The quality of gear reducers begins with the selection of materials. Common materials include:

- Steel Alloys: Known for their strength and durability, often used for gears and housings.

- Aluminum Alloys: Lightweight and corrosion-resistant, suitable for specific applications.

- Plastics: Sometimes utilized for lightweight and low-load applications.

Material preparation involves cutting, machining, and treating these materials to ensure they meet the required specifications. Techniques like heat treatment may be applied to enhance hardness and wear resistance.

2. Forming

The forming stage transforms raw materials into the desired shapes. Key techniques include:

- Casting: Pouring molten metal into molds to create complex shapes, commonly used for housings.

- Forging: Shaping metal using compressive forces, ideal for producing strong gears.

- Machining: Precision cutting processes such as turning and milling are employed to achieve exact dimensions and tolerances.

Advanced manufacturing technologies like Computer Numerical Control (CNC) machining play a crucial role in enhancing precision and reducing production time.

3. Assembly

During the assembly stage, components are brought together to form the gear reducer. This includes:

- Gear Installation: Gears are fitted onto shafts and aligned according to specifications.

- Housing Assembly: The assembled gears are encased in their respective housings, ensuring proper sealing and fit.

- Lubrication: Appropriate lubricants are applied to reduce friction and wear.

Automated assembly lines are increasingly being used to enhance efficiency and consistency in the assembly process.

4. Finishing

Finishing processes improve the aesthetic and functional qualities of the gear reducers. Techniques include:

- Surface Treatment: Processes such as anodizing, plating, or painting can enhance corrosion resistance and appearance.

- Balancing: Ensures that rotating components are balanced to prevent vibrations during operation.

- Testing: Final testing is conducted to verify the performance of the gear reducer before it leaves the factory.

Quality Assurance in Gear Reducer Manufacturing

Quality assurance (QA) is critical in ensuring that gear reducers meet international standards and client expectations. Key components of QA include:

Relevant International Standards

B2B buyers should ensure that their suppliers comply with recognized quality standards such as:

- ISO 9001: A widely adopted standard that outlines the requirements for a quality management system (QMS).

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: Relevant for gear reducers used in the oil and gas industry, ensuring safety and performance.

Quality Control Checkpoints

Quality control (QC) processes involve several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspection of raw materials and components upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to detect issues early and minimize waste.

- Final Quality Control (FQC): Comprehensive testing of the finished product to ensure it meets all design and performance criteria.

Common Testing Methods

Testing methods used in the gear reducer industry include:

- Load Testing: Assessing the performance under various load conditions to ensure reliability.

- Vibration Analysis: Monitoring vibrations to detect potential issues that could affect performance.

- Noise Testing: Evaluating noise levels to ensure compliance with industry standards.

Verifying Supplier Quality Control

For international B2B buyers, verifying the quality control measures of potential suppliers is essential. Here are actionable steps:

- Conduct Audits: Regular audits of supplier facilities can provide insights into their manufacturing processes and quality control practices.

- Request Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including results from IQC, IPQC, and FQC.

- Utilize Third-Party Inspection Services: Engaging third-party inspectors can provide an unbiased assessment of the supplier’s quality control measures and product quality.

Quality Control and Certification Nuances

Understanding the nuances of quality control and certification is crucial for international buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Consider the following:

- Regional Standards Compliance: Different regions may have specific standards and regulations that gear reducers must meet. Familiarize yourself with these requirements to ensure compliance.

- Documentation and Traceability: Ensure suppliers maintain detailed records of their quality assurance processes, including traceability of materials and components.

- Cultural and Communication Barriers: Be aware of potential cultural differences in business practices and communication styles when engaging with international suppliers. Clear communication about quality expectations is vital for successful partnerships.

Conclusion

For B2B buyers in the gear reducer market, a comprehensive understanding of manufacturing processes and quality assurance practices is essential for making informed decisions. By focusing on material quality, manufacturing techniques, and robust quality control measures, buyers can enhance their procurement strategies and ensure that the gear reducers they source meet their operational needs and industry standards.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for gear reducer Sourcing

Understanding the cost structure and pricing dynamics of gear reducer sourcing is crucial for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis will break down the cost components, highlight price influencers, and provide actionable buyer tips to ensure effective procurement strategies.

Cost Components

-

Materials: The raw materials used in manufacturing gear reducers, such as metals (steel, aluminum), plastics, and composites, significantly influence costs. The choice of material impacts durability, performance, and ultimately, pricing. Sustainable and eco-friendly materials may incur higher initial costs but can lead to long-term savings and compliance with global standards.

-

Labor: Labor costs vary widely based on geographic location, skill levels, and local labor laws. Regions with higher wages may lead to increased manufacturing costs. However, advanced automation technologies can offset labor expenses by improving efficiency.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and factory management. Efficient manufacturing processes and technologies, like CAD/CAM, can reduce overhead costs, enhancing overall competitiveness.

-

Tooling: Tooling costs can be substantial, especially for custom gear reducers. Buyers should be aware that initial investments in specialized tooling can impact the overall cost structure. However, these costs can be amortized over larger production volumes.

-

Quality Control (QC): Implementing rigorous quality control measures is essential to ensure product reliability. Although QC may add to the cost, it helps in reducing long-term operational failures and warranty claims, thus enhancing the Total Cost of Ownership (TCO).

Illustrative Image (Source: Google Search)

-

Logistics: Shipping, handling, and customs duties can significantly affect final pricing, especially for international transactions. Understanding Incoterms can help buyers negotiate better shipping terms and manage costs effectively.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market competition and the perceived value of their products. Buyers should compare multiple suppliers to gauge average margins in the market.

Price Influencers

-

Volume/MOQ: Larger orders often lead to lower per-unit costs. Suppliers may offer discounts for bulk purchases, which can be a significant cost-saving strategy for buyers.

-

Specifications/Customization: Custom gear reducers tailored to specific applications usually come at a premium. Buyers need to balance the need for customization with budget constraints.

-

Materials and Quality Certifications: High-quality materials and certifications (ISO, CE) can increase costs but provide assurance of performance and reliability. Buyers should assess the importance of these factors based on their operational requirements.

-

Supplier Factors: The reputation, reliability, and service level of suppliers can impact pricing. Established suppliers may charge more but often provide better support and product quality.

-

Incoterms: Understanding shipping terms can influence costs significantly. FOB (Free on Board) can lead to lower costs compared to CIF (Cost, Insurance, and Freight), where the supplier bears more responsibility.

Buyer Tips

-

Negotiation: Always negotiate prices, especially for larger orders. Suppliers may have room for flexibility on pricing, especially if they wish to secure a deal.

-

Cost-Efficiency: Consider the Total Cost of Ownership rather than just the upfront price. Evaluate long-term savings from reliability, maintenance, and energy efficiency.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, suppliers in Europe may have higher costs due to stricter regulations compared to those in South America or Africa.

-

Research and Comparison: Conduct thorough market research to understand price ranges and supplier capabilities. This knowledge empowers buyers to make informed decisions and leverage competitive offers.

Disclaimer

Prices can vary significantly based on market conditions, material costs, and supplier negotiations. The information provided is indicative and should be used as a guideline for budgeting and procurement strategies. Always obtain quotes from multiple suppliers to ensure competitive pricing.

Spotlight on Potential gear reducer Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘gear reducer’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for gear reducer

When engaging in the procurement of gear reducers, it is essential for international B2B buyers to be familiar with critical technical properties and industry terminology. This understanding not only enhances communication with suppliers but also ensures that the selected gear reducers meet specific operational needs.

Key Technical Properties

-

Material Grade

– Definition: The quality and composition of materials used in manufacturing gear reducers, such as cast iron, aluminum, or steel.

– Importance: Material grade affects the durability, weight, and thermal conductivity of the gear reducer. Higher-grade materials typically offer better performance and longevity, which is crucial for heavy-duty applications. -

Torque Rating

– Definition: The maximum torque that a gear reducer can handle without failing.

– Importance: Understanding torque ratings helps buyers choose a gear reducer suitable for their application. Insufficient torque ratings can lead to equipment failure and increased maintenance costs. -

Gear Ratio

– Definition: The ratio of the number of teeth on the driven gear to the number of teeth on the driving gear.

– Importance: Gear ratios influence speed and torque. A higher gear ratio results in higher torque and lower speed, which is essential in applications requiring significant power. Buyers must align gear ratios with their machinery requirements. -

Efficiency Rating

– Definition: A measurement of the gear reducer’s ability to transmit power without loss.

– Importance: Efficiency ratings are crucial for energy conservation and operational cost reductions. Higher efficiency reduces energy costs and enhances the overall performance of the equipment. -

Tolerance

– Definition: The permissible limit or limits of variation in a physical dimension or measured value.

– Importance: Tolerance specifications ensure that the gear reducer components fit together correctly. Precision in manufacturing tolerances prevents operational issues and extends equipment lifespan. -

Service Factor

– Definition: A multiplier applied to the motor’s power rating to account for varying load conditions.

– Importance: The service factor helps buyers assess the capacity of a gear reducer in real-world conditions. Selecting a gear reducer with an appropriate service factor ensures reliability under different operational stresses.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: B2B buyers must understand whether they are dealing directly with OEMs or third-party manufacturers, as this can impact product quality and warranty conditions. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers plan their budgets and inventory levels. It also aids in understanding the supplier’s production capabilities. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting a quote for specific goods or services.

– Importance: An RFQ streamlines the procurement process by allowing buyers to compare pricing and terms from multiple suppliers, facilitating better decision-making. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international rules that clarify the responsibilities of buyers and sellers in the shipping process.

– Importance: Understanding Incoterms is essential for managing logistics and cost responsibilities in international trade, ensuring that buyers are aware of their obligations regarding shipping, insurance, and tariffs.

-

Lead Time

– Definition: The amount of time taken from the placement of an order until it is fulfilled.

– Importance: Lead time is critical for project planning and inventory management. Buyers should factor in lead times when scheduling maintenance or production activities to avoid delays. -

Warranty Period

– Definition: The duration for which a manufacturer guarantees the functionality and quality of a product.

– Importance: A clear understanding of warranty terms helps buyers assess the risk of potential failures and the level of support they can expect from suppliers.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions, negotiate effectively, and ensure that they procure gear reducers that meet their operational requirements.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the gear reducer Sector

Market Overview & Key Trends

The gear reducer market is witnessing robust growth, projected to reach approximately USD 15.67 billion by 2033, driven by the increasing demand for automation across various sectors, including automotive, industrial, and construction. Key drivers of this growth include the rising adoption of energy-efficient machinery and advanced technologies, such as the Internet of Things (IoT) and artificial intelligence (AI). For international B2B buyers from Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for strategic sourcing and investment decisions.

Emerging trends highlight the integration of smart technologies in gear reducer manufacturing. Automation in production processes enhances efficiency and reduces lead times, which is vital for buyers looking for timely delivery and reliability. Additionally, customization is becoming increasingly important, with manufacturers offering tailored solutions to meet specific application needs. Buyers should look for suppliers that can provide bespoke options to ensure compatibility with their machinery and operational requirements.

Geopolitical factors and fluctuating raw material prices continue to pose challenges, making supply chain diversification a necessity. Buyers are encouraged to assess suppliers’ ability to mitigate risks through strategic partnerships and local sourcing, which can enhance supply chain resilience. Furthermore, staying updated on regulatory compliance is essential, as adherence to international standards can significantly impact product quality and marketability.

Sustainability & Ethical Sourcing in B2B

Sustainability has emerged as a critical concern in the gear reducer sector, reflecting a broader shift towards environmentally responsible practices in manufacturing. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to reducing their environmental impact through sustainable sourcing and production processes. This includes the use of recycled materials and energy-efficient manufacturing techniques, which not only lower carbon footprints but also align with global sustainability goals.

For B2B buyers, understanding the importance of ethical supply chains is paramount. By partnering with manufacturers that uphold high environmental and ethical standards, companies can enhance their brand reputation and appeal to environmentally conscious consumers. Buyers should seek suppliers that hold certifications such as ISO 14001 (Environmental Management) or similar green certifications, which indicate compliance with rigorous environmental standards.

Moreover, the adoption of eco-friendly materials in gear reducer production is gaining traction. Buyers should inquire about the materials used in manufacturing and prefer those that are recyclable or sourced from sustainable practices. This not only supports environmental initiatives but can also lead to cost savings in the long run, as sustainable practices often correlate with improved operational efficiencies.

Brief Evolution/History

The evolution of gear reducers dates back to the early industrial age when they were primarily used in mechanical systems to control speed and torque. Initially crafted from heavy metals, advancements in materials science have led to the incorporation of lighter, more durable materials, enhancing performance and efficiency. The introduction of computer-aided design (CAD) and manufacturing (CAM) technologies revolutionized the production process, allowing for more precise and intricate designs.

As industries continue to evolve, the shift towards automation and smart manufacturing has transformed the gear reducer landscape. Today, gear reducers are integral to various applications, from automotive transmissions to industrial machinery, reflecting a growing reliance on high-performance gear systems that can operate efficiently in a rapidly changing technological environment. Understanding this historical context can help international B2B buyers appreciate the advancements that have shaped current market dynamics and sourcing strategies.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of gear reducer

-

What criteria should I use to vet suppliers of gear reducers?

When vetting suppliers, focus on their industry reputation, experience, and production capabilities. Request references and case studies from previous clients, particularly those in your sector. Evaluate their certifications (e.g., ISO 9001), which indicate quality management standards. Additionally, assess their technological capabilities, such as the use of CAD/CAM in manufacturing, and inquire about their commitment to sustainable practices. This ensures that the supplier can meet your specific requirements and adhere to international quality standards. -

Can gear reducers be customized to meet my specific application needs?

Yes, many manufacturers offer customization options for gear reducers. When discussing your requirements, specify the desired torque, speed ratios, and environmental conditions (e.g., temperature, humidity). Be clear about the application—whether it’s for automotive, industrial, or agricultural use—so the supplier can tailor the design accordingly. Customization may involve changes in materials, dimensions, or performance characteristics, which can enhance efficiency and longevity in your particular application. -

What are the typical minimum order quantities (MOQs) and lead times for gear reducers?

Minimum order quantities can vary significantly based on the supplier and the complexity of the gear reducer. Generally, MOQs range from 50 to 500 units, depending on the level of customization required. Lead times can also differ; standard products may be available within 4-6 weeks, while customized solutions might take 8-12 weeks or longer. Always clarify these details upfront to align your procurement schedules and avoid delays in your production process. -

What payment terms are common when sourcing gear reducers internationally?

Payment terms vary by supplier but commonly include options like a 30% deposit with the order and the remaining 70% prior to shipping. Some suppliers may offer letters of credit or payment upon delivery. It’s crucial to negotiate terms that provide you with security while ensuring the supplier feels comfortable proceeding with the order. Additionally, consider the implications of currency exchange rates and transaction fees when dealing with international payments. -

How can I ensure the quality of gear reducers before accepting delivery?

To ensure quality, request a Certificate of Compliance (CoC) and conduct a pre-shipment inspection (PSI) if possible. This inspection can verify that the products meet your specifications and international standards. Many suppliers also offer warranty guarantees, which can further protect your investment. Establishing quality assurance processes, such as regular audits of the supplier’s facility, can also help maintain high standards throughout the production process. -

What certifications should I look for in gear reducer manufacturers?

Look for certifications such as ISO 9001 for quality management systems and ISO 14001 for environmental management. Other relevant certifications include CE marking for compliance with European standards, and specific industry-related certifications depending on your sector (e.g., automotive, aerospace). These certifications indicate that the manufacturer adheres to rigorous quality and safety standards, which is essential for ensuring the reliability and performance of the gear reducers. -

What logistics considerations should I keep in mind when importing gear reducers?

Logistics considerations include understanding shipping methods (air vs. sea), customs regulations, and duties applicable to gear reducers in your country. Ensure you are aware of lead times and potential delays, especially when shipping internationally. Collaborate with a logistics partner who understands the nuances of importing industrial equipment, and confirm that the supplier provides proper documentation to facilitate smooth customs clearance. -

How should I handle disputes with gear reducer suppliers?

Dispute resolution should start with clear communication and documentation of the issues. Ensure that your contracts include clauses detailing how disputes will be handled, including mediation or arbitration processes. If necessary, involve a third-party mediator to facilitate discussions. Maintaining a good relationship with your supplier can often prevent disputes from escalating, so approach issues collaboratively and aim for mutually beneficial solutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for gear reducer

In the rapidly evolving landscape of gear reducer manufacturing, strategic sourcing emerges as a critical component for international B2B buyers. The integration of advanced technologies such as IoT and AI, coupled with a focus on sustainability and customization, offers significant advantages. Buyers should prioritize suppliers who embrace innovation and demonstrate a commitment to eco-friendly practices, ensuring that their operations align with global sustainability goals.

As the gear reducer market continues to grow—projected to reach USD 15.67 billion by 2033—it’s imperative for businesses in Africa, South America, the Middle East, and Europe to leverage these trends. Engaging with manufacturers that offer tailored solutions can enhance operational efficiency and reduce costs. Moreover, diversifying supply chains can mitigate risks associated with fluctuating raw material prices and geopolitical tensions.

Looking ahead, international buyers are encouraged to stay informed about market dynamics and emerging technologies. By forging strategic partnerships with forward-thinking manufacturers, companies can position themselves for success in an increasingly competitive environment. Embrace the opportunities that lie ahead in the gear reducer market, and ensure your sourcing strategies are as dynamic as the industry itself.