Your Ultimate Guide to Sourcing Urethane Wheels

Introduction: Navigating the Global Market for urethane wheels

Urethane wheels are an essential component in various industrial applications, providing an optimal blend of durability, flexibility, and performance. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek to enhance their operational efficiency, understanding the critical role of urethane wheels becomes paramount. These wheels offer superior resistance to wear and chemicals, making them ideal for environments that demand reliability and minimal maintenance.

This comprehensive guide delves into the multifaceted world of urethane wheels, covering key aspects that are vital for informed sourcing decisions. We explore the different types of urethane wheels available on the market, the materials used in their manufacturing, and the quality control measures that ensure their performance. Buyers will also gain insights into reputable suppliers, pricing structures, and emerging market trends that influence purchasing decisions.

By equipping buyers with actionable knowledge, this guide empowers them to make strategic choices that align with their operational needs. Whether you are managing logistics in Nigeria or manufacturing in the UK, understanding the nuances of urethane wheels will enable you to optimize your supply chain, enhance product reliability, and ultimately drive your business forward. In a competitive global landscape, the right information is your most valuable asset—let this guide be your roadmap to success in sourcing urethane wheels.

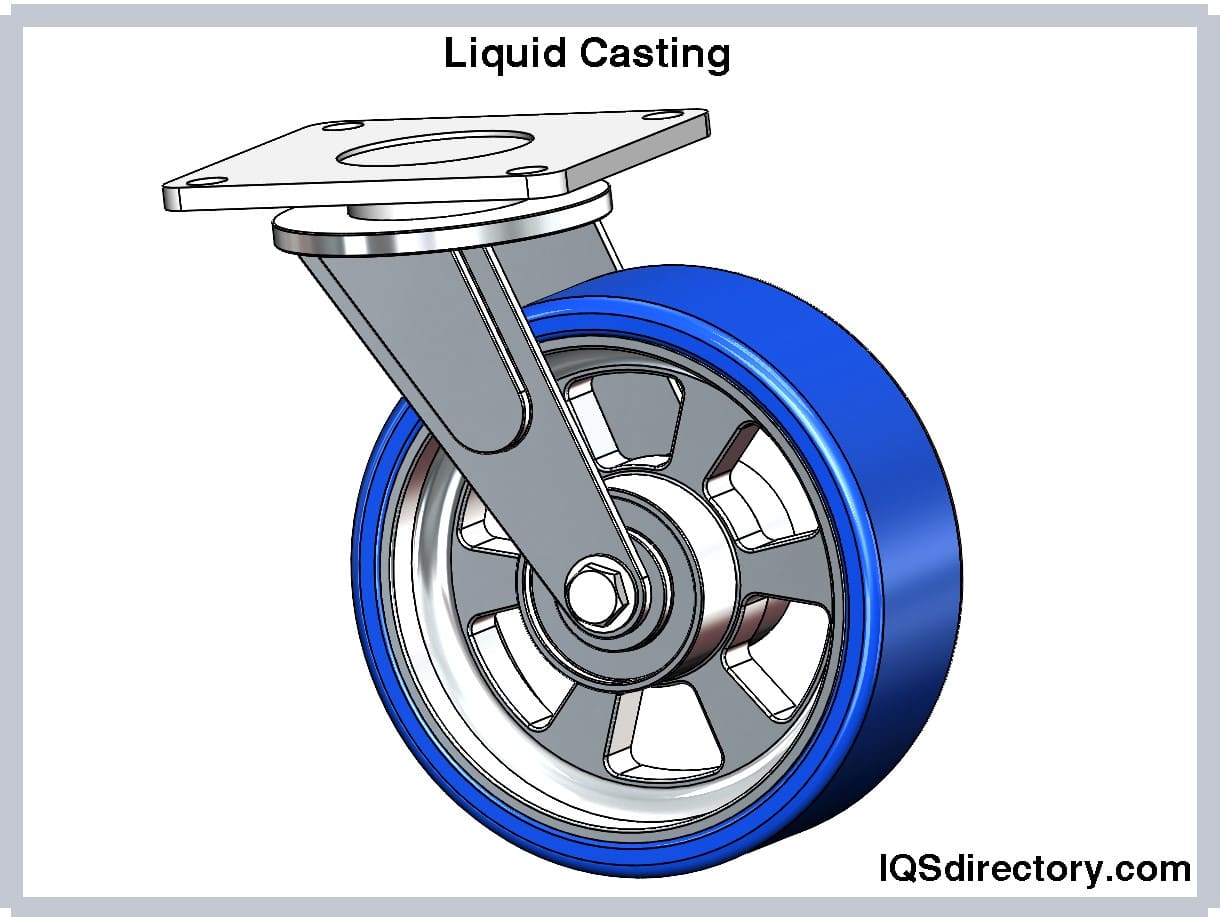

Understanding urethane wheels Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Heavy Duty Urethane Wheels | Designed to carry substantial loads; reinforced for durability. | Industrial machinery, shipping carts | Pros: High load capacity, excellent wear resistance. Cons: Higher initial cost. |

| Robot Urethane Wheels | Custom designs with tight tolerances; resistant to chemicals and extreme conditions. | Robotics, automated systems | Pros: Enhanced performance in harsh environments. Cons: Requires precise specifications. |

| Flanged Urethane Wheels | Features a flange to absorb shock and vibration; ideal for guiding. | Conveyors, heavy-duty equipment | Pros: Reduces equipment wear, improves stability. Cons: May not be suitable for all surfaces. |

| V-Groove Urethane Wheels | Grooved design for better traction on rails; accommodates curves. | Track-guided vehicles, carts | Pros: Improved maneuverability, suitable for uneven surfaces. Cons: Limited to specific applications. |

| Conductive Urethane Wheels | Incorporates conductive additives to prevent static buildup. | Electronics, sensitive equipment | Pros: Protects electronic components, enhances safety. Cons: Higher manufacturing complexity. |

Heavy Duty Urethane Wheels

Heavy duty urethane wheels are engineered to handle significant weight loads, making them essential in industrial settings where machinery and equipment transportation is frequent. Their reinforced construction ensures durability, allowing them to withstand abrasive environments. When considering these wheels, buyers should assess the load capacity required for their specific applications and evaluate the potential return on investment, as the initial cost may be higher than alternatives.

Robot Urethane Wheels

Robot urethane wheels are specially designed for automated systems, offering tight tolerances and resistance to harsh environmental factors such as chemicals and extreme temperatures. These wheels are crucial for maintaining operational efficiency in robotics applications. Buyers should focus on the specific requirements of their robotic systems, including size and material properties, to ensure compatibility and optimal performance.

Flanged Urethane Wheels

Flanged urethane wheels are notable for their ability to absorb shock and vibration, which is critical in applications involving heavy loads and dynamic movements. They provide stability and reduce wear on both the wheels and the equipment they support. Buyers should consider the specific surface conditions and application demands, as these wheels are best suited for guided systems where stability is paramount.

V-Groove Urethane Wheels

V-groove urethane wheels feature a grooved design that enhances traction on tracks, making them ideal for applications requiring navigation along curved paths. These wheels are commonly used in track-guided vehicles and material handling systems. Buyers need to evaluate the track specifications and ensure that the wheel design aligns with their operational needs, particularly in environments with uneven surfaces.

Conductive Urethane Wheels

Conductive urethane wheels are manufactured with specialized additives to dissipate static electricity, making them essential in industries where sensitive electronic components are handled. These wheels prevent damage due to static buildup, enhancing safety in electronic manufacturing and assembly. Buyers should assess their operational environment to determine if static control is a significant concern, as the complexity of manufacturing these wheels may lead to higher costs.

Related Video: Mercedes Models Explained (2020 model range) | Let Me Explain

Key Industrial Applications of urethane wheels

| Industry/Sector | Specific Application of Urethane Wheels | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Conveyor Systems | Enhanced durability and reduced maintenance costs | Load capacity, durometer rating, and environmental resistance |

| Logistics & Warehousing | Material Handling Carts | Improved load handling and safety during transportation | Wheel size, tread design, and compatibility with equipment |

| Agriculture | Agricultural Equipment | Increased longevity and performance in harsh environments | Customization options and resistance to chemical exposure |

| Robotics | Robotic Mobility Applications | Precision movement and reduced vibration for improved operation | Tight tolerances and specific hardness requirements |

| Food Processing | Equipment Wheels for Processing Machines | Compliance with hygiene standards and reduced contamination risks | FDA compliance and resistance to chemicals and oils |

Manufacturing

In manufacturing, urethane wheels are commonly utilized in conveyor systems. Their robust construction allows them to handle heavy loads while minimizing wear and tear. This durability translates to lower maintenance costs and less downtime, which is critical for operational efficiency. For international buyers, especially in regions like Africa and South America, understanding the load capacity and durometer rating is essential to ensure that the wheels can withstand specific manufacturing processes and environmental conditions.

Logistics & Warehousing

In the logistics and warehousing sector, urethane wheels are integral to material handling carts. These wheels enhance load handling capabilities and improve safety during transportation, reducing the risk of accidents. Buyers should consider wheel size and tread design, as these factors influence maneuverability and traction on various surfaces. Particularly in Europe and the Middle East, where high traffic and diverse floor conditions are common, choosing the right wheels can significantly impact operational efficiency.

Illustrative Image (Source: Google Search)

Agriculture

Urethane wheels are increasingly used in agricultural equipment, providing essential performance in demanding outdoor environments. Their resistance to wear, chemicals, and harsh weather conditions ensures that they last longer than traditional wheels, minimizing replacement costs. Buyers in Africa, where agricultural machinery faces unique challenges, should prioritize sourcing custom solutions that meet specific requirements, including tread design for traction and load capacity for heavy equipment.

Robotics

In robotics, urethane wheels are crucial for mobility applications. They are designed with tight tolerances to ensure precision movement while dampening vibrations that could affect performance. This is particularly important for robotics used in manufacturing and logistics. International buyers should focus on sourcing wheels that meet specific hardness requirements and can withstand the operational stresses typical in these applications, especially in technologically advanced markets like Europe.

Food Processing

Urethane wheels are widely used in food processing equipment due to their compliance with hygiene standards. These wheels help minimize contamination risks and are resistant to chemicals and oils commonly found in processing environments. For B2B buyers, particularly in regions with strict food safety regulations, it is vital to ensure that the wheels meet FDA compliance and are suitable for the specific processing conditions they will encounter.

Related Video: 10 Nifty Uses for Oscillating Multitool Saws

Strategic Material Selection Guide for urethane wheels

When selecting urethane wheels for various applications, understanding the materials used in their construction is crucial for ensuring optimal performance and longevity. Below is an analysis of common materials utilized in urethane wheels, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

1. Polyurethane (PU)

Key Properties: Polyurethane is known for its excellent abrasion resistance, flexibility, and load-bearing capacity. It typically withstands temperatures ranging from -30°C to 80°C and can endure pressures up to 100 psi.

Pros & Cons: Polyurethane wheels are highly durable and can last significantly longer than rubber or plastic alternatives. They are also resistant to chemicals, oils, and solvents, making them suitable for a variety of industrial environments. However, the manufacturing process can be complex and may lead to higher costs compared to basic rubber wheels.

Impact on Application: Polyurethane’s compatibility with various media, including oils and chemicals, makes it ideal for warehouses and manufacturing facilities. Its shock-absorbing properties also enhance safety and reduce wear on equipment.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM (American Society for Testing and Materials) or DIN (Deutsches Institut für Normung). In regions like Europe, adherence to REACH regulations concerning chemical safety is also essential.

2. Thermoplastic Polyurethane (TPU)

Key Properties: TPU offers similar benefits to traditional polyurethane but with enhanced elasticity and temperature resistance, typically ranging from -40°C to 90°C. It also exhibits excellent tear strength and resilience.

Pros & Cons: The primary advantage of TPU is its flexibility, making it suitable for applications requiring high levels of maneuverability. However, it can be more expensive than standard polyurethane and may not perform as well under extreme load conditions.

Impact on Application: TPU is particularly effective in environments where wheel flexibility is crucial, such as in robotics and automated systems. Its resistance to UV light also makes it suitable for outdoor applications.

Considerations for International Buyers: Buyers in regions with stringent environmental regulations should confirm that the TPU meets local compliance standards, such as those set by the European Union. Additionally, understanding the specific durometer ratings available can help in selecting the right wheel for the application.

3. Reinforced Urethane

Key Properties: Reinforced urethane combines traditional urethane with materials like fiberglass or steel for added strength. This material can withstand extreme temperatures and heavy loads, often rated for applications exceeding 200 psi.

Pros & Cons: The key advantage of reinforced urethane is its exceptional durability and load capacity, making it ideal for heavy-duty applications such as cranes and industrial machinery. The downside is that it can be heavier and more expensive to manufacture, which may not be suitable for all applications.

Impact on Application: This material is particularly beneficial in industries such as construction and manufacturing, where heavy loads and harsh conditions are common. Its resistance to wear and deformation under pressure ensures long-term reliability.

Considerations for International Buyers: Buyers should be aware of the specific load ratings and ensure that the wheels meet local safety standards. In regions like South America and Africa, understanding the local market’s demand for heavy-duty applications can guide purchasing decisions.

4. Conductive Urethane

Key Properties: Conductive urethane is designed to dissipate static electricity, making it suitable for environments where static discharge can damage sensitive equipment. It typically operates effectively within a temperature range of -20°C to 60°C.

Pros & Cons: The main advantage of conductive urethane is its ability to protect electronic components, making it ideal for industries such as electronics manufacturing. However, it may not be as durable as standard urethane options, leading to a shorter lifespan.

Impact on Application: This material is essential in environments where static-sensitive equipment is used, such as in clean rooms or electronic assembly lines. Its ability to prevent static buildup enhances operational safety.

Considerations for International Buyers: Buyers should verify that the conductive urethane complies with industry standards for electrostatic discharge (ESD) protection. Understanding the specific requirements for ESD in different regions can aid in compliance and product selection.

| Material | Typical Use Case for Urethane Wheels | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane (PU) | Manufacturing, warehousing | Excellent durability and chemical resistance | Higher manufacturing complexity and cost | Medium |

| Thermoplastic Polyurethane (TPU) | Robotics, automated systems | High elasticity and UV resistance | More expensive, lower load capacity | High |

| Reinforced Urethane | Heavy-duty machinery, cranes | Exceptional load capacity and durability | Heavier, potentially higher cost | High |

| Conductive Urethane | Electronics manufacturing, clean rooms | Protects sensitive equipment from static discharge | Shorter lifespan compared to standard urethane | Medium |

This guide provides actionable insights into material selection for urethane wheels, helping international B2B buyers make informed decisions tailored to their specific operational needs.

In-depth Look: Manufacturing Processes and Quality Assurance for urethane wheels

Manufacturing Processes for Urethane Wheels

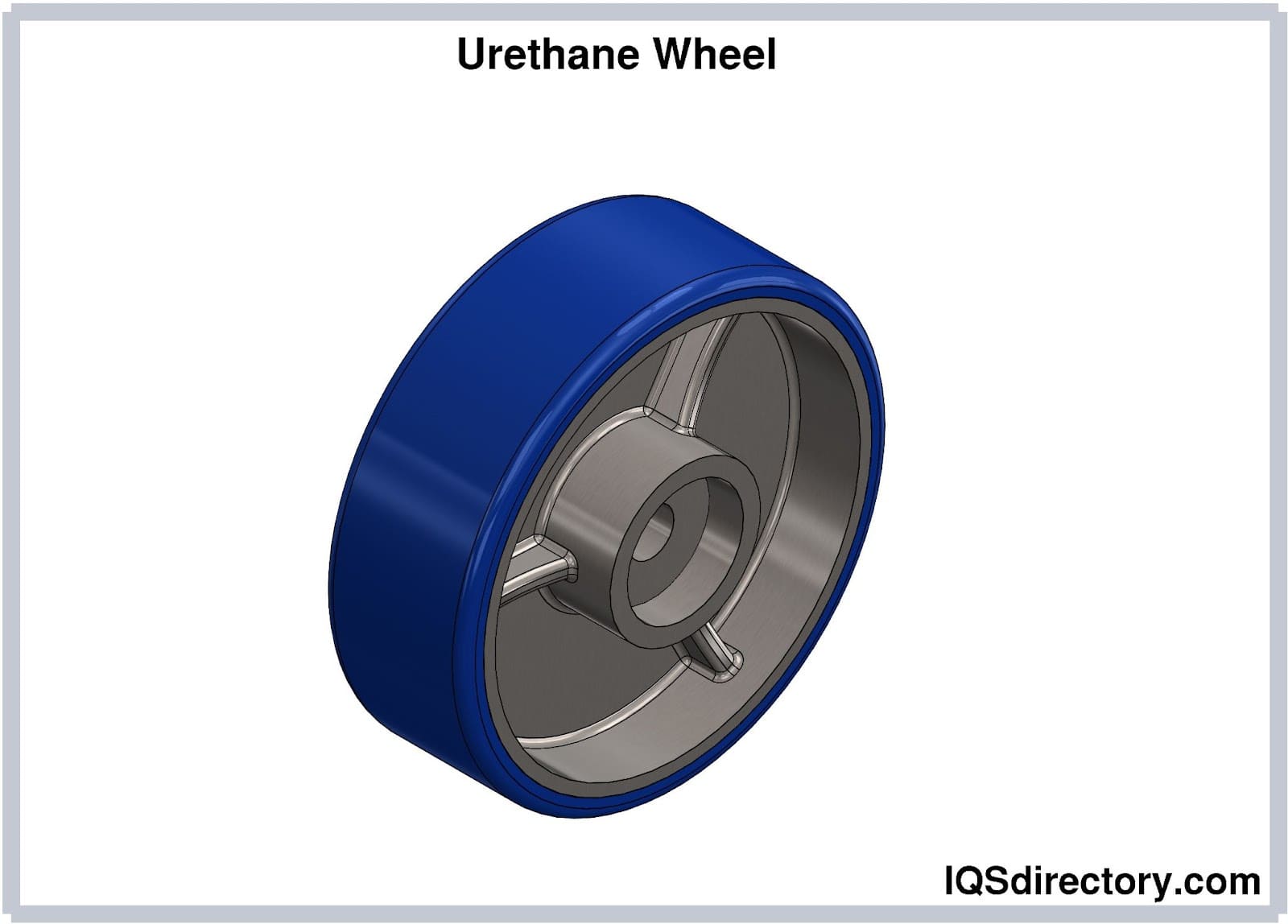

The manufacturing of urethane wheels involves several critical stages, each designed to ensure that the final product meets the demands of various industrial applications. Understanding these processes can help B2B buyers make informed decisions when sourcing urethane wheels.

Material Preparation

The first stage in the manufacturing process is the preparation of raw materials. Urethane wheels are primarily made from polyurethane, a versatile polymer that offers excellent wear resistance and load-bearing capabilities. Manufacturers typically utilize two main types of polyurethane: thermosetting and thermoplastic.

-

Selection of Raw Materials: The quality of raw materials directly affects the performance of the final product. Buyers should ensure that suppliers use high-grade polyurethane formulations, often enhanced with additives for improved properties like UV resistance, chemical resistance, or enhanced durability.

-

Mixing: The raw materials are precisely mixed according to specified formulations. This step may involve adding colorants, fillers, or specific additives to enhance performance characteristics.

Forming

Once the materials are prepared, the next step is forming the urethane wheels. This process typically includes:

-

Molding: The mixed polyurethane is poured into molds that define the shape and size of the wheels. Manufacturers may use different molding techniques, such as compression molding or injection molding, depending on the complexity and volume of production.

-

Curing: After molding, the wheels undergo a curing process, which involves heating the molded parts to allow the polyurethane to set and achieve its final hardness. The curing time and temperature are critical, as they influence the mechanical properties of the wheels.

Assembly

In some cases, urethane wheels may require additional components, such as bearings or metal cores, especially for heavy-duty applications. The assembly process involves:

-

Inserting Components: For wheels that include metal cores, these components are inserted into the molded urethane before the final curing stage.

-

Bonding: A chemical bond is created between the urethane and any inserted components to ensure structural integrity and performance.

Finishing

The finishing stage enhances the aesthetic and functional properties of the wheels. Key activities include:

-

Trimming and Smoothing: Excess material from the molding process is trimmed, and surfaces are smoothed to reduce friction and enhance performance.

-

Quality Inspection: Each batch of wheels undergoes rigorous inspection to ensure they meet specifications and quality standards.

Quality Assurance for Urethane Wheels

Quality assurance (QA) is crucial in the manufacturing of urethane wheels, ensuring that products are reliable and meet the stringent requirements of various applications. This section outlines the key quality assurance processes and standards that B2B buyers should consider.

International Standards

Manufacturers of urethane wheels often adhere to international quality standards, which can provide buyers with confidence in the reliability of the products:

-

ISO 9001: This standard focuses on quality management systems and is applicable across industries. It ensures that manufacturers consistently meet customer and regulatory requirements.

-

CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

-

API Standards: Particularly relevant for industries such as oil and gas, API standards provide guidelines for quality assurance in the manufacturing of specific components.

Quality Control Checkpoints

The quality control process typically consists of several checkpoints, ensuring that defects are identified and addressed throughout production:

-

Incoming Quality Control (IQC): This initial inspection checks the quality of raw materials upon receipt. Ensuring the quality of inputs is critical to the overall quality of the final product.

-

In-Process Quality Control (IPQC): During production, samples are taken at various stages to monitor quality. This helps identify any deviations from quality standards early in the process.

-

Final Quality Control (FQC): After production, a final inspection is conducted to ensure that the finished wheels meet all specifications and standards before they are shipped.

Common Testing Methods

Several testing methods are employed to verify the performance and quality of urethane wheels:

-

Load Capacity Testing: Wheels are subjected to weight tests to ensure they can handle specified loads without deformation or failure.

-

Durability Testing: This involves simulating real-world conditions to assess the wear and tear of the wheels over time.

-

Chemical Resistance Testing: For wheels intended for use in harsh environments, manufacturers will test how well the wheels resist various chemicals.

Verifying Supplier Quality Control

For B2B buyers, verifying a supplier’s quality control processes is essential to ensure they receive high-quality products. Here are some actionable insights:

-

Supplier Audits: Conduct regular audits of potential suppliers to assess their manufacturing processes and quality control measures. This can provide valuable insights into their operational standards.

-

Requesting Quality Reports: Suppliers should provide documentation of their quality control processes and testing results. This includes certifications and compliance with international standards.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality assurance processes and the products being manufactured.

Considerations for International Buyers

When sourcing urethane wheels from manufacturers in different regions, B2B buyers should be aware of certain nuances:

-

Regulatory Compliance: Ensure that suppliers understand and comply with local regulations and international standards relevant to your market.

-

Cultural and Operational Differences: Be mindful of cultural differences that may affect communication and negotiation. Establish clear expectations regarding quality and delivery timelines.

-

Logistics and Supply Chain: Factor in potential delays due to customs or logistical challenges when sourcing internationally. Establish robust communication channels to manage these risks effectively.

By understanding the manufacturing processes and quality assurance protocols for urethane wheels, B2B buyers can make informed decisions that enhance operational efficiency and reliability.

Related Video: Amazing scenes。Top 6 Most Popular Factory Manufacturing Videos in China

Comprehensive Cost and Pricing Analysis for urethane wheels Sourcing

Understanding the cost structure and pricing dynamics of urethane wheels is crucial for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis breaks down the key components of cost and the factors influencing pricing, providing actionable insights for effective sourcing strategies.

Cost Components of Urethane Wheels

-

Materials: The primary cost driver in urethane wheels is the quality of the polyurethane used. High-performance formulations, including additives for UV resistance or enhanced abrasion, can increase material costs significantly. Buyers should evaluate the specific material requirements based on their application to avoid overspending on unnecessary features.

-

Labor: Labor costs can vary widely depending on the manufacturing location. Regions with lower labor costs might seem attractive, but they may compromise quality. Ensure that the manufacturer employs skilled labor to maintain production standards.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses. Manufacturers with efficient operations might offer lower prices due to reduced overhead. It’s beneficial to assess the operational efficiency of potential suppliers.

-

Tooling: Custom tooling can add to the initial costs, especially for specialized wheel designs. However, investing in high-quality tooling can lead to better precision and durability, ultimately reducing replacement costs.

-

Quality Control (QC): Implementing stringent QC processes incurs additional costs but is essential for ensuring product reliability. Buyers should prioritize suppliers with robust QC measures to minimize long-term expenses associated with defects.

-

Logistics: Shipping costs can significantly impact the total cost of ownership. Factors such as distance, shipping method, and packaging play a role. Understanding Incoterms is crucial for clarifying responsibilities and costs associated with transportation.

-

Margin: Suppliers typically include a profit margin in their pricing. This can vary based on market conditions and the supplier’s positioning. Buyers should be aware of typical margins in the industry to negotiate effectively.

Price Influencers

-

Volume/MOQ: Pricing often decreases with higher order volumes. Establishing long-term relationships with suppliers can also lead to better pricing structures.

-

Specifications/Customization: Custom wheels tailored to specific applications may come at a premium. Clearly defining requirements upfront can help in receiving accurate quotes.

-

Material Quality/Certifications: Wheels with certifications (e.g., ISO, FDA compliance) may cost more but can enhance reliability and safety. Buyers should weigh the benefits against the added costs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality and service may charge more but provide peace of mind.

-

Incoterms: Understanding the implications of different Incoterms (e.g., FOB, CIF) can help buyers manage shipping costs and risks effectively.

Buyer Tips

-

Negotiation: Engage in open discussions with suppliers about pricing structures. Leverage your purchasing power, especially if you can commit to larger volumes or longer contracts.

-

Cost-Efficiency: Focus on the total cost of ownership rather than just the upfront price. Consider factors like maintenance, durability, and replacement frequency when evaluating options.

-

Pricing Nuances for International Buyers: Currency fluctuations, tariffs, and import duties can significantly affect pricing for international buyers. It’s advisable to factor these into your budget planning.

-

Supplier Evaluation: Conduct thorough due diligence on potential suppliers. Look for reviews, certifications, and their capacity to meet your specific requirements.

-

Trial Orders: If feasible, consider placing trial orders to assess quality and performance before committing to larger purchases.

Disclaimer

Prices for urethane wheels can vary widely based on the factors outlined above and are subject to change. It is essential for buyers to seek updated quotes and perform due diligence to ensure they make informed purchasing decisions.

Spotlight on Potential urethane wheels Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘urethane wheels’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for urethane wheels

Key Technical Properties of Urethane Wheels

When selecting urethane wheels for industrial applications, understanding the following technical properties is crucial for ensuring optimal performance and longevity:

-

Material Grade: Urethane wheels are typically manufactured from high-quality polyurethane, known for its resilience, flexibility, and chemical resistance. Different grades exist depending on the application, with higher grades providing better durability and performance under extreme conditions. This is particularly important for industries that face rigorous operational environments, as selecting the right material can significantly reduce maintenance costs and downtime.

-

Load Capacity: This property indicates the maximum weight a wheel can safely support. It is essential to calculate the total weight of the load, including the cart and its contents, and select wheels with a load rating that exceeds this value. A proper load capacity ensures stability and minimizes premature wear, which is critical for maintaining operational efficiency in heavy-duty applications.

-

Durometer Rating: The durometer scale measures the hardness of the urethane material, influencing the wheel’s grip and shock-absorption capabilities. Softer wheels (lower durometer ratings) provide better traction and are suited for uneven surfaces, while harder wheels (higher ratings) are ideal for smooth, high-traffic areas. Understanding this rating helps buyers choose the right wheel for their specific floor conditions, enhancing both safety and efficiency.

-

Tolerance: Tolerance refers to the allowable deviation from a specified dimension. Tight tolerances in wheel manufacturing ensure precision in fit and functionality, particularly for applications requiring exact measurements, such as robotics or conveyor systems. Investing in wheels with appropriate tolerances can prevent operational issues and ensure seamless integration into existing equipment.

-

Tread Design: The tread pattern affects traction and rolling resistance. Smooth treads are suitable for flat surfaces, while grooved or patterned treads provide better grip on inclines or wet floors. Selecting the right tread design is crucial for ensuring safety and efficiency in various operational environments.

-

Environmental Resistance: Urethane wheels can be formulated to resist UV rays, chemicals, and extreme temperatures. Understanding the environmental conditions in which the wheels will operate allows buyers to select wheels that maintain their integrity and performance over time, reducing the likelihood of replacement.

Common Trade Terminology

Navigating the procurement of urethane wheels involves familiarizing oneself with industry-specific terminology:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce components that are used in another company’s end product. When sourcing urethane wheels, buyers should consider whether they are purchasing from an OEM, which often guarantees compatibility and quality.

-

MOQ (Minimum Order Quantity): MOQ is the smallest number of units that a supplier is willing to sell. Understanding the MOQ is essential for buyers to manage inventory levels and avoid overcommitting resources, especially in smaller operations or when testing new products.

-

RFQ (Request for Quotation): An RFQ is a document issued when a buyer wants to receive price offers from suppliers. It is crucial for buyers to detail their requirements clearly to ensure they receive accurate and competitive pricing for their needed urethane wheels.

-

Incoterms (International Commercial Terms): These are a set of predefined commercial terms published by the International Chamber of Commerce, which clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risks associated with purchasing urethane wheels from global suppliers.

-

Customization: This term refers to the ability to modify wheels according to specific application needs, such as size, tread design, or material properties. Customization can greatly enhance performance and compatibility, making it a valuable consideration for buyers with unique operational requirements.

Understanding these technical properties and trade terms equips international B2B buyers with the knowledge necessary to make informed purchasing decisions regarding urethane wheels, ultimately leading to improved operational efficiencies and product reliability.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the urethane wheels Sector

Market Overview & Key Trends

The global urethane wheels market is experiencing significant growth, driven by increased demand across various industries such as logistics, manufacturing, and construction. Key trends influencing this market include the rising focus on operational efficiency, the shift toward automation, and the growing preference for customized solutions. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed purchasing decisions.

One notable trend is the adoption of advanced manufacturing technologies, including 3D printing and precision molding. These technologies allow for the production of high-performance urethane wheels tailored to specific applications, enhancing durability and performance while reducing lead times. Additionally, the increasing awareness of safety and operational standards is prompting businesses to invest in high-quality urethane wheels that can withstand challenging conditions without compromising on performance.

Another emerging trend is the shift towards digital sourcing platforms, enabling buyers to connect directly with manufacturers and suppliers worldwide. This trend is particularly beneficial for buyers in regions like Nigeria and Brazil, where local sourcing options may be limited. Utilizing these platforms can streamline procurement processes, reduce costs, and improve product traceability.

Lastly, the market is witnessing a growing emphasis on load capacity and wheel design. Buyers are increasingly considering the specific requirements of their operations, such as floor conditions and load specifications, to select the most suitable wheels for their applications. This focus on tailored solutions is critical for enhancing operational efficiency and minimizing maintenance costs.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a pivotal concern in the urethane wheels sector, with buyers increasingly prioritizing environmentally friendly practices throughout their supply chains. The production of urethane wheels can have significant environmental impacts, including resource consumption and waste generation. Thus, B2B buyers should seek suppliers that implement sustainable practices, such as reducing energy consumption during manufacturing and utilizing recycled materials.

Ethical sourcing is equally important, as it ensures that materials are obtained from responsible suppliers who adhere to fair labor practices. Buyers can look for manufacturers that provide transparency regarding their supply chain processes, including certifications that demonstrate compliance with environmental and social standards.

Illustrative Image (Source: Google Search)

The use of “green” certifications, such as ISO 14001 for environmental management systems, can also guide buyers in making sustainable choices. Additionally, opting for urethane wheels made from bio-based materials or those that minimize VOC emissions can further reduce environmental impact. As sustainability becomes a competitive differentiator, B2B buyers are encouraged to incorporate these criteria into their sourcing strategies, aligning their procurement practices with broader corporate social responsibility goals.

Brief Evolution/History

The evolution of urethane wheels dates back to the mid-20th century when polyurethane was first developed as a versatile alternative to traditional materials like rubber and plastic. Initially used in niche applications, the unique properties of urethane—such as its resilience, abrasion resistance, and load-bearing capacity—soon gained recognition across various industries.

As manufacturing technologies advanced, urethane wheels became more widely adopted in sectors such as logistics, robotics, and heavy machinery. Today, urethane wheels are integral to modern operational strategies, offering solutions that enhance efficiency, reduce maintenance, and improve safety. The ongoing innovation in urethane formulations and manufacturing techniques continues to drive the market forward, making it essential for B2B buyers to stay informed about the latest developments and trends.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of urethane wheels

-

How can I effectively vet suppliers of urethane wheels?

When vetting suppliers, consider their experience in manufacturing urethane wheels and their specialization in your required application. Request references from previous clients and verify their production capabilities, including machinery and technology used. Additionally, evaluate their compliance with international quality standards, such as ISO certifications, which indicate reliability. Conducting site visits or virtual tours can also provide insights into their operational practices and help establish trust. -

What customization options are typically available for urethane wheels?

Many manufacturers offer customization options for urethane wheels, including size, tread design, hardness (durometer), and load capacity. Discuss your specific application requirements with potential suppliers to explore tailored solutions, such as special coatings for chemical resistance or specific additives for enhanced performance. Ensure that the supplier can provide samples or prototypes to test before finalizing orders, as this will help confirm that the wheels meet your operational needs. -

What are the minimum order quantities (MOQs) and lead times for urethane wheels?

MOQs for urethane wheels vary by supplier and can range from a few dozen to several hundred units, depending on the customization level and complexity of the order. Lead times can also differ based on production capacity and the availability of materials, typically ranging from 2 to 8 weeks. To avoid production delays, communicate your needs clearly and confirm the supplier’s ability to meet your timelines during the negotiation process. -

How should I handle payment terms and methods when sourcing urethane wheels internationally?

Establishing clear payment terms is crucial when engaging with international suppliers. Common methods include wire transfers, letters of credit, or payment through escrow services for added security. Negotiate favorable terms, such as a partial upfront payment with the balance due upon delivery. Always ensure you have a clear understanding of the currency exchange rates and any associated fees to avoid unexpected costs that can affect your budget. -

What quality assurance measures should I expect from suppliers of urethane wheels?

Reputable suppliers should have rigorous quality assurance (QA) processes in place, including material inspections, in-process testing, and final product evaluations. Request documentation of their QA protocols and certifications that demonstrate compliance with international standards. Additionally, inquire about the possibility of third-party inspections to ensure that the wheels meet your specific performance requirements before shipment. -

What certifications should I look for when sourcing urethane wheels?

Look for suppliers that hold relevant industry certifications, such as ISO 9001 for quality management systems or ISO 14001 for environmental management. These certifications indicate a commitment to quality and sustainability. Additionally, if your application requires compliance with specific industry standards (e.g., FDA for food-related applications), ensure that the supplier can provide documentation to support their products’ suitability for your needs. -

What logistics considerations should I keep in mind when importing urethane wheels?

When importing urethane wheels, consider shipping methods, costs, and potential customs duties. Collaborate with your supplier to understand their shipping options and ensure they provide proper packaging to prevent damage during transit. Familiarize yourself with the import regulations of your country, as well as any restrictions on materials. Engaging a reliable freight forwarder can help streamline the logistics process and mitigate potential delays. -

How can I resolve disputes with suppliers effectively?

To resolve disputes effectively, establish clear communication channels and document all agreements in writing. If issues arise, address them promptly and professionally, starting with direct discussions to seek amicable solutions. If necessary, refer to the terms outlined in your contract regarding dispute resolution processes, which may include mediation or arbitration. Maintaining a cordial relationship with your supplier can facilitate smoother negotiations and minimize future conflicts.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for urethane wheels

In summary, the strategic sourcing of urethane wheels is pivotal for enhancing operational efficiency across various industries. Key takeaways include understanding load capacities, durometer ratings, and the specific environmental conditions in which the wheels will operate. Investing in high-performance urethane wheels not only minimizes maintenance costs but also ensures longevity and reliability, which are critical for maintaining productivity.

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, it is essential to approach sourcing with a comprehensive understanding of your unique operational needs. Prioritize suppliers who offer customization options and have a proven track record of quality and support.

As you look to the future, consider the evolving demands of your industry and the potential for innovation in urethane wheel technology. By making informed sourcing decisions today, you position your business for sustained growth and competitive advantage. Engage with reputable manufacturers to explore the best solutions tailored to your specific requirements, ensuring your operations remain smooth and efficient for years to come.