Master Sourcing Stainless Hinges: Your Essential B2B Guide

Introduction: Navigating the Global Market for stainless hinges

Stainless hinges play a crucial role in various industries, serving as the backbone of functionality and durability in products ranging from doors and cabinets to heavy machinery. For B2B buyers across Africa, South America, the Middle East, and Europe, the selection of high-quality stainless hinges is not just a technical choice; it significantly influences product performance, maintenance costs, and overall customer satisfaction. As global markets become increasingly interconnected, understanding the nuances of hinge types, materials, and manufacturing standards is essential for effective procurement strategies.

This comprehensive guide provides a roadmap tailored for international buyers, detailing the diverse types of stainless hinges available, including butt, concealed, and soft-close hinges. It delves into critical material considerations such as corrosion resistance and load capacity, ensuring you select hinges that withstand the specific environmental conditions of your region. Additionally, the guide covers manufacturing processes and quality assurance protocols to help you identify reliable suppliers.

Buyers will find actionable insights on cost optimization and supplier selection, along with market-specific analyses that address the unique demands of various regions. With a dedicated FAQ section, this resource empowers B2B professionals to make informed decisions, ensuring that they secure the right stainless hinges that align with their operational needs and enhance their competitive edge in the global market.

Understanding stainless hinges Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Butt Hinge | Simple design with two leaves joined by a pin; versatile | Doors, cabinetry, furniture | Pros: Reliable, widely available; Cons: May not suit all aesthetics. |

| Concealed Hinge | Hidden when the door is closed; offers adjustability | High-end furniture, modern cabinetry | Pros: Sleek appearance, adjustable; Cons: Complex installation. |

| Soft-Close Hinge | Integrated damping mechanism for quiet closing | Premium cabinetry, office furniture | Pros: Enhances durability, reduces noise; Cons: Higher cost, installation challenges. |

| Pivot Hinge | Mounted at top and bottom, allowing 360° rotation | Heavy doors, commercial applications | Pros: Handles heavy loads, smooth operation; Cons: Costly, complex installation. |

| Continuous Hinge | Long hinge providing uniform support along the door edge | Industrial enclosures, storage solutions | Pros: Strong support, durable; Cons: Requires more material and labor. |

Butt Hinge

Butt hinges are a staple in the hinge market, characterized by their straightforward design consisting of two rectangular plates connected by a pin. Their versatility makes them suitable for various applications, including wooden and metal doors, cabinetry, and furniture. For B2B buyers, key considerations include selecting the appropriate material grade, such as stainless steel for corrosion resistance, and ensuring they meet specific load ratings based on the application.

Concealed Hinge

Concealed hinges, often favored in upscale cabinetry and modern furniture, are designed to be invisible when the door is closed. This type offers adjustability, which is essential for precise door alignment, making it a popular choice in high-end projects. Buyers should focus on the hinge’s adjustment range, load capacity, and compatibility with different cabinet overlays. Collaborating with reputable manufacturers is crucial to ensure quality and performance, especially in markets that value aesthetics.

Soft-Close Hinge

Soft-close hinges are engineered with a damping mechanism that allows doors to close gently, preventing slamming and prolonging the hinge’s lifespan. This feature is increasingly sought after in both residential and commercial settings, such as kitchens and office environments. When purchasing, buyers should evaluate the reliability of the damping system, installation ease, and compatibility with existing hardware. While they may come at a higher price point, the benefits of reduced maintenance and enhanced user experience can justify the investment.

Pivot Hinge

Pivot hinges are ideal for heavy or high-traffic doors, as they are mounted at the top and bottom rather than on the side. This design allows for smooth rotation and effective weight distribution, making them suitable for commercial and institutional applications. B2B buyers should assess load ratings and the durability of the bearing systems, particularly in humid climates where corrosion resistance is vital. The complexity and cost of installation should also be factored into purchasing decisions.

Continuous Hinge

Continuous hinges, also known as piano hinges, provide support along the entire length of the door, making them ideal for heavy-duty applications such as industrial enclosures and storage solutions. Their design offers uniform support and durability, but they often require more material and labor to install. Buyers should consider the specific material needs, weight capacity, and the hinge’s ability to withstand environmental factors relevant to their industry.

Related Video: Concealed Door Hinges | Stainless Door Hardware

Key Industrial Applications of stainless hinges

| Industry/Sector | Specific Application of Stainless Hinges | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Heavy-duty doors in commercial buildings | Enhanced durability and corrosion resistance | Material grade, load capacity, and weather resistance |

| Automotive | Vehicle doors and compartments | Lightweight yet strong; reduces wear and tear | Compliance with automotive standards, weight specifications |

| Marine | Hatches and access doors on vessels | Superior corrosion resistance in marine environments | Saltwater resistance, manufacturing quality, and certifications |

| Food Processing | Equipment access doors | Hygiene compliance and easy maintenance | FDA compliance, corrosion resistance, and ease of cleaning |

| Furniture Manufacturing | Cabinetry and high-end furniture | Aesthetic appeal and functionality | Design compatibility, load capacity, and finish options |

Construction

In the construction sector, stainless hinges are primarily used for heavy-duty doors in commercial buildings. These hinges provide exceptional durability and corrosion resistance, making them ideal for environments where exposure to moisture and varying temperatures is common. For international buyers, particularly in regions like Africa and the Middle East, sourcing hinges that can withstand harsh climates is crucial. Key considerations include material grade, load capacity, and resistance to environmental factors to ensure longevity and reliability in high-traffic areas.

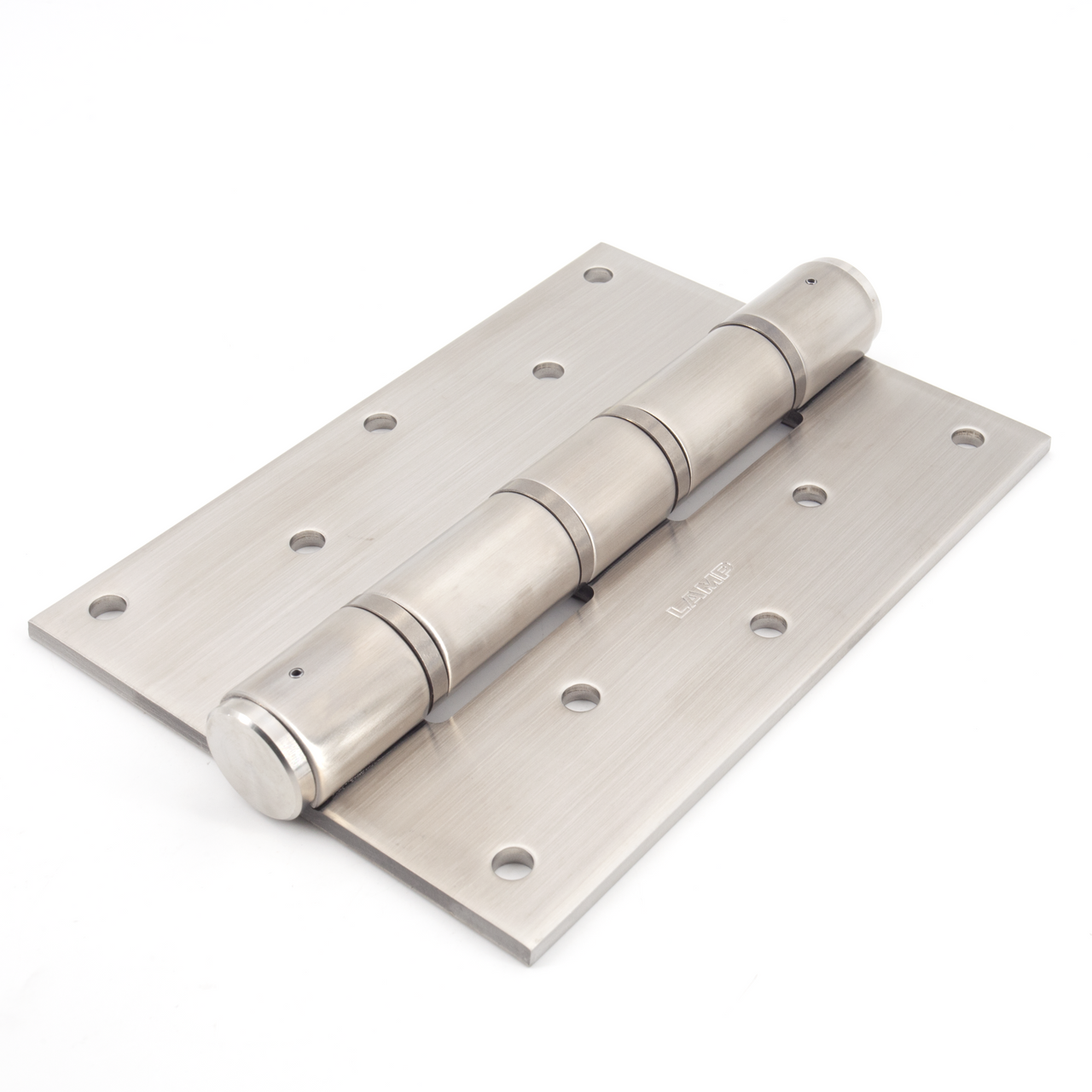

Illustrative Image (Source: Google Search)

Automotive

Stainless hinges play a vital role in the automotive industry, particularly for vehicle doors and compartments. Their lightweight yet strong construction helps reduce overall vehicle weight while enhancing durability, thus minimizing wear and tear over time. International B2B buyers in this sector must ensure compliance with automotive manufacturing standards and consider weight specifications to maintain vehicle performance. Additionally, sourcing hinges that can withstand vibration and exposure to various elements is essential for optimal function.

Marine

In the marine industry, stainless hinges are utilized for hatches and access doors on vessels. Their superior corrosion resistance is critical in marine environments where exposure to saltwater can quickly deteriorate standard materials. Buyers in this sector should focus on sourcing hinges that meet saltwater resistance standards and ensure high manufacturing quality. Certifications for marine use are also vital, as they guarantee that the hinges will perform reliably under challenging conditions, contributing to the overall safety and functionality of the vessel.

Food Processing

Stainless hinges are essential in the food processing industry, particularly for equipment access doors. These hinges must meet stringent hygiene compliance standards, as they are often exposed to cleaning agents and require regular maintenance. International buyers should prioritize sourcing hinges that are FDA compliant and made from materials that resist corrosion, ensuring that they can withstand frequent cleaning without compromising performance. The ease of cleaning and maintenance is a significant benefit that can enhance operational efficiency.

Furniture Manufacturing

In furniture manufacturing, stainless hinges are commonly used in cabinetry and high-end furniture designs. They provide both aesthetic appeal and functionality, allowing for smooth operation while maintaining the overall look of the furniture. For B2B buyers, it is essential to consider design compatibility, load capacity, and finish options when sourcing these hinges. Ensuring that the hinges align with the specific design and usage requirements of the furniture will enhance the product’s marketability and customer satisfaction.

Related Video: Industrial Hinges: Differences Between Right & Left Hand Slip Joint Hinges

Strategic Material Selection Guide for stainless hinges

When selecting stainless hinges for various applications, understanding the properties and implications of different materials is essential for B2B buyers. Here, we analyze four common materials used in stainless hinges, focusing on their performance characteristics, advantages, disadvantages, and considerations for international buyers.

1. Stainless Steel 304

Key Properties:

Stainless Steel 304 is known for its excellent corrosion resistance and good mechanical properties. It can withstand temperatures up to 870°C (1600°F) and offers moderate strength, making it suitable for a variety of environments.

Pros & Cons:

The durability of 304 stainless steel hinges is a significant advantage, as they resist rust and oxidation, particularly in indoor applications. However, they may not be ideal for highly corrosive environments, such as coastal areas or industrial settings with exposure to harsh chemicals. The manufacturing complexity is moderate, and while the cost is generally low to medium, it can vary based on market conditions.

Impact on Application:

304 stainless steel hinges are compatible with a wide range of media, making them suitable for general-purpose applications in furniture, cabinetry, and light industrial use.

Considerations for International Buyers:

Buyers from Africa, South America, the Middle East, and Europe should ensure compliance with regional standards such as ASTM and DIN. For instance, in Europe, EN 10088-1 specifies the requirements for stainless steels, which may influence purchasing decisions.

2. Stainless Steel 316

Key Properties:

Stainless Steel 316 offers superior corrosion resistance compared to 304, especially in marine environments due to the addition of molybdenum. It can handle temperatures up to 870°C (1600°F) and is particularly resilient against chlorides.

Pros & Cons:

The primary advantage of 316 stainless steel hinges is their durability in harsh conditions, including exposure to saltwater and chemicals. However, they are more expensive than 304, which may be a limiting factor for budget-conscious buyers. The manufacturing process is more complex due to the alloying elements, which can lead to increased costs.

Impact on Application:

316 stainless steel hinges are ideal for marine, chemical processing, and outdoor applications where corrosion is a concern.

Considerations for International Buyers:

Buyers should be aware of the specific standards and regulations governing marine-grade materials in their regions. For example, compliance with ISO standards is crucial for buyers in Europe and the Middle East.

3. Stainless Steel 430

Key Properties:

Stainless Steel 430 is a ferritic stainless steel known for its good corrosion resistance, particularly in less aggressive environments. It has a lower temperature rating, withstanding up to 815°C (1500°F).

Pros & Cons:

The cost of 430 stainless steel hinges is relatively low, making them an attractive option for budget-sensitive projects. However, their corrosion resistance is inferior to 304 and 316, limiting their application in high-humidity or corrosive environments. The manufacturing complexity is lower, which can lead to cost savings.

Impact on Application:

These hinges are suitable for indoor applications, such as residential doors and lightweight commercial use, where exposure to moisture is limited.

Considerations for International Buyers:

Buyers should consider regional preferences and standards, as 430 stainless steel may not meet the requirements for more demanding applications in Europe or the Middle East.

4. Duplex Stainless Steel (e.g., 2205)

Key Properties:

Duplex stainless steel combines the properties of both austenitic and ferritic stainless steels, offering high strength and excellent corrosion resistance. It can withstand temperatures up to 300°C (572°F) and is particularly resistant to stress corrosion cracking.

Pros & Cons:

The key advantage of duplex stainless steel hinges is their high strength-to-weight ratio, making them suitable for heavy-duty applications. However, the material is more expensive and requires specialized manufacturing processes, which can increase lead times and costs.

Impact on Application:

Duplex stainless steel hinges are ideal for industrial applications, offshore environments, and other demanding settings where strength and corrosion resistance are paramount.

Considerations for International Buyers:

Buyers should ensure compliance with specific standards for duplex materials, such as ASTM A240/A240M, which governs the specifications for stainless steel plates and sheets.

Summary Table

| Material | Typical Use Case for stainless hinges | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel 304 | General-purpose applications | Excellent corrosion resistance | Not suitable for highly corrosive environments | Medium |

| Stainless Steel 316 | Marine and chemical processing | Superior corrosion resistance | Higher cost compared to 304 | High |

| Stainless Steel 430 | Indoor residential and light commercial | Cost-effective option | Limited corrosion resistance | Low |

| Duplex Stainless Steel 2205 | Heavy-duty industrial applications | High strength and corrosion resistance | Higher cost and manufacturing complexity | High |

This guide provides a comprehensive overview of the strategic material selection for stainless hinges, enabling international B2B buyers to make informed decisions that align with their operational needs and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for stainless hinges

The manufacturing of stainless hinges involves several critical stages that ensure the final product meets the durability and performance requirements expected in various applications. For B2B buyers, understanding these processes is essential for making informed sourcing decisions.

Manufacturing Process of Stainless Hinges

1. Material Preparation

The first step in hinge manufacturing is the selection and preparation of stainless steel. The most commonly used grades are 304 and 316, with 316 being preferred for environments exposed to moisture and corrosion. Raw materials are often sourced from reputable suppliers to ensure quality.

- Material Inspection: Incoming materials undergo rigorous inspection to confirm compliance with specifications. Certificates of compliance should be requested to verify material grades.

- Cutting: Stainless steel sheets are cut into required dimensions using laser cutting or shearing techniques, ensuring precision that is crucial for the final product.

2. Forming

Once the materials are prepared, the forming process shapes the hinge components.

- Bending and Stamping: Techniques such as deep drawing, stamping, and bending are used to create the leaf and knuckle of the hinge. Automated presses are often employed for consistency and efficiency.

- Punching: Holes for pins and screws are punched into the leaves, following precise measurements to ensure proper alignment during assembly.

3. Assembly

After forming, the individual components are assembled.

- Pin Insertion: The hinge knuckles are aligned, and a pin is inserted to connect the leaves. This step is critical as it determines the hinge’s ability to rotate smoothly.

- Welding (if applicable): For certain hinge types, components may be welded to enhance strength, particularly in heavy-duty applications.

4. Finishing

Finishing touches are applied to improve aesthetics and corrosion resistance.

- Surface Treatment: Common finishing processes include polishing, passivation, or applying protective coatings. Passivation is particularly important for stainless steel as it enhances corrosion resistance by removing free iron from the surface.

- Quality Checks: Each batch undergoes visual inspections for defects, ensuring only top-quality products proceed to the next stage.

Quality Assurance in Stainless Hinge Manufacturing

Quality assurance is critical to ensuring that stainless hinges meet international standards and customer expectations.

International Standards

B2B buyers should be familiar with relevant international standards that govern hinge quality:

- ISO 9001: This standard outlines the requirements for a quality management system (QMS). Manufacturers certified under ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- CE Marking: In Europe, CE marking indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: For hinges used in the oil and gas industry, API (American Petroleum Institute) standards may apply, ensuring products meet industry-specific requirements.

Quality Control Checkpoints

Manufacturers typically implement a multi-tiered quality control process:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified requirements. This includes verifying certificates of compliance and performing physical inspections.

- In-Process Quality Control (IPQC): During manufacturing, random samples are tested for dimensional accuracy and functional performance to detect issues early in the process.

- Final Quality Control (FQC): Before shipment, finished hinges undergo thorough inspections, including functional tests and visual checks for defects.

Common Testing Methods

Testing methods for stainless hinges may include:

- Load Testing: Hinges are subjected to weights that simulate real-world usage to ensure they can withstand specified loads without failure.

- Corrosion Resistance Testing: This involves exposing hinges to saline environments or other corrosive conditions to evaluate their performance over time.

- Dimensional Verification: Precision instruments are used to ensure that hinges meet specified dimensions and tolerances.

Verifying Supplier Quality Control

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is crucial. Here are some actionable steps:

- Supplier Audits: Conducting periodic audits of potential suppliers can provide insights into their manufacturing processes, quality control systems, and compliance with international standards.

- Requesting Quality Reports: Ask for detailed quality assurance reports, including results from IQC, IPQC, and FQC processes. These reports can reveal the manufacturer’s commitment to quality.

- Third-Party Inspections: Engaging third-party inspection agencies can add an extra layer of assurance. These agencies can provide unbiased evaluations of the supplier’s quality systems and products.

Regional Considerations for B2B Buyers

Buyers from different regions may face unique challenges and opportunities when sourcing stainless hinges:

- Africa: Engage with local suppliers familiar with regional conditions to ensure products are suitable for diverse climates.

- South America: Consider the import regulations and tariffs that may impact costs and timelines. Establishing relationships with local distributors can streamline the procurement process.

- Middle East: Focus on suppliers that understand the specific requirements for high-temperature and high-humidity environments, which can affect hinge performance.

- Europe (e.g., Italy): Look for manufacturers with a strong reputation for design and aesthetics, as European markets often prioritize these factors in product selection.

By understanding the intricacies of manufacturing processes and quality assurance protocols for stainless hinges, B2B buyers can make informed decisions that enhance their procurement strategies, ensuring they select products that deliver both quality and value.

Related Video: How Millions of Door Hinges are Produced in a Chinese Stainless Steel Factory

Comprehensive Cost and Pricing Analysis for stainless hinges Sourcing

Understanding the cost structure and pricing dynamics for stainless hinges is critical for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis delves into the key components of costs, the influencers on pricing, and actionable tips for buyers to navigate this complex landscape effectively.

Cost Components

-

Materials: The primary cost driver for stainless hinges is the quality of the raw materials used. Stainless steel grades (e.g., 304, 316) vary in price based on their corrosion resistance and strength. Buyers should prioritize high-quality materials to ensure durability, which ultimately minimizes replacement costs.

-

Labor: Labor costs fluctuate depending on the region of manufacturing. In areas with higher labor costs, such as Western Europe, the overall production cost may be elevated. Conversely, regions in Asia or Eastern Europe may offer lower labor costs, impacting the final price.

-

Manufacturing Overhead: This includes costs associated with the production facility, utilities, and administrative expenses. Efficient manufacturing processes can help keep overhead costs down, which is reflected in the pricing of hinges.

-

Tooling: Tooling costs are significant for custom designs or specialized hinges. Initial investments in molds and dies can be substantial, but they can be amortized over larger production runs, making bulk purchases more cost-effective.

-

Quality Control (QC): Rigorous QC processes ensure that products meet specified standards. While this adds to the cost, it is essential for minimizing defects and ensuring customer satisfaction, which can save costs related to returns and warranty claims.

-

Logistics: Shipping and handling costs are critical, especially for international transactions. Factors such as distance, shipping method, and customs duties can significantly affect the total cost.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This margin can vary based on competition, supplier reputation, and product uniqueness.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders often attract discounts due to economies of scale. Buyers should evaluate their needs carefully to negotiate favorable pricing based on projected usage.

-

Specifications/Customization: Customized hinges can incur additional costs due to tooling and design requirements. Buyers should clearly define specifications to avoid unexpected expenses.

-

Materials and Quality Certifications: The presence of certifications (e.g., ISO, CE) can influence pricing. Certified products may command higher prices but provide assurance of quality and compliance.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more, but they often offer superior quality and service.

-

Incoterms: Understanding Incoterms is vital for international trade. They dictate the responsibilities of buyers and sellers in terms of shipping, insurance, and risk, influencing the overall cost structure.

Buyer Tips

-

Negotiation: Leverage your purchasing power to negotiate better terms and pricing. Establishing long-term relationships with suppliers can lead to more favorable conditions.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO), which includes initial price, maintenance costs, and lifespan. Investing in higher-quality hinges may lead to lower long-term costs.

-

Pricing Nuances: Be aware that prices can fluctuate based on market demand, raw material prices, and geopolitical factors. Staying informed about market trends can aid in strategic purchasing decisions.

-

Regional Considerations: Different regions may have varying standards and expectations for hinge performance. Tailor your sourcing strategy to align with local market requirements.

Disclaimer

Prices for stainless hinges can vary widely based on the factors mentioned above. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing. Always consider the specific needs of your project and the reliability of suppliers when making purchasing decisions.

Spotlight on Potential stainless hinges Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘stainless hinges’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for stainless hinges

Understanding the critical specifications and terminology associated with stainless hinges is essential for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. This knowledge enables informed decision-making and fosters successful procurement strategies.

Key Technical Properties of Stainless Hinges

-

Material Grade

– Stainless steel hinges come in various grades, with 304 and 316 being the most common. Grade 304 offers good corrosion resistance in general environments, while grade 316 is preferred for marine or highly corrosive conditions due to its enhanced resistance.

– B2B Importance: Choosing the right material grade ensures longevity and performance, reducing maintenance costs and enhancing customer satisfaction. -

Load Capacity

– This specification indicates the maximum weight a hinge can support without failing. It’s critical to match the load capacity of the hinge with the door or panel it will support.

– B2B Importance: Understanding load capacity helps prevent premature failure of installations, ensuring safety and reliability, especially in high-traffic or heavy-use applications. -

Tolerance

– Tolerance refers to the permissible limit or limits of variation in the physical dimensions of the hinge. This is crucial for ensuring proper fit and function within the intended application.

– B2B Importance: Accurate tolerances facilitate easier installation and operation, minimizing the risk of malfunction or damage over time. -

Finish Type

– The finish of a stainless hinge affects its aesthetic and functional properties. Common finishes include brushed, polished, and powder-coated options.

– B2B Importance: The right finish can enhance the visual appeal of products while also providing additional corrosion resistance, which is vital in humid climates. -

Pin Type

– The hinge pin can be removable or non-removable. Removable pins allow for easy maintenance or replacement, while non-removable pins enhance security.

– B2B Importance: Understanding pin types helps buyers select hinges that align with their specific application requirements, balancing convenience with security.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the hinge industry, OEMs provide products that meet specific requirements of brands or builders.

– Relevance: Knowing OEM partners can help buyers ensure they are sourcing high-quality components that meet industry standards. -

MOQ (Minimum Order Quantity)

– This term refers to the smallest quantity of a product that a supplier is willing to sell. MOQs can vary significantly between suppliers and hinge types.

– Relevance: Understanding MOQs aids buyers in budgeting and inventory management, ensuring they meet supplier requirements while minimizing excess stock. -

RFQ (Request for Quotation)

– An RFQ is a formal document sent to suppliers requesting price quotes for specific products, in this case, hinges. It outlines the quantity, specifications, and delivery requirements.

– Relevance: Submitting RFQs helps buyers compare pricing and terms from different suppliers, facilitating better negotiation and procurement decisions. -

Incoterms (International Commercial Terms)

– These are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions.

– Relevance: Familiarity with Incoterms helps buyers navigate shipping responsibilities, costs, and risks associated with international purchases of stainless hinges. -

Lead Time

– This term refers to the time it takes from placing an order until it is delivered. It includes manufacturing, shipping, and any potential delays.

– Relevance: Understanding lead times is crucial for project planning and inventory management, ensuring that production schedules are adhered to without unnecessary delays.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of the stainless hinge market with confidence, ensuring their sourcing decisions align with both operational needs and market expectations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the stainless hinges Sector

Market Overview & Key Trends

The global stainless hinges market is experiencing significant growth driven by rising construction activities, increased demand in the automotive sector, and the expansion of the furniture industry. As international B2B buyers navigate this landscape, they must be aware of several key trends shaping the market. One major driver is the increasing focus on durability and corrosion resistance, making stainless steel a preferred material in environments exposed to moisture or extreme conditions, such as in Africa and South America.

Additionally, technological advancements are influencing sourcing strategies. The integration of smart technologies into hinge designs, such as sensors and automation features, is becoming more prevalent, particularly in European markets where efficiency and innovation are prioritized. Buyers are increasingly looking for suppliers who can provide not only traditional products but also innovative solutions that enhance functionality and user experience.

Sustainability is another crucial factor impacting purchasing decisions. B2B buyers are more inclined to partner with manufacturers that adhere to sustainable practices and offer environmentally friendly products. This trend is particularly strong in Europe, where regulatory frameworks encourage the adoption of green materials and processes. Understanding these market dynamics will enable buyers to make informed decisions, align with regional preferences, and leverage opportunities for cost optimization.

Sustainability & Ethical Sourcing in B2B

As the global market shifts towards sustainability, the stainless hinges sector is no exception. The environmental impact of hinge production, particularly concerning raw material extraction and processing, necessitates a commitment to ethical sourcing. B2B buyers must prioritize suppliers who demonstrate transparency in their supply chains and adhere to environmentally responsible practices. This includes sourcing stainless steel from manufacturers who employ recycled materials and sustainable production methods.

Certification programs such as ISO 14001 for environmental management and LEED (Leadership in Energy and Environmental Design) are becoming increasingly important. Buyers should seek out suppliers that possess these certifications, as they not only indicate a commitment to sustainability but also enhance the credibility of their products in eco-conscious markets.

Moreover, the demand for ‘green’ materials is rising. Buyers should consider hinges made from recycled stainless steel or those that can be easily recycled at the end of their life cycle. By investing in sustainable products, companies can not only reduce their ecological footprint but also appeal to a growing segment of consumers and businesses that prioritize ethical sourcing in their purchasing decisions.

Brief Evolution/History

The evolution of stainless hinges can be traced back to the early 20th century when stainless steel was first developed as a corrosion-resistant alternative to traditional metals. Initially, the application of stainless steel in hinges was limited due to higher costs and manufacturing complexities. However, as production techniques improved and the benefits of stainless steel became more widely recognized, its use expanded across various industries.

Today, stainless hinges are integral to numerous applications, from residential doors to heavy industrial machinery. Their evolution reflects broader trends in material science and manufacturing, highlighting the growing importance of durability, aesthetics, and sustainability. This historical context is essential for B2B buyers, as it underscores the value of investing in high-quality components that not only meet current demands but also anticipate future needs in an increasingly competitive marketplace.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of stainless hinges

-

What criteria should I use to vet suppliers of stainless hinges?

When vetting suppliers, focus on their industry experience, manufacturing capabilities, and compliance with international standards. Request references from existing clients and check their reputation through reviews and ratings. Ensure they have certifications such as ISO 9001 for quality management systems. Additionally, assess their production capacity and flexibility to meet your demand, especially if you are operating in fluctuating markets like Africa or South America. -

Can I customize stainless hinges according to my specifications?

Many manufacturers offer customization options, including size, finish, and features like soft-close mechanisms. When seeking custom hinges, provide detailed specifications and drawings. Discuss lead times for production and any additional costs associated with customization. It’s advisable to confirm that the supplier has experience with bespoke projects to ensure they can meet your quality standards and timelines. -

What are typical minimum order quantities (MOQs) for stainless hinges?

MOQs can vary significantly between suppliers and hinge types. Generally, for standard stainless hinges, MOQs can range from 100 to 500 units. However, for customized hinges, the MOQ might be higher due to setup costs. Always clarify MOQs before placing an order, as this can affect your inventory management and budget planning. Consider negotiating MOQs with suppliers if you require smaller quantities. -

What are standard lead times for ordering stainless hinges internationally?

Lead times depend on the supplier’s location, production capacity, and your order size. Typically, lead times can range from 4 to 12 weeks. For urgent orders, some suppliers may offer expedited processing at an additional cost. Always communicate your project deadlines clearly to the supplier and request a written confirmation of the lead time to avoid delays that could impact your business operations. -

How do I ensure quality assurance and certifications for stainless hinges?

Request documentation of the supplier’s quality assurance processes, including inspection protocols and testing methods. Certifications like ISO 9001 or ASTM standards for materials can provide assurance of quality. Additionally, consider conducting an on-site inspection of the manufacturing facility if feasible, or use third-party inspection services to verify compliance with your quality requirements before shipment. -

What logistics considerations should I keep in mind when sourcing stainless hinges?

Logistics play a critical role in international sourcing. Evaluate shipping methods (air vs. sea), costs, and estimated delivery times. Be aware of customs regulations and tariffs that may apply to your shipments, particularly when importing from different regions. Collaborating with a logistics partner experienced in international trade can help streamline the process and minimize potential delays. -

What steps should I take if a dispute arises with my hinge supplier?

In case of a dispute, start by addressing the issue directly with the supplier to seek an amicable resolution. Document all communications and agreements. If the issue cannot be resolved through negotiation, review the contract terms regarding dispute resolution. Many suppliers agree to mediation or arbitration as a first step before escalating to legal proceedings, which can be a more efficient and cost-effective approach. -

How can I manage payment terms effectively with international suppliers?

Establish clear payment terms upfront, such as deposits, milestones, or full payment before shipping. Common payment methods include bank transfers, letters of credit, or payment platforms that offer buyer protection. Be cautious of upfront payments, especially with new suppliers. Consider using escrow services for larger transactions to ensure that funds are only released upon satisfactory delivery of goods. Always clarify currency exchange risks and fees when dealing with international transactions.

Illustrative Image (Source: Google Search)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for stainless hinges

In summary, strategic sourcing of stainless hinges is essential for international B2B buyers aiming to enhance product longevity, performance, and aesthetic appeal across diverse applications. The key takeaways emphasize the importance of selecting the right hinge type based on technical specifications, material quality, and environmental conditions. By prioritizing suppliers with robust quality control processes and a proven track record, buyers can mitigate risks associated with product failures and maintenance costs.

Investing time in understanding the nuances of hinge types—ranging from butt hinges to soft-close mechanisms—will ultimately lead to better purchasing decisions and increased customer satisfaction. Moreover, as market dynamics continue to evolve, leveraging regional insights and maintaining flexibility in sourcing strategies will be crucial for competitive advantage.

As we look to the future, B2B buyers in Africa, South America, the Middle East, and Europe should embrace innovative sourcing practices and stay informed about emerging trends in the hinge market. By doing so, they can ensure they are well-positioned to meet the demands of their respective markets and drive sustainable growth. Take action today—evaluate your hinge sourcing strategy and align it with your business goals for tomorrow.