Master the Art of Sourcing Electric Hoists for Optimal

Introduction: Navigating the Global Market for electric hoist

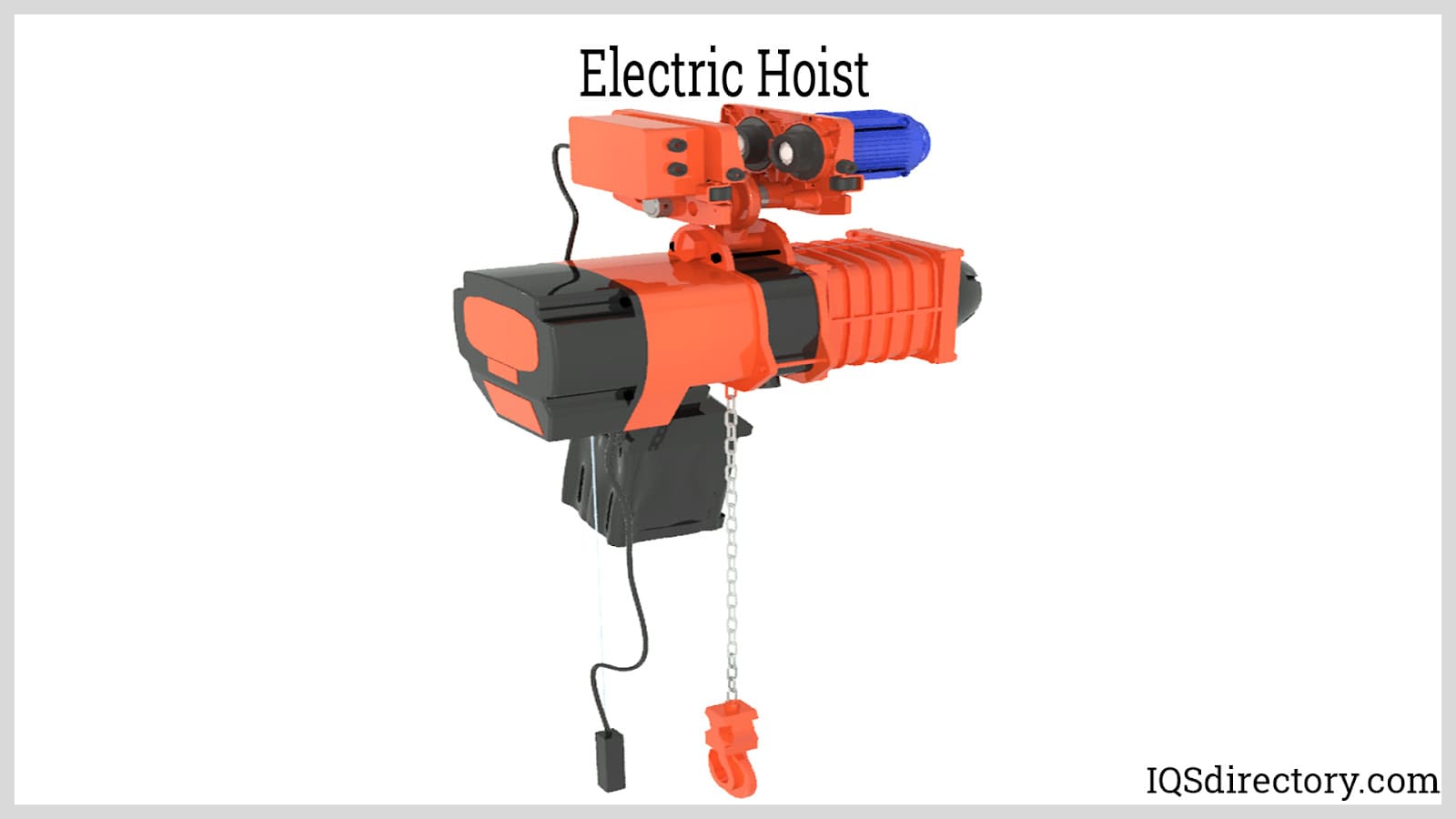

Electric hoists have become indispensable tools across various industries, facilitating the efficient lifting and moving of heavy loads in manufacturing, construction, and logistics. As global markets expand, understanding the nuances of sourcing electric hoists is critical for international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe. In this guide, we delve into the multifaceted world of electric hoists, providing actionable insights that empower buyers to make informed decisions.

Illustrative Image (Source: Google Search)

Throughout this comprehensive guide, we will explore different types of electric hoists, including wire rope and chain hoists, and discuss material considerations that impact durability and performance. Additionally, we will examine manufacturing and quality control processes that ensure reliability and safety standards are met. Understanding the landscape of suppliers is vital, as it can significantly influence pricing and availability.

Cost analysis will also be a focal point, providing buyers with a framework to assess value and budget effectively. Furthermore, we will address common FAQs to clarify any uncertainties that may arise during the sourcing process. By equipping B2B buyers with the necessary tools and knowledge, this guide aims to streamline the purchasing journey and enhance operational efficiency, making it a vital resource for companies navigating the global market for electric hoists.

Understanding electric hoist Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wire Rope Hoist | Uses a wire rope for lifting; high load capacity. | Construction, manufacturing, shipping. | Pros: High durability and load capacity. Cons: Requires regular maintenance. |

| Chain Hoist | Utilizes a chain for lifting; compact design. | Warehousing, automotive, maintenance. | Pros: Lightweight and portable. Cons: Limited lifting height. |

| Electric Winch | Designed for pulling loads; often portable. | Construction, marine applications. | Pros: Versatile and easy to use. Cons: May require more power than other types. |

| Pneumatic Hoist | Operated by compressed air; ideal for hazardous areas. | Food processing, pharmaceuticals. | Pros: Safe for explosive environments. Cons: Requires air supply and may have lower lifting capacity. |

| Electric Overhead Crane | Integrated hoist with a bridge; larger lifting area. | Heavy industry, large warehouses. | Pros: Efficient for large loads and areas. Cons: High initial investment and space requirements. |

Wire Rope Hoist

Wire rope hoists are renowned for their high load capacity and durability, making them ideal for heavy-duty applications in sectors like construction and manufacturing. They typically feature a robust design that can handle substantial weights, but they require regular maintenance to ensure optimal performance. Buyers should consider the operational environment, as these hoists are best suited for permanent installations where heavy lifting is a frequent requirement.

Chain Hoist

Chain hoists are characterized by their compact and lightweight design, making them highly portable and easy to operate. They are commonly used in warehousing and automotive sectors where space is a premium and mobility is essential. While they offer great flexibility, buyers should be aware of their limitations in lifting height and overall load capacity compared to wire rope hoists.

Electric Winch

Electric winches are designed primarily for pulling rather than lifting, providing versatility in various applications such as construction and marine operations. Their portability and ease of use make them attractive for buyers looking for multi-functional equipment. However, they may require a higher power supply, which should be factored into purchasing decisions, especially in remote or off-grid locations.

Pneumatic Hoist

Pneumatic hoists operate using compressed air, making them suitable for environments where electrical equipment poses a risk, such as in food processing or pharmaceutical industries. These hoists are ideal for hazardous locations due to their explosion-proof design. Buyers should consider the need for a consistent air supply and the potential limitations in lifting capacity when evaluating pneumatic options.

Electric Overhead Crane

Electric overhead cranes integrate hoists with a bridge system, allowing for the efficient movement of heavy loads across large areas. They are particularly beneficial in heavy industries and large warehouses where space and load efficiency are critical. However, the high initial investment and substantial space requirements can be a barrier for some buyers, making it essential to assess the long-term operational needs before purchasing.

Related Video: Wire rope electric hoist rope guide

Key Industrial Applications of electric hoist

| Industry/Sector | Specific Application of electric hoist | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Lifting heavy materials on-site | Increases efficiency and safety in material handling | Load capacity, durability, and weather resistance |

| Manufacturing | Assembly line support | Streamlines production processes and reduces labor costs | Compatibility with existing systems and ease of maintenance |

| Warehousing & Logistics | Loading and unloading goods | Enhances operational efficiency and reduces injury risks | Space requirements and lifting speed |

| Mining | Transporting materials within mines | Improves safety and productivity in hazardous environments | Explosion-proof features and robust design |

| Oil & Gas | Hoisting equipment in drilling operations | Facilitates safe and efficient equipment handling | Compliance with industry standards and certifications |

Construction

In the construction industry, electric hoists are pivotal for lifting heavy materials such as steel beams, concrete blocks, and other structural components. They enhance operational efficiency by significantly reducing the time and labor required for material handling, which is crucial in fast-paced construction environments. International buyers should consider load capacity and durability, especially in regions with harsh weather conditions, to ensure reliable operation.

Manufacturing

Electric hoists play a vital role in manufacturing settings, particularly on assembly lines where they assist in moving components and finished products. By automating the lifting process, businesses can streamline production, minimize manual labor, and reduce operational costs. Buyers should focus on compatibility with existing systems and ease of maintenance to ensure seamless integration and minimal downtime.

Warehousing & Logistics

In warehousing and logistics, electric hoists are used for loading and unloading goods from trucks and shelves. This application is essential for improving operational efficiency and minimizing the risk of injuries associated with manual lifting. When sourcing electric hoists, businesses should consider the spatial requirements and lifting speed to optimize workflow and ensure safety in busy warehouse environments.

Mining

The mining industry utilizes electric hoists for transporting materials within mines, where safety and efficiency are paramount. These hoists can handle heavy loads in challenging conditions, significantly improving productivity. Buyers in this sector must prioritize features such as explosion-proof designs and robust construction to comply with safety regulations and withstand harsh mining environments.

Oil & Gas

In the oil and gas sector, electric hoists are essential for hoisting equipment during drilling operations. They facilitate the safe and efficient handling of heavy machinery and components, reducing the risk of accidents. Buyers should ensure that the hoists meet industry standards and certifications, focusing on features like corrosion resistance and operational reliability in extreme conditions to enhance safety and efficiency.

Related Video: Safe Hoist Operations

Strategic Material Selection Guide for electric hoist

When selecting materials for electric hoists, several factors influence performance, durability, and cost-effectiveness. Here, we analyze four common materials used in the construction of electric hoists, highlighting their key properties, advantages, disadvantages, and considerations for international B2B buyers.

Steel

Key Properties: Steel is renowned for its high tensile strength, making it an ideal choice for load-bearing components. It typically has a temperature rating of up to 400°C and can withstand high pressures. Corrosion resistance can be enhanced through galvanization or coatings.

Pros & Cons: The primary advantage of steel is its durability and strength, which ensures long-term reliability in heavy-duty applications. However, it is relatively heavy, which can complicate installation and affect mobility. Additionally, steel can be susceptible to rust if not properly treated, leading to increased maintenance costs.

Impact on Application: Steel is compatible with a wide range of media, including various chemicals, making it suitable for diverse industrial environments. However, its weight can be a limitation in applications requiring lightweight solutions.

Considerations for International Buyers: Buyers in regions like Africa and South America should consider local steel standards, such as ASTM or EN, to ensure compliance with safety regulations. The availability of treated steel can also vary, impacting sourcing decisions.

Aluminum

Key Properties: Aluminum is lightweight yet strong, with a temperature rating of approximately 200°C. It exhibits excellent corrosion resistance, particularly in marine environments, and is non-magnetic, making it suitable for sensitive applications.

Pros & Cons: The main advantage of aluminum is its lightweight nature, which facilitates easier handling and installation. However, it is generally less strong than steel, which may limit its use in extremely heavy lifting applications. Additionally, aluminum can be more expensive than steel.

Impact on Application: Aluminum is ideal for applications in corrosive environments, such as coastal regions or industries involving chemicals. Its lightweight nature can also improve efficiency in operations where mobility is essential.

Considerations for International Buyers: Buyers from the Middle East and Europe should be aware of the specific grades of aluminum that meet local standards, such as EN or JIS. The cost implications of sourcing aluminum versus steel should also be evaluated based on local market conditions.

Composite Materials

Key Properties: Composite materials, such as fiberglass or carbon fiber, offer high strength-to-weight ratios and excellent corrosion resistance. Their temperature ratings can vary widely depending on the resin used, but many can withstand temperatures up to 120°C.

Pros & Cons: The primary advantage of composites is their lightweight and high strength, making them suitable for specialized applications. However, they can be more expensive and complex to manufacture, often requiring specialized processes.

Impact on Application: Composites are particularly beneficial in applications where weight savings are critical, such as aerospace or portable hoisting solutions. Their resistance to corrosion makes them suitable for harsh environments.

Considerations for International Buyers: Buyers should consider the availability of composite materials in their region, as well as any specific certifications required for use in their applications. Understanding the manufacturing capabilities of local suppliers is crucial for sourcing.

Cast Iron

Key Properties: Cast iron is known for its excellent compressive strength and durability, with a temperature rating of up to 300°C. It has good wear resistance but is brittle compared to other materials.

Pros & Cons: The primary advantage of cast iron is its ability to withstand heavy loads without deformation. However, its brittleness can lead to cracking under impact, making it less suitable for dynamic applications. Additionally, it is heavier than other materials.

Impact on Application: Cast iron is well-suited for fixed hoisting applications where load stability is crucial. However, its weight can be a disadvantage in mobile applications.

Considerations for International Buyers: Buyers in Europe and the Middle East should ensure compliance with local standards for cast iron components, such as EN or ASTM. The sourcing of high-quality cast iron can vary significantly by region, affecting overall costs.

Summary Table

| Material | Typical Use Case for electric hoist | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial lifting | High strength and durability | Heavy and prone to rust | Medium |

| Aluminum | Lightweight portable hoisting | Lightweight and corrosion-resistant | Less strong than steel | High |

| Composite | Specialized applications | High strength-to-weight ratio | Expensive and complex to manufacture | High |

| Cast Iron | Fixed hoisting applications | Excellent compressive strength | Brittle and heavy | Medium |

This guide provides insights for international B2B buyers to make informed decisions regarding material selection for electric hoists, ensuring compliance with local standards and suitability for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for electric hoist

Manufacturing Processes for Electric Hoists

Understanding the manufacturing processes involved in the production of electric hoists is essential for international B2B buyers. This knowledge helps in assessing suppliers’ capabilities and ensuring that the products meet your specific requirements. The manufacturing process can be broadly divided into four main stages: material preparation, forming, assembly, and finishing.

1. Material Preparation

The quality of the raw materials significantly impacts the performance and durability of electric hoists. Common materials used include:

- Steel: High-strength steel is often used for the hoist frame and load-bearing components.

- Aluminum: Lightweight hoists may incorporate aluminum for ease of handling.

- Electrical Components: Copper for wiring and specialized alloys for motor components.

Before manufacturing, raw materials undergo rigorous inspections to verify their quality and compliance with relevant standards. This initial quality control (IQC) ensures that only materials that meet specified criteria are utilized in production.

2. Forming

This stage involves shaping the raw materials into the required components. Key techniques include:

- Cutting: Steel and aluminum sheets are cut using laser cutting or plasma cutting technologies for precision.

- Bending and Stamping: Components are bent or stamped into specific shapes using hydraulic presses, ensuring they fit together perfectly during assembly.

- Casting: Some complex components, like gear housings, may be produced via casting methods, which allow for intricate designs.

Investing in modern forming techniques can lead to higher precision, reduced waste, and lower production costs, making it an important consideration for buyers looking to evaluate suppliers.

3. Assembly

The assembly process is crucial as it combines all individual components into a functioning electric hoist. This stage includes:

- Component Integration: Motors, gear systems, and structural components are assembled with high precision.

- Electrical Wiring: Proper wiring of the electrical systems is essential for functionality and safety.

- Quality Checkpoints: Assembly lines should include in-process quality control (IPQC) checkpoints to monitor assembly quality, ensuring that all components fit and function as intended.

B2B buyers should inquire about the assembly process and any specific quality checks performed to ensure the reliability of the final product.

4. Finishing

After assembly, electric hoists undergo finishing processes to enhance durability and appearance. This may include:

- Painting and Coating: Components are often coated with anti-corrosive paint or other protective finishes to prolong lifespan, particularly in harsh environments.

- Final Assembly Checks: A final quality check (FQC) is performed to verify that the product meets all specifications and standards before shipment.

Quality Assurance in Electric Hoist Manufacturing

Quality assurance (QA) is vital in the manufacturing of electric hoists to ensure safety, reliability, and compliance with international standards. Buyers must be aware of various QA processes and standards that reputable manufacturers adhere to.

Relevant International Standards

- ISO 9001: This standard focuses on quality management systems and is crucial for ensuring consistent product quality.

- CE Marking: Required for products sold in the European Economic Area, CE marking signifies that the product meets safety, health, and environmental protection standards.

- API Standards: For hoists used in oil and gas applications, adherence to American Petroleum Institute (API) standards may be necessary.

Quality Control Checkpoints

To maintain high-quality standards, manufacturers typically implement multiple checkpoints throughout the production process:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to catch defects early.

- Final Quality Control (FQC): A comprehensive check of the finished product before it leaves the factory.

Common Testing Methods

Manufacturers employ various testing methods to ensure the reliability and safety of electric hoists, including:

- Load Testing: Simulating operational loads to ensure the hoist can handle specified weights.

- Electrical Testing: Verifying the functionality of electrical components and safety systems.

- Durability Testing: Assessing the long-term performance of the hoist under simulated working conditions.

Verifying Supplier Quality Control

For international B2B buyers, verifying a supplier’s quality control processes is essential to mitigate risks associated with product quality. Here are several strategies:

-

Supplier Audits: Conduct regular audits of suppliers to assess their manufacturing processes, quality control measures, and compliance with international standards.

-

Request Quality Reports: Ask suppliers for documentation of their quality control processes, including inspection reports and certifications.

-

Third-Party Inspections: Engage independent inspection agencies to evaluate the quality of products before shipment. This can provide additional assurance of compliance with specified standards.

-

Certifications Verification: Confirm that the suppliers hold relevant certifications (e.g., ISO 9001, CE marking) and are up-to-date with their renewal.

Conclusion

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance practices for electric hoists is crucial for making informed purchasing decisions. By focusing on the key stages of manufacturing and the importance of rigorous quality control, buyers can better assess potential suppliers and ensure they are investing in reliable, high-quality products that meet international standards.

Related Video: Amazing Production Process with Modern Machines and Skilful Workers

Comprehensive Cost and Pricing Analysis for electric hoist Sourcing

To effectively navigate the complexities of sourcing electric hoists, international B2B buyers must grasp the cost structure, pricing influencers, and strategic negotiation tactics that can significantly impact their procurement decisions.

Cost Structure of Electric Hoists

Understanding the cost components involved in electric hoist manufacturing is crucial for buyers:

-

Materials: This includes the raw materials used in the construction of the hoist, such as steel, aluminum, and electrical components. Prices can fluctuate based on market demand, sourcing location, and material specifications.

-

Labor: Labor costs vary significantly by region. For example, labor is typically cheaper in parts of Africa and South America compared to Europe. Understanding local labor markets can provide insights into potential savings.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, maintenance, and depreciation of machinery. Efficient manufacturing processes can help reduce these costs, impacting the final price.

-

Tooling: Costs associated with the tools and equipment required for production. Custom tooling can be an added expense but may be necessary for specialized hoists.

-

Quality Control (QC): Ensuring the hoist meets safety and performance standards incurs costs. Certifications (e.g., CE marking in Europe) may also add to the price.

-

Logistics: Transportation and handling costs can vary widely based on the distance from the supplier, shipping methods, and the complexity of the supply chain.

-

Margin: Suppliers will typically add a profit margin to cover their costs and ensure profitability. Understanding average margins in your target market can aid in price negotiations.

Price Influencers

Several factors can influence the pricing of electric hoists:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for volume discounts, significantly reducing the per-unit cost.

-

Specifications and Customization: Customized hoists may require additional investment in design and tooling, which can increase costs. Buyers should balance their needs against budget constraints.

-

Material Quality and Certifications: Higher quality materials and additional certifications can drive up costs. Buyers should assess whether the added expense aligns with their operational requirements.

-

Supplier Factors: Supplier reputation, reliability, and service levels can influence pricing. Established suppliers may charge a premium for their reliability and support.

-

Incoterms: Understanding the implications of shipping terms can help buyers manage costs. For instance, choosing “FOB” (Free on Board) may result in lower upfront costs, but buyers must consider potential additional charges at the destination.

Buyer Tips

To maximize value when sourcing electric hoists, consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing, especially if you can commit to larger order volumes. Leverage competitive quotes to negotiate better terms.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs. A lower initial price may lead to higher long-term costs if the hoist is less durable or requires more maintenance.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa and South America should be aware of currency fluctuations and import tariffs, which can impact overall costs. Establishing a clear understanding of these factors will assist in making informed purchasing decisions.

-

Local Partnerships: Consider working with local distributors or partners familiar with the market dynamics and logistics. They can provide insights into local pricing trends and sourcing opportunities.

Disclaimer

The prices discussed in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific project requirements. Always conduct thorough market research and supplier evaluations before finalizing purchases.

Spotlight on Potential electric hoist Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘electric hoist’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for electric hoist

Key Technical Properties of Electric Hoists

When sourcing electric hoists, understanding their technical specifications is crucial for making informed decisions. Below are essential properties that international B2B buyers should consider:

-

Load Capacity: This specification indicates the maximum weight the hoist can safely lift. Typically measured in kilograms or tons, understanding load capacity is vital for ensuring safety and compliance with operational requirements. Buyers should assess their lifting needs against the load capacity to avoid equipment failure and potential hazards.

-

Lift Height: This parameter describes the maximum distance the hoist can elevate a load. Lift height is critical for applications in confined spaces or when lifting to specific heights. Buyers should ensure that the chosen hoist meets their operational vertical requirements.

-

Power Supply: Electric hoists operate on various power sources, including single-phase or three-phase electricity. Understanding the power supply requirements helps buyers determine compatibility with existing electrical infrastructure. This also influences installation costs and operational efficiency.

-

Speed: The lifting speed of the hoist affects productivity. Measured in meters per minute, higher speeds can enhance operational efficiency, especially in high-demand environments. Buyers should balance speed with load safety and stability during operations.

-

Material Grade: The construction material of an electric hoist, such as steel or aluminum, impacts durability and weight. Higher-grade materials ensure longevity and resistance to wear and tear, which is particularly important in harsh working conditions. Buyers should assess the material quality to ensure it meets their operational demands.

-

Safety Features: Essential safety features include overload protection, emergency stop buttons, and limit switches. These features are crucial for preventing accidents and ensuring operator safety. Buyers should prioritize hoists with robust safety mechanisms to comply with industry regulations and protect personnel.

Common Trade Terminology

Familiarity with industry jargon is equally important for effective communication and negotiation. Here are some common terms related to electric hoists:

-

OEM (Original Equipment Manufacturer): Refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers and ensure product authenticity.

-

MOQ (Minimum Order Quantity): This term indicates the smallest amount of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory planning, especially for international buyers looking to manage their supply chain effectively.

-

RFQ (Request for Quotation): A formal document sent to suppliers requesting pricing and terms for specific products or services. An RFQ enables buyers to compare offers from multiple suppliers, ensuring they secure the best deal.

-

Incoterms (International Commercial Terms): A set of international rules that define the responsibilities of buyers and sellers in shipping goods. Familiarity with Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), helps buyers understand shipping costs and responsibilities, which is vital for international transactions.

-

Lead Time: The amount of time from placing an order to receiving the product. Understanding lead times is crucial for project planning and ensuring that operations are not delayed due to late deliveries.

-

Warranty: A guarantee provided by the manufacturer regarding the condition of the hoist and its parts. A clear understanding of warranty terms can protect buyers against defects and ensure they receive adequate support during the product’s lifecycle.

By grasping these technical properties and trade terminologies, international B2B buyers can make well-informed decisions, ensuring that the electric hoists they procure meet their operational needs while adhering to safety and quality standards.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the electric hoist Sector

Market Overview & Key Trends

The electric hoist sector is experiencing significant transformation driven by technological advancements, increasing industrial automation, and the growing demand for efficient lifting solutions. Global drivers such as urbanization, infrastructure development, and the expansion of manufacturing industries in regions like Africa and South America are propelling market growth. Buyers in these regions are particularly focused on sourcing electric hoists that enhance operational efficiency and safety while meeting diverse industrial needs.

Current and emerging B2B tech trends include the integration of IoT (Internet of Things) and AI (Artificial Intelligence) in electric hoist systems. These technologies allow for real-time monitoring, predictive maintenance, and improved operational performance. Buyers should prioritize suppliers who offer these smart solutions, as they can significantly reduce downtime and maintenance costs.

Additionally, sourcing trends are shifting towards more localized supply chains to mitigate risks associated with global logistics disruptions. This is particularly important for international buyers from regions like the Middle East and Europe, where supply chain reliability is paramount. Establishing partnerships with local manufacturers or distributors can lead to faster delivery times and better service support.

Finally, a focus on regulatory compliance and safety standards is essential. Buyers should ensure that their suppliers adhere to international safety certifications, as these are critical for minimizing liability and ensuring operational integrity.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone of B2B purchasing decisions in the electric hoist sector. The environmental impact of manufacturing processes and product lifecycle management is under scrutiny, with buyers increasingly seeking suppliers who prioritize eco-friendly practices. This includes the use of sustainable materials, energy-efficient manufacturing processes, and the ability to recycle or safely dispose of equipment at the end of its lifecycle.

Ethical sourcing is equally important, as buyers are more aware of the social implications of their purchasing decisions. A transparent supply chain that demonstrates fair labor practices and responsible sourcing of raw materials is vital. Buyers should look for suppliers who hold certifications such as ISO 14001 (Environmental Management) or other recognized sustainability standards.

Furthermore, opting for ‘green’ certifications for electric hoists can enhance a company’s reputation and compliance with local regulations, particularly in Europe where sustainability regulations are stringent. Buyers should inquire about the availability of such certifications and the materials used in the production of electric hoists to ensure they align with their sustainability goals.

Brief Evolution/History

The electric hoist has evolved significantly since its inception in the early 20th century, transitioning from purely mechanical devices to sophisticated, electronically controlled systems. Initially designed for simple lifting tasks, advancements in electrical engineering and materials science have led to the development of compact, high-capacity electric hoists that are now integral to various industries, including construction, manufacturing, and logistics.

The introduction of microprocessor technology in the late 20th century revolutionized electric hoists, enabling features such as variable speed control, overload protection, and remote operation. Today, electric hoists are not only essential for lifting heavy loads but also play a crucial role in enhancing workplace safety and efficiency, making them a vital component of modern industrial operations.

In conclusion, as international B2B buyers navigate the electric hoist market, a strategic focus on technological innovations, sustainability practices, and supply chain dynamics will be essential for making informed purchasing decisions that align with their operational and ethical standards.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of electric hoist

-

How can I effectively vet suppliers for electric hoists?

When sourcing electric hoists, begin by researching potential suppliers’ reputations through online reviews and industry forums. Verify their business credentials, including registration and certifications relevant to your country. Request references from previous clients, and consider conducting factory audits if possible. Additionally, check if they comply with international standards such as ISO and CE, which can assure quality and safety. Building a relationship through communication can also provide insights into their reliability and customer service. -

Are customization options available for electric hoists?

Many suppliers offer customization options to meet specific operational needs. This can include modifications in load capacity, lifting height, and control systems. When discussing customization, clearly outline your requirements and ask for detailed specifications. Ensure that the supplier has the capability and experience to deliver tailored solutions. Keep in mind that customized products might have longer lead times and could impact the pricing. -

What are the typical minimum order quantities (MOQ) and lead times?

MOQs for electric hoists can vary significantly among suppliers, often ranging from one unit to several dozen. Inquire about the MOQ early in the negotiation process to align with your budget and demand forecasts. Lead times can also differ based on customization, supplier location, and shipping logistics. Generally, expect lead times of 4-12 weeks. Always confirm these details in writing to avoid misunderstandings later. -

What payment terms should I expect when sourcing electric hoists?

Payment terms can vary widely depending on the supplier and the buyer’s negotiation power. Common arrangements include a deposit upfront (20-50%) and the balance upon delivery or after inspection. For international transactions, consider using secure payment methods such as letters of credit or escrow services to mitigate risks. Ensure to clarify currency exchange rates and any additional fees that may apply. -

What quality assurance measures and certifications should I look for?

Quality assurance is critical in the procurement of electric hoists. Look for certifications such as ISO 9001 (quality management) and compliance with CE standards. Ask suppliers about their quality control processes, including testing procedures and warranties offered on their products. Request documentation of these certifications and any inspection reports that can assure the quality of the hoists being supplied. -

How should I manage logistics for importing electric hoists?

Managing logistics effectively involves understanding the shipping process, including customs clearance, tariffs, and insurance. Coordinate with your supplier to determine the best shipping methods, whether by air or sea, based on your urgency and budget. Work with a freight forwarder experienced in international shipments to streamline the process. Keep documentation organized, including invoices, packing lists, and bills of lading, to facilitate smooth customs clearance. -

What should I do in case of disputes with suppliers?

To minimize disputes, establish clear contracts that outline terms and conditions, including delivery timelines, payment terms, and quality expectations. If a dispute arises, try to resolve it amicably through direct communication. Should informal discussions fail, consult the contract for dispute resolution mechanisms, such as mediation or arbitration. Engaging legal counsel familiar with international trade law can also provide guidance on protecting your interests. -

How can I ensure after-sales support and service for electric hoists?

After-sales support is crucial for the long-term performance of electric hoists. Inquire about the supplier’s warranty policies and the availability of spare parts. Ask whether they provide on-site training for your staff or remote support for troubleshooting. Establishing a clear communication channel for after-sales inquiries can help address issues promptly. Consider suppliers with a local presence in your region for more accessible support and quicker response times.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for electric hoist

In conclusion, strategic sourcing for electric hoists represents a pivotal opportunity for international B2B buyers in regions such as Africa, South America, the Middle East, and Europe. By focusing on supplier relationships, leveraging technology, and understanding local market dynamics, companies can enhance operational efficiency and reduce costs.

Key takeaways include the importance of evaluating supplier capabilities, ensuring compliance with local regulations, and adopting innovative solutions that integrate digital technologies. Buyers should prioritize suppliers that offer robust after-sales support and flexible financing options, as these factors significantly impact long-term partnerships and project success.

As the demand for electric hoists continues to grow, staying ahead of market trends and fostering collaborations with reliable suppliers will be crucial. Investing in strategic sourcing not only streamlines procurement processes but also positions companies to adapt swiftly to changing market conditions.

Looking ahead, B2B buyers are encouraged to actively engage with industry experts, attend relevant trade shows, and utilize digital platforms to enhance their sourcing strategies. By doing so, they can ensure their operations remain competitive and future-ready in an increasingly globalized market.

Illustrative Image (Source: Google Search)