Master Spring Compression: Essential Insights for B2B

Introduction: Navigating the Global Market for spring compression

In today’s competitive industrial landscape, spring compression components play a pivotal role in the reliability and efficiency of machinery across various sectors. For international B2B buyers, particularly those operating in dynamic markets such as Africa, South America, the Middle East, and Europe, understanding the intricacies of compression springs is not just beneficial—it’s essential. These seemingly simple coiled devices are critical in managing loads, absorbing shocks, and ensuring the seamless operation of automated systems and CNC equipment.

This comprehensive guide delves into the multifaceted world of spring compression, covering essential topics such as the different types of springs, including compression, torsion, and constant force springs, as well as their material properties and manufacturing quality control standards. We will explore sourcing strategies, evaluating suppliers, and understanding the cost implications of various spring types. Additionally, market trends and practical FAQs will equip buyers with the insights necessary for making informed decisions.

By leveraging the information contained within this guide, B2B buyers will be empowered to select the right spring components tailored to their specific operational needs. Whether you are in Egypt, Saudi Arabia, Brazil, or Germany, this resource aims to enhance your sourcing strategies, optimize your supply chain, and ultimately reduce downtime and costs associated with machinery failures.

Understanding spring compression Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Compression Springs | Coiled design that compresses under load. | Automotive, industrial machinery, robotics. | Pros: Cost-effective, versatile. Cons: Limited load capacity over time. |

| Torsion Springs | Twists to store energy, allowing rotational motion. | Door hinges, automotive components. | Pros: Efficient for rotational applications. Cons: Requires precise installation. |

| Constant Force Springs | Provides a consistent force over a range of motion. | Cable reels, retractable mechanisms. | Pros: Reliable force output. Cons: Limited displacement range. |

| Extension Springs | Stretches to absorb energy and exert force. | Trampolines, garage doors, automotive. | Pros: Simple design, effective for tension applications. Cons: Vulnerable to fatigue. |

| Wave Springs | Flat design that offers high force in a compact space. | Aerospace, automotive, and electronics. | Pros: Space-saving, lightweight. Cons: More complex manufacturing process. |

Compression Springs

Compression springs are the most common type, characterized by their helical coil structure that compresses under load. They are widely used in automotive, industrial machinery, and robotics applications due to their ability to absorb shock and store energy. When purchasing, buyers should consider factors such as load requirements, material choices (e.g., stainless steel for corrosion resistance), and the spring constant to ensure optimal performance and longevity.

Torsion Springs

Torsion springs are designed to twist and store energy, making them ideal for applications requiring rotational motion, such as door hinges and automotive components. Their performance depends on precise installation and alignment. Buyers should evaluate the torque specifications and installation space before procurement, as improper fitting can lead to mechanical failure.

Constant Force Springs

Constant force springs deliver a steady force throughout their range of motion, making them suitable for applications like cable reels and retractable mechanisms. Their ability to maintain consistent tension is crucial in designs requiring reliability. B2B buyers should assess the required force output and the spring’s travel distance to match their specific applications.

Extension Springs

Extension springs are designed to stretch and store energy, commonly found in trampolines, garage doors, and various automotive applications. Their straightforward design allows for effective energy absorption under tension, but they are susceptible to fatigue over time. Buyers should consider the maximum load and cycle frequency to ensure the selected spring meets durability requirements.

Wave Springs

Wave springs offer a unique flat design that provides high force in a compact form factor, making them popular in aerospace, automotive, and electronics industries. They are advantageous for applications where space is limited and weight is a concern. However, the manufacturing process can be more complex, which may impact lead times and costs. Buyers should weigh the benefits of space savings against potential price increases when considering these springs.

Key Industrial Applications of spring compression

| Industry/Sector | Specific Application of spring compression | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Suspension systems | Enhances vehicle stability and comfort, reducing wear on components. | Ensure springs are rated for specific load and travel requirements. |

| Manufacturing | CNC machinery | Provides precise control of moving parts, reducing downtime and maintenance costs. | Look for high-cycle durability and correct sizing to avoid misalignment. |

| Robotics | Actuators and grippers | Improves performance in repetitive tasks, increasing efficiency and accuracy. | Consider custom spring designs to meet specific motion requirements. |

| Aerospace | Landing gear mechanisms | Ensures reliability and safety in critical applications during takeoff and landing. | Source high-quality, corrosion-resistant materials for reliability. |

| Electronics | Device enclosures | Protects internal components from shock and vibration, enhancing device longevity. | Focus on compact designs that meet specific spatial constraints. |

Automotive

In the automotive sector, compression springs are integral to suspension systems, where they absorb shocks and maintain vehicle stability. These springs help to mitigate the impact of road irregularities, ensuring a smoother ride and prolonging the lifespan of other suspension components. For international B2B buyers, particularly in regions like Africa and the Middle East, sourcing springs that are rated for the specific loads and travel distances of local road conditions is crucial. This ensures performance reliability and safety under varying environmental factors.

Manufacturing

Within the manufacturing industry, compression springs are used extensively in CNC machinery to control the movement of components. They provide the necessary force to maintain precision during operations, thereby reducing the likelihood of machine downtime due to misalignment or wear. For buyers in South America and Europe, it is essential to choose springs that can withstand high-cycle environments and are sized accurately to avoid operational inefficiencies. Collaborating with suppliers that offer both standard and custom spring solutions can greatly enhance operational effectiveness.

Robotics

In robotics, compression springs are vital in actuators and grippers, where they facilitate the precise movement required for repetitive tasks. Their ability to provide consistent force and return motion enhances the efficiency and accuracy of robotic systems. For B2B buyers, particularly in technologically advancing regions, sourcing custom-designed springs tailored to specific robotic applications can significantly improve performance and reduce failure rates. This is especially important in sectors where precision is paramount, such as electronics assembly.

Aerospace

The aerospace industry relies heavily on compression springs in landing gear mechanisms, where they ensure the safe and reliable operation of aircraft during takeoff and landing. These springs must meet rigorous safety standards and be made from high-quality, corrosion-resistant materials to withstand extreme conditions. For international buyers in regions like Europe and the Middle East, it is critical to partner with suppliers who understand the stringent regulatory requirements and can provide springs that guarantee reliability and performance in critical applications.

Electronics

In the electronics sector, compression springs are often used within device enclosures to protect sensitive components from shock and vibration. This is essential for maintaining device integrity and longevity, particularly in portable electronics that are subject to frequent handling. B2B buyers in Africa and South America should prioritize sourcing springs that are compact and designed to fit specific spatial constraints while ensuring they meet performance criteria for durability. Collaborating with manufacturers who specialize in miniaturized spring designs can enhance product reliability in competitive markets.

Related Video: Simple Method Adjusting & Weakening A Compression Spring

Strategic Material Selection Guide for spring compression

When selecting materials for compression springs, international B2B buyers must consider various factors, including the specific application, environmental conditions, and compliance with regional standards. Below is an analysis of four common materials used in spring compression, focusing on their properties, advantages, disadvantages, and implications for buyers in Africa, South America, the Middle East, and Europe.

1. Music Wire

Key Properties: Music wire is a high-carbon steel known for its excellent tensile strength and elasticity. It typically operates well under temperatures up to 200°C and offers good fatigue resistance.

Pros & Cons:

– Advantages: High strength-to-weight ratio, good fatigue life, and relatively low cost make music wire a popular choice for various applications.

– Disadvantages: It has limited corrosion resistance unless treated, and its performance can degrade in high-temperature environments.

Impact on Application: Music wire is suitable for applications requiring high load capacity and resilience. However, it may not be ideal for corrosive environments, such as those found in some industrial sectors in South America or coastal regions in Africa.

Considerations for Buyers: Buyers should ensure compliance with ASTM A228 standards. In regions like Europe, DIN standards may apply, and it’s essential to verify the supplier’s certifications.

2. Stainless Steel

Key Properties: Stainless steel springs, particularly those made from grades like 302 and 316, exhibit excellent corrosion resistance and can withstand temperatures up to 400°C.

Pros & Cons:

– Advantages: Superior durability and resistance to oxidation and corrosion make stainless steel springs ideal for harsh environments.

– Disadvantages: Higher manufacturing costs and complexity compared to carbon steels can increase the overall price of the spring.

Impact on Application: Stainless steel is particularly advantageous in applications exposed to moisture or chemicals, such as automotive or marine environments. This material is suitable for buyers in the Middle East, where humidity can be a concern.

Considerations for Buyers: Compliance with ASTM A313 or equivalent standards is crucial. Buyers should also consider local availability and supplier capabilities in regions like Egypt or Saudi Arabia.

3. Oil-Tempered Steel

Key Properties: Oil-tempered steel springs are heat-treated to enhance their strength and fatigue resistance. They can typically handle temperatures up to 250°C.

Pros & Cons:

– Advantages: Excellent fatigue resistance and cost-effectiveness make oil-tempered springs a common choice for high-stress applications.

– Disadvantages: They may have lower corrosion resistance than stainless steel and require protective coatings for longevity in corrosive environments.

Impact on Application: Ideal for automotive and industrial applications, oil-tempered springs can perform well under significant cyclic loads but may not be suitable for environments with high humidity or exposure to chemicals.

Considerations for Buyers: Buyers should ensure that the springs meet ASTM A313 standards and consider the need for additional coatings or treatments, particularly in humid regions of Africa or South America.

4. Inconel

Key Properties: Inconel is a nickel-chromium alloy known for its ability to withstand extreme temperatures and corrosive environments, operating effectively at temperatures over 700°C.

Pros & Cons:

– Advantages: Exceptional strength and corrosion resistance make Inconel ideal for high-performance applications in extreme conditions.

– Disadvantages: The high cost and complexity of manufacturing can limit its use to specialized applications.

Impact on Application: Inconel springs are suitable for aerospace, chemical processing, and high-temperature applications. This material is particularly relevant for buyers in Europe and the Middle East, where such conditions are prevalent.

Considerations for Buyers: Compliance with ASTM B168 or similar standards is critical. Buyers should also assess the availability of Inconel springs in their region, as sourcing can be more challenging compared to more common materials.

Summary Table

| Material | Typical Use Case for spring compression | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Music Wire | General industrial applications | High strength-to-weight ratio | Limited corrosion resistance | Low |

| Stainless Steel | Marine and chemical environments | Excellent corrosion resistance | Higher manufacturing costs | High |

| Oil-Tempered Steel | Automotive and industrial machinery | Excellent fatigue resistance | Requires protective coatings for durability | Medium |

| Inconel | Aerospace and high-temperature applications | Exceptional strength and corrosion resistance | High cost and manufacturing complexity | High |

This guide provides a comprehensive overview of material options for compression springs, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for spring compression

The manufacturing process for compression springs is crucial for ensuring their performance and reliability in various applications. Understanding these processes, along with the quality assurance protocols, is essential for B2B buyers, particularly those operating in regions such as Africa, South America, the Middle East, and Europe. This section provides a comprehensive overview of the typical manufacturing stages, key techniques, and quality control measures that should be considered when sourcing compression springs.

Manufacturing Processes for Compression Springs

Material Preparation

The first stage in the manufacturing of compression springs involves selecting the right materials. Common materials include high-carbon steel, stainless steel, and alloy steel, each offering different properties such as strength, fatigue resistance, and corrosion resistance. The chosen material is then prepared through processes like:

- Wire Drawing: Reducing the diameter of the wire to the required specifications.

- Annealing: Heating the wire to relieve internal stresses, improving ductility and workability.

Proper material preparation is critical, as it affects the spring’s final performance and longevity.

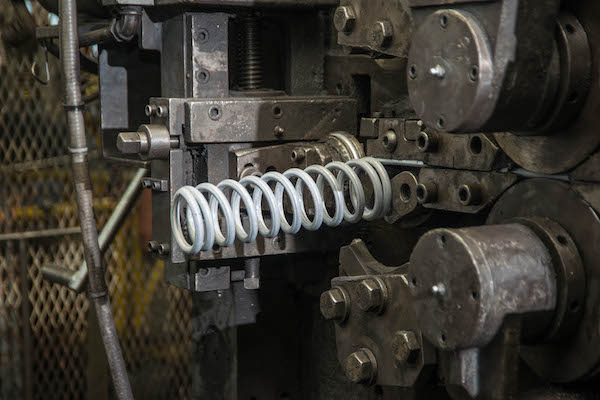

Forming

Once the material is prepared, the next step is forming the spring. This involves several key techniques:

- Coiling: The wire is wound into a helix using a coiling machine. Precision is vital here; the machine settings must match the desired coil diameter and number of turns.

- Heat Treatment: After coiling, springs often undergo heat treatment to enhance their mechanical properties. This process can include hardening, tempering, or stress relieving, depending on the application requirements.

- End Grinding: To ensure flat ends for proper seating and alignment within assemblies, the ends of the springs are ground to a flat finish.

Assembly and Finishing

In many cases, compression springs are part of larger assemblies. During the assembly stage, springs may be combined with other components, which may involve additional processes such as:

- Welding: For certain applications, springs may be welded to other components to create a robust assembly.

- Surface Treatment: Finishing processes, such as shot peening, surface coating, or plating, are applied to improve corrosion resistance and reduce wear.

Quality Assurance Measures

Quality assurance is a fundamental aspect of spring manufacturing, ensuring that products meet industry standards and customer specifications. Here are key components of a robust quality assurance framework:

Relevant International Standards

B2B buyers should ensure that their suppliers adhere to internationally recognized standards, such as:

- ISO 9001: This standard focuses on quality management systems and is applicable to any organization, ensuring consistent quality and continuous improvement.

- CE Marking: For products sold in Europe, compliance with CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: In industries like oil and gas, API standards ensure that products meet specific safety and performance criteria.

Quality Control Checkpoints

A comprehensive quality control process includes several checkpoints throughout the manufacturing cycle:

- Incoming Quality Control (IQC): This initial inspection verifies that raw materials meet specified standards before production begins.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing help identify defects early, minimizing waste and rework.

- Final Quality Control (FQC): This final inspection ensures that the finished products conform to all specifications and standards before shipping.

Common Testing Methods

Testing methods used in the quality assurance of compression springs include:

- Tensile Testing: Measures the spring’s ability to withstand tension, ensuring it meets force requirements.

- Fatigue Testing: Assesses how well the spring can endure repeated loading cycles without failure.

- Dimensional Inspection: Uses precise measuring tools to confirm that the spring dimensions match specifications.

Verifying Supplier Quality Control

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is crucial. Here are effective strategies:

- Supplier Audits: Conducting regular audits of suppliers helps ensure compliance with quality standards and identifies areas for improvement.

- Quality Assurance Reports: Requesting detailed quality assurance reports from suppliers can provide insights into their manufacturing processes and quality control measures.

- Third-Party Inspections: Engaging third-party inspection services offers an unbiased evaluation of the supplier’s adherence to quality standards.

Quality Control and Certification Nuances

Buyers should be aware of specific quality control and certification nuances when dealing with international suppliers. Consider the following:

- Regional Standards: Different regions may have varying standards and regulations. Familiarizing yourself with these can help avoid compliance issues.

- Documentation: Ensure that suppliers provide complete documentation, including certifications, test reports, and compliance statements, to facilitate smooth customs clearance and regulatory compliance.

- Cultural Considerations: Understanding cultural differences in business practices can enhance communication and collaboration with suppliers, leading to better quality outcomes.

Conclusion

In summary, the manufacturing processes and quality assurance practices for compression springs are integral to ensuring product reliability and performance. B2B buyers should prioritize suppliers that demonstrate a commitment to high-quality standards and effective quality control measures. By understanding the manufacturing stages, relevant standards, and verification processes, buyers can make informed decisions that enhance their operational efficiency and product quality.

Related Video: Spring Manufacturing Plant

Comprehensive Cost and Pricing Analysis for spring compression Sourcing

In sourcing compression springs for international B2B applications, understanding the cost structure and pricing dynamics is crucial. This section outlines the key components that influence costs and pricing, along with actionable insights for buyers, particularly from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The choice of materials significantly affects the cost of compression springs. Common materials include carbon steel, stainless steel, and specialty alloys. Stainless steel springs, while more expensive, offer superior corrosion resistance and fatigue life, making them ideal for high-cycle applications.

-

Labor: Labor costs can vary widely based on the manufacturing location. Countries with lower labor costs may offer competitive pricing; however, this might come at the expense of quality or reliability. Understanding the labor market of your supplier’s region is vital in assessing overall cost.

-

Manufacturing Overhead: This includes the indirect costs associated with production, such as factory utilities, equipment depreciation, and administrative expenses. Efficient manufacturing processes can reduce overhead costs, which can be passed on to buyers.

-

Tooling: Custom tooling may be necessary for specialized spring designs. The initial investment in tooling can be significant, but when amortized over large production runs, it can lead to lower per-unit costs.

-

Quality Control (QC): Implementing stringent QC measures ensures the reliability of springs, especially in critical applications. The costs associated with QC processes can vary, and buyers should consider this when evaluating supplier pricing.

-

Logistics: Shipping costs, including freight, customs duties, and insurance, can add substantially to the total cost. Understanding Incoterms and their implications on shipping responsibilities is essential for budgeting.

-

Margin: Suppliers will add a profit margin to their costs. This margin can vary based on the supplier’s market position, reputation, and the complexity of the order.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly impact pricing. Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their needs while maximizing cost efficiency.

-

Specifications/Customization: Custom springs or those with specific specifications will typically incur higher costs due to the additional engineering and production requirements. Clear communication of specifications can help avoid unnecessary costs.

-

Materials and Quality Certifications: Springs made from high-quality materials and those that meet specific industry standards (e.g., ISO certifications) may command higher prices. However, investing in certified products can result in lower long-term costs due to reduced failure rates.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality and delivery may charge more, but they can also mitigate risks associated with poor-quality products.

-

Incoterms: Understanding the implications of different Incoterms (e.g., FOB, CIF) is crucial for international buyers. These terms dictate who bears the shipping costs and risks, affecting overall pricing.

Buyer Tips

-

Negotiation: Always engage suppliers in discussions about pricing, especially for larger orders. Highlighting your potential for ongoing business can incentivize suppliers to offer better terms.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes initial purchase price, maintenance, and replacement costs. A cheaper spring may not be cost-effective in the long run if it leads to frequent replacements.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, suppliers in Europe may have higher labor costs but offer superior quality assurance compared to those in lower-cost regions.

-

Customization Considerations: If your application requires specific customizations, discuss these early in the sourcing process. This can help streamline production and avoid last-minute price hikes.

Disclaimer

Prices can vary widely based on market conditions, material availability, and supplier negotiations. Always request quotes from multiple suppliers to ensure competitive pricing tailored to your specific needs.

Spotlight on Potential spring compression Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘spring compression’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for spring compression

Key Technical Properties for Compression Springs

Understanding the essential technical properties of compression springs is crucial for international B2B buyers, especially those involved in manufacturing and assembly processes. Here are some critical specifications to consider:

-

Material Grade

– Definition: The material used in spring manufacturing, commonly stainless steel, music wire, or alloy steel.

– B2B Importance: Material grade affects the spring’s durability, corrosion resistance, and performance under load. Choosing the right material is essential for applications exposed to harsh environments, ensuring longevity and reliability. -

Spring Constant (k)

– Definition: A measure of the stiffness of a spring, defined as the force required to compress the spring by one unit of length (N/m).

– B2B Importance: Understanding the spring constant is vital for ensuring that the spring meets specific load requirements in machinery. An incorrect spring constant can lead to mechanical failure, resulting in costly downtime. -

Tolerance

– Definition: The allowable deviation from specified dimensions during manufacturing, typically expressed as a range (e.g., ±0.01 mm).

– B2B Importance: Tight tolerances are crucial for precision applications. Inconsistent tolerances can lead to misalignment and failure in machinery, affecting overall operational efficiency. -

Free Length

– Definition: The length of the spring when it is not subjected to any external forces.

– B2B Importance: The free length determines how much compression can occur and impacts the spring’s fit in assembly. Incorrect free lengths can result in inadequate performance or mechanical interference. -

Coil Diameter

– Definition: The diameter of the spring’s coils, which can be either the outer or inner diameter.

– B2B Importance: The coil diameter affects the spring’s ability to fit within specific machinery parts. A mismatch can lead to installation issues and affect the overall performance of the application. -

Fatigue Life

– Definition: The number of cycles a spring can undergo before it fails due to material fatigue.

– B2B Importance: Understanding fatigue life is critical for high-cycle applications. Selecting springs with inadequate fatigue ratings can lead to premature failure and increased maintenance costs.

Common Trade Terms in Spring Compression

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B marketplace. Here are several key terms to know:

- OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: OEMs often require specific spring designs for their products. Understanding OEM specifications ensures that buyers source the right components for their needs.

Illustrative Image (Source: Google Search)

-

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers plan their inventory and budget. It can affect cash flow, especially for smaller businesses or those entering new markets. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and terms for specific products or services.

– Importance: An RFQ is a critical step in the procurement process, enabling buyers to compare costs and terms from multiple suppliers, ensuring they secure the best deal. -

Incoterms (International Commercial Terms)

– Definition: A series of predefined international trade terms that outline the responsibilities of buyers and sellers in shipping and freight.

– Importance: Understanding Incoterms is essential for international transactions, as they dictate shipping costs, risk management, and responsibilities, helping to avoid disputes. -

Lead Time

– Definition: The amount of time from placing an order to receiving the goods.

– Importance: Knowing the lead time is vital for planning production schedules and inventory management. Long lead times can disrupt operations, especially in just-in-time manufacturing environments. -

Certification

– Definition: Documentation that verifies a product meets specific standards or regulations.

– Importance: Certifications, such as ISO or ASTM, ensure that springs meet quality and safety standards, which is crucial for compliance in many industries.

Illustrative Image (Source: Google Search)

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing compression springs, ultimately enhancing operational efficiency and product reliability.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the spring compression Sector

Market Overview & Key Trends

The spring compression sector is experiencing significant transformation, driven by both global market dynamics and technological advancements. Key drivers include the increasing demand for automation in manufacturing processes and the need for enhanced equipment reliability across various industries such as automotive, aerospace, and consumer electronics. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek to optimize production efficiency, they are turning to advanced sourcing strategies that leverage data analytics and predictive maintenance technologies.

Emerging trends in the market are reshaping sourcing practices. The integration of Industry 4.0 technologies, such as IoT and AI, is enabling real-time monitoring of spring performance, allowing for predictive maintenance that minimizes downtime. Additionally, the rise of e-commerce platforms for industrial components is making it easier for buyers to compare suppliers and prices, driving competition and potentially lowering costs. Buyers are increasingly looking for suppliers who can provide customized solutions, as generic options may not meet the specific requirements of complex machinery.

Furthermore, the shift towards sustainability is becoming a pivotal aspect of sourcing decisions. International buyers are increasingly prioritizing suppliers that offer eco-friendly materials and practices, reflecting a broader commitment to corporate social responsibility. In regions with emerging economies, such as Africa and South America, there is also a growing emphasis on local sourcing to support regional development and reduce carbon footprints associated with transportation.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer just a buzzword; it has become a crucial component of strategic sourcing in the spring compression sector. The environmental impact of manufacturing processes, including resource depletion and waste generation, is prompting buyers to seek suppliers with robust sustainability practices. Ethical sourcing involves ensuring that materials are sourced responsibly and that suppliers adhere to fair labor practices, which is especially important in regions such as Africa and South America where labor standards may vary.

International buyers should look for suppliers who are certified by recognized sustainability standards, such as ISO 14001 for environmental management systems or the Global Reporting Initiative (GRI) for corporate sustainability reporting. Additionally, the use of recycled materials in the production of compression springs is gaining traction, as it reduces the demand for virgin materials and minimizes waste.

Investing in ‘green’ certifications can also enhance a company’s reputation and appeal to environmentally conscious customers. Buyers should conduct thorough due diligence on their suppliers’ sustainability claims, ensuring transparency in their supply chains and verifying the authenticity of certifications. By prioritizing sustainable and ethical sourcing, companies not only contribute to environmental conservation but also position themselves competitively in the marketplace.

Brief Evolution/History

The history of spring compression technology dates back to ancient civilizations, where simple coil springs were utilized for various mechanical applications. However, the modern era of spring manufacturing began in the 19th century with the industrial revolution, which saw advancements in metallurgy and mass production techniques. As industries evolved, the demand for high-performance compression springs grew, leading to innovations in design and materials.

Today, the spring compression sector is characterized by advanced engineering practices, including computer-aided design (CAD) and finite element analysis (FEA), allowing for the creation of springs that meet specific load and fatigue requirements. The focus has shifted from merely producing springs to providing comprehensive solutions that enhance machine performance and reliability, reflecting the industry’s adaptation to the dynamic needs of global markets.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of spring compression

-

What criteria should I use to vet suppliers for compression springs?

When vetting suppliers for compression springs, consider their industry experience, reputation, and certifications (e.g., ISO 9001). Request references from past clients and assess their production capabilities and quality control processes. It’s also essential to evaluate their ability to meet your specific requirements, such as customization options and minimum order quantities (MOQ). Finally, check their financial stability and responsiveness to inquiries, as these factors can indicate reliability in fulfilling orders. -

Can I customize compression springs to meet specific application needs?

Yes, many suppliers offer customization options for compression springs. You can specify dimensions, materials, and load requirements based on your application. It’s advisable to provide detailed specifications and performance criteria to ensure the final product meets your expectations. Collaborating with suppliers who have engineering expertise can also help optimize designs for unique applications, leading to improved performance and longevity. -

What are typical lead times and minimum order quantities (MOQs) for compression springs?

Lead times and MOQs can vary significantly depending on the supplier, the complexity of the order, and the production capabilities. Generally, lead times can range from a few weeks to several months for custom springs. MOQs may vary from as low as 100 units for standard springs to higher quantities for customized designs. Always clarify these details before placing an order to avoid unexpected delays or costs. -

What payment terms should I expect when sourcing compression springs internationally?

Payment terms can differ by supplier and region. Common practices include upfront payments, partial payments before shipment, or payment upon delivery. For international transactions, using letters of credit can provide security for both parties. Be sure to negotiate terms that are favorable and comfortable for your organization while ensuring clarity on currency conversions, transaction fees, and potential tariffs. -

What quality assurance (QA) measures should suppliers provide?

Suppliers should offer comprehensive QA measures to ensure the reliability and performance of compression springs. Request documentation of their quality control processes, including inspection protocols, testing standards, and certifications. Common tests include tensile strength, fatigue testing, and dimensional checks. Additionally, consider asking for a certificate of compliance that guarantees the springs meet specific industry standards and regulations relevant to your market. -

How can I manage logistics when sourcing compression springs internationally?

Managing logistics effectively involves understanding shipping options, customs regulations, and potential tariffs. Collaborate with suppliers who have experience in international shipping to streamline the process. Use freight forwarders to handle logistics and ensure compliance with local regulations. Additionally, factor in lead times for shipping and customs clearance when planning your production schedules to avoid delays. -

What steps can I take to resolve disputes with suppliers?

To resolve disputes with suppliers, start by communicating openly about the issues. Document all correspondence and agreements to provide clarity. If the dispute involves product quality or delivery issues, request a formal review or inspection. If necessary, escalate the matter through mediation or arbitration, as outlined in your contract. Establishing clear terms in your supplier agreement regarding dispute resolution can help avoid conflicts in the future. -

What certifications should I look for in compression spring suppliers?

When sourcing compression springs, look for suppliers with relevant certifications that demonstrate compliance with industry standards. Key certifications include ISO 9001 for quality management systems, ISO 14001 for environmental management, and any specific certifications applicable to your industry (e.g., automotive or aerospace). Certifications can provide assurance of the supplier’s commitment to quality and adherence to safety regulations, which is crucial for minimizing risks in your supply chain.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for spring compression

As global industries continue to evolve, the importance of strategic sourcing for compression springs cannot be overstated. Key takeaways highlight the critical nature of selecting the right spring type, size, and material to prevent machine failures and ensure operational efficiency. By investing in high-quality, appropriately specified compression springs, companies can mitigate risks associated with downtime and enhance the longevity of their equipment.

Actionable insights include utilizing spring calculators, engaging with trusted suppliers for custom solutions, and understanding the specific requirements of your machinery to avoid common pitfalls such as over-compression and material fatigue. These steps not only improve performance but also contribute to cost savings over time.

Looking ahead, international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are encouraged to embrace a proactive approach in their sourcing strategies. By fostering partnerships with reputable manufacturers and leveraging advanced technologies, organizations can position themselves for success in a competitive landscape. Prioritize strategic sourcing today to empower your operations and drive sustainable growth in the future.