Your Ultimate Guide to Sourcing Continous Hinge

Introduction: Navigating the Global Market for continous hinge

In today’s competitive global market, continuous hinges serve as a crucial component across various industries, offering unmatched durability and functionality for doors, cabinets, and equipment enclosures. Their unique design, which spans the full length of an opening, ensures even load distribution and enhances structural integrity, making them ideal for high-traffic environments in sectors such as manufacturing, transportation, and construction. For international B2B buyers—particularly those operating in Africa, South America, the Middle East, and Europe—understanding the diverse applications and specifications of continuous hinges is essential for making informed purchasing decisions.

This comprehensive guide delves into the multifaceted world of continuous hinges, covering critical topics such as types (including geared and non-geared variants), materials (from stainless steel to brass), and manufacturing processes. We also explore quality control measures and identify leading suppliers that meet international standards. Additionally, the guide provides insights into cost factors, current market trends, and answers to frequently asked questions, empowering buyers to navigate the complexities of sourcing these essential components.

By leveraging the information presented, B2B buyers can enhance their procurement strategies, ensuring they select the right continuous hinge solutions tailored to their specific operational needs. Equip yourself with the knowledge necessary to make strategic sourcing decisions that drive efficiency and reliability in your projects.

Understanding continous hinge Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Continuous Hinge | Made from various materials; spans full length of doors; available in standard lengths. | Doors, cabinets, toolboxes | Pros: Strong, durable, cost-effective. Cons: Limited customization options. |

| Geared Continuous Hinge | Incorporates gears for added mechanical advantage; allows for heavy-duty applications. | Heavy machinery, industrial doors | Pros: Enhanced load-bearing capacity. Cons: Higher cost and complexity. |

| Custom Continuous Hinge | Tailored specifications including size, hole patterns, and finishes; made to fit specific applications. | Specialty equipment, custom cabinetry | Pros: Perfect fit for unique applications. Cons: Longer lead times for production. |

| Piano Hinge | A subtype of continuous hinge; traditionally used on piano lids; offers smooth operation. | Musical instruments, lightweight doors | Pros: Aesthetic appeal and smooth functionality. Cons: May not handle heavy loads as effectively. |

| Security Continuous Hinge | Features pinned or staked pins to prevent removal; designed for high-security applications. | Safes, secure lockers, commercial facilities | Pros: Enhanced security features. Cons: Potentially more expensive due to added features. |

Standard Continuous Hinge

The standard continuous hinge is a versatile and widely used option in various applications. It spans the entire length of doors and cabinets, providing stability and alignment. Typically made from materials like steel or stainless steel, these hinges are ideal for environments requiring durability and frequent use. When purchasing, buyers should consider the hinge’s load capacity and compatibility with their specific installation needs, as well as the availability of standard lengths and finishes.

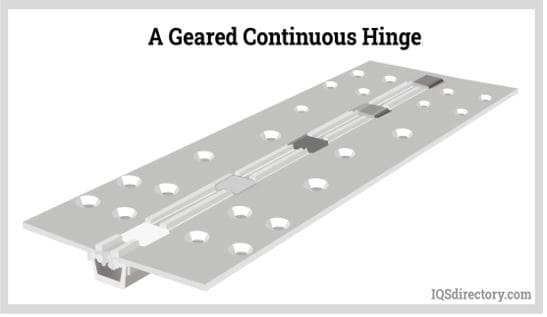

Geared Continuous Hinge

Geared continuous hinges are designed for heavy-duty applications where additional mechanical advantage is needed. The incorporation of gears allows these hinges to bear significant weight, making them suitable for industrial doors and heavy machinery. Buyers should evaluate their specific load requirements and the hinge’s operational complexity, as geared hinges can be more expensive and may require specialized installation and maintenance.

Custom Continuous Hinge

Custom continuous hinges offer tailored solutions to meet specific application requirements. Buyers can specify dimensions, hole patterns, and finishes, ensuring a perfect fit for unique applications. This flexibility is particularly beneficial for specialty equipment and custom cabinetry. However, buyers should be prepared for potentially longer lead times and higher costs associated with bespoke manufacturing processes.

Piano Hinge

Piano hinges, a subtype of continuous hinge, are traditionally used on piano lids, offering smooth operation and aesthetic appeal. They are well-suited for lightweight doors and applications where appearance matters. While they provide excellent functionality, buyers should be cautious about their load-bearing capacity, especially in heavier applications. The choice of material and finish can also impact the hinge’s performance and longevity.

Security Continuous Hinge

Security continuous hinges are engineered with features like pinned or staked pins to prevent removal, making them ideal for high-security applications. These hinges are commonly used in safes, secure lockers, and commercial facilities where safety is paramount. When considering a security hinge, buyers should assess the level of security required and the associated costs, as enhanced security features can lead to higher prices compared to standard options.

Related Video: All the main Blum hinge types explained!

Key Industrial Applications of continous hinge

| Industry/Sector | Specific Application of Continuous Hinge | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Industrial machinery doors | Enhances safety and accessibility for maintenance | Material strength, corrosion resistance, and customization options |

| Transportation | Commercial vehicle compartments | Provides secure access while ensuring structural integrity | Load capacity, weather resistance, and compliance with safety standards |

| Construction | Heavy-duty access doors | Offers durability and alignment for high-traffic areas | Size specifications, weight tolerance, and installation ease |

| Marine | Boat hatches and lids | Ensures water-tight seals and smooth operation in harsh conditions | Corrosion resistance, material choice, and customization for specific applications |

| Retail and Hospitality | Display cases and cabinets | Improves aesthetics while providing functional access | Design compatibility, security features, and finish options |

Manufacturing: Industrial Machinery Doors

Continuous hinges are essential in manufacturing settings, particularly for industrial machinery doors. These hinges allow for smooth operation and easy access for maintenance, which is crucial in high-output environments. They solve the problem of wear and misalignment often seen with traditional hinges, ensuring that machinery remains operational with minimal downtime. Buyers should focus on sourcing hinges made from durable materials that can withstand heavy use, with options for customization to fit specific machinery designs.

Transportation: Commercial Vehicle Compartments

In the transportation sector, continuous hinges are widely used in commercial vehicle compartments, such as those found in buses and trucks. They provide secure access to storage areas while maintaining the structural integrity of the vehicle. The benefit lies in their ability to withstand frequent use and exposure to varying environmental conditions. Buyers in this sector should consider the load capacity and weather resistance of the hinges, as well as compliance with relevant safety standards to ensure reliability.

Construction: Heavy-Duty Access Doors

Continuous hinges are critical in the construction industry, particularly for heavy-duty access doors used in commercial buildings. These hinges provide the necessary durability and alignment for doors that experience high traffic. They help prevent issues like sagging or misalignment, which can compromise security and accessibility. When sourcing continuous hinges for construction applications, buyers should prioritize size specifications, weight tolerance, and ease of installation to ensure a seamless fit and function.

Marine: Boat Hatches and Lids

In marine applications, continuous hinges are utilized for boat hatches and lids, where they must provide a water-tight seal while allowing for smooth operation. The harsh marine environment requires hinges that can resist corrosion and withstand exposure to saltwater. The benefits of using continuous hinges in this context include enhanced safety and operational efficiency. Buyers should focus on sourcing materials specifically designed for marine use, ensuring that the hinges are customized to fit the unique dimensions of the boat.

Retail and Hospitality: Display Cases and Cabinets

Continuous hinges are also popular in the retail and hospitality sectors, particularly for display cases and cabinets. They enhance the aesthetic appeal of these fixtures while providing functional access to merchandise. The use of continuous hinges helps to maintain alignment and smooth operation, which is vital in high-traffic retail environments. Buyers should consider design compatibility, security features, and finish options when sourcing hinges for these applications to ensure they meet both functional and aesthetic needs.

Related Video: Continuous Hinge Installation and Operation

Strategic Material Selection Guide for continous hinge

When selecting materials for continuous hinges, B2B buyers must consider various factors, including performance characteristics, application suitability, and regional compliance standards. Below, we analyze four common materials used in continuous hinge manufacturing, focusing on their properties, advantages and disadvantages, application impacts, and considerations for international buyers.

1. Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures. It typically has a temperature rating up to 800°F (427°C) and is suitable for environments exposed to moisture.

Pros & Cons: The durability of stainless steel makes it ideal for heavy-duty applications, ensuring a long lifespan even in harsh conditions. However, it is more expensive than other materials, which can impact budget considerations. Manufacturing processes for stainless steel can also be complex, requiring specialized equipment.

Impact on Application: Stainless steel is particularly suitable for applications in food processing, marine environments, and chemical processing due to its resistance to rust and corrosion.

Considerations for International Buyers: Buyers should ensure compliance with international standards like ASTM A240 for stainless steel. In regions like Europe, buyers may also need to consider EU regulations regarding food safety.

2. Aluminum

Key Properties: Aluminum is lightweight, has good corrosion resistance, and can handle moderate loads. It typically performs well in temperatures up to 400°F (204°C) and is often anodized for enhanced durability.

Pros & Cons: The lightweight nature of aluminum makes it easy to handle and install, which can reduce labor costs. However, it may not be suitable for heavy-duty applications due to its lower load-bearing capacity compared to steel. Additionally, aluminum can be more susceptible to wear over time.

Impact on Application: Aluminum continuous hinges are ideal for applications where weight is a critical factor, such as in aerospace or portable equipment.

Considerations for International Buyers: Buyers should verify compliance with standards such as ASTM B221 for aluminum extrusions. In regions like South America, local suppliers may have specific preferences for aluminum grades.

3. Brass

Key Properties: Brass offers good corrosion resistance and has a warm aesthetic appeal. It performs adequately in moderate temperature ranges, typically up to 300°F (149°C), making it suitable for indoor applications.

Pros & Cons: The aesthetic quality of brass makes it a popular choice for decorative applications. However, it is less durable than stainless steel and can tarnish over time, requiring maintenance. Additionally, brass is generally more expensive than aluminum.

Impact on Application: Brass is often used in high-end cabinetry, furniture, and decorative hardware where appearance is paramount.

Considerations for International Buyers: Compliance with standards like ASTM B36 for brass is essential. Buyers in regions with high humidity, such as parts of Africa, should consider the need for protective coatings to prevent tarnishing.

4. Mild Steel

Key Properties: Mild steel is strong and cost-effective, with a typical temperature rating of up to 500°F (260°C). However, it is prone to rust and corrosion if not properly coated.

Pros & Cons: The affordability of mild steel makes it an attractive option for budget-conscious projects. However, its susceptibility to corrosion limits its use in outdoor or high-moisture applications unless treated with protective coatings.

Impact on Application: Mild steel continuous hinges are commonly used in industrial applications, such as machinery and storage solutions.

Considerations for International Buyers: Buyers should ensure that mild steel products comply with relevant standards like ASTM A36. In regions like the Middle East, where humidity can be high, corrosion-resistant coatings may be necessary.

Summary Table

| Material | Typical Use Case for Continuous Hinge | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, marine applications | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Aerospace, portable equipment | Lightweight and easy to install | Lower load capacity | Medium |

| Brass | Decorative cabinetry, furniture | Aesthetic appeal | Prone to tarnishing | High |

| Mild Steel | Industrial machinery, storage | Cost-effective | Susceptible to rust without coating | Low |

This strategic material selection guide provides international B2B buyers with insights into the properties, advantages, and considerations for various materials used in continuous hinges. Understanding these factors will assist in making informed purchasing decisions tailored to specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for continous hinge

Continuous hinges, also known as piano hinges, are vital components in a wide range of applications, from industrial doors to custom cabinetry. Understanding the manufacturing processes and quality assurance (QA) measures behind these products is crucial for international B2B buyers, particularly those sourcing from Africa, South America, the Middle East, and Europe. This section details the typical manufacturing processes, quality control protocols, and how buyers can ensure they are purchasing high-quality continuous hinges.

Manufacturing Processes for Continuous Hinges

The manufacturing of continuous hinges involves several key stages, each critical to ensuring the final product meets industry standards and customer specifications.

1. Material Preparation

The first step in the manufacturing process is the selection and preparation of materials. Continuous hinges are typically made from metals such as stainless steel, brass, aluminum, or steel, chosen based on the application’s specific requirements, such as strength, corrosion resistance, and aesthetic appeal.

- Material Sourcing: It is essential for buyers to verify the origin and quality of the raw materials. Ensuring that materials come from reputable suppliers can prevent future issues related to durability and performance.

- Cutting and Sizing: Once materials are sourced, they are cut to size using precision machinery. This stage often involves laser cutting or shearing to ensure clean edges and accurate dimensions.

2. Forming

Forming is the next critical step, where the flat metal sheets are shaped into the hinge structure.

- Bending Techniques: Advanced bending techniques, such as swaging and offsetting, are employed to create the hinge’s knuckles and barrel. This is crucial for ensuring that the hinge operates smoothly and can withstand repeated use.

- Roll Forming: In many cases, continuous hinges are produced using a roll-forming process, where metal is fed through a series of rollers to achieve the desired profile. This method allows for high-volume production while maintaining consistent quality.

3. Assembly

After forming, the components of the continuous hinge are assembled.

- Pin Insertion: A hinge pin is inserted into the knuckles, allowing the hinge to pivot. Depending on the design, pins may be staked or welded in place for added security.

- Custom Features: Buyers can often request custom features such as pre-drilled holes or specific hole patterns to facilitate installation.

4. Finishing

The finishing stage enhances both the appearance and durability of the hinge.

- Surface Treatments: Common finishing processes include polishing, plating, and anodizing. These treatments improve corrosion resistance and can enhance aesthetic qualities.

- Quality Checks: Throughout the manufacturing process, operators conduct in-line inspections to ensure that each hinge meets specified tolerances and finishes.

Quality Assurance for Continuous Hinges

Quality assurance is essential in the manufacturing of continuous hinges to ensure that they meet international standards and customer expectations.

International Standards

International standards such as ISO 9001 are crucial for manufacturers looking to assure buyers of their quality management systems. This certification indicates that the manufacturer adheres to globally recognized quality processes.

- CE Marking: In Europe, products must often meet CE marking requirements, indicating compliance with safety, health, and environmental protection standards.

- API Standards: For hinges used in the oil and gas industry, compliance with American Petroleum Institute (API) standards may be necessary.

Quality Control Checkpoints

Quality control is integrated into various stages of the manufacturing process, ensuring that defects are identified and addressed early.

- Incoming Quality Control (IQC): This involves checking raw materials upon receipt to verify that they meet specified standards.

- In-Process Quality Control (IPQC): During production, checkpoints are established to monitor critical dimensions and functional aspects of the hinges.

- Final Quality Control (FQC): After assembly, a thorough inspection is conducted to ensure the finished product meets all specifications before packaging.

Testing Methods

Several testing methods are employed to verify the performance and durability of continuous hinges:

- Load Testing: Hinges are subjected to load tests to ensure they can withstand specified weights and stresses without failure.

- Corrosion Resistance Tests: Especially for hinges intended for outdoor or industrial applications, corrosion resistance is tested through salt spray or other environmental exposure tests.

- Functional Testing: This includes checking the smooth operation of the hinge, ensuring it opens and closes correctly.

How B2B Buyers Can Verify Supplier Quality

For international B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, verifying the quality of suppliers is crucial.

- Supplier Audits: Conducting on-site audits can provide insights into the supplier’s manufacturing processes, quality control measures, and adherence to international standards.

- Requesting Quality Reports: Buyers should request detailed quality reports that outline the results of IQC, IPQC, and FQC processes.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the product quality and compliance with specified standards.

Conclusion

Understanding the manufacturing processes and quality assurance measures for continuous hinges is vital for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with rigorous quality control practices, buyers can ensure they are sourcing high-quality products that meet their specific needs. Moreover, leveraging audits, quality reports, and third-party inspections will further enhance the reliability of their suppliers, ultimately leading to successful procurement outcomes.

Related Video: How 1 Million Chocolate Bars Are Made in Factory | Surprising Chocolate Production Process

Comprehensive Cost and Pricing Analysis for continous hinge Sourcing

Continuous hinges are critical components in various applications, requiring careful consideration of cost structures and pricing strategies when sourcing. Understanding these elements will enable international B2B buyers, especially from Africa, South America, the Middle East, and Europe, to make informed decisions.

Cost Components

-

Materials: The choice of materials significantly influences the cost. Common materials for continuous hinges include stainless steel, aluminum, brass, and plastic. Stainless steel is typically more expensive but offers superior durability and corrosion resistance, making it ideal for harsh environments. Conversely, aluminum may be more cost-effective but less robust.

-

Labor: Labor costs can vary depending on the manufacturing location. In regions with higher labor costs, such as Europe, the overall production costs may rise. However, labor-intensive customization processes, such as hole punching and bending, can further increase costs.

-

Manufacturing Overhead: This encompasses the costs associated with running the manufacturing facility, including utilities, maintenance, and administrative expenses. Buyers should inquire about how suppliers allocate these costs in their pricing models.

Illustrative Image (Source: Google Search)

-

Tooling: Custom tooling for specific hinge designs can add significant expenses. Buyers should assess whether the supplier has existing tooling for their needs or if new tools must be created, which could lead to higher initial costs.

-

Quality Control (QC): Rigorous quality control processes ensure product reliability and adherence to standards. Suppliers with robust QC systems may charge higher prices, reflecting their commitment to quality.

-

Logistics: Transportation costs can significantly affect the final price, especially for international shipments. Factors such as shipping distance, mode of transport, and customs duties must be considered.

-

Margin: Suppliers typically include a profit margin that can vary widely based on market competition and demand. Understanding the market landscape can help buyers gauge if the margins are reasonable.

Price Influencers

-

Volume/MOQ: Purchasing in bulk can lead to substantial discounts. Suppliers often have minimum order quantities (MOQs) that can impact pricing; negotiating lower MOQs can be beneficial for smaller buyers.

-

Specifications/Customization: Custom hinges tailored to specific applications tend to cost more than standard products. Buyers should clearly define their requirements to avoid unnecessary customization costs.

-

Materials and Quality Certifications: Higher-quality materials and certifications (such as ISO or ASTM standards) can drive up costs but may provide long-term savings through enhanced durability and performance.

-

Supplier Factors: The supplier’s reputation, experience, and production capabilities can influence pricing. Established suppliers may charge more due to their reliability and track record.

-

Incoterms: The chosen Incoterms (International Commercial Terms) affect pricing by determining the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk. Understanding these terms can prevent unexpected expenses.

Buyer Tips

-

Negotiation: Engage in open discussions with suppliers about pricing structures. Be prepared to negotiate based on your order size and the potential for long-term partnerships.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO) rather than just the purchase price. Consider factors such as lifespan, maintenance costs, and performance to ensure the best value.

-

Pricing Nuances: Be aware of regional pricing differences and how local economic conditions may affect costs. For example, suppliers in developing regions may offer lower prices due to reduced labor costs but might lack quality control measures.

-

Request Quotes: When sourcing, request comprehensive quotes from multiple suppliers to compare costs effectively. Ensure that quotes include all relevant components, such as shipping and handling, to facilitate accurate comparisons.

Disclaimer

Prices for continuous hinges can vary widely based on the factors outlined above. Buyers should treat any indicative prices as a starting point for negotiations and seek detailed quotes tailored to their specific needs.

Spotlight on Potential continous hinge Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘continous hinge’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for continous hinge

Continuous hinges are vital components in various industrial applications, providing durability and functionality. Understanding their essential technical properties and trade terminology is crucial for B2B buyers, particularly when selecting the right hinge for specific needs. Below are key specifications and commonly used terms that facilitate informed purchasing decisions.

Essential Technical Properties

-

Material Grade

– Continuous hinges can be made from several materials, including stainless steel, aluminum, brass, and carbon steel. The choice of material affects durability, corrosion resistance, and weight. For example, stainless steel is preferred in high-humidity environments, while aluminum is lighter and easier to install. Understanding material grades ensures that the hinge can withstand the operational environment. -

Load Capacity

– This specification refers to the maximum weight a hinge can support. It is critical for applications where the hinge bears significant weight, such as in heavy doors or lids. Buyers should assess the load capacity to prevent premature wear or failure, which could lead to safety hazards and increased maintenance costs. -

Pin Diameter

– The pin is the central pivot point of the hinge, and its diameter influences the hinge’s strength and rotation smoothness. A larger pin diameter typically offers greater load-bearing capacity and durability. Buyers should consider pin diameter when evaluating the hinge’s suitability for their application. -

Leaf Thickness

– The thickness of the hinge leaves affects its overall strength and rigidity. Thicker leaves provide better support and are ideal for heavy-duty applications. Buyers must balance the need for strength with any space constraints in their designs. -

Length and Width

– Continuous hinges come in standard lengths (usually 6 to 8 feet) and various widths. Custom lengths can be ordered based on specific requirements. Understanding the dimensions helps ensure a proper fit and function for the application, minimizing installation issues. -

Hole Configuration

– The arrangement and size of the holes in the hinge leaves are essential for secure mounting. Common configurations include staggered and adjacent holes. Custom hole patterns may also be requested to accommodate specific installation needs, enhancing ease of use and ensuring alignment.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is crucial for buyers to ensure compatibility and quality in the components they source. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest number of units a supplier is willing to sell. This term is important for budget-conscious buyers as it directly impacts inventory costs and cash flow. Understanding MOQ helps in planning procurement effectively. -

RFQ (Request for Quotation)

– An RFQ is a standard business process where a buyer requests price quotes from suppliers for specific products or services. Buyers should prepare detailed RFQs to receive accurate and competitive pricing, ensuring they get the best value. -

Incoterms (International Commercial Terms)

– These are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) relating to international commercial law. Familiarity with Incoterms is vital for buyers involved in global trade, as they define the responsibilities of buyers and sellers in shipping, insurance, and tariffs. -

Lead Time

– This term indicates the time between placing an order and receiving the product. Knowing lead times helps buyers plan their projects and manage supply chain expectations. It is essential for maintaining operational efficiency. -

Custom Fabrication

– Custom fabrication involves modifying standard products to meet specific requirements, such as altering dimensions or adding features. Understanding custom fabrication options allows buyers to tailor products to their unique applications, enhancing operational efficiency and performance.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of purchasing continuous hinges, ensuring they select the most suitable products for their applications.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the continous hinge Sector

Market Overview & Key Trends

The continuous hinge market is experiencing significant growth driven by increasing demand across various sectors such as construction, automotive, and industrial machinery. A key driver is the global push towards efficient, durable, and aesthetic solutions for door and lid mechanisms. Continuous hinges, also known as piano hinges, are favored for their ability to distribute weight evenly, enhancing the longevity and reliability of applications ranging from cabinetry to heavy-duty doors.

Emerging B2B technology trends are reshaping sourcing strategies, particularly in regions like Africa, South America, the Middle East, and Europe. Innovations such as automated manufacturing processes and advanced materials are allowing suppliers to offer customized solutions at competitive prices. The rise of e-commerce platforms is also facilitating easier access for international buyers, enabling them to compare products, request quotes, and place orders seamlessly.

Moreover, the demand for customization is on the rise. Buyers are increasingly seeking hinges tailored to specific application needs, including variations in length, thickness, and material. This trend is particularly pronounced in emerging markets where local requirements may differ significantly from established standards. For B2B buyers, understanding these dynamics is crucial for making informed sourcing decisions that align with both their operational needs and market expectations.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a central theme in the continuous hinge sector, driven by both regulatory pressures and consumer preferences for environmentally friendly products. Buyers are increasingly scrutinizing the environmental impact of their purchases, focusing on suppliers who adopt sustainable practices. This includes sourcing materials with lower carbon footprints and employing energy-efficient manufacturing processes.

Ethical supply chains are also gaining prominence. B2B buyers from regions like Africa and South America are particularly sensitive to issues related to labor practices and environmental stewardship. Engaging with suppliers who can demonstrate compliance with international labor standards and sustainability certifications is essential for mitigating risks and enhancing brand reputation.

When sourcing continuous hinges, buyers should look for products that feature ‘green’ certifications, such as ISO 14001 for environmental management or certifications related to recycled materials. Utilizing sustainable materials, such as recycled steel or eco-friendly coatings, not only reduces environmental impact but can also appeal to a growing base of environmentally conscious consumers.

Brief Evolution/History

The evolution of continuous hinges dates back to their original use in pianos, where they served as a reliable mechanism for supporting the heavy lids of these instruments. Over time, the versatility of continuous hinges led to their adoption in a wide range of applications, from furniture to industrial machinery. This historical context underscores the hinge’s adaptability and its importance in various industries today.

In recent years, advancements in manufacturing techniques have enabled the production of continuous hinges that meet diverse and demanding specifications. The ability to customize hinges for specific applications has become a standard expectation among B2B buyers, ensuring that the products not only perform well but also align with aesthetic and functional requirements. Understanding this evolution helps buyers appreciate the value and potential of continuous hinges in their own operations.

Related Video: How Global Trade Runs on U.S. Dollars | WSJ

Frequently Asked Questions (FAQs) for B2B Buyers of continous hinge

-

What should I consider when vetting suppliers for continuous hinges?

When vetting suppliers, focus on their experience and reputation in the industry. Check for certifications like ISO 9001, which indicates a quality management system. Look for customer reviews and case studies that demonstrate successful projects. Also, consider their ability to customize products according to your specifications, as well as their capacity to handle bulk orders. Engage directly with potential suppliers to assess their responsiveness and willingness to communicate effectively. -

Can continuous hinges be customized to fit specific applications?

Yes, continuous hinges can be highly customized to meet specific application needs. You can specify dimensions, materials, finishes, and hole patterns to ensure compatibility with your designs. Many manufacturers offer services such as hole punching, bending, and cutting to tailor the hinges precisely for your requirements. Providing detailed specifications and technical drawings will help suppliers understand your needs better, ensuring a more accurate product. -

What are the typical minimum order quantities (MOQs) and lead times for continuous hinges?

Minimum order quantities for continuous hinges can vary significantly based on the supplier and the complexity of customization. Generally, MOQs range from 100 to 500 units. Lead times also depend on the supplier’s production capacity and your order size, often ranging from 2 to 8 weeks. It’s advisable to confirm these details during initial discussions to manage your project timelines effectively. -

What payment terms should I expect when sourcing continuous hinges internationally?

Payment terms can vary widely among suppliers and regions. Common practices include a deposit (usually 30-50%) upfront, with the balance due upon shipment or delivery. Some suppliers may offer net payment terms, depending on your creditworthiness and relationship history. Always clarify payment methods accepted, such as wire transfers or letters of credit, and ensure you understand any additional fees related to international transactions.

Illustrative Image (Source: Google Search)

-

How can I ensure quality assurance and certifications for continuous hinges?

To ensure quality, request samples from potential suppliers before placing a bulk order. Confirm that the supplier adheres to international quality standards and possesses relevant certifications, such as ISO or ASTM standards for materials. Additionally, inquire about their quality control processes, including testing methods and inspection protocols. A reputable supplier should be willing to provide documentation and assurance regarding the quality of their products. -

What logistics considerations should I keep in mind when importing continuous hinges?

Logistics is crucial when importing continuous hinges. Assess shipping options that best suit your budget and timeline, considering factors like freight costs, customs duties, and delivery times. Work with suppliers who have experience in international shipping to ensure compliance with local regulations. It’s also advisable to use a reliable logistics partner to manage the complexities of customs clearance and ensure timely delivery. -

How should I handle disputes with suppliers regarding continuous hinges?

To handle disputes effectively, maintain clear and open communication with your supplier from the outset. Document all agreements, specifications, and communications to serve as reference points in case of issues. If a dispute arises, approach it professionally by discussing the problem directly with the supplier. If resolution is not possible, consider mediation or arbitration as a means of resolving conflicts without resorting to litigation. -

What are the common applications for continuous hinges in various industries?

Continuous hinges are versatile and used across multiple industries. Common applications include industrial machinery, toolboxes, storage lockers, and commercial vehicles. They are also employed in high-traffic environments such as schools and hospitals due to their durability and ability to distribute weight evenly. Understanding the specific needs of your industry will help you choose the right type of continuous hinge for your project, ensuring optimal performance and longevity.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for continous hinge

In conclusion, continuous hinges present a robust solution for various applications, offering unparalleled strength, durability, and aesthetic appeal. For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, strategic sourcing of these hinges can lead to significant cost savings and improved operational efficiency. Understanding the diverse range of materials, customization options, and applications is essential in selecting the right hinge that meets specific requirements.

Moreover, the ability to customize continuous hinges based on dimensions, hole configurations, and finishes enables businesses to tailor solutions that enhance product functionality and longevity. It is crucial for buyers to engage with reputable manufacturers who can provide comprehensive support, including prototyping and inventory management.

As the market for continuous hinges continues to evolve, embracing innovative designs and sustainable materials will be key to maintaining a competitive edge. International buyers should proactively seek partnerships with suppliers who prioritize quality, customization, and reliability. By doing so, they can ensure that their projects are equipped with the best possible hardware, paving the way for success in a global marketplace.