Your Ultimate Guide to Sourcing Diamond Mesh

Introduction: Navigating the Global Market for diamond mesh

As the global demand for versatile construction and design solutions continues to rise, diamond mesh has emerged as a critical material for various applications across industries. Known for its distinctive diamond-shaped apertures, this innovative wire mesh is not only a staple for security fencing and architectural features but also serves as a robust option for infill panels and safety barriers. For international B2B buyers from Africa, South America, the Middle East, and Europe, understanding the nuances of diamond mesh is essential for making informed sourcing decisions that align with project requirements and market trends.

This comprehensive guide delves into the multifaceted world of diamond mesh, covering key aspects such as types of mesh, material specifications, manufacturing processes, and quality control standards. Buyers will gain insights into the latest market trends, supplier options, and pricing strategies, ensuring they can navigate the complexities of sourcing effectively.

By equipping buyers with actionable knowledge, this guide empowers them to evaluate their needs accurately, select the appropriate materials, and optimize their procurement strategies. Whether you are looking for high-security solutions or aesthetic designs, understanding diamond mesh will enable you to enhance your projects while maximizing value and performance.

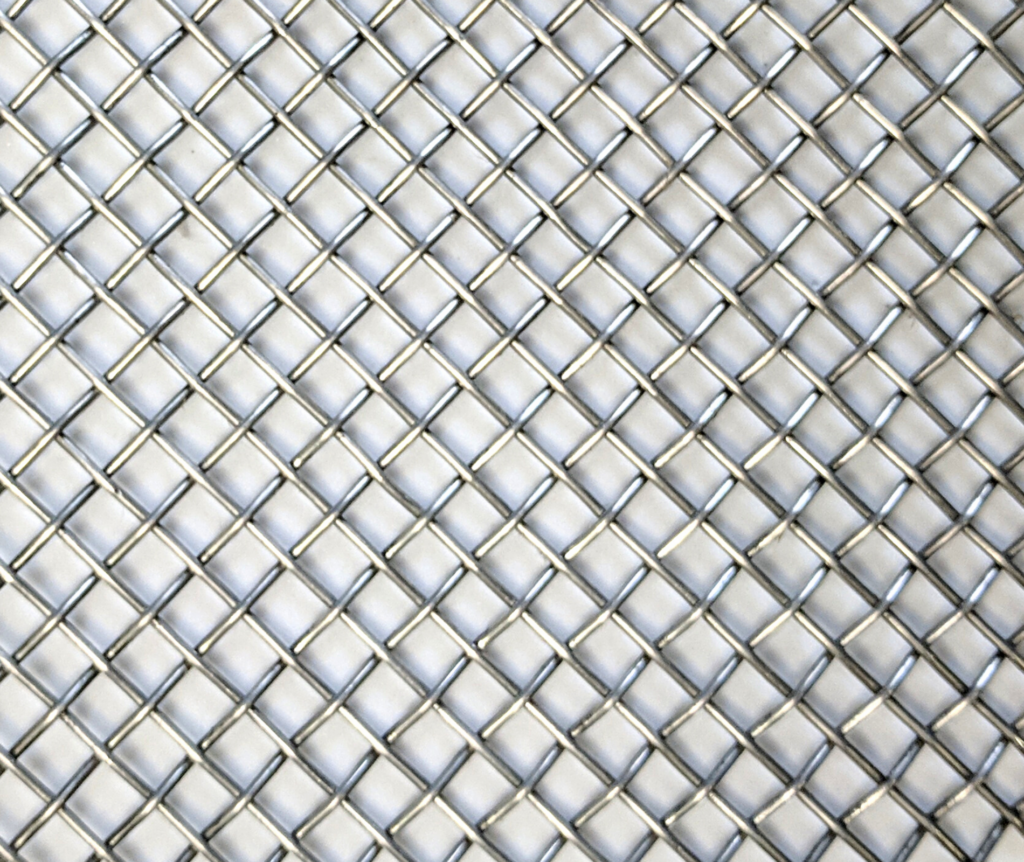

Illustrative Image (Source: Google Search)

Understanding diamond mesh Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Woven Diamond Mesh | Flexible, inter-crimp weave style, customizable aperture size | Fencing, window guards, decorative applications | Pros: Versatile, adaptable to surfaces; Cons: Less rigid than welded mesh. |

| Welded Diamond Mesh | Rigid construction, fuses wires at intersections | High-security fencing, industrial applications | Pros: Enhanced strength and stability; Cons: Limited flexibility. |

| Stainless Steel Mesh | Corrosion-resistant, durable, maintains structural integrity | Food processing, chemical plants, architectural uses | Pros: Long-lasting, hygienic; Cons: Higher upfront cost. |

| Galvanized Steel Mesh | Coated with zinc for corrosion resistance | Outdoor fencing, agricultural applications | Pros: Cost-effective, suitable for outdoor use; Cons: May be less durable in harsh environments. |

| PVC-Coated Diamond Mesh | Plastic coating for added protection and color options | Residential fencing, decorative panels | Pros: Aesthetic appeal, weather resistant; Cons: Coating may wear off over time. |

Woven Diamond Mesh

Woven diamond mesh is characterized by its flexible inter-crimp weave style, allowing it to adapt to various surfaces and applications. This type is particularly suitable for fencing, window guards, and decorative installations. When considering woven diamond mesh, buyers should evaluate the required flexibility, as it can conform to uneven surfaces. Additionally, customization options for aperture size and wire gauge can enhance its suitability for specific projects, making it a versatile choice.

Welded Diamond Mesh

Welded diamond mesh is known for its rigid construction, where wires are fused at their intersections, providing enhanced strength and stability. This type is ideal for high-security fencing and industrial applications where durability is crucial. Buyers should consider the specific security needs of their projects, as welded mesh is less flexible than woven options. Its structural integrity makes it suitable for load-bearing applications, although it may not accommodate irregular surfaces as effectively.

Stainless Steel Mesh

Stainless steel diamond mesh offers superior corrosion resistance and durability, making it an excellent choice for environments such as food processing and chemical plants. This type maintains its structural integrity over time, ensuring longevity and hygienic conditions. B2B buyers should weigh the higher upfront costs against the long-term benefits of reduced maintenance and replacement needs. Its applications extend to architectural uses, where aesthetic appeal meets functionality.

Galvanized Steel Mesh

Galvanized steel diamond mesh features a zinc coating that provides corrosion resistance, making it suitable for outdoor fencing and agricultural applications. This type is cost-effective and widely used in various sectors due to its balance of durability and affordability. Buyers should consider the environmental conditions in which the mesh will be used, as its lifespan may be affected by harsh weather. While it is generally durable, it may not perform as well in extreme conditions compared to stainless steel options.

PVC-Coated Diamond Mesh

PVC-coated diamond mesh combines the benefits of traditional wire mesh with a plastic coating that offers additional protection and aesthetic options. This type is commonly used in residential fencing and decorative panels, providing a colorful and weather-resistant solution. Buyers should assess the importance of appearance and environmental factors when selecting this type, as the coating can wear off over time. Its versatility and visual appeal make it a popular choice for less industrial applications, but durability should be considered in high-traffic or harsh environments.

Related Video: Denoising Diffusion Probabilistic Models | DDPM Explained

Key Industrial Applications of diamond mesh

| Industry/Sector | Specific Application of diamond mesh | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural Reinforcement | Enhances stability and load-bearing capacity of structures. | Material type (e.g., stainless steel), custom sizing, compliance with local building codes. |

| Agriculture | Animal Enclosures | Provides secure fencing for livestock, preventing escapes and protecting against predators. | Durability against weather elements, anti-corrosion features, and customization for specific animal types. |

| Security | Fencing and Barriers | Acts as a deterrent against trespassers and vandalism, enhancing site security. | Height and gauge requirements, resistance to cutting or climbing, and aesthetic considerations for visibility. |

| Manufacturing | Safety Guards and Cages | Protects workers from machinery hazards, ensuring compliance with safety regulations. | Compliance with safety standards, material strength, and ease of installation. |

| Architecture | Decorative Screens | Adds aesthetic appeal to buildings while providing functional separation or shading. | Design flexibility, material finish options, and environmental adaptability. |

Construction

In the construction industry, diamond mesh is primarily used for structural reinforcement. Its unique diamond-shaped apertures allow for a high strength-to-weight ratio, making it ideal for enhancing the stability and load-bearing capacity of various structures. International buyers should consider the material type, such as stainless steel for corrosion resistance, and ensure that the mesh complies with local building codes to avoid future complications.

Agriculture

In agriculture, diamond mesh serves as effective animal enclosures, providing secure fencing that prevents livestock from escaping and protects them from predators. This application is crucial for farmers seeking to safeguard their investments. Buyers in regions with varying climates, such as Africa and South America, must prioritize durability against weather elements and consider anti-corrosion features to ensure longevity.

Security

For security applications, diamond mesh is utilized in fencing and barriers to deter trespassers and vandalism. Its robust design provides a physical barrier that enhances site security, making it a popular choice for commercial properties and industrial sites. Key considerations for B2B buyers include the desired height and gauge of the mesh, resistance to cutting or climbing, and aesthetic factors that may affect visibility and deterrence effectiveness.

Manufacturing

In the manufacturing sector, diamond mesh is employed for safety guards and cages around machinery. This application is vital for protecting workers from potential hazards and ensuring compliance with safety regulations. Buyers should focus on materials that meet safety standards, assess the required strength for specific applications, and consider ease of installation to minimize downtime during setup.

Architecture

Architecturally, diamond mesh is used for decorative screens that enhance the aesthetic appeal of buildings while providing functional benefits such as shading or separation. This versatility makes it a favored choice among designers. Buyers should seek options that offer design flexibility, various material finishes, and the ability to adapt to environmental conditions, ensuring that the final product aligns with the project’s vision and practical requirements.

Related Video: Uses of Metals and Non Metals

Strategic Material Selection Guide for diamond mesh

When selecting diamond mesh for various applications, the choice of material is crucial to achieving optimal performance and longevity. Here, we analyze four common materials used in diamond mesh production, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Stainless Steel Wire

Key Properties:

Stainless steel wire offers excellent corrosion resistance, high tensile strength, and the ability to withstand extreme temperatures. It typically has a temperature rating of up to 800°C (1472°F) and is resistant to rust and oxidation.

Pros & Cons:

The durability of stainless steel makes it suitable for high-security applications and environments exposed to moisture or chemicals. However, it is more expensive than other materials, which can impact budget considerations. Manufacturing complexity is moderate, as it requires specialized equipment for weaving or welding.

Impact on Application:

Stainless steel diamond mesh is ideal for security fencing, architectural screens, and infill panels in environments where corrosion is a concern.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM A313 for stainless steel wire. They should also consider the availability of local suppliers to mitigate import costs.

Low-Carbon Steel Wire

Key Properties:

Low-carbon steel wire is characterized by its flexibility and strength, with a lower tensile strength compared to stainless steel. It is generally suitable for applications with less exposure to corrosive elements.

Pros & Cons:

This material is cost-effective, making it a popular choice for budget-sensitive projects. However, it is less durable in harsh environments and may require additional coatings for corrosion resistance. Manufacturing processes are straightforward, allowing for quick production.

Impact on Application:

Low-carbon steel diamond mesh is commonly used for temporary fencing, animal enclosures, and decorative applications where aesthetics are more important than longevity.

Considerations for International Buyers:

Buyers should be aware of local regulations regarding the use of low-carbon steel, particularly in outdoor applications. Compliance with standards like ASTM A824 can also be essential.

Aluminum-Alloy Wire

Key Properties:

Aluminum-alloy wire is lightweight, resistant to corrosion, and has a lower strength compared to steel. It performs well in applications where weight is a critical factor, with temperature ratings typically around 600°F (316°C).

Pros & Cons:

The main advantage of aluminum-alloy wire is its lightweight nature, making it easy to handle and install. However, its lower strength limits its use in high-security applications. Manufacturing is relatively simple, but the cost can be moderate depending on the alloy used.

Impact on Application:

Aluminum diamond mesh is often used in decorative applications, automotive grilles, and lightweight barriers where ease of installation is a priority.

Considerations for International Buyers:

Buyers should check for compliance with regional standards such as JIS H 4000 for aluminum alloy products. Additionally, they should consider the environmental impact of aluminum extraction and processing.

PVC-Coated Wire

Key Properties:

PVC-coated wire combines the strength of steel with a protective plastic layer, enhancing its resistance to corrosion and UV exposure. The coating can withstand temperatures up to 140°F (60°C) without degrading.

Pros & Cons:

The primary advantage of PVC-coated wire is its aesthetic appeal and enhanced corrosion resistance. However, the coating can wear off over time, especially in high-abrasion environments. The manufacturing process is more complex due to the additional coating step.

Impact on Application:

PVC-coated diamond mesh is commonly used in residential fencing, garden enclosures, and areas where visual appeal is important.

Considerations for International Buyers:

Buyers should ensure that the coating meets local environmental regulations, particularly concerning PVC disposal. Compliance with standards like ASTM D-2240 for coatings may also be necessary.

Summary Table

| Material | Typical Use Case for diamond mesh | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel Wire | Security fencing, architectural screens | Excellent corrosion resistance | Higher cost compared to alternatives | High |

| Low-Carbon Steel Wire | Temporary fencing, animal enclosures | Cost-effective | Less durable in harsh environments | Low |

| Aluminum-Alloy Wire | Decorative applications, automotive grilles | Lightweight and easy to install | Lower strength limits applications | Medium |

| PVC-Coated Wire | Residential fencing, garden enclosures | Aesthetic appeal and UV resistance | Coating can wear off over time | Medium |

This guide provides a comprehensive overview of the materials used in diamond mesh, equipping international B2B buyers with the insights needed to make informed purchasing decisions tailored to their specific needs and environments.

In-depth Look: Manufacturing Processes and Quality Assurance for diamond mesh

Diamond mesh is a versatile material utilized in various applications, from security fencing to decorative panels. Understanding its manufacturing processes and quality assurance protocols is crucial for international B2B buyers, especially those from diverse regions like Africa, South America, the Middle East, and Europe. This section will provide a detailed overview of the typical manufacturing stages, quality assurance standards, and actionable insights for ensuring reliable procurement.

Manufacturing Processes for Diamond Mesh

The production of diamond mesh typically involves four main stages: material preparation, forming, assembly, and finishing. Each stage plays a critical role in determining the final product’s quality and performance.

1. Material Preparation

The first step in manufacturing diamond mesh is selecting the appropriate materials. Common materials include:

- Stainless Steel: Known for its corrosion resistance and strength.

- Low-Carbon Steel: Often chosen for its cost-effectiveness.

- Aluminum Alloys: Ideal for lightweight applications.

- Copper and Brass: Preferred for aesthetic designs.

Once the material is selected, it undergoes processing, which may involve drawing the wire through dies to achieve the desired diameter. This ensures uniformity and consistency in the product.

2. Forming

In the forming stage, manufacturers employ two primary techniques: weaving and welding.

- Weaving: Involves interlacing wires to create the diamond pattern. This method offers flexibility, making it suitable for applications requiring adaptability to irregular surfaces.

- Welding: Involves fusing wires at their intersections using heat or electricity. This method produces a rigid and dimensionally stable mesh, which is advantageous for high-security or load-bearing applications.

3. Assembly

During assembly, the formed mesh is cut to size and prepared for any additional processing. Depending on customer specifications, this may include:

- Customization of aperture sizes

- Coating applications (e.g., PVC for weather resistance)

- Fabrication into specific shapes or panels

This stage ensures that the mesh meets the precise requirements of the intended application.

4. Finishing

The finishing stage enhances the mesh’s durability and aesthetic appeal. Common finishing processes include:

- Galvanization: Applying a zinc coating to prevent rust.

- Powder Coating: Providing a colored finish that also adds a layer of protection.

- Electropolishing: Improving the surface finish of stainless steel for enhanced corrosion resistance.

These finishing touches are critical for ensuring the longevity and functionality of diamond mesh in its application.

Quality Assurance for Diamond Mesh

Quality assurance (QA) is essential to ensure that diamond mesh meets international standards and customer expectations. Here are key aspects of the QA process:

International and Industry-Specific Standards

B2B buyers should be aware of various standards that govern the quality of diamond mesh:

- ISO 9001: This international standard focuses on quality management systems and is relevant for any manufacturer aiming to ensure consistent quality and customer satisfaction.

- CE Marking: Required for products sold in the European Economic Area, it signifies compliance with safety and environmental standards.

- API Standards: Relevant for diamond mesh used in oil and gas applications, ensuring that products meet the necessary safety and performance criteria.

Quality Control Checkpoints

The quality control process typically includes several checkpoints:

- Incoming Quality Control (IQC): Inspection of raw materials to ensure they meet specified requirements before production.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to detect any deviations from quality standards.

- Final Quality Control (FQC): Comprehensive testing of the finished product to confirm that it meets all required specifications.

Common Testing Methods

Testing methods for diamond mesh may include:

- Tensile Strength Testing: Evaluating the mesh’s ability to withstand pulling forces.

- Corrosion Resistance Testing: Assessing how well the material can resist rust and degradation.

- Dimensional Checks: Ensuring that the mesh dimensions meet specified tolerances.

Verifying Supplier Quality Control

For B2B buyers, verifying a supplier’s quality control measures is paramount. Here are actionable steps:

- Conduct Audits: Regular audits of suppliers can help assess their compliance with quality standards and manufacturing processes.

- Request Quality Reports: Ask suppliers for documentation of their quality control processes, including test results and certifications.

- Third-Party Inspections: Consider hiring third-party inspection services to evaluate the quality of the products before shipment. This is particularly useful for international transactions where trust in local suppliers may vary.

QC and Certification Nuances for International Buyers

International buyers should be aware of specific nuances regarding quality control and certifications:

- Regulatory Compliance: Different regions may have unique regulations regarding product safety and performance. Understanding these requirements is crucial for avoiding compliance issues.

- Cultural Expectations: Quality perceptions can differ across regions. Buyers from Europe may have different expectations than those from Africa or South America. Clear communication about quality standards is essential.

- Logistics Considerations: Ensure that quality control measures are in place not just at the manufacturing site but also during transportation to minimize risks of damage or degradation.

By understanding the manufacturing processes and quality assurance protocols for diamond mesh, international B2B buyers can make informed decisions, ensuring they procure products that meet their specific needs and standards. This knowledge is vital for establishing long-term partnerships with reliable suppliers and achieving successful project outcomes.

Related Video: The Production Planning Process

Comprehensive Cost and Pricing Analysis for diamond mesh Sourcing

When sourcing diamond mesh, understanding the comprehensive cost structure and pricing dynamics is crucial for B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. This section delves into the essential cost components, price influencers, and actionable buyer tips to optimize purchasing decisions.

Cost Components

-

Materials: The choice of material significantly impacts the overall cost of diamond mesh. Common materials include stainless steel, low-carbon steel, aluminum alloy, and galvanized steel. Stainless steel, while more expensive, offers superior corrosion resistance and durability, making it suitable for outdoor and high-security applications.

-

Labor: Labor costs can vary based on the complexity of the manufacturing process (weaving vs. welding) and the region of production. Skilled labor in regions with higher wages will increase costs, while automated processes may reduce labor costs but require significant initial investment.

-

Manufacturing Overhead: This includes utilities, maintenance, and indirect labor costs associated with production facilities. Efficient manufacturing practices can help mitigate overhead costs, which can be a significant component of the overall pricing structure.

-

Tooling: Initial tooling costs for custom designs or specifications can be substantial. These costs are often amortized over larger production runs, so higher volume orders can lead to lower per-unit tooling costs.

-

Quality Control (QC): Ensuring that the diamond mesh meets specific industry standards often incurs additional costs. Rigorous QC processes are essential for high-quality products, particularly for applications requiring certifications.

-

Logistics: Shipping costs can vary dramatically based on distance, transportation method, and volume. International buyers should consider Incoterms that define the responsibilities of buyers and sellers regarding shipping and delivery costs.

-

Margin: Suppliers will typically apply a profit margin to cover their costs and ensure profitability. This margin can vary based on competition, market demand, and the supplier’s positioning.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders generally lead to discounts due to economies of scale, so negotiating for higher volumes can yield cost savings.

-

Specifications/Customization: Customized specifications such as wire gauge, aperture size, and coatings can increase costs. Standard products are usually more economical, but tailored solutions might be necessary for specific applications.

-

Material Quality/Certifications: Higher-quality materials and those with specific certifications (e.g., ISO, ASTM) often command higher prices. Buyers should weigh the benefits of these certifications against the additional costs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their products but often provide better quality assurance and customer service.

-

Incoterms: Different Incoterms can impact the total landed cost. For instance, terms like DDP (Delivered Duty Paid) may lead to higher upfront costs but simplify logistics for the buyer.

Buyer Tips

-

Negotiate: Always negotiate pricing and terms with suppliers. Leveraging multiple quotes can provide a competitive edge and highlight the market rate for diamond mesh.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also long-term costs associated with maintenance, durability, and potential replacements. Investing in higher-quality products can lead to lower TCO.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, import duties, and tariffs that may affect pricing. It’s advisable to work with suppliers who understand the local market dynamics and can offer insights into cost structures.

-

Plan for Logistics: Factor in logistics costs in your total budget. Choose suppliers with efficient shipping practices or those located closer to your operations to minimize costs.

Disclaimer on Pricing

Prices for diamond mesh can vary widely based on the factors mentioned above. It is advisable for buyers to conduct market research and obtain multiple quotes to ensure they are receiving competitive pricing tailored to their specific needs and circumstances.

Spotlight on Potential diamond mesh Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘diamond mesh’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for diamond mesh

Understanding the essential technical properties and trade terminology related to diamond mesh is vital for international B2B buyers. This knowledge ensures informed purchasing decisions, optimizing project outcomes while managing costs and compliance.

Key Technical Properties of Diamond Mesh

-

Material Grade

– Definition: Refers to the type of material used in the construction of the diamond mesh, such as stainless steel, galvanized steel, aluminum, or copper.

– Importance: Different materials offer varying levels of durability, corrosion resistance, and aesthetic appeal. Choosing the right material grade is essential for ensuring longevity and suitability for specific environments. -

Aperture Size

– Definition: The clear space between the wires of the mesh, measured in millimeters or inches.

– Importance: Aperture size directly affects the mesh’s strength, visibility, and functionality. Smaller apertures may provide better security, while larger ones may be more appropriate for ventilation and visibility in architectural applications. -

Wire Gauge

– Definition: The thickness of the wire used in the mesh, usually measured in American Wire Gauge (AWG).

– Importance: A lower gauge number indicates a thicker wire, which generally offers greater strength and durability. Selecting the appropriate wire gauge is crucial for ensuring the mesh can withstand required loads and environmental conditions. -

Manufacturing Method

– Definition: The technique used to create the diamond mesh, either through weaving or welding.

– Importance: Each method imparts unique characteristics to the mesh. Woven mesh is more flexible, making it suitable for uneven surfaces, while welded mesh provides increased stability and strength, particularly in high-security applications. -

Coating Options

– Definition: Refers to any additional protective layer applied to the mesh, such as PVC, galvanization, or powder coating.

– Importance: Coatings enhance corrosion resistance, durability, and aesthetic qualities. Selecting the right coating can significantly impact maintenance needs and the mesh’s performance in specific environments. -

Tolerance

– Definition: The permissible limit of variation in a physical dimension of the mesh.

– Importance: Tolerance affects the fit and function of the mesh in its intended application. Understanding tolerance levels helps ensure compatibility with existing structures or components.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Buyers should understand whether they are sourcing from OEMs to ensure they are getting authentic products that meet specific quality and performance standards. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Understanding MOQ helps buyers assess whether a supplier meets their purchasing needs without incurring excessive costs or surplus inventory. -

RFQ (Request for Quotation)

– Definition: A formal document issued by a buyer to solicit price offers from suppliers.

– Relevance: Submitting an RFQ allows buyers to compare pricing and terms from multiple suppliers, facilitating better negotiation and decision-making. -

Incoterms (International Commercial Terms)

– Definition: A set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions.

– Relevance: Familiarity with Incoterms is crucial for understanding shipping responsibilities, risk transfer, and cost allocation between parties. -

Lead Time

– Definition: The time taken from placing an order to delivery.

– Relevance: Knowing lead times helps buyers plan their projects effectively, ensuring that materials arrive when needed to avoid delays. -

Certification Standards

– Definition: Industry-specific standards that products must meet to ensure quality and safety.

– Relevance: Buyers should verify that their diamond mesh products comply with relevant certification standards to meet regulatory requirements and ensure product reliability.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions, enhancing their procurement processes and project outcomes in the diamond mesh market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the diamond mesh Sector

Market Overview & Key Trends

The diamond mesh sector is experiencing significant growth driven by various global factors, including urbanization, infrastructure development, and rising security concerns. In regions such as Africa, South America, the Middle East, and Europe, the demand for versatile materials like diamond mesh is escalating. This material is increasingly utilized in applications ranging from construction and safety barriers to decorative elements in architecture.

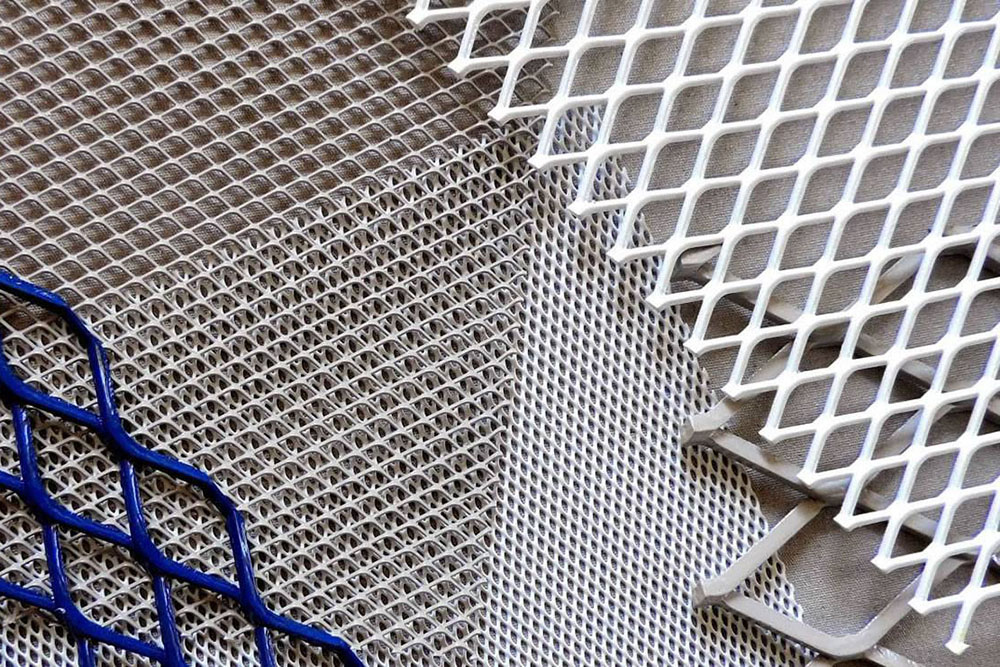

Illustrative Image (Source: Google Search)

Emerging trends in B2B sourcing include the integration of advanced technologies such as automation and digital supply chain management. These innovations enhance production efficiency, reduce lead times, and allow for real-time inventory management. Additionally, the shift towards e-commerce platforms for procurement is reshaping how international buyers engage with suppliers. Buyers can now access a broader range of products and manufacturers across continents, fostering competitive pricing and quality assurance.

Another critical market dynamic is the growing emphasis on customization. Buyers are increasingly seeking tailored solutions that meet specific project requirements, prompting manufacturers to adopt flexible production methods. This trend is particularly evident in sectors like construction and manufacturing, where bespoke diamond mesh can provide competitive advantages in both functionality and aesthetics.

Sustainability & Ethical Sourcing in B2B

The environmental impact of manufacturing processes is a pivotal concern for B2B buyers in the diamond mesh sector. As sustainability becomes a priority, businesses are urged to adopt environmentally friendly practices. This includes using sustainable materials and minimizing waste during production. Buyers should inquire about the materials used in diamond mesh, favoring options like recycled steel or aluminum, which not only reduce ecological footprints but also enhance brand reputation.

The importance of ethical supply chains cannot be overstated. International buyers are increasingly evaluating suppliers based on their adherence to ethical sourcing practices, including fair labor standards and responsible material sourcing. Certifications such as ISO 14001 for environmental management and Fair Trade certifications are becoming essential criteria for selecting suppliers. By prioritizing vendors with these certifications, businesses can ensure their diamond mesh products align with sustainability goals while also appealing to environmentally conscious consumers.

Brief Evolution/History

The development of diamond mesh can be traced back to the early 20th century, primarily within the construction and fencing industries. Initially, the material was used for basic applications, but advancements in manufacturing techniques, such as weaving and welding, have significantly enhanced its versatility and strength. Over the decades, as urbanization accelerated and security concerns grew, the application of diamond mesh expanded into various sectors, including agriculture, architecture, and industrial safety. Today’s diamond mesh is a refined product that balances durability, aesthetic appeal, and functionality, catering to a diverse range of international B2B needs.

In conclusion, understanding the market dynamics, sustainability imperatives, and historical context of diamond mesh is essential for international B2B buyers. By leveraging this knowledge, businesses can make informed decisions that align with their operational goals and ethical standards.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of diamond mesh

-

What should I consider when vetting suppliers for diamond mesh?

When vetting suppliers, focus on their experience, production capabilities, and reputation in the industry. Check for certifications such as ISO 9001, which indicates quality management practices. Request references from previous clients to assess reliability. Evaluate their responsiveness and customer service to ensure they can meet your needs. Additionally, consider the supplier’s location and logistical capabilities, as proximity may affect shipping times and costs. -

Can I customize my diamond mesh order?

Yes, many suppliers offer customization options for diamond mesh. You can specify wire gauge, aperture size, material type, and dimensions to meet your project requirements. When placing an order, clearly communicate your specifications and any unique needs. Some suppliers may have minimum order quantities (MOQs) for custom products, so verify these details upfront to avoid unexpected costs. -

What are the typical minimum order quantities (MOQs) and lead times for diamond mesh?

MOQs for diamond mesh can vary significantly by supplier and product type. Generally, MOQs can range from a few hundred square meters to several thousand, depending on the material and customization. Lead times also vary; standard products may ship within a few weeks, while custom orders could take longer. Always confirm these details with your supplier before placing an order to ensure they align with your project timelines. -

What quality assurance measures should I look for in a supplier?

Quality assurance is critical when sourcing diamond mesh. Look for suppliers that implement rigorous QA processes, including material inspections, dimensional checks, and performance testing. Ask for documentation of their quality control procedures and any relevant certifications. Additionally, inquire about their return policies and warranty offerings, as these can provide further assurance of product reliability. -

What certifications or standards should diamond mesh products meet?

Diamond mesh products should adhere to relevant industry standards, which may vary by region. Common certifications include ISO, ASTM, and EN standards, which indicate compliance with safety and performance criteria. Depending on your application, additional certifications related to corrosion resistance or environmental impact may also be important. Always request documentation to verify that the products meet these standards. -

How can I manage logistics and shipping for my diamond mesh order?

Effective logistics management is essential for timely delivery. Discuss shipping options with your supplier, including freight forwarders and customs clearance services. Consider the total cost of logistics, including shipping fees, import duties, and insurance. Establish clear timelines and track your shipment using the supplier’s tracking system. Additionally, ensure that the packaging is robust to prevent damage during transit. -

What should I do in case of a dispute with my supplier?

In case of a dispute, maintain open communication with your supplier to resolve the issue amicably. Review your contract to understand the terms and conditions regarding quality, delivery, and payment. Document all correspondence and evidence related to the dispute. If the matter cannot be resolved directly, consider mediation or arbitration as a next step. Having a clear dispute resolution clause in your contracts can also mitigate risks. -

Are there specific payment terms I should negotiate when sourcing diamond mesh?

Payment terms can significantly impact your cash flow. Common terms include deposits (often 30-50%) with the balance due upon delivery. Negotiate terms that allow for flexibility, such as payment upon inspection or extended payment periods for larger orders. Consider using letters of credit or escrow services for high-value transactions to protect both parties. Always ensure that payment terms are clearly outlined in the contract to avoid misunderstandings.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for diamond mesh

In conclusion, strategic sourcing of diamond mesh offers significant advantages for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. Understanding the diverse applications, manufacturing processes, and material properties of diamond mesh enables buyers to make informed decisions tailored to their specific needs. Key takeaways include the importance of assessing application requirements, material compatibility, and the total cost of ownership, which can greatly influence long-term performance and budgetary outcomes.

Moreover, leveraging relationships with reliable suppliers is crucial. Consignment inventory models, for instance, can enhance cash flow and reduce the risks associated with overstocking. As the demand for versatile and durable mesh solutions continues to grow, international buyers are encouraged to explore innovative sourcing strategies that align with their operational goals.

Looking ahead, the evolution of diamond mesh applications presents exciting opportunities for businesses ready to adapt to emerging market trends. By prioritizing strategic sourcing, B2B buyers can position themselves for success in a competitive landscape. Engage with trusted suppliers today to explore how diamond mesh can elevate your projects and drive your business forward.