Your Ultimate Guide to Sourcing Zip Lock Bag Plastic

Introduction: Navigating the Global Market for zip lock bag plastic

In an increasingly interconnected global marketplace, zip lock bag plastic has emerged as an essential component across diverse industries. From food preservation to pharmaceutical packaging, these versatile bags offer unparalleled convenience, security, and protection for a wide array of products. For international B2B buyers, particularly those operating in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of zip lock bag sourcing is critical for optimizing supply chains and ensuring product integrity.

This comprehensive guide serves as a vital resource, equipping buyers with in-depth insights into the various types of zip lock bags, including custom options, materials used, and manufacturing processes. It also delves into quality control measures that guarantee product safety and reliability, alongside a detailed analysis of leading suppliers and their offerings. Buyers will find valuable information regarding cost factors and market trends that influence purchasing decisions, as well as a dedicated FAQ section addressing common concerns.

By empowering informed sourcing decisions, this guide not only enhances operational efficiency but also fosters strategic partnerships with reputable manufacturers. In a landscape where quality and compliance are paramount, mastering the art of sourcing zip lock bag plastic can lead to significant competitive advantages and sustainable business growth.

Understanding zip lock bag plastic Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Polyethylene Zip Lock Bags | Made from low-density polyethylene (LDPE); flexible and durable. | Food packaging, medical supplies, electronics. | Pros: Cost-effective, moisture-resistant. Cons: Less eco-friendly; limited temperature resistance. |

| Polypropylene Zip Lock Bags | More rigid than polyethylene; transparent and has a glossy finish. | Retail packaging, industrial parts storage. | Pros: Higher clarity, better for display. Cons: Generally more expensive than polyethylene. |

| Biodegradable Zip Lock Bags | Made from plant-based materials; designed to decompose. | Eco-conscious brands, organic products. | Pros: Environmentally friendly, aligns with sustainability goals. Cons: Higher cost, may have shorter shelf life. |

| Tamper-Evident Zip Lock Bags | Features a seal that shows evidence of tampering; often used for security. | Pharmaceuticals, high-value item shipping. | Pros: Enhances security, builds consumer trust. Cons: Higher production costs; may not be necessary for all applications. |

| Custom Printed Zip Lock Bags | Offers branding opportunities with custom designs and sizes. | Marketing promotions, product launches. | Pros: Increases brand visibility, tailored solutions. Cons: Longer lead times, potentially higher costs. |

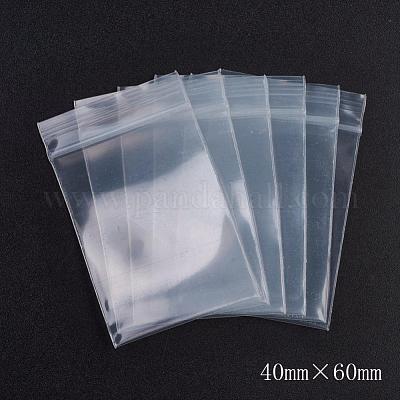

Polyethylene Zip Lock Bags

Polyethylene zip lock bags are the most common type, made from low-density polyethylene (LDPE). They are known for their flexibility and durability, making them suitable for a wide range of applications, including food packaging and medical supplies. When considering B2B purchases, buyers should note their cost-effectiveness and moisture resistance. However, they are less eco-friendly and have limited resistance to high temperatures, which may affect their suitability for certain products.

Illustrative Image (Source: Google Search)

Polypropylene Zip Lock Bags

Polypropylene zip lock bags are made from a more rigid plastic, offering a glossy finish and higher clarity than polyethylene. This makes them ideal for retail packaging and storing industrial parts, where visibility is crucial. B2B buyers should consider their aesthetic appeal and durability, but be aware that they typically come at a higher cost. Their rigidity can also limit flexibility compared to polyethylene options.

Biodegradable Zip Lock Bags

Biodegradable zip lock bags are manufactured from plant-based materials designed to decompose over time, appealing to eco-conscious brands. They are increasingly popular in markets focused on sustainability, particularly for organic products. While they align well with environmental goals, buyers should consider their higher cost and potentially shorter shelf life compared to traditional plastic bags, which may affect long-term storage solutions.

Tamper-Evident Zip Lock Bags

Tamper-evident zip lock bags include a seal that indicates whether the bag has been opened, making them essential for industries such as pharmaceuticals and high-value item shipping. These bags enhance security and build consumer trust, particularly in sensitive applications. However, buyers should factor in the higher production costs and assess whether the added security is necessary for their specific use case.

Custom Printed Zip Lock Bags

Custom printed zip lock bags offer businesses a way to enhance brand visibility through tailored designs and sizes. They are particularly useful for marketing promotions and product launches. While they can significantly elevate a brand’s presence, buyers must consider longer lead times and potentially higher costs associated with custom orders. These bags can create a unique customer experience but require careful planning and budgeting.

Key Industrial Applications of zip lock bag plastic

| Industry/Sector | Specific Application of zip lock bag plastic | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Packaging of perishable goods | Extends shelf life and ensures freshness | Compliance with FDA/USDA standards for food safety |

| Pharmaceuticals | Storage of medical supplies and samples | Maintains product integrity and safety | Must meet stringent health regulations and sterility |

| Electronics | Protection of small electronic components | Prevents moisture and dust contamination | Requirements for anti-static properties and durability |

| Agriculture | Packaging of seeds and fertilizers | Protects against moisture and pests | Need for UV resistance and durability in various climates |

| Retail and E-commerce | Organizing and shipping small items | Enhances customer experience through neat presentation | Custom sizing and branding options for market differentiation |

Food and Beverage

In the food and beverage industry, zip lock bags are essential for packaging perishable goods such as fruits, vegetables, and meats. These bags provide an airtight seal that helps extend the shelf life of products, ensuring freshness during transport and storage. For international buyers, especially from regions like Africa and South America, it’s crucial to source bags that comply with FDA and USDA standards to ensure food safety. Additionally, buyers should consider the bags’ thickness and material to meet specific storage needs.

Pharmaceuticals

Zip lock bags play a vital role in the pharmaceutical sector by securely storing medical supplies, samples, and medications. These bags help maintain product integrity by preventing contamination and exposure to external elements. International B2B buyers must ensure that the bags meet stringent health regulations, including sterility and safe material standards. Sourcing from manufacturers that provide certifications will be essential for compliance in various markets, particularly in the Middle East and Europe.

Electronics

In the electronics industry, zip lock bags are used to protect small components from moisture, dust, and static electricity. This application is critical for maintaining the functionality of sensitive electronic parts during storage and transport. Buyers from regions like Europe and Africa should prioritize sourcing bags with anti-static properties and durable materials to prevent damage. Custom sizes may also be necessary to accommodate various components, making it essential to partner with flexible manufacturers.

Agriculture

Zip lock bags are increasingly utilized in agriculture for packaging seeds and fertilizers, providing protection against moisture and pests. This application is particularly beneficial in tropical regions where humidity can affect product quality. Buyers should look for bags with UV resistance and durability to withstand varying climates. Sourcing from manufacturers that understand agricultural needs will ensure that the products meet local environmental conditions and regulatory requirements.

Retail and E-commerce

In the retail and e-commerce sectors, zip lock bags are commonly used for organizing and shipping small items, enhancing the customer experience through neat presentation. They allow businesses to offer a professional appearance while ensuring that products remain secure during transit. Buyers should consider custom sizing and branding options to differentiate their products in competitive markets. Additionally, ensuring that the bags are recyclable can align with sustainability goals, appealing to environmentally conscious consumers across Europe and the Middle East.

Related Video: How To Choose Size and Mil Reclosable ClearZip Plastic Bags

Strategic Material Selection Guide for zip lock bag plastic

When selecting materials for zip lock bags, it’s essential to consider the properties, advantages, and limitations of each material type. This analysis focuses on four common materials used in the manufacturing of zip lock bags: Low-Density Polyethylene (LDPE), High-Density Polyethylene (HDPE), Polypropylene (PP), and Biodegradable Plastics. Each material has unique characteristics that can significantly affect product performance and suitability for various applications.

Low-Density Polyethylene (LDPE)

Key Properties:

LDPE is known for its flexibility and toughness. It has a low melting point (approximately 105-115°C) and excellent resistance to impact and moisture. LDPE also demonstrates good chemical resistance, making it suitable for various applications.

Pros & Cons:

The primary advantages of LDPE include its low cost, ease of processing, and excellent sealing properties. However, it is less durable than other materials and can be prone to tearing under stress. Its lower temperature resistance may limit its use in high-heat applications.

Impact on Application:

LDPE is ideal for food storage and packaging due to its moisture barrier properties. It is also compatible with a wide range of products, including non-food items.

Considerations for International Buyers:

LDPE is widely accepted under various international standards, including ASTM and ISO. Buyers in regions like Europe and South America should ensure compliance with food safety regulations, especially for food-grade applications.

High-Density Polyethylene (HDPE)

Key Properties:

HDPE offers higher tensile strength and rigidity compared to LDPE, with a melting point of around 120-130°C. It provides excellent chemical resistance and is less permeable to moisture.

Pros & Cons:

The advantages of HDPE include its durability and resistance to impact, making it suitable for heavier items. However, it can be more expensive than LDPE and may require more complex manufacturing processes.

Impact on Application:

HDPE is often used for industrial applications and packaging that require strength and durability, such as medical supplies and electronic components.

Considerations for International Buyers:

HDPE complies with various global standards, including ASTM and DIN. Buyers from the Middle East and Africa should be aware of local regulations regarding plastic waste management and recycling.

Polypropylene (PP)

Key Properties:

Polypropylene is characterized by its high melting point (160-170°C) and excellent chemical resistance. It is also lightweight and has a good balance of flexibility and strength.

Pros & Cons:

PP’s advantages include its resistance to moisture and chemicals, making it suitable for a variety of applications. However, it can be more expensive than both LDPE and HDPE, and its manufacturing process can be more complex.

Impact on Application:

PP is often used for packaging that requires a high level of clarity and strength, such as medical and food applications. Its compatibility with various media makes it a versatile choice.

Considerations for International Buyers:

PP is compliant with FDA regulations for food contact, making it suitable for food packaging in Europe and North America. Buyers should verify compliance with local regulations in their respective regions.

Biodegradable Plastics

Key Properties:

Biodegradable plastics are designed to decompose more quickly than traditional plastics. They can be made from renewable resources and have varying properties depending on their formulation.

Pros & Cons:

The key advantage of biodegradable plastics is their reduced environmental impact. However, they can be more expensive and may not offer the same durability as conventional plastics.

Impact on Application:

These materials are suitable for environmentally conscious applications, such as food packaging and single-use items. Their compatibility with composting processes can enhance sustainability efforts.

Considerations for International Buyers:

Buyers from Europe and South America are increasingly favoring biodegradable options due to stringent environmental regulations. Compliance with local standards for biodegradability is essential.

Summary Table

| Material | Typical Use Case for zip lock bag plastic | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Low-Density Polyethylene (LDPE) | Food storage, general packaging | Low cost, excellent sealing properties | Less durable, lower temperature resistance | Low |

| High-Density Polyethylene (HDPE) | Industrial packaging, medical supplies | High strength, excellent chemical resistance | Higher cost, complex manufacturing | Med |

| Polypropylene (PP) | Food and medical packaging | High clarity and strength | More expensive, complex processing | High |

| Biodegradable Plastics | Environmentally-friendly packaging | Reduced environmental impact | Higher cost, potential durability issues | Med |

This strategic material selection guide provides international B2B buyers with a comprehensive overview of the key materials used in zip lock bag production, enabling informed decisions that align with their specific needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for zip lock bag plastic

Manufacturing Processes for Zip Lock Bag Plastic

The manufacturing of zip lock bags involves several critical stages to ensure the production of high-quality, durable products. Understanding these processes is essential for B2B buyers, particularly those sourcing from regions such as Africa, South America, the Middle East, and Europe.

Illustrative Image (Source: Google Search)

Main Stages of Manufacturing

-

Material Preparation

– Raw Material Selection: The primary materials used in zip lock bag production are polyethylene (PE) and polypropylene (PP). These materials are chosen for their flexibility, durability, and food-safe properties.

– Pelletizing: Raw plastic is processed into small pellets, which facilitate easier handling and melting in subsequent stages. -

Forming

– Extrusion: The plastic pellets are heated and melted, then extruded through a die to create thin sheets of plastic. This is a continuous process that ensures uniform thickness.

– Blown Film Process: In some cases, a blown film process is used, where air is blown into the extruded plastic to create a tubular shape, allowing for lightweight and flexible bags. -

Assembly

– Cutting and Sealing: The extruded sheets are cut into individual pieces. The zip lock mechanism is integrated by creating an interlocking closure, often through heat sealing or adhesive bonding.

– Printing and Customization: For branding purposes, many manufacturers offer custom printing options. This can be done using flexographic or digital printing techniques. -

Finishing

– Quality Control: After assembly, bags undergo a series of checks for defects, ensuring that only products meeting quality standards move forward.

– Packaging: Finished products are then packaged for shipment, often using eco-friendly practices to appeal to environmentally conscious buyers.

Quality Assurance in Zip Lock Bag Production

Quality assurance is paramount in the manufacturing of zip lock bags, especially given their applications in food packaging and sensitive materials. International B2B buyers must be familiar with the standards and practices that govern quality control in this sector.

Relevant International Standards

- ISO 9001: This is a widely recognized quality management standard that ensures manufacturers have consistent processes in place to meet customer requirements and enhance satisfaction.

- CE Marking: This indicates compliance with European health, safety, and environmental protection standards, essential for buyers in Europe.

- FDA and USDA Compliance: For bags intended for food contact, manufacturers must comply with FDA regulations in the U.S. and USDA standards for food safety.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– Raw materials are inspected upon arrival to ensure they meet specified standards. This includes checking for contamination and material integrity. -

In-Process Quality Control (IPQC)

– During the manufacturing process, regular checks are conducted to monitor parameters such as temperature, pressure, and thickness. This helps in identifying and correcting issues in real-time. -

Final Quality Control (FQC)

– Once production is complete, each batch of zip lock bags undergoes a thorough inspection for defects, functionality of the zip lock mechanism, and compliance with size specifications.

Common Testing Methods

- Physical Testing: This includes tensile strength tests to ensure the bags can withstand weight and pressure without breaking.

- Seal Integrity Tests: Ensures that the zip lock mechanism provides a reliable seal that is airtight and waterproof.

- Migration Testing: Particularly important for food-contact bags, this test assesses the migration of substances from the plastic into food items.

Verifying Supplier Quality Control

For international B2B buyers, especially those from diverse regions, verifying a supplier’s quality assurance processes is critical. Here are some actionable steps to consider:

-

Supplier Audits

– Conduct regular audits of potential suppliers to assess their manufacturing processes, quality control measures, and compliance with international standards. This can be done in person or through third-party services. -

Quality Reports

– Request detailed quality assurance reports from suppliers. These should outline their processes, testing results, and compliance with relevant standards.

-

Third-Party Inspections

– Engage third-party inspection agencies to evaluate the manufacturing facilities and processes. This adds an additional layer of verification and assurance. -

Certifications and Accreditations

– Check for certifications that demonstrate compliance with international standards (e.g., ISO, CE). This can be a reliable indicator of a supplier’s commitment to quality.

QC Nuances for International B2B Buyers

Understanding the specific quality control nuances is essential for B2B buyers from Africa, South America, the Middle East, and Europe. Consider the following:

- Cultural and Regulatory Differences: Be aware that regulations and quality expectations can vary significantly between regions. Familiarize yourself with local standards that may affect product acceptance.

- Communication: Ensure clear communication with suppliers regarding quality expectations and standards. Language barriers can sometimes complicate this, so using detailed specifications and visual aids can help.

- Sustainability Practices: Increasingly, buyers are looking for suppliers that adhere to sustainable practices. Inquire about the environmental impact of manufacturing processes and the recyclability of the products.

By understanding the manufacturing processes and quality assurance protocols for zip lock bags, international B2B buyers can make informed decisions, ensuring they source high-quality products that meet their operational needs.

Related Video: Plastic Bag Mass Production Factory in Korea. Plastic Bag Manufacturing Process.

Comprehensive Cost and Pricing Analysis for zip lock bag plastic Sourcing

When sourcing zip lock bags, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis provides insights into the various cost components, price influencers, and practical tips for negotiating favorable terms, particularly for buyers from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary cost driver in zip lock bag production is the raw materials, typically polyethylene or polypropylene. The type and quality of plastic significantly affect the price. For instance, eco-friendly or food-grade materials may incur higher costs.

-

Labor: Labor costs vary by region, influenced by local wage standards and the complexity of the manufacturing process. Countries with lower labor costs can offer competitive pricing but may also affect quality.

-

Manufacturing Overhead: This encompasses utilities, maintenance, and facility costs. Efficient production facilities often lead to lower overhead costs, which can be passed on to buyers.

-

Tooling: The initial investment in molds and machinery for production can be substantial, especially for custom sizes or designs. This cost is typically amortized over large production runs, making it less significant per unit at higher volumes.

-

Quality Control (QC): Ensuring that products meet specified standards incurs additional costs. Manufacturers often include QC processes to comply with FDA or USDA regulations, which can raise the price but ensures reliability.

-

Logistics: Shipping and handling costs are critical, particularly for international buyers. Factors such as distance, shipping method, and Incoterms (e.g., FOB, CIF) impact these costs significantly.

-

Margin: Suppliers typically add a profit margin that can range from 10% to 30%, depending on their market positioning and competitive landscape.

Price Influencers

-

Volume/MOQ: Manufacturers often have minimum order quantities (MOQs) that can significantly affect pricing. Larger orders typically result in lower per-unit costs due to economies of scale.

-

Specifications/Customization: Custom sizes, colors, or printed logos can lead to increased costs. Buyers should weigh the benefits of customization against potential price increases.

-

Materials: As mentioned, the choice of materials plays a crucial role in pricing. Sustainable or specialized materials command higher prices but may appeal to environmentally conscious consumers.

-

Quality/Certifications: Products that meet specific quality standards (e.g., FDA-approved) often come at a premium. Buyers should consider the importance of these certifications relative to their market requirements.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established manufacturers may charge more due to their proven track record.

-

Incoterms: Understanding Incoterms is vital for pricing. Different terms can shift responsibilities and costs between the buyer and seller, affecting the overall price.

Buyer Tips

-

Negotiate: Leverage volume commitments to negotiate better pricing. Suppliers are often willing to adjust prices for larger orders or long-term contracts.

-

Cost-Efficiency: Analyze the total cost of ownership, including procurement, shipping, and storage costs. Sometimes a lower initial price may lead to higher overall expenses.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, European suppliers may have higher labor costs compared to manufacturers in Africa or South America, impacting price negotiations.

-

Research Suppliers: Conduct thorough research on potential suppliers, focusing on their reputation, product quality, and service reliability. This can help in securing better terms and pricing.

-

Understand Market Trends: Stay informed about market trends in raw materials and production technologies, as these can affect pricing dynamics over time.

Disclaimer

Prices for zip lock bags can fluctuate based on market conditions, material availability, and geopolitical factors. Always request updated quotes and conduct due diligence before making purchasing decisions.

Spotlight on Potential zip lock bag plastic Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘zip lock bag plastic’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for zip lock bag plastic

Key Technical Properties of Zip Lock Bag Plastic

Understanding the essential technical properties of zip lock bags is crucial for international B2B buyers, particularly when sourcing products that meet specific operational needs. Here are some critical specifications to consider:

-

Material Grade: The most common materials used for zip lock bags are Polyethylene (PE) and Polypropylene (PP). PE bags are typically more flexible and have good moisture resistance, making them ideal for food storage. PP bags, on the other hand, offer higher clarity and strength, which is beneficial for packaging non-food items. Selecting the right material grade ensures that the bags are suitable for their intended use and comply with safety regulations.

-

Thickness: Measured in mils (one mil equals 0.001 inches), the thickness of a zip lock bag impacts its durability and usability. Common thicknesses range from 2 mils (lightweight) to 6 mils (heavy-duty). A thicker bag generally provides better protection against punctures and tears, which is especially important for industrial applications. Buyers should assess the required thickness based on the contents being stored or transported.

-

Tolerance: This refers to the allowable variation in dimensions of the bags. For instance, a zip lock bag may be specified as 10″ x 12″ with a tolerance of ±0.5″. Tighter tolerances are essential for applications requiring precise measurements, such as in packaging machinery. Understanding tolerance is critical for ensuring compatibility with existing systems and minimizing waste.

-

Seal Strength: The effectiveness of the zip lock mechanism is paramount for maintaining the integrity of the bag’s contents. Seal strength is typically evaluated in terms of peel strength and burst strength. High peel strength ensures the bag remains securely closed, while burst strength indicates how much internal pressure the bag can withstand without breaking. Buyers should prioritize bags with high seal strength for applications involving liquids or sensitive materials.

-

Temperature Resistance: Zip lock bags can be exposed to varying temperatures, especially in food storage or shipping scenarios. The temperature resistance of the material determines its suitability for specific applications. For example, some bags are designed to withstand freezing temperatures, while others can tolerate higher heat for microwave use. Knowing the temperature resistance helps buyers select the right product for their needs.

Common Trade Terms in Zip Lock Bag Procurement

Navigating the procurement process requires familiarity with specific industry jargon. Here are some common trade terms relevant to zip lock bags:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or products that are used in another company’s end product. For zip lock bags, an OEM might manufacture bags that are then branded and sold by a retailer. Understanding OEM relationships can help buyers identify sourcing opportunities and ensure product quality.

-

MOQ (Minimum Order Quantity): This is the smallest number of units a supplier is willing to sell in a single order. MOQs can vary significantly between manufacturers, impacting purchasing decisions. Buyers should evaluate their needs against MOQs to manage inventory effectively and avoid overstocking.

-

RFQ (Request for Quotation): An RFQ is a document issued by buyers to suppliers asking for price quotes for specific products or services. For zip lock bags, an RFQ would detail specifications such as size, material, and quantity. This process helps buyers compare options and negotiate better terms.

-

Incoterms (International Commercial Terms): These are a series of pre-defined commercial terms published by the International Chamber of Commerce, which define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, insurance, and risk management, crucial for effective supply chain management.

-

Lead Time: This refers to the amount of time it takes from placing an order until it is received. Understanding lead times is essential for inventory planning and ensuring timely delivery of zip lock bags to meet production schedules or market demands.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring they select the right zip lock bags that meet their operational and compliance needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the zip lock bag plastic Sector

Market Overview & Key Trends

The global market for zip lock bags is witnessing significant growth, driven by rising demand across various sectors such as food packaging, pharmaceuticals, and consumer goods. Key trends shaping this market include the increasing adoption of customized packaging solutions, as businesses look to enhance brand visibility and meet specific consumer needs. Furthermore, the shift towards e-commerce is propelling demand for zip lock bags, which are favored for their convenience and ability to protect products during transit.

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of the technological advancements in production processes. Innovations such as automated manufacturing and advanced sealing technologies are improving product quality and reducing costs. Additionally, the emergence of digital platforms for sourcing and procurement is transforming traditional supply chains, enabling buyers to easily compare suppliers and negotiate terms.

Market dynamics are also influenced by regional economic factors. For example, in Europe, stringent regulations regarding plastic use are pushing manufacturers to innovate towards sustainable alternatives. Conversely, in Africa and South America, the growing middle class and urbanization are driving demand for packaged goods, leading to an uptick in zip lock bag utilization. Buyers should stay informed about these regional trends to tailor their sourcing strategies effectively.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration in the zip lock bag sector, as environmental concerns over plastic waste intensify. B2B buyers must recognize the importance of ethical sourcing—selecting suppliers who prioritize eco-friendly practices and materials. Recyclable and biodegradable options are increasingly available, allowing businesses to reduce their carbon footprint while still meeting packaging needs.

Buyers should look for suppliers that offer green certifications such as FSC (Forest Stewardship Council) or ISO 14001, which indicate compliance with environmental management standards. Additionally, sourcing from manufacturers that utilize post-consumer recycled (PCR) materials can further enhance sustainability efforts.

Incorporating sustainable practices not only meets consumer expectations but also mitigates potential regulatory risks, especially in regions like Europe where regulations around plastic use are tightening. By prioritizing sustainability in their sourcing strategies, businesses can enhance their brand reputation and appeal to environmentally conscious consumers.

Brief Evolution/History

The zip lock bag, originally developed in the 1960s, has evolved from a simple food storage solution to a versatile packaging option used across various industries. Initially, these bags were designed for home use, but over the decades, their applications expanded dramatically. The introduction of more durable materials and improved sealing technologies in the 1980s and 1990s enabled manufacturers to cater to industrial needs, including medical and electronic packaging. Today, the focus on sustainability and customization continues to drive innovation, making zip lock bags an essential component of modern packaging solutions for international B2B buyers.

Related Video: Specialization and Trade: Crash Course Economics #2

Frequently Asked Questions (FAQs) for B2B Buyers of zip lock bag plastic

-

How can I effectively vet suppliers of zip lock bags?

When vetting suppliers, start by checking their certifications and compliance with international standards such as ISO, FDA, and USDA. Look for reviews or testimonials from previous clients, especially those in your region. Consider requesting samples to assess product quality and durability. Engage in direct communication to gauge responsiveness and professionalism. If possible, visit the supplier’s facility or utilize third-party inspection services to ensure they meet your requirements before placing a bulk order. -

Can I customize my zip lock bags?

Yes, many manufacturers offer customization options for zip lock bags, including size, thickness, color, and printing. When negotiating customization, provide clear specifications and artwork files. Understand the limitations of the materials and processes used, as this can impact cost and lead times. Additionally, inquire about minimum order quantities (MOQ) for custom products, as these may vary significantly between suppliers. -

What are the typical minimum order quantities (MOQs) and lead times?

MOQs for zip lock bags can vary widely based on the supplier and product specifications. On average, you may find MOQs ranging from 1,000 to 10,000 units for standard products. Custom orders typically require higher MOQs. Lead times can also vary; expect 2 to 4 weeks for standard products and longer for customized bags. Always confirm these details with your supplier to align your production schedule with your supply chain needs. -

What payment methods are commonly accepted by suppliers?

Most suppliers accept various payment methods, including bank transfers, credit cards, and PayPal. For large orders, consider using a letter of credit to protect your investment. Discuss payment terms early in the negotiation process to avoid misunderstandings. Be wary of suppliers requesting full payment upfront, especially if they lack a strong reputation; a deposit followed by payment upon delivery can be a safer approach. -

What quality assurance processes should suppliers have in place?

Quality assurance (QA) is critical when sourcing zip lock bags. Look for suppliers who conduct regular quality checks throughout the manufacturing process, including raw material inspections and final product testing. Request documentation of their QA procedures and any certifications that demonstrate compliance with safety and quality standards. Additionally, consider establishing a mutual agreement for third-party inspections before shipment to ensure the products meet your expectations. -

How can I handle disputes with suppliers?

To handle disputes effectively, maintain clear and open communication with your supplier. Document all agreements and communications to provide a reference point during conflicts. If issues arise, first attempt to resolve them amicably through dialogue. If a resolution cannot be reached, refer to the terms outlined in your contract regarding dispute resolution methods, such as mediation or arbitration. Having a clear understanding of these processes can help mitigate risks in international trade. -

What logistics considerations should I be aware of?

When sourcing zip lock bags internationally, consider shipping options, costs, and delivery times. Discuss logistics with your supplier to determine who is responsible for shipping arrangements and customs clearance. Understand the implications of Incoterms (International Commercial Terms) that define responsibilities in the shipping process. Additionally, factor in potential tariffs and duties that may apply to your imports, as these can significantly affect overall costs. -

What certifications should I look for when sourcing food-safe zip lock bags?

For food-safe zip lock bags, ensure your supplier holds certifications such as FDA approval for food contact, USDA organic certification, and any relevant local food safety standards. These certifications confirm that the materials used are safe for food storage and handling. Request documentation to verify these certifications and inquire about the supplier’s compliance with GMP (Good Manufacturing Practices) to ensure a high standard of quality and safety in their production processes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for zip lock bag plastic

Strategic sourcing in the zip lock bag plastic sector is pivotal for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. As the demand for sustainable and efficient packaging solutions continues to rise, aligning with manufacturers who prioritize quality, compliance, and environmental responsibility is essential. Buyers should leverage the diverse range of suppliers available, focusing on those that offer custom solutions to meet specific needs and market trends.

Key takeaways include the importance of evaluating suppliers based on their certifications, such as FDA and USDA approvals, and their commitment to sustainability. Engaging with manufacturers that provide eco-friendly options not only enhances brand reputation but also aligns with global shifts towards greener practices.

Looking ahead, the zip lock bag market is poised for growth as industries recognize the value of versatile packaging solutions. Buyers are encouraged to remain proactive in their sourcing strategies, exploring partnerships that can offer innovation and flexibility. By doing so, they will not only enhance operational efficiency but also position themselves at the forefront of a rapidly evolving marketplace. Engage with suppliers today to secure a competitive advantage in the future of packaging.