Your Ultimate Guide to Sourcing Heating Element

Introduction: Navigating the Global Market for heating element

Navigating the global market for heating elements requires a strategic approach, particularly for B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe. Heating elements are critical components in numerous applications, from industrial heating systems to household appliances, playing a vital role in energy efficiency and operational effectiveness. Understanding the intricacies of this market is essential for informed decision-making.

This comprehensive guide delves into various facets of heating elements, including the types available—such as resistive, induction, and radiant heating elements—and the materials commonly used, including metal, ceramic, and polymer options. We will explore manufacturing and quality control processes, ensuring that buyers are equipped to assess supplier reliability and product integrity.

Moreover, this guide provides insights into supplier landscapes, helping international buyers identify reputable manufacturers and distributors. Cost considerations are also addressed, offering a detailed analysis of pricing factors that can influence procurement strategies.

Additionally, we answer frequently asked questions (FAQs) to clarify common uncertainties in the heating element market. By utilizing this guide, B2B buyers will empower themselves to make informed sourcing decisions, ensuring that they not only meet their operational needs but also capitalize on opportunities for innovation and cost savings in their respective markets.

Understanding heating element Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Resistive Heating Elements | Simple design, high efficiency, low cost | Industrial ovens, toasters, heaters | Pros: Cost-effective, easy to use. Cons: Limited lifespan, less efficient at higher temperatures. |

| Induction Heating Elements | Uses electromagnetic fields for heating | Metalworking, cooking appliances | Pros: Fast heating, energy-efficient. Cons: Requires compatible cookware, higher initial cost. |

| Ceramic Heating Elements | High thermal stability, even heat distribution | Space heaters, electric stoves | Pros: Durable, safe operation. Cons: Slower heating time, can be expensive. |

| Infrared Heating Elements | Direct heat transfer, instant warmth | Drying processes, heating in greenhouses | Pros: Quick heating, energy-efficient. Cons: Limited range, higher upfront cost. |

| Fired Heaters | Combustion-based heating, robust design | Oil refineries, chemical processing | Pros: High efficiency, suitable for large-scale operations. Cons: Environmental regulations, higher maintenance. |

Resistive Heating Elements

Resistive heating elements are among the most common types used in various applications. They operate by converting electrical energy into heat through resistance. These elements are ideal for applications requiring consistent and direct heat, such as in industrial ovens and toasters. When considering a purchase, buyers should evaluate the operational costs, as these elements can have a shorter lifespan and may become less efficient at higher temperatures.

Induction Heating Elements

Induction heating elements utilize electromagnetic fields to generate heat directly in conductive materials. This method provides fast and efficient heating, making it popular in metalworking and cooking appliances. Buyers should consider the compatibility of their existing equipment with induction technology, as it often requires specific materials for optimal performance. While the initial investment may be higher, the energy savings can justify the cost over time.

Ceramic Heating Elements

Ceramic heating elements are known for their high thermal stability and even heat distribution. They are frequently used in space heaters and electric stoves. One of the key advantages of ceramic elements is their durability, which can lead to lower replacement costs over time. However, they may have slower heating times and can be more expensive than other types. Buyers should assess their heating needs and budget when considering these options.

Infrared Heating Elements

Infrared heating elements provide direct heat transfer, offering instant warmth without heating the surrounding air. They are commonly used in drying processes and in applications like greenhouses where quick heating is essential. While they are energy-efficient and provide rapid heating, their effectiveness can be limited by distance. Buyers should weigh the benefits of quick heating against the potential higher upfront costs.

Fired Heaters

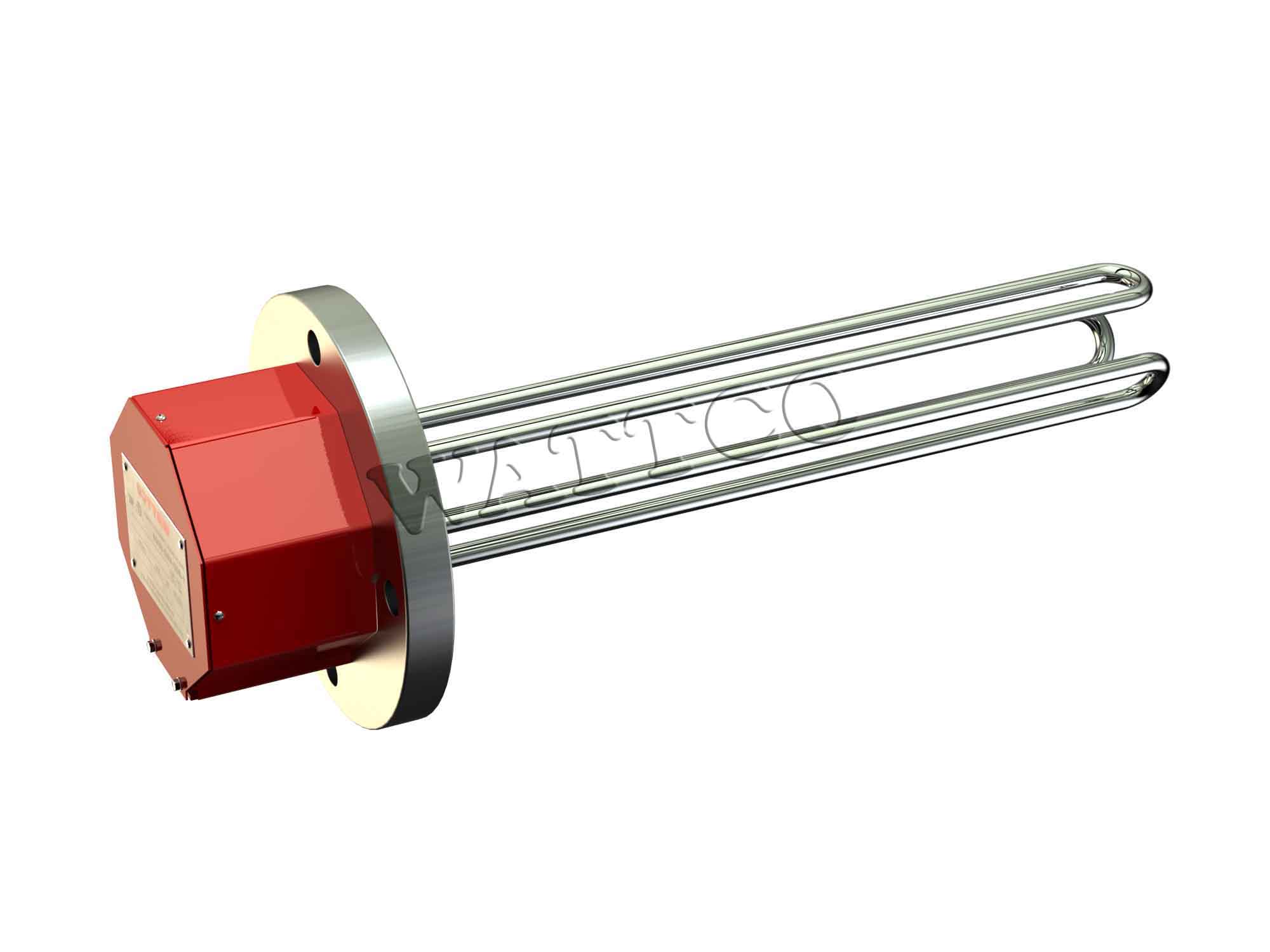

Fired heaters rely on combustion to generate heat and are designed for robust industrial applications, such as in oil refineries and chemical processing plants. These systems are highly efficient for large-scale operations but come with considerations regarding environmental regulations and maintenance requirements. Buyers in industries with strict compliance measures should ensure that the fired heater systems they choose meet all regulatory standards while also considering long-term operational costs.

Related Video: What is a heating element?

Key Industrial Applications of heating element

| Industry/Sector | Specific Application of Heating Element | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Industrial Ovens and Furnaces | Enhanced efficiency in material processing | Energy consumption, temperature uniformity, durability |

| Food Processing | Food Dehydration Equipment | Improved product quality and shelf life | Compliance with food safety standards, energy efficiency |

| Chemical Processing | Reactor Heating Systems | Consistent reaction temperatures | Material compatibility, safety standards, energy efficiency |

| Textile Industry | Dyeing Machines | Consistent color application and quality | Temperature control, energy costs, machine compatibility |

| HVAC Systems | Heating, Ventilation, and Air Conditioning | Improved climate control and energy savings | Energy efficiency ratings, regulatory compliance, maintenance |

Manufacturing: Industrial Ovens and Furnaces

In the manufacturing sector, heating elements are integral to industrial ovens and furnaces used for processes such as metal treatment, glass melting, and ceramics firing. These heating elements provide precise temperature control, which is essential for achieving desired material properties. For B2B buyers, sourcing high-quality heating elements can lead to improved operational efficiency and reduced energy costs. Buyers should consider factors such as energy consumption, temperature uniformity, and the durability of heating elements to ensure they meet the rigorous demands of industrial applications.

Food Processing: Food Dehydration Equipment

Heating elements in food processing applications, particularly in food dehydration equipment, play a critical role in extending the shelf life of products while maintaining quality. By providing controlled heat, these elements help in the removal of moisture, thereby preventing spoilage. For international buyers, especially in regions like Africa and South America, it’s vital to source heating elements that comply with local food safety standards. Additionally, energy efficiency is a key consideration, as it directly impacts operational costs and sustainability goals.

Chemical Processing: Reactor Heating Systems

In the chemical processing industry, heating elements are crucial for reactor heating systems, where maintaining a consistent temperature is vital for chemical reactions. These systems ensure optimal reaction rates and product yields. Buyers must focus on sourcing heating elements that are compatible with various chemicals and can withstand extreme conditions. Safety standards and energy efficiency are also critical, as improper heating can lead to hazardous situations and increased operational costs.

Textile Industry: Dyeing Machines

Heating elements are essential in dyeing machines within the textile industry, where they ensure that dye is applied uniformly and effectively. By providing consistent heat, these elements contribute to better color application and overall product quality. B2B buyers should prioritize sourcing heating elements that offer precise temperature control and are compatible with different dyeing processes. Additionally, energy costs and machine compatibility should be evaluated to ensure a smooth integration into existing operations.

HVAC Systems: Heating, Ventilation, and Air Conditioning

In HVAC systems, heating elements are vital for maintaining comfortable indoor environments. They enable efficient heating and can significantly reduce energy consumption when sourced correctly. Buyers should consider energy efficiency ratings and regulatory compliance when selecting heating elements for HVAC applications. Furthermore, the reliability of these components is crucial, as they directly impact the overall performance of climate control systems, especially in diverse climates across regions like the Middle East and Europe.

Related Video: How PTC Heating Element Technology Works

Strategic Material Selection Guide for heating element

When selecting materials for heating elements, international B2B buyers must consider various factors that influence performance, durability, and compliance with regional standards. Below are analyses of four common materials used in heating elements, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

1. Nickel-Chromium Alloys (NiCr)

Key Properties:

Nickel-chromium alloys are known for their excellent high-temperature resistance, typically rated for temperatures up to 1,200°C (2,192°F). They exhibit good corrosion resistance, particularly in oxidizing environments.

Pros & Cons:

– Advantages: High thermal stability and resistance to oxidation make NiCr alloys suitable for high-performance applications. They are relatively easy to manufacture and can be formed into various shapes.

– Disadvantages: The cost of nickel can be high, impacting overall manufacturing expenses. Additionally, they may not perform well in reducing atmospheres.

Impact on Application:

NiCr alloys are ideal for applications requiring consistent performance at high temperatures, such as industrial furnaces and laboratory equipment. However, they may not be suitable for environments with corrosive gases.

Considerations for International Buyers:

Buyers should ensure compliance with ASTM standards, particularly ASTM B168 for wire and strip forms. Given the cost volatility of nickel, it is advisable to consider long-term supply agreements to manage price fluctuations.

2. Stainless Steel

Key Properties:

Stainless steel offers good corrosion resistance and can withstand temperatures up to 800°C (1,472°F). It is available in various grades, with 304 and 316 being the most common for heating elements.

Pros & Cons:

– Advantages: Stainless steel is durable, cost-effective, and widely available. Its resistance to oxidation and corrosion makes it suitable for various applications, including food processing and chemical industries.

– Disadvantages: While it performs well in many environments, it may not be the best choice for high-temperature applications compared to nickel-chromium alloys.

Impact on Application:

Stainless steel heating elements are commonly used in domestic appliances, industrial heaters, and commercial cooking equipment. They are particularly effective in applications where hygiene is critical.

Considerations for International Buyers:

Buyers should verify compliance with local standards, such as DIN and JIS, particularly in food-related applications. The availability of stainless steel in local markets can also influence procurement decisions.

3. Molybdenum Disilicide (MoSi2)

Key Properties:

Molybdenum disilicide can operate at temperatures up to 1,800°C (3,272°F) and has excellent oxidation resistance. It is particularly effective in reducing atmospheres.

Pros & Cons:

– Advantages: MoSi2 offers outstanding thermal efficiency and is suitable for high-temperature applications. Its resistance to thermal shock makes it ideal for rapid heating processes.

– Disadvantages: The brittleness of molybdenum disilicide can complicate manufacturing and handling. It is also more expensive than other materials.

Impact on Application:

This material is often used in high-temperature furnaces and kilns, particularly in ceramics and metallurgy. Its ability to maintain performance in extreme conditions is a significant advantage.

Considerations for International Buyers:

Buyers should ensure that MoSi2 components meet relevant international standards for high-temperature applications. Given its cost, it is essential to assess the total lifecycle cost versus performance benefits.

4. Silicon Carbide (SiC)

Key Properties:

Silicon carbide can withstand temperatures up to 1,600°C (2,912°F) and is known for its high thermal conductivity and resistance to thermal shock.

Pros & Cons:

– Advantages: SiC is highly durable and can operate efficiently in harsh environments, making it suitable for industrial applications. Its high thermal conductivity allows for rapid heating.

– Disadvantages: The manufacturing process can be complex and costly, which may affect the overall price of heating elements made from this material.

Impact on Application:

Silicon carbide is often used in applications such as electric furnaces and semiconductor manufacturing. Its ability to handle extreme conditions makes it a preferred choice in high-tech industries.

Considerations for International Buyers:

Buyers should consider the availability of SiC in their regions and ensure compliance with relevant standards. The higher initial investment may be justified by long-term performance benefits.

Summary Table

| Material | Typical Use Case for heating element | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nickel-Chromium Alloys | Industrial furnaces, laboratory equipment | High thermal stability | High material cost | High |

| Stainless Steel | Domestic appliances, food processing | Cost-effective and durable | Lower temperature rating | Medium |

| Molybdenum Disilicide | High-temperature furnaces, kilns | Outstanding thermal efficiency | Brittle and expensive | High |

| Silicon Carbide | Electric furnaces, semiconductor industry | Highly durable and efficient | Complex manufacturing process | High |

This guide provides valuable insights for international B2B buyers, enabling informed decisions regarding material selection for heating elements based on their specific applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for heating element

Manufacturing Processes for Heating Elements

The manufacturing of heating elements is a complex process that involves several key stages. Each stage is critical to ensuring that the final product meets the necessary performance and safety standards. Below is an outline of the main manufacturing processes involved in producing heating elements, along with key techniques used at each stage.

1. Material Preparation

The first step in manufacturing heating elements is the selection and preparation of materials. Common materials include:

- Nickel-Chromium Alloys: Known for their high resistance and ability to withstand high temperatures.

- Copper: Used for its excellent thermal conductivity, often in conjunction with other materials.

- Ceramics: Employed for insulation and resistance properties.

Key Techniques:

– Sourcing Quality Raw Materials: Ensure materials are sourced from reputable suppliers to guarantee consistency and performance.

– Testing and Certification: Prior to use, raw materials should undergo rigorous testing to confirm they meet industry standards.

2. Forming

Once the materials are prepared, the next phase is forming. This involves shaping the materials into their intended designs.

Techniques:

– Wire Drawing: This technique is used for creating fine wires from larger diameter materials. The process involves pulling the material through a series of dies to achieve the desired thickness.

– Stamping: For elements that require specific shapes, stamping machines can cut and shape materials with high precision.

3. Assembly

After forming, the next step is assembly, where different components are brought together to create the final heating element.

Key Techniques:

– Welding: Often used to join different sections of the heating element. Techniques such as TIG (Tungsten Inert Gas) welding are popular due to their precision and strength.

– Soldering: In some designs, soldering is used to connect electrical components, ensuring a reliable electrical connection.

4. Finishing

Finishing is the final stage of the manufacturing process, focusing on enhancing the performance and aesthetics of the heating element.

Techniques:

– Coating: Applying protective coatings can improve resistance to oxidation and corrosion, extending the lifespan of the heating element.

– Testing: Final products must undergo testing to ensure they meet the specified performance criteria.

Quality Assurance in Heating Element Manufacturing

Quality assurance (QA) is essential in the manufacturing of heating elements to ensure that products are reliable, safe, and meet international standards. The following outlines the key components of a robust quality assurance framework.

International Standards

Adherence to international standards is critical for B2B buyers, especially in regions such as Africa, South America, the Middle East, and Europe. Key standards include:

- ISO 9001: Focuses on quality management systems, ensuring consistent quality in manufacturing processes.

- CE Marking: Indicates compliance with European safety, health, and environmental protection standards.

- API Standards: Relevant for heating elements used in the oil and gas industry, ensuring safety and performance.

Quality Control Checkpoints

Quality control (QC) should be integrated throughout the manufacturing process, incorporating several checkpoints:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early.

- Final Quality Control (FQC): Comprehensive testing of finished products before they are shipped to customers.

Common Testing Methods

Testing methods employed in the QC process include:

- Electrical Testing: To ensure the heating element operates correctly under specified conditions.

- Thermal Imaging: Used to detect hot spots and ensure uniform heating.

- Mechanical Testing: Assessing the strength and durability of the materials used.

Verifying Supplier Quality Control

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are several actionable steps buyers can take:

-

Supplier Audits: Conduct thorough audits of potential suppliers to evaluate their manufacturing processes and quality assurance measures. This includes reviewing documentation and witnessing processes firsthand.

-

Request Quality Reports: Ask suppliers for detailed quality assurance reports that outline their QC processes, including results from previous tests and certifications achieved.

-

Third-Party Inspections: Engage third-party inspection agencies to conduct independent evaluations of the supplier’s facilities and products. This adds an additional layer of verification.

-

Certifications Verification: Ensure that suppliers hold relevant certifications (ISO, CE, etc.) and that these certifications are current and valid.

Conclusion

Understanding the manufacturing processes and quality assurance practices for heating elements is vital for B2B buyers seeking reliable suppliers. By familiarizing themselves with these processes, international buyers can make informed decisions, ensuring that they procure high-quality products that meet their specific needs. Engaging in thorough supplier evaluations and insisting on adherence to international standards will further safeguard their investments in heating elements.

Related Video: Tubular Heating Element Manufacturing Process

Comprehensive Cost and Pricing Analysis for heating element Sourcing

When sourcing heating elements, understanding the comprehensive cost structure and pricing analysis is crucial for international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe. This analysis encompasses various cost components, price influencers, and actionable buyer tips that can lead to better sourcing decisions.

Cost Components

-

Materials: The choice of materials significantly impacts costs. Common materials for heating elements include nickel-chromium alloys, silicon carbide, and ceramic. Pricing can fluctuate based on market demand and material availability, so buyers should stay informed about commodity price trends.

-

Labor: Labor costs vary by region and are influenced by local wage standards, skills availability, and manufacturing practices. Countries with lower labor costs can offer competitive pricing, but this may come with trade-offs in quality or consistency.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, facility maintenance, and administrative expenses. Buyers should inquire about the supplier’s operational efficiency, which can affect pricing.

-

Tooling: Initial tooling costs for custom heating elements can be substantial. If tooling is required for specific designs, it is essential to understand how these costs are amortized over production runs, as larger orders can help reduce the per-unit cost.

-

Quality Control (QC): Implementing stringent quality control processes ensures product reliability but adds to costs. Buyers should verify the QC certifications of suppliers to ensure they meet required standards, which may also affect pricing.

-

Logistics: Transportation and handling costs are critical, especially for international shipments. Factors such as distance, shipping method, and customs duties can influence overall costs. It’s advisable to evaluate Incoterms carefully to understand liability and cost-sharing with suppliers.

-

Margin: Suppliers will typically include a profit margin in their pricing. Understanding typical margins in the heating element market can help buyers negotiate better deals.

Price Influencers

-

Volume and Minimum Order Quantity (MOQ): Larger orders usually come with discounts, making it advantageous for buyers to consolidate purchases when possible.

-

Specifications and Customization: Custom heating elements tailored to specific applications may incur additional costs. Clearly defining specifications upfront can prevent unexpected price increases.

-

Quality and Certifications: Higher quality and certified products often come at a premium. Buyers should weigh the long-term benefits of investing in higher-quality components against initial costs.

-

Supplier Factors: The supplier’s reputation, production capacity, and location can all influence pricing. Establishing a strong relationship with suppliers may lead to better terms and pricing.

-

Incoterms: Understanding the implications of Incoterms (International Commercial Terms) is vital. They dictate the responsibilities of buyers and sellers regarding shipping costs and risks, impacting the total cost of ownership.

Buyer Tips

-

Negotiate Effectively: Always enter negotiations with a clear understanding of your needs and market benchmarks. Be prepared to discuss alternatives and flexible terms to reach a mutually beneficial agreement.

-

Focus on Cost-Efficiency: Evaluate not just the purchase price but the total cost of ownership, including installation, maintenance, and energy consumption over the product’s lifespan.

-

Pricing Nuances: International buyers should be aware of currency fluctuations, tariffs, and trade regulations that could affect pricing. Keeping abreast of geopolitical developments can also provide insights into potential price changes.

-

Research and Compare: Don’t settle for the first offer. Collect quotes from multiple suppliers and compare not only prices but also quality and service levels. This competitive analysis can lead to significant savings.

In conclusion, buyers of heating elements should approach sourcing with a comprehensive understanding of cost structures and pricing influences. By leveraging this knowledge, they can negotiate more effectively, optimize their procurement strategies, and ultimately achieve greater value in their purchases.

Spotlight on Potential heating element Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘heating element’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for heating element

Key Technical Properties of Heating Elements

When sourcing heating elements, understanding their critical specifications is essential for ensuring optimal performance and compatibility with your applications. Here are some key properties to consider:

-

Material Grade

Heating elements are commonly made from materials such as nickel-chromium alloys, silicon carbide, or ceramic. The material grade affects durability, thermal conductivity, and resistance to oxidation. For instance, nickel-chromium alloys are favored for their high-temperature performance, making them suitable for industrial applications. Buyers should ensure the material aligns with the operating environment to prevent premature failure. -

Watt Density

This refers to the amount of power (in watts) that a heating element can safely dissipate per unit area. High watt density is ideal for applications requiring rapid heat-up times, while lower densities are suitable for uniform heat distribution. Understanding watt density helps buyers select elements that meet specific heating requirements without risking overheating or damage to surrounding materials. -

Tolerance

Tolerance specifies the allowable deviation in dimensions and resistance of the heating element. Tight tolerances are critical in applications where precise temperature control is necessary, such as in medical devices or laboratory equipment. Buyers should inquire about tolerance levels to ensure the heating elements will function correctly within their systems.

-

Operating Temperature Range

Each heating element has a defined range of temperatures in which it can operate efficiently. Selecting an element with an appropriate operating temperature range is crucial to avoid failure and ensure longevity. Buyers should evaluate their application’s temperature requirements and verify that the chosen element can withstand them. -

Insulation Type

The insulation surrounding heating elements plays a vital role in safety and efficiency. Common insulation materials include mica, ceramic, and fiberglass. Each type has distinct thermal and electrical properties, impacting the element’s performance. Buyers should consider the insulation type based on the operational environment and safety standards. -

Voltage Rating

The voltage rating indicates the maximum voltage the heating element can handle. It is essential to match this rating with the voltage supplied in your application to prevent damage or unsafe conditions. Understanding the voltage requirements is particularly important for international buyers, as voltage standards can vary across regions.

Common Trade Terminology

Familiarity with industry jargon can facilitate smoother transactions and better understanding between suppliers and buyers. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the heating element industry, understanding OEM specifications is crucial for ensuring compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell in a single order. Knowing the MOQ is vital for buyers to ensure they can meet their production needs without excess inventory. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing for specific products or services. It is an important step in the purchasing process, as it allows buyers to compare costs and make informed decisions. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for clarifying costs, risks, and logistics associated with shipping heating elements across borders. -

Lead Time

This term refers to the time it takes from placing an order to receiving the goods. Knowing the lead time is critical for planning inventory and production schedules, especially in industries with tight timelines. -

Certification

Certification indicates that a heating element meets specific industry standards or regulations. Certifications such as CE, UL, or ISO assure buyers of the product’s quality and safety, which is especially important for compliance in various markets.

By understanding these essential technical properties and trade terms, B2B buyers can make more informed decisions, ensuring the heating elements they procure meet their operational needs while facilitating smoother transactions with suppliers.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the heating element Sector

Market Overview & Key Trends

The heating element sector is experiencing a significant transformation driven by various global factors, including technological advancements, changing consumer preferences, and sustainability initiatives. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions.

One of the most notable trends is the increasing adoption of energy-efficient heating solutions. Businesses are prioritizing products that not only meet regulatory standards but also offer long-term cost savings. This trend is particularly relevant in developing markets where energy costs can be a significant operational burden. Furthermore, the integration of smart technologies into heating systems is emerging as a key differentiator. Buyers should look for suppliers who offer IoT-enabled heating elements that allow for real-time monitoring and optimization, enhancing operational efficiency.

Illustrative Image (Source: Google Search)

Additionally, the market is witnessing a shift towards localized sourcing. Buyers are increasingly favoring suppliers who can demonstrate agility and responsiveness to changing market conditions. This trend is essential for African and South American markets, where logistical challenges can impact supply chains. As such, establishing relationships with regional manufacturers or distributors can provide buyers with a strategic advantage.

Lastly, regulatory pressures surrounding environmental standards are shaping the market landscape. Companies must navigate complex compliance requirements, particularly in Europe and the Middle East, where stringent regulations govern energy consumption and emissions. Buyers should prioritize suppliers with robust compliance frameworks and a proven track record of sustainability.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer just a buzzword; it is a critical component of B2B procurement strategies in the heating element sector. The environmental impact of traditional heating technologies has led to a growing demand for greener alternatives. For international buyers, this means sourcing products that minimize carbon footprints and use sustainable materials.

Ethical supply chains are essential for fostering trust and transparency. Buyers should prioritize suppliers who adhere to ethical sourcing practices, ensuring that materials are obtained responsibly and that labor conditions are fair. Certifications such as ISO 14001 for environmental management and FSC certification for sustainable materials can serve as indicators of a supplier’s commitment to sustainability.

Furthermore, the use of innovative materials in heating element production is gaining traction. Biodegradable and recyclable materials are becoming more prevalent, offering buyers the opportunity to align their procurement practices with environmental goals. Collaborating with suppliers that invest in research and development of sustainable technologies can enhance a company’s brand reputation while meeting consumer demand for eco-friendly products.

Brief Evolution/History

The heating element industry has evolved significantly over the past few decades. Initially dominated by traditional resistive heating methods, the sector has seen the introduction of advanced materials and technologies that enhance performance and efficiency. The transition from conventional heating elements to more sophisticated solutions, such as ceramic and induction heating, has allowed businesses to meet the growing demand for energy-efficient products.

This evolution is particularly important for B2B buyers, as it reflects the broader trend towards innovation in manufacturing processes. Understanding the historical context of heating technologies can provide insights into current market dynamics and future developments, allowing buyers to make strategic sourcing decisions that align with their operational needs. As companies increasingly prioritize sustainability and efficiency, the historical advancements in heating technology will play a crucial role in shaping future procurement strategies.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of heating element

-

What should I consider when vetting suppliers for heating elements?

When vetting suppliers, focus on their industry experience, certifications, and reputation. Check for ISO certifications and any relevant quality management systems to ensure compliance with international standards. It’s beneficial to request references from previous clients and to conduct site visits if possible. Additionally, consider the supplier’s capacity for customization, as well as their financial stability, to assess whether they can meet your long-term needs. -

Can heating elements be customized for specific applications?

Yes, many suppliers offer customization options for heating elements to cater to specific applications. You should communicate your requirements clearly, including material specifications, size, wattage, and voltage. Ensure that the supplier has experience with custom designs and can provide prototypes for testing. Discuss the timeline for customization, as this can impact your overall procurement schedule. -

What are the typical minimum order quantities (MOQs) and lead times for heating elements?

MOQs for heating elements can vary significantly based on the supplier and the complexity of the product. Standard orders may range from a few dozen to several hundred units. Lead times typically range from 4 to 12 weeks, depending on the supplier’s production capabilities and your order size. Always confirm these details upfront to avoid unexpected delays in your supply chain.

Illustrative Image (Source: Google Search)

-

What payment terms are common in international B2B transactions for heating elements?

Common payment terms include advance payments, letters of credit, and open account terms. Advance payments may be required for new suppliers, while established suppliers might offer net 30 or net 60 terms. It’s crucial to negotiate payment terms that align with your cash flow and risk tolerance. Additionally, ensure that the payment method is secure and provides adequate protection against fraud. -

How can I ensure quality assurance and compliance with international standards?

To ensure quality assurance, request detailed documentation of the supplier’s quality control processes, including inspection and testing protocols. Ask for certificates of compliance with relevant international standards, such as CE or UL. Establish a clear agreement regarding quality expectations, and consider third-party inspections before shipment. Regular audits can also help maintain compliance over time. -

What logistics considerations should I be aware of when sourcing heating elements?

Logistics considerations include shipping methods, customs regulations, and import duties, which can vary by region. Choose a reliable logistics partner who understands the complexities of international shipping and can provide cost-effective solutions. Be aware of lead times for shipping and factor in potential delays at customs. Also, consider the implications of packaging to prevent damage during transit. -

How should I handle disputes with suppliers?

To effectively handle disputes, establish a clear contract that outlines terms, conditions, and processes for conflict resolution. Maintain open communication with your supplier to address issues promptly. If disputes arise, consider mediation or arbitration as alternatives to litigation. Document all correspondence and agreements to ensure clarity and support your position if formal proceedings are necessary. -

What certifications should I look for in heating elements?

Look for certifications that demonstrate compliance with international safety and performance standards. Common certifications include ISO 9001 for quality management, IEC for electrical safety, and RoHS for hazardous substances. These certifications not only ensure product safety and reliability but also enhance your credibility as a buyer in international markets. Always verify the authenticity of these certifications with the issuing bodies.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for heating element

In the rapidly evolving landscape of the heating element industry, strategic sourcing emerges as a critical component for international B2B buyers aiming to enhance operational efficiency and reduce costs. By leveraging supplier diversity and focusing on long-term partnerships, organizations can tap into innovative technologies and sustainable practices that drive competitiveness.

Key Takeaways for buyers in regions such as Africa, South America, the Middle East, and Europe include:

- Supplier Evaluation: Prioritize suppliers with a proven track record in quality and reliability to mitigate risks associated with procurement.

- Market Trends: Stay informed about emerging technologies, such as energy-efficient heating solutions, which can lead to significant cost savings and environmental benefits.

- Regulatory Compliance: Understand local regulations and standards that may impact sourcing decisions, ensuring that products meet regional requirements.

As we look ahead, the demand for advanced heating solutions will only increase. Buyers are encouraged to adopt a proactive approach in their sourcing strategies, embracing innovation and sustainability. Collaborate with forward-thinking suppliers to not only meet current needs but also to anticipate future market trends. Take the next step today—evaluate your sourcing strategies and position your business for success in this dynamic industry.