Master Sourcing Spring-Loaded Hinges: A Comprehensive B2B

Introduction: Navigating the Global Market for spring-loaded hinges

In the ever-evolving landscape of international manufacturing and construction, spring-loaded hinges play a pivotal role in ensuring functionality, safety, and efficiency across a myriad of applications. These innovative components are integral to a range of industries, from automotive to aerospace, and are crucial for applications requiring automatic closure and secure positioning. As B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe seek reliable solutions, understanding the nuances of spring-loaded hinges becomes essential for informed decision-making.

This comprehensive guide delves into the various types of spring-loaded hinges, including their distinct materials and manufacturing processes, as well as the quality control measures that ensure product reliability. Buyers will gain insights into cost factors, market trends, and an overview of reputable suppliers across the globe. Additionally, the guide addresses frequently asked questions, demystifying common concerns and equipping buyers with the knowledge to navigate the complexities of sourcing these critical components.

By leveraging this guide, international B2B buyers can make strategic sourcing decisions that align with their operational requirements and budget constraints. With a focus on actionable insights and expert recommendations, this resource empowers you to optimize your supply chain and enhance your competitive advantage in the global market.

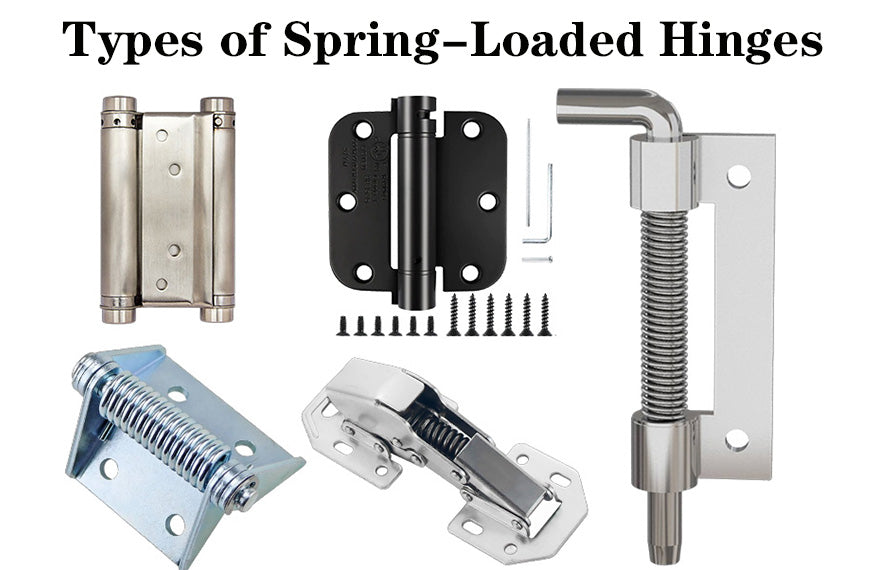

Illustrative Image (Source: Google Search)

Understanding spring-loaded hinges Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Spring-Loaded | Simple design, automatic closure, adjustable tension | Doors, cabinets, equipment enclosures | Pros: Cost-effective, easy installation. Cons: Limited adjustability. |

| Heavy-Duty Spring-Loaded | Robust construction, high load capacity, corrosion-resistant | Industrial machinery, large doors | Pros: Durable, suitable for high-traffic areas. Cons: Higher cost, heavier weight. |

| Self-Closing | Integrated mechanism for automatic closure, adjustable speed | Fire doors, safety barriers | Pros: Enhances safety, compliant with regulations. Cons: May require regular maintenance. |

| Adjustable Tension | Allows customization of closing speed and force | Commercial applications, furniture | Pros: Versatile, tailored performance. Cons: More complex installation. |

| Multi-Position | Allows door to stay open at multiple angles, easy to set | Exhibition displays, partition walls | Pros: Flexible usage, enhances accessibility. Cons: May be less secure when fully closed. |

Standard Spring-Loaded Hinges

Standard spring-loaded hinges are characterized by their straightforward design that facilitates automatic closure. They are often adjustable, allowing users to set the tension to suit specific requirements. These hinges are widely used in everyday applications like doors and cabinets, providing a cost-effective solution for businesses. When considering a purchase, buyers should evaluate the installation simplicity and maintenance needs, as they generally have limited adjustability compared to other types.

Heavy-Duty Spring-Loaded Hinges

Heavy-duty variants are built to withstand significant loads and are often constructed from corrosion-resistant materials, making them ideal for industrial environments. These hinges are commonly used in machinery and large doors, where durability and reliability are paramount. Buyers should consider the hinge’s load capacity and the specific environmental conditions it will face, as these factors will influence long-term performance. While they may come at a higher price point, their longevity often justifies the investment.

Self-Closing Hinges

Self-closing hinges feature an integrated mechanism that ensures doors close automatically after being opened. This functionality is essential in applications like fire doors and safety barriers, where compliance with safety regulations is critical. For buyers, the advantages include enhanced safety and convenience, but regular maintenance may be required to ensure the mechanism operates smoothly. Understanding the regulatory requirements in your region can also guide purchasing decisions.

Adjustable Tension Hinges

These hinges provide the flexibility to customize the closing speed and force, making them suitable for various commercial applications and furniture. The ability to adjust tension allows businesses to tailor performance to specific needs, enhancing user experience. However, buyers should be aware that the installation process can be more complex than standard options, requiring careful attention to ensure optimal operation. Evaluating the need for adjustability will be crucial for making the right choice.

Multi-Position Hinges

Multi-position hinges allow doors to remain open at various angles, offering flexibility in usage, especially in exhibition displays and partition walls. This feature enhances accessibility and user convenience. However, buyers should weigh the potential security concerns when doors are not fully closed. Understanding the application context—such as foot traffic and security requirements—will help businesses determine if this hinge type aligns with their operational needs.

Related Video: Different Types of Hinges – Choosing the Right Hinge for Your Application

Key Industrial Applications of spring-loaded hinges

| Industry/Sector | Specific Application of spring-loaded hinges | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Door and trunk closures | Enhances user experience by providing smooth operation | Material durability, resistance to environmental factors |

| Industrial Equipment | Safety guard doors in manufacturing plants | Improves safety by ensuring doors close automatically | Compliance with safety regulations, ease of installation |

| Agriculture | Livestock gates and enclosures | Facilitates easier access while ensuring secure closure | Customization options, ability to withstand harsh conditions |

| Construction | Access panels in HVAC systems | Provides easy access for maintenance while maintaining insulation | Size and weight specifications, thermal resistance |

| Electronics | Enclosures for electronic devices | Protects sensitive components while allowing easy access | Size compatibility, electromagnetic interference protection |

Automotive Applications

In the automotive sector, spring-loaded hinges are commonly used for door and trunk closures. These hinges ensure that doors close smoothly and securely, enhancing user experience and safety. For international B2B buyers, particularly in regions like Africa and South America, sourcing hinges that offer durability against environmental conditions such as humidity and dust is crucial. Buyers should also consider the weight capacity of the hinges to ensure they can withstand the demands of heavy vehicle doors.

Industrial Equipment Applications

Spring-loaded hinges are vital in manufacturing plants, particularly for safety guard doors. These hinges ensure that doors close automatically, thereby enhancing workplace safety by minimizing the risk of accidents. Buyers in the Middle East and Europe should prioritize suppliers who can provide hinges that comply with local safety regulations. Additionally, ease of installation and maintenance should be considered to minimize downtime in production environments.

Agricultural Applications

In agriculture, spring-loaded hinges are often found in livestock gates and enclosures. They facilitate easy access for farmers while ensuring that gates close securely to prevent livestock escape. For buyers in regions like Kenya, where weather conditions can be harsh, sourcing hinges made from corrosion-resistant materials is essential. Customization options that fit specific gate sizes and styles can also enhance usability in diverse agricultural settings.

Construction Applications

In the construction industry, spring-loaded hinges are utilized for access panels in HVAC systems. They provide easy access for maintenance personnel while maintaining the necessary insulation. Buyers in Europe and South America should ensure that the selected hinges meet specific size and weight specifications to fit various panel designs. Additionally, thermal resistance is a critical factor, as it helps maintain energy efficiency in building operations.

Electronics Applications

Spring-loaded hinges are used in enclosures for electronic devices to protect sensitive components while allowing for easy access during maintenance or upgrades. For B2B buyers in Africa and the Middle East, sourcing hinges that are compatible with specific device sizes and offer electromagnetic interference protection is essential. Ensuring that the hinges can withstand the operational environment, including temperature and humidity variations, will enhance the longevity of electronic products.

Strategic Material Selection Guide for spring-loaded hinges

When selecting materials for spring-loaded hinges, it is essential to consider their specific properties, advantages, disadvantages, and the impact on applications. Below is an analysis of four common materials used in the manufacture of spring-loaded hinges, tailored for international B2B buyers.

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures. It typically has a temperature rating of up to 800°F (427°C) and is suitable for various environmental conditions.

Pros & Cons: The durability of stainless steel makes it an ideal choice for outdoor applications or environments with high humidity. However, it can be more expensive than other materials, which may impact budget-sensitive projects. Manufacturing complexity is moderate, requiring specific tooling and processes.

Impact on Application: Stainless steel is compatible with a wide range of media, including water, oils, and chemicals, making it versatile for industrial applications.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM A240 or DIN 1.4301. In regions like Africa and South America, where corrosion is a concern, stainless steel is often preferred.

Plastic (Polymer)

Key Properties: Plastics, particularly reinforced polymers, offer lightweight characteristics and excellent corrosion resistance. They can withstand temperatures up to 200°F (93°C), depending on the specific polymer used.

Pros & Cons: The primary advantage of plastic hinges is their low cost and lightweight nature, making them suitable for applications where weight savings are critical. However, they may not withstand high mechanical loads and can become brittle at lower temperatures.

Impact on Application: Plastic hinges are ideal for applications in environments that require chemical resistance, such as food processing or pharmaceuticals.

Considerations for International Buyers: Compliance with food safety standards (e.g., FDA or EU regulations) is crucial for buyers in the food industry. Additionally, understanding the specific polymer’s properties is essential for ensuring compatibility with the intended application.

Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has a good strength-to-weight ratio. It can typically handle temperatures up to 400°F (204°C).

Pros & Cons: Aluminum hinges are easy to manufacture and can be anodized for enhanced corrosion resistance. However, they may not be as strong as stainless steel and can be more expensive than plastic options.

Impact on Application: Aluminum is suitable for applications where weight is a concern, such as in aerospace or automotive industries. It is also compatible with various media but may not perform well in highly corrosive environments.

Considerations for International Buyers: Buyers should consider compliance with standards like ASTM B221 for aluminum alloys. In Europe, EN 573-3 is a relevant standard. Understanding local market preferences for aluminum grades is also important.

Brass

Key Properties: Brass is known for its excellent machinability and corrosion resistance, particularly in marine environments. It typically has a temperature rating of up to 300°F (149°C).

Pros & Cons: Brass hinges are aesthetically pleasing and provide good durability. However, they can be more expensive than other materials and may not be suitable for high-load applications.

Impact on Application: Brass is often used in decorative applications, such as furniture or cabinetry, where appearance is important. It also has good compatibility with water and low-pressure applications.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM B36 for brass. In regions like the Middle East, where aesthetics are often prioritized, brass may be the preferred choice for decorative applications.

Summary Table

| Material | Typical Use Case for spring-loaded hinges | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Outdoor and industrial applications | Excellent corrosion resistance | Higher cost | High |

| Plastic | Food processing and pharmaceuticals | Lightweight and cost-effective | Limited load-bearing capacity | Low |

| Aluminum | Aerospace and automotive industries | Good strength-to-weight ratio | Less strength than stainless steel | Medium |

| Brass | Decorative applications | Aesthetic appeal | Higher cost and lower strength | Medium |

This guide provides a comprehensive overview of material options for spring-loaded hinges, enabling international buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for spring-loaded hinges

Manufacturing spring-loaded hinges involves several critical stages, each integral to ensuring the final product meets the desired specifications and quality standards. Below is a comprehensive overview of the manufacturing processes and quality assurance measures typically employed in the production of spring-loaded hinges, tailored for international B2B buyers.

Manufacturing Processes

1. Material Preparation

The first step in manufacturing spring-loaded hinges is selecting the appropriate materials, typically stainless steel, brass, or plastic, depending on the application’s specific requirements such as corrosion resistance and strength.

- Material Sourcing: Ensure that suppliers provide certifications verifying material quality and compliance with international standards.

- Cutting: Materials are cut into required sizes using precision cutting tools. This can involve shearing for sheet metal or sawing for larger components.

2. Forming

This stage involves shaping the raw materials into hinge components. Various techniques can be employed, including:

- Stamping: This process uses a die to cut and shape metal sheets into specific designs. It is efficient for high-volume production.

- Bending: Components may require bending to achieve the desired angles and shapes. This can be done using hydraulic or mechanical presses.

3. Assembly

Once the individual parts are formed, they are assembled into the final product. Key aspects include:

- Spring Installation: The spring mechanism, which provides the loading feature, is installed. This can be a coil or torsion spring, depending on the hinge design.

- Joining Components: Components are joined using methods such as welding, riveting, or using fasteners. The choice of joining technique can impact the hinge’s overall strength and functionality.

4. Finishing

The final stage focuses on enhancing the hinge’s appearance and corrosion resistance. Common finishing processes include:

- Plating: Electroplating or galvanizing can provide a protective layer to prevent corrosion.

- Polishing: This improves the aesthetic appeal and smoothness of the hinge surface.

- Coating: Additional coatings may be applied to improve resistance to wear and environmental factors.

Quality Assurance

Quality assurance is vital in the manufacturing process of spring-loaded hinges to ensure product reliability and safety.

International Standards

Compliance with international standards is essential for B2B buyers to ensure product quality:

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: For products sold within the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For hinges used in industrial applications, adherence to American Petroleum Institute standards may be necessary, particularly in oil and gas sectors.

Quality Control Checkpoints

Establishing robust quality control checkpoints throughout the manufacturing process ensures defects are identified and corrected early:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival at the facility to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during production to catch deviations in real-time.

- Final Quality Control (FQC): Comprehensive testing of finished products to ensure they meet all specifications before shipping.

Common Testing Methods

B2B buyers should be aware of the various testing methods used to verify hinge quality:

- Functional Testing: Assessing the operational functionality of the hinge under simulated conditions.

- Load Testing: Determining the load-bearing capacity of the hinge to ensure it meets application requirements.

- Corrosion Resistance Testing: Subjecting hinges to environments that simulate operational conditions to evaluate their durability.

Verification of Supplier Quality Control

To ensure the reliability of suppliers, B2B buyers should consider the following actions:

- Supplier Audits: Conduct regular audits of suppliers to evaluate their manufacturing processes and quality assurance practices. This can provide insight into their commitment to quality.

- Requesting Documentation: Buyers should ask for quality assurance documentation, including inspection reports and certificates of compliance with relevant standards.

- Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased assessment of product quality and compliance with standards.

Quality Control and Certification Nuances for International Buyers

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should navigate several nuances in quality control and certification:

- Regional Compliance: Be aware of the specific compliance requirements in your region. For instance, certain products might need different certifications to be sold in the EU versus the Middle East.

- Cultural Considerations: Understand the cultural context of the supplier’s country, which can influence business practices and quality standards.

- Language Barriers: Ensure that quality documentation is available in a language that is understandable to your team to avoid miscommunication.

By focusing on these manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions when sourcing spring-loaded hinges, ensuring they receive high-quality products that meet their specifications and regulatory requirements.

Related Video: How its made: Efficient Construction Sites & #Fabrication Factory Insights | #Manufacturing Factory

Comprehensive Cost and Pricing Analysis for spring-loaded hinges Sourcing

Understanding the cost structure and pricing dynamics of spring-loaded hinges is essential for international B2B buyers, especially those from diverse markets such as Africa, South America, the Middle East, and Europe. This analysis will break down the key components influencing costs, pricing factors, and offer actionable insights for negotiations.

Cost Components

-

Materials: The choice of raw materials significantly impacts the cost of spring-loaded hinges. Common materials include stainless steel, brass, and high-strength plastics. The fluctuation in raw material prices due to market demand can affect overall costs.

-

Labor: Labor costs vary widely based on the manufacturing location. Countries with lower labor costs may provide competitive pricing, but this often comes with trade-offs in quality and lead times.

-

Manufacturing Overhead: This includes costs related to utilities, equipment depreciation, and indirect labor. Overhead can vary based on the efficiency of the manufacturing process and the scale of production.

-

Tooling: Custom tooling for specialized designs can be a significant upfront cost. However, it is amortized over larger production runs, making it more cost-effective for bulk orders.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability and compliance with international standards. This may add to costs but is crucial for maintaining quality, especially in regulated markets.

-

Logistics: Shipping costs can vary significantly based on the supplier’s location and the buyer’s destination. Factors such as freight costs, insurance, and customs duties must be considered in the total cost.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This can vary widely based on market competition and the perceived value of the product.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) often dictate pricing. Higher volumes usually result in lower per-unit costs due to economies of scale.

-

Specifications/Customization: Customized hinges may incur additional costs due to unique design requirements. Buyers should assess the necessity of custom features against their budget.

-

Materials: The quality and type of materials directly influence pricing. Premium materials can offer better durability but at a higher cost.

-

Quality/Certifications: Products that meet specific certifications (e.g., ISO, CE) might command higher prices due to the assurance of quality and safety.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium for their track record of quality and service.

-

Incoterms: Understanding the terms of trade (Incoterms) is crucial. They dictate who is responsible for shipping costs, insurance, and customs clearance, directly affecting the total landed cost.

Buyer Tips

-

Negotiation: Leverage volume purchasing to negotiate better pricing. Establish long-term relationships with suppliers for more favorable terms.

-

Cost-Efficiency: Consider total cost of ownership (TCO) rather than just the purchase price. Factor in potential savings from higher-quality products that reduce maintenance costs.

-

International Pricing Nuances: Be aware of currency fluctuations, tariffs, and local market conditions that can affect pricing. Understanding these factors can provide leverage in negotiations.

-

Supplier Evaluation: Conduct thorough due diligence on suppliers. Assess their production capabilities, quality control processes, and customer service reputation to ensure you select a reliable partner.

Disclaimer

Prices for spring-loaded hinges can vary significantly based on the aforementioned factors. It is advisable for buyers to obtain multiple quotes and conduct a comprehensive cost analysis to make informed purchasing decisions.

Spotlight on Potential spring-loaded hinges Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘spring-loaded hinges’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for spring-loaded hinges

When engaging in the procurement of spring-loaded hinges, understanding the essential technical properties and industry-specific terminology is crucial for making informed decisions. This section outlines the key specifications and terms that B2B buyers should be aware of.

Key Technical Properties

-

Material Grade

– Definition: The type and quality of material used in manufacturing the hinge, such as stainless steel, brass, or plastic composites.

– Importance: Material grade affects the hinge’s strength, corrosion resistance, and durability. For instance, stainless steel is ideal for outdoor applications, while plastic hinges may be suitable for lighter, indoor use. -

Load Capacity

– Definition: The maximum weight that the hinge can support without failure.

– Importance: Knowing the load capacity is vital for ensuring that the hinge can handle the specific demands of the application. Exceeding this limit can lead to hinge failure and potential safety hazards. -

Tolerance

– Definition: The permissible limit of variation in the hinge’s dimensions, which ensures proper fit and function.

– Importance: Tight tolerances are critical in applications where precision is required. Poor tolerances can lead to misalignment and malfunction, impacting overall performance. -

Spring Force

– Definition: The force exerted by the spring within the hinge, which affects how the hinge operates (e.g., how quickly it closes).

– Importance: Understanding spring force is essential for applications requiring specific opening and closing speeds. A mismatch can lead to user frustration or operational inefficiencies. -

Finish and Coating

– Definition: The surface treatment applied to the hinge, such as powder coating or galvanization.

– Importance: The finish not only affects aesthetics but also impacts corrosion resistance and wear. Selecting the right coating can extend the hinge’s lifespan, especially in harsh environments. -

Operating Temperature Range

– Definition: The range of temperatures within which the hinge can operate effectively.

– Importance: For international buyers, understanding the operating temperature is crucial, particularly in regions with extreme weather conditions. A hinge that cannot withstand local temperatures may fail prematurely.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Significance: Understanding OEM relationships is essential for buyers seeking specific hinge designs or customizations, as these manufacturers often have proprietary technologies. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units that a supplier is willing to sell.

– Significance: Knowing the MOQ is crucial for budgeting and inventory management. Buyers should ensure that the MOQ aligns with their purchasing needs to avoid excess inventory costs. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to invite them to bid on specific products or services.

– Significance: An RFQ allows buyers to compare pricing and terms from multiple suppliers, facilitating better negotiation and selection processes. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules that define the responsibilities of sellers and buyers in international transactions.

– Significance: Familiarity with Incoterms helps buyers understand shipping costs, insurance, and risk transfer, which is particularly relevant for international procurement. -

Lead Time

– Definition: The time taken from placing an order to the delivery of the product.

– Significance: Understanding lead times is crucial for project planning and supply chain management. Buyers must account for lead times to avoid delays in production or project timelines. -

Warranty

– Definition: A guarantee provided by the manufacturer regarding the condition of the product and the terms of repair or replacement.

– Significance: A strong warranty can provide peace of mind and reduce long-term costs associated with product failures. Buyers should always clarify warranty terms before finalizing a purchase.

By grasping these essential properties and terms, international B2B buyers can make more informed decisions, ensuring that they select the right spring-loaded hinges for their specific applications while optimizing their procurement processes.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the spring-loaded hinges Sector

In the spring-loaded hinges sector, various market dynamics and trends are shaping the landscape for international B2B buyers. The global demand for spring-loaded hinges is driven by the increasing need for efficient mechanical solutions across industries such as automotive, aerospace, and furniture. As manufacturers seek to optimize product performance and enhance user experience, innovations in design and materials are becoming critical. Emerging technologies, including additive manufacturing and advanced materials, are revolutionizing the production process, allowing for custom solutions that meet specific client requirements.

Illustrative Image (Source: Google Search)

Furthermore, the integration of smart technologies into traditional mechanical components is gaining traction. This trend is particularly relevant for buyers in Africa, South America, the Middle East, and Europe, where there is a growing emphasis on automation and smart manufacturing. As businesses look to streamline operations, sourcing hinges that can integrate with IoT devices or smart systems is becoming a priority. The shift toward remote monitoring and predictive maintenance is also influencing purchasing decisions, with buyers seeking suppliers who can provide data-driven insights into product performance.

Sustainability & Ethical Sourcing in B2B

The environmental impact of manufacturing processes and the materials used in producing spring-loaded hinges is an increasingly pressing concern for B2B buyers. Sustainable sourcing practices not only help reduce carbon footprints but also enhance brand reputation and compliance with international regulations. Buyers are encouraged to seek suppliers who prioritize ethical sourcing and have transparent supply chains, ensuring that materials are obtained responsibly and sustainably.

In this context, certifications such as ISO 14001 for environmental management and the use of recycled materials are becoming essential. Buyers should assess potential suppliers for their commitment to sustainability, including the implementation of eco-friendly practices in their operations. By choosing partners who align with their sustainability goals, businesses can contribute to a circular economy while also meeting the growing consumer demand for environmentally responsible products.

Brief Evolution/History

The evolution of spring-loaded hinges can be traced back to their early applications in the automotive industry, where they were first utilized to enhance door mechanisms. Over the decades, advancements in materials science have led to the development of more durable and lightweight options, making these hinges suitable for a broader range of applications. The introduction of computer-aided design (CAD) and simulation technologies has further refined hinge design, enabling manufacturers to produce highly specialized products that cater to the unique needs of various industries. As the market continues to evolve, the focus on customization and integration with modern technologies will likely drive future innovations in the spring-loaded hinge sector.

By understanding these market dynamics, sourcing trends, and sustainability practices, B2B buyers can make informed decisions that align with their operational goals and ethical standards. This comprehensive approach not only enhances procurement strategies but also positions companies as leaders in sustainability and innovation within their respective markets.

Related Video: Global National: June 11, 2025 | US ambassador to Canada hints at progress on trade deal

Frequently Asked Questions (FAQs) for B2B Buyers of spring-loaded hinges

-

How can I effectively vet suppliers of spring-loaded hinges?

To vet suppliers, start by researching their reputation in the industry through online reviews and testimonials. Request references from previous clients, and verify their business credentials and experience in manufacturing spring-loaded hinges. Additionally, consider visiting their facilities, if possible, to assess their production capabilities and quality control measures. Utilizing platforms such as Alibaba or Global Sources can also help identify reputable suppliers with verified profiles. -

Are customization options available for spring-loaded hinges?

Yes, many manufacturers offer customization options for spring-loaded hinges to meet specific requirements. Buyers should communicate their specifications, including dimensions, materials, and finishes, to potential suppliers. It’s essential to inquire about the supplier’s ability to accommodate custom orders and any associated costs. Ensure that you receive prototypes or samples to evaluate the quality before placing a large order. -

What are the typical minimum order quantities (MOQ) and lead times for spring-loaded hinges?

Minimum order quantities for spring-loaded hinges can vary significantly depending on the supplier and the complexity of the order. Generally, MOQs may range from 100 to 1,000 units. Lead times can also differ; standard production typically takes 4-6 weeks, while custom orders may require additional time. Always discuss these details upfront with suppliers to ensure they align with your project timelines and needs. -

What payment methods are commonly accepted by suppliers?

Payment methods can vary by supplier and region. Common options include bank transfers, letters of credit, and payment platforms like PayPal or Alibaba Trade Assurance. When dealing with international suppliers, be aware of currency fluctuations and consider using secure payment methods that offer buyer protection. It is advisable to negotiate payment terms that minimize risk, such as partial payments upfront and the remainder upon delivery. -

What quality assurance certifications should I look for?

When sourcing spring-loaded hinges, look for suppliers with recognized quality assurance certifications such as ISO 9001, which indicates a commitment to quality management systems. Other relevant certifications may include CE marking for European markets or specific industry certifications relevant to your sector. Requesting documentation and conducting audits can further ensure that the supplier adheres to high manufacturing standards. -

How should I approach logistics when importing spring-loaded hinges?

Logistics is crucial when importing spring-loaded hinges. First, determine the most efficient shipping method based on your budget and timeline—options include air freight for speed or sea freight for cost-effectiveness. Consider working with a freight forwarder to manage customs clearance and documentation. Additionally, understand any import tariffs or regulations in your country that may affect the total cost and delivery time. -

What steps should I take in case of a dispute with a supplier?

In case of a dispute, start by communicating directly with the supplier to resolve the issue amicably. Document all correspondence and agreements. If the dispute cannot be settled, consider leveraging third-party mediation or arbitration services. Additionally, familiarize yourself with the terms outlined in your contract, including any clauses related to dispute resolution, to guide your actions effectively. -

What should I know about the return policy for defective spring-loaded hinges?

It is essential to clarify the return policy with your supplier before placing an order. Most reputable suppliers will have a clear policy regarding defective products, including procedures for returns and replacements. Ensure that you understand the timeframe for reporting defects and any conditions that apply, such as needing to provide evidence like photographs. Establishing a good relationship with your supplier can also facilitate smoother resolutions in case of issues.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for spring-loaded hinges

In conclusion, the strategic sourcing of spring-loaded hinges presents a unique opportunity for international B2B buyers to enhance product performance and operational efficiency. Key takeaways include the importance of selecting high-quality materials, understanding the specifications that meet your specific application needs, and leveraging innovative manufacturing techniques such as additive manufacturing to optimize design flexibility.

Value of Strategic Sourcing: By adopting a strategic sourcing approach, companies can not only reduce costs but also improve supply chain resilience. Engaging with suppliers who prioritize quality and reliability will ensure that your products meet stringent safety and performance standards, particularly in diverse markets across Africa, South America, the Middle East, and Europe.

Looking Ahead: As the demand for customized and sustainable solutions grows, international buyers are encouraged to explore partnerships with manufacturers who are committed to innovation and sustainability. Investing in high-quality spring-loaded hinges today will position your business for success in the future. Embrace the potential of strategic sourcing to drive your operations forward and stay ahead in an increasingly competitive landscape.