Unlock Efficiency with Vertical Conveyors: A Comprehensive

Introduction: Navigating the Global Market for vertical conveyor

In the fast-evolving landscape of global logistics and manufacturing, vertical conveyors stand out as pivotal solutions for optimizing space and enhancing operational efficiency. These systems facilitate the vertical movement of goods, significantly reducing the footprint required for storage and transportation within warehouses and production facilities. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe (including key markets such as Mexico and France) navigate the complexities of sourcing, understanding the nuances of vertical conveyors becomes essential.

This comprehensive guide delves into various aspects of vertical conveyors, including different types—such as reciprocating lifts, spiral conveyors, and incline systems—alongside insights into materials, manufacturing standards, and quality control processes. Buyers will also find valuable information on leading suppliers, cost considerations, and market trends that are shaping the future of vertical transport solutions.

Equipped with this knowledge, decision-makers can make informed sourcing choices that align with their operational needs and budget constraints. By understanding the functionality and integration of vertical conveyors, B2B buyers can enhance their supply chain efficiency, reduce bottlenecks, and ultimately drive productivity within their operations. This guide empowers you to navigate the global market with confidence, ensuring you select the right vertical conveyor solutions for your business.

Understanding vertical conveyor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vertical Reciprocating Conveyor (VRC) | Moves loads vertically between two or more levels; typically powered by hydraulic or electric systems. | Warehouses, manufacturing, and distribution centers. | Pros: High load capacity, space-saving. Cons: Requires significant floor space; not suitable for small loads. |

| Spiral Conveyor | Continuous loop design that allows for efficient vertical transport; compact footprint. | Food processing, pharmaceuticals, and packaging. | Pros: Space-efficient, continuous operation. Cons: Higher initial cost; limited to specific load types. |

| Incline/Decline Conveyor | Designed to move products at an angle; can handle various load sizes. | Food processing, retail, and material handling. | Pros: Versatile for different load types; easy integration. Cons: Requires more space than vertical options. |

| Automated Guided Vehicles (AGVs) | Mobile systems that transport loads to and from vertical conveyors autonomously. | Manufacturing, logistics, and warehousing. | Pros: Reduces labor costs, enhances safety. Cons: High initial investment; requires infrastructure adjustments. |

| Scissor Lift | Offers vertical movement for loads; can be used for lifting personnel as well. | Maintenance, assembly lines, and construction sites. | Pros: Versatile, can handle various load types; good for tight spaces. Cons: Limited height compared to other conveyors; slower operation. |

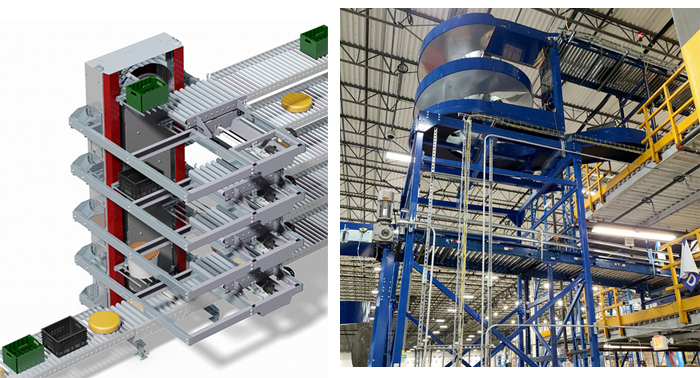

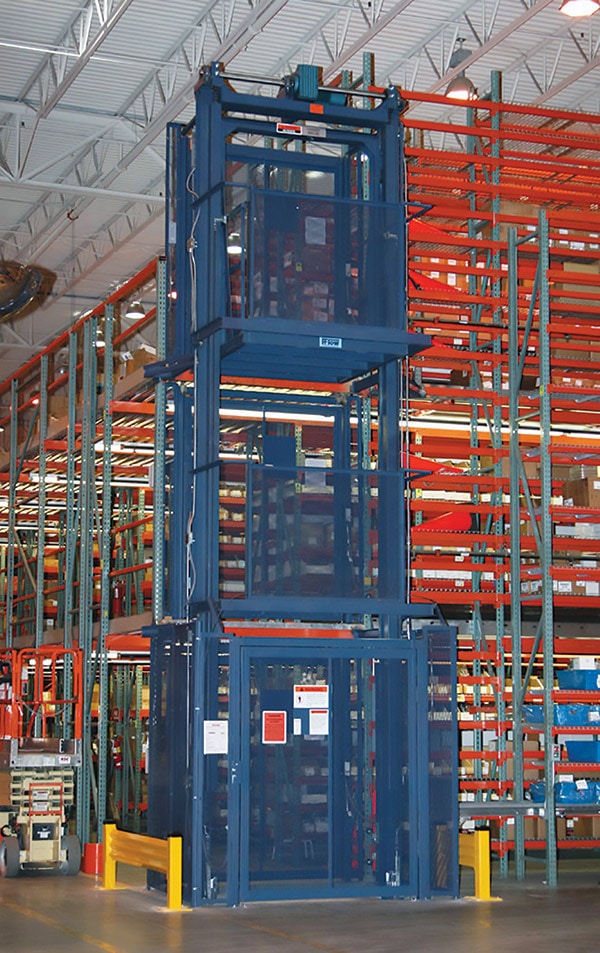

Vertical Reciprocating Conveyor (VRC)

The Vertical Reciprocating Conveyor (VRC) is designed to transport heavy loads vertically between multiple levels. Typically powered by hydraulic or electric systems, VRCs excel in environments where high load capacity is essential, such as warehouses and manufacturing facilities. When considering a VRC, buyers should evaluate the load size and weight, as well as the available floor space, since these systems require a larger footprint compared to other vertical transport options.

Spiral Conveyor

Spiral conveyors are characterized by their continuous loop design, allowing for efficient vertical transport while maintaining a compact footprint. They are commonly used in industries such as food processing and pharmaceuticals, where space is often limited. Buyers should consider the specific load types and weights, as spiral conveyors are best suited for lightweight packages. The initial investment can be higher, but the space-saving benefits often justify the cost.

Incline/Decline Conveyor

Incline and decline conveyors are designed to move products at an angle, making them versatile for various applications. They are often used in food processing, retail, and material handling sectors. While they can handle a range of load sizes, buyers must account for the space required for installation, as these systems generally take up more room than vertical options. Their adaptability makes them a popular choice, but they may not be as efficient for high-volume vertical transport.

Automated Guided Vehicles (AGVs)

AGVs are autonomous mobile systems that can transport loads to and from vertical conveyors, enhancing efficiency in manufacturing and logistics environments. These systems reduce the need for manual labor and improve safety by minimizing human interaction with heavy loads. However, buyers should consider the high initial investment and necessary infrastructure adjustments. Evaluating the operational routes and load capacities is crucial to ensure compatibility with existing systems.

Scissor Lift

Scissor lifts provide vertical movement for loads and can also be utilized for lifting personnel. They are particularly beneficial in maintenance, assembly lines, and construction sites where space is at a premium. While scissor lifts can handle various load types, they have limitations in terms of height compared to other vertical conveyors. Buyers should assess their specific lifting needs and consider the speed of operation, as scissor lifts tend to be slower than other vertical transport solutions.

Related Video: Alpine Conveyors – Vertical Conveyors for Elevation Changes, Accumulation or Buffer Zones

Key Industrial Applications of vertical conveyor

| Industry/Sector | Specific Application of Vertical Conveyor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Vertical transport of heavy machinery parts | Reduces labor costs and increases safety | Load capacity, speed of operation, and automation options |

| Retail and E-commerce | Automated order fulfillment systems | Enhances efficiency and speeds up delivery times | Integration with existing systems, scalability, and reliability |

| Food and Beverage | Transporting packaged goods between processing levels | Maintains hygiene standards and reduces handling | Compliance with food safety regulations, ease of cleaning |

| Pharmaceuticals | Elevating materials in multi-level storage facilities | Optimizes space utilization and improves access | Customization for load types, safety features, and automation compatibility |

| Construction | Moving construction materials on-site | Streamlines workflows and reduces downtime | Durability, adaptability to different environments, and maintenance support |

Key Industrial Applications of Vertical Conveyor

Manufacturing

In manufacturing, vertical conveyors are essential for transporting heavy machinery parts between different stages of production. They effectively reduce the need for manual handling, thereby minimizing labor costs and enhancing safety in environments where heavy lifting is common. Buyers should consider the load capacity and speed of operation when sourcing these systems, as well as the potential for automation to further streamline processes.

Retail and E-commerce

In the retail and e-commerce sectors, vertical conveyors are utilized in automated order fulfillment systems to efficiently move products from storage to packing stations. This application not only speeds up delivery times but also enhances overall operational efficiency. International buyers should prioritize sourcing solutions that can seamlessly integrate with their existing systems, ensuring scalability and reliability to meet fluctuating demand.

Food and Beverage

Vertical conveyors play a critical role in the food and beverage industry by transporting packaged goods between processing levels while adhering to strict hygiene standards. This application helps reduce manual handling, thus lowering the risk of contamination. Buyers in this sector must ensure that the conveyors comply with food safety regulations and are designed for easy cleaning to maintain sanitary conditions.

Pharmaceuticals

In pharmaceutical facilities, vertical conveyors elevate materials within multi-level storage systems, optimizing space utilization and improving access to critical inventory. This application is particularly beneficial for maintaining a streamlined workflow in environments where efficiency is paramount. When sourcing vertical conveyors for pharmaceuticals, buyers should focus on customization options for different load types, as well as essential safety features and automation compatibility.

Construction

In the construction industry, vertical conveyors are used to move materials on-site, significantly streamlining workflows and reducing downtime. This application is vital in managing the flow of heavy construction materials, ensuring that projects remain on schedule. Buyers should consider the durability of the conveyors and their adaptability to various environments, along with the availability of maintenance support to ensure long-term operational efficiency.

Related Video: Prorunner MK1 – Vertical conveyor

Strategic Material Selection Guide for vertical conveyor

When selecting materials for vertical conveyors, it is crucial to consider their properties, advantages, disadvantages, and how they align with specific applications. Below, we analyze four common materials used in vertical conveyor systems, providing actionable insights for international B2B buyers.

Steel

Key Properties:

Steel is renowned for its high strength and durability. It typically has a temperature rating of up to 400°F (204°C) and exhibits excellent corrosion resistance when treated with coatings like galvanization or powder coating.

Pros & Cons:

The primary advantage of steel is its robustness, making it suitable for heavy loads and high-stress environments. However, it can be more expensive than other materials and may require additional treatments to prevent rust, especially in humid climates.

Impact on Application:

Steel is ideal for applications involving heavy machinery or bulk materials. Its compatibility with various media makes it a preferred choice in manufacturing and warehousing sectors.

Considerations for International Buyers:

Buyers should ensure compliance with local standards such as ASTM in the U.S. or EN standards in Europe. Additionally, understanding local corrosion risks and selecting appropriate coatings is vital, especially in regions with high humidity like parts of Africa and South America.

Aluminum

Key Properties:

Aluminum is lightweight yet strong, with a temperature rating of approximately 300°F (149°C). It offers good corrosion resistance and is easily machinable.

Pros & Cons:

Aluminum’s lightweight nature allows for easier handling and installation. However, it may not support as heavy loads as steel and can be more costly per pound.

Impact on Application:

Aluminum is suitable for applications requiring frequent movement or reconfiguration, such as in modular systems. Its corrosion resistance makes it ideal for environments with moisture or chemicals.

Considerations for International Buyers:

Buyers should consider the availability of aluminum in their region, as well as compliance with standards like DIN in Europe. The cost of aluminum can vary significantly based on local market conditions, which is crucial for budgeting.

Plastic (Polymer)

Key Properties:

Plastics, particularly high-density polyethylene (HDPE) or polypropylene, are lightweight and resistant to a wide range of chemicals. They generally operate effectively within a temperature range of -40°F to 180°F (-40°C to 82°C).

Pros & Cons:

Plastic materials are cost-effective and provide excellent corrosion resistance. However, they may not be suitable for very heavy loads and can deform under high temperatures.

Impact on Application:

Plastics are ideal for food processing and pharmaceutical applications due to their non-corrosive nature. They are also useful in environments where hygiene is paramount.

Considerations for International Buyers:

Ensure compliance with food safety regulations (like FDA in the U.S. or EFSA in Europe) if applicable. Additionally, consider local recycling regulations, as plastic waste management varies significantly across regions.

Stainless Steel

Key Properties:

Stainless steel provides exceptional corrosion resistance and can withstand temperatures up to 1500°F (815°C). It is known for its durability and strength.

Pros & Cons:

The main advantage of stainless steel is its resistance to rust and staining, making it ideal for harsh environments. However, it is generally more expensive than both aluminum and plastic.

Impact on Application:

Stainless steel is particularly suitable for food and beverage industries, as well as pharmaceutical applications, where hygiene is critical.

Considerations for International Buyers:

Buyers should be aware of the different grades of stainless steel and their specific applications. Compliance with international standards such as JIS in Japan or ASTM in the U.S. is essential to ensure product quality and safety.

Summary Table

| Material | Typical Use Case for vertical conveyor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery transport | High strength and durability | Requires corrosion treatment | High |

| Aluminum | Modular conveyor systems | Lightweight and easy to handle | Not suitable for very heavy loads | Medium |

| Plastic | Food processing and pharmaceuticals | Cost-effective and corrosion-resistant | May deform under high temperatures | Low |

| Stainless Steel | Food and beverage industries | Exceptional corrosion resistance | Higher cost compared to others | High |

This guide provides a comprehensive overview of material options for vertical conveyors, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for vertical conveyor

Manufacturing vertical conveyors involves a series of systematic processes designed to ensure that each unit meets rigorous quality standards while optimizing efficiency and performance. For international B2B buyers, understanding these processes and the associated quality assurance measures is critical for making informed purchasing decisions. Below is a comprehensive overview of the typical manufacturing stages and quality control (QC) practices relevant to vertical conveyors.

Manufacturing Processes for Vertical Conveyors

1. Material Preparation

The initial stage of manufacturing vertical conveyors involves selecting and preparing materials. Common materials include:

- Steel: Often used for the frame and structural components due to its strength and durability.

- Aluminum: Preferred for lightweight applications where reduced weight is essential.

- Plastic and Composites: Used for components that require corrosion resistance or reduced friction.

Key Techniques:

– Cutting: Raw materials are cut to size using methods such as laser cutting or plasma cutting, ensuring precision for subsequent assembly.

– Surface Treatment: Processes like galvanization or powder coating enhance corrosion resistance and improve the aesthetic appeal of the conveyor components.

2. Forming

Once materials are prepared, they undergo various forming processes to achieve desired shapes and specifications.

- Bending: Metal sheets are bent using hydraulic or mechanical presses to create frames and supports.

- Welding: Components are joined using welding techniques, ensuring structural integrity. MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding are common methods employed.

3. Assembly

The assembly phase is critical for ensuring that all parts function seamlessly together.

- Sub-assembly: Individual components such as motors, rollers, and control panels are assembled first. This modular approach facilitates easier troubleshooting and maintenance.

- Final Assembly: Sub-assemblies are integrated into the main conveyor structure. This process often involves precise alignment and fitting of components to ensure smooth operation.

4. Finishing

The finishing stage enhances both the performance and appearance of the vertical conveyor.

- Painting and Coating: Final coatings are applied to provide additional protection against wear and environmental factors.

- Installation of Control Systems: This includes wiring and programming of any automation features, ensuring that the conveyor meets operational specifications.

Quality Assurance Practices

Quality assurance is paramount in the manufacturing of vertical conveyors. Adherence to international standards and specific industry regulations guarantees reliability and safety.

International Standards

- ISO 9001: This standard focuses on quality management systems and is applicable to all manufacturing processes. Compliance demonstrates a commitment to quality and continuous improvement.

- CE Marking: Required in the European Union, CE marking indicates that the product meets health, safety, and environmental protection standards.

Industry-Specific Standards

- API (American Petroleum Institute): Relevant for conveyors used in the oil and gas industry, API standards ensure that equipment can withstand harsh environments and operational demands.

Quality Control Checkpoints

Quality control is typically integrated at various stages of the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify that they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing checks are performed during manufacturing to detect defects early. This may include dimensional inspections and functional tests.

- Final Quality Control (FQC): The completed conveyor is subjected to rigorous testing, including load testing and performance evaluations, to ensure it meets all operational requirements.

Common Testing Methods

B2B buyers should be aware of the various testing methods that manufacturers may employ:

- Load Testing: Ensures that the conveyor can handle its specified load capacity without failure.

- Functional Testing: Verifies that all moving parts operate correctly and that the control systems function as intended.

- Safety Testing: Assesses the safety mechanisms in place to protect operators and equipment.

Verifying Supplier Quality Control

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, can take several steps to ensure supplier quality control:

-

Supplier Audits: Conducting regular audits of suppliers can help verify their adherence to quality standards and manufacturing processes. This can include facility visits and reviews of quality management systems.

-

Requesting Quality Reports: Suppliers should provide documentation detailing their quality assurance processes, including results from IQC, IPQC, and FQC.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide unbiased verification of product quality and compliance with international standards.

Quality Control Nuances for International Buyers

When sourcing vertical conveyors internationally, buyers should consider the following nuances:

- Cultural and Regulatory Differences: Understand the local manufacturing practices and regulatory requirements in the supplier’s country, as these may impact quality and compliance.

- Language Barriers: Ensure clear communication regarding quality expectations and specifications to avoid misunderstandings.

- Shipping and Handling: Consider how conveyors will be transported and installed, as improper handling can affect performance and safety.

By understanding the manufacturing processes and quality assurance practices associated with vertical conveyors, international B2B buyers can make informed decisions that align with their operational needs and quality expectations. Engaging in thorough due diligence during the supplier selection process will ultimately lead to enhanced productivity and reduced operational risks.

Related Video: The Production Planning Process

Comprehensive Cost and Pricing Analysis for vertical conveyor Sourcing

When sourcing vertical conveyors, understanding the cost structure and pricing dynamics is crucial for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. Below is a detailed analysis that covers cost components, price influencers, and strategic buyer tips.

Cost Components

-

Materials: The cost of materials is a significant factor in the overall price of vertical conveyors. Common materials include steel, aluminum, and various plastics. The choice of material affects durability and weight capacity, which can influence both initial costs and long-term operational efficiency.

-

Labor: Labor costs encompass both direct labor for manufacturing and indirect labor for assembly and installation. Regions with lower labor costs may provide competitive pricing, but it’s essential to assess the skill level and experience of the workforce, as these can impact the quality of the final product.

Illustrative Image (Source: Google Search)

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, maintenance, and administrative expenses. Efficient manufacturing processes can lower overhead costs, allowing suppliers to offer more competitive pricing.

-

Tooling: Tooling costs involve the creation of specialized equipment necessary for manufacturing vertical conveyors. Customization or unique designs can significantly increase tooling expenses. Buyers should inquire about tooling costs upfront, especially if they require bespoke solutions.

-

Quality Control (QC): Implementing rigorous quality control processes ensures that the conveyors meet safety and performance standards. QC costs can vary based on the complexity of the system and the level of certification required (e.g., ISO, CE).

-

Logistics: Shipping and handling costs can vary widely depending on the supplier’s location and the buyer’s destination. Consideration of Incoterms is critical, as they define the responsibilities of buyers and sellers in the shipping process.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure business sustainability. Understanding the market dynamics can help buyers gauge whether the margins are reasonable based on industry standards.

Price Influencers

-

Volume/MOQ: Buying in bulk often leads to discounts. Understanding the minimum order quantities (MOQ) can help buyers negotiate better pricing, especially for larger projects.

-

Specifications/Customization: Custom features and specifications can increase costs. Buyers should assess whether standard models can meet their needs to avoid unnecessary expenses.

-

Material Quality/Certifications: Higher-quality materials and compliance with international certifications usually come at a premium. Buyers should evaluate the necessity of these certifications based on their operational requirements.

-

Supplier Factors: The reputation and reliability of the supplier influence pricing. Established suppliers may command higher prices but offer better warranties and support.

-

Incoterms: The chosen Incoterms can significantly affect overall costs. Understanding who bears the risk and costs of transportation is vital for accurate budgeting.

Buyer Tips

-

Negotiate: Always negotiate pricing and terms. Suppliers often have room to adjust their prices based on order size and payment terms.

-

Focus on Total Cost of Ownership (TCO): Consider not only the upfront costs but also maintenance, energy consumption, and potential downtime when evaluating total costs. A slightly higher initial investment in a more efficient conveyor could lead to significant long-term savings.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, import duties, and local taxes that can affect the final price.

-

Conduct Market Research: Familiarize yourself with regional market trends and competitor pricing to better inform your negotiations.

-

Seek Multiple Quotes: Obtaining quotes from various suppliers can provide leverage in negotiations and help identify the best value for your investment.

Disclaimer

The prices discussed herein are indicative and can vary based on specific requirements, supplier locations, and market conditions. Always verify costs and terms directly with suppliers before making purchasing decisions.

Spotlight on Potential vertical conveyor Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘vertical conveyor’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for vertical conveyor

Key Technical Properties of Vertical Conveyors

Understanding the essential technical properties of vertical conveyors is crucial for B2B buyers. Here are several critical specifications that should be considered:

-

Load Capacity: This defines the maximum weight the conveyor can safely transport. It’s vital for buyers to assess their operational needs to ensure that the vertical conveyor can handle the expected loads without compromising safety or performance. Overloading a conveyor can lead to breakdowns, safety hazards, and increased maintenance costs.

-

Speed: Measured in feet per minute (FPM), speed is an important factor that affects throughput. Buyers must align the conveyor speed with their operational workflow to minimize bottlenecks. A properly timed vertical conveyor can significantly enhance productivity by reducing wait times in loading and unloading processes.

-

Material Grade: The materials used in the construction of vertical conveyors can vary significantly, impacting durability and maintenance. Common materials include steel, stainless steel, and aluminum. Buyers should consider the corrosiveness of their environment, as well as the types of products being transported, to select an appropriate material grade that ensures longevity and reliability.

-

Dimensions and Footprint: The size of the conveyor, including height, width, and overall footprint, is critical for fitting into existing warehouse layouts. Buyers must measure available space to ensure the vertical conveyor will fit without obstructing other operations. A compact design can optimize space utilization, especially in facilities with limited floor space.

-

Drive Mechanism: The type of drive (e.g., hydraulic, electric) influences the conveyor’s efficiency and operational costs. Hydraulic systems are often preferred for heavy loads due to their power, while electric systems can provide faster and more energy-efficient operations. Understanding the advantages and limitations of each system helps buyers choose the best fit for their specific needs.

-

Safety Features: Key safety elements such as emergency stops, guards, and sensors are essential to prevent accidents. Buyers should prioritize conveyors with robust safety features to protect workers and ensure compliance with local regulations. Investing in safety can reduce liability and enhance overall operational efficiency.

Common Trade Terminology in Vertical Conveyors

Familiarity with trade terminology can facilitate better negotiations and decision-making. Here are several important terms relevant to vertical conveyors:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. For buyers, working with OEMs can ensure quality and compatibility of components, leading to better overall performance of vertical conveyor systems.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory effectively and reduce costs. Negotiating lower MOQs can be beneficial, particularly for smaller operations or startups.

-

RFQ (Request for Quotation): An RFQ is a formal document sent to suppliers to request pricing and terms for specific products or services. Buyers should provide clear specifications to receive accurate quotes, which can assist in comparing options and making informed purchasing decisions.

-

Incoterms (International Commercial Terms): These are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping responsibilities, risk transfer, and cost allocation, which is essential for smooth international procurement processes.

-

Lead Time: This refers to the time taken from placing an order to receiving the goods. It is a critical factor in supply chain management, affecting inventory levels and production schedules. Buyers should consider lead times when planning orders to maintain efficiency and meet customer demands.

-

Throughput: This term describes the amount of material or items passing through a system or process in a given period. For vertical conveyors, maximizing throughput is often a key goal, as it directly impacts operational efficiency and profitability. Understanding throughput metrics can help buyers assess the performance of various conveyor options.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions that align with their operational goals and enhance their logistics capabilities.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the vertical conveyor Sector

Market Overview & Key Trends

The vertical conveyor market is experiencing significant growth driven by advancements in automation, increasing demand for efficient material handling solutions, and the rise of e-commerce logistics. Key global drivers include the need to optimize warehouse space and improve operational efficiency, particularly in manufacturing and distribution sectors. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for informed sourcing decisions.

Emerging technologies, such as automated guided vehicles (AGVs) and robotics, are revolutionizing vertical conveyor systems. These technologies facilitate seamless integration with existing conveyor lines, enhancing throughput and reducing manual labor. Furthermore, the growing trend towards smart warehousing and the Internet of Things (IoT) is leading to the development of vertical conveyor systems equipped with real-time monitoring and analytics capabilities, allowing for data-driven decision-making.

Regional differences also play a role in market dynamics. For instance, European buyers may prioritize sustainability and energy efficiency, while those in Africa and South America may focus on cost-effectiveness and adaptability to local conditions. Understanding these regional nuances can help international buyers tailor their sourcing strategies effectively.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone of the vertical conveyor sector, with increasing pressure on manufacturers to minimize their environmental footprint. The production and operation of vertical conveyors can significantly impact energy consumption, waste generation, and resource depletion. As a result, many companies are prioritizing the use of sustainable materials and processes.

International buyers should seek suppliers that demonstrate a commitment to sustainability through certifications such as ISO 14001, which focuses on effective environmental management systems. Additionally, opting for conveyors made from recycled or eco-friendly materials not only reduces the environmental impact but can also enhance brand reputation among increasingly eco-conscious consumers.

Ethical sourcing practices are equally important. Buyers should ensure that their suppliers adhere to fair labor practices and promote safe working conditions throughout their supply chains. This commitment to ethical sourcing not only aligns with corporate social responsibility goals but also fosters long-term relationships with suppliers who share similar values.

Brief Evolution/History

The vertical conveyor has evolved significantly since its inception in the early 20th century. Initially designed for simple material handling tasks, these systems have transformed into complex, automated solutions integral to modern warehousing and logistics. The introduction of advanced technologies, such as programmable logic controllers (PLCs) and sensor integration, has enhanced the functionality and efficiency of vertical conveyors.

Today, vertical conveyors are not just about lifting products; they play a pivotal role in optimizing space, increasing throughput, and improving safety in warehouses and manufacturing plants. As industries continue to adapt to changing market demands, the evolution of vertical conveyors reflects a broader trend towards automation and efficiency in material handling solutions.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of vertical conveyor

-

What should I consider when vetting suppliers for vertical conveyors?

When vetting suppliers, prioritize their industry experience, reputation, and customer reviews. Verify their certifications and compliance with international safety standards. Request case studies or references from similar industries, particularly those relevant to your region, such as Africa, South America, or Europe. Assess their financial stability and capacity to meet your needs. Finally, consider their responsiveness and willingness to engage in discussions about customization or integration with existing systems. -

Can vertical conveyors be customized to fit my specific needs?

Yes, many suppliers offer customization options for vertical conveyors. Discuss your operational requirements, such as load capacity, height, and integration with existing systems. Custom features may include specific loading methods, materials, or automation levels. It’s essential to communicate your needs clearly during the initial discussions to ensure that the final product meets your expectations and operational goals. -

What are the typical minimum order quantities (MOQ) and lead times for vertical conveyors?

MOQs vary significantly between suppliers and depend on the complexity of the conveyor system. Standard models may have lower MOQs, while custom solutions might require larger orders. Lead times can range from a few weeks for standard models to several months for customized systems. Always ask for detailed timelines upfront, including production, assembly, and shipping, to align with your operational schedules. -

What payment terms should I expect when purchasing vertical conveyors?

Payment terms can differ based on the supplier and your relationship with them. Common practices include a deposit (often 30-50%) upfront, with the balance due upon delivery or installation. Some suppliers may offer financing options or extended payment terms for larger orders. Clarify these terms early in negotiations to avoid misunderstandings and ensure smooth transaction processes. -

What quality assurance measures should I look for in a vertical conveyor?

Quality assurance measures vary by supplier, but look for ISO certifications or other relevant industry standards. Ensure that the supplier conducts regular testing and inspections throughout the manufacturing process. Request documentation of these quality checks and any certifications associated with the materials used. It’s also beneficial to inquire about their warranty policies and how they handle potential defects or issues post-purchase. -

How can I ensure effective logistics for shipping vertical conveyors internationally?

Effective logistics involve clear communication with your supplier about shipping methods, costs, and timelines. Determine whether the supplier can handle shipping or if you need to arrange it independently. Be aware of potential customs regulations and import duties in your country that may affect delivery. Establish a detailed shipping agreement that outlines responsibilities for both parties to avoid unexpected delays or costs. -

What steps should I take if there is a dispute with my supplier?

In the event of a dispute, start by reviewing the contract to understand your rights and obligations. Document all communications and issues thoroughly. Initiate a discussion with the supplier to resolve the matter amicably. If informal discussions fail, consider mediation or arbitration as stipulated in your contract. Maintaining a professional relationship is key, as it may facilitate a resolution that benefits both parties. -

What certifications should I look for in vertical conveyor suppliers?

Look for suppliers with certifications relevant to your industry and region, such as ISO 9001 for quality management or ISO 14001 for environmental management. Depending on your sector, additional certifications like CE marking in Europe or compliance with local safety standards in Africa or South America may be necessary. These certifications indicate adherence to industry best practices and regulatory requirements, enhancing the reliability of your supplier.

Illustrative Image (Source: Google Search)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for vertical conveyor

In conclusion, the strategic sourcing of vertical conveyors presents a significant opportunity for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. By understanding the various loading methods, integration options, and the specific needs of your operations, businesses can optimize their logistics and enhance efficiency. Vertical conveyors not only streamline product flow but also reduce manual labor, leading to improved productivity and cost savings.

Key takeaways for buyers include:

– Evaluate Needs: Assess your specific vertical transport requirements to determine the most suitable conveyor type.

– Integration Strategy: Consider how vertical conveyors can be integrated with existing systems, such as AGVs or forklifts, for seamless operations.

– Future Growth: Invest in scalable solutions that accommodate evolving business demands, especially as markets continue to expand.

Looking ahead, the demand for efficient material handling solutions is expected to grow, driven by technological advancements and increasing market competition. As you navigate this landscape, prioritize partnerships with reliable suppliers who can provide innovative, high-quality vertical conveyor systems tailored to your operational needs. Embrace this opportunity to enhance your supply chain efficiency and stay ahead in the global market.