Your Ultimate Guide to Sourcing Toroidal Inductor

Introduction: Navigating the Global Market for toroidal inductor

In today’s rapidly evolving technological landscape, toroidal inductors have emerged as essential components in various electronic applications. These magnetic devices, characterized by their doughnut shape, play a critical role in filtering electrical signals, managing electromagnetic interference (EMI), and enhancing the efficiency of power supplies and transformers. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the intricacies of toroidal inductors is vital for making informed sourcing decisions.

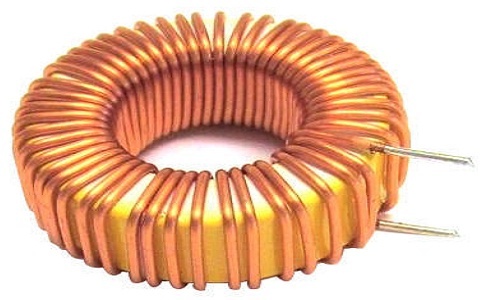

Illustrative Image (Source: Google Search)

This comprehensive guide delves into the diverse types of toroidal inductors, the materials used in their construction, and the manufacturing and quality control processes that ensure their reliability. It also highlights key suppliers and offers insights into cost considerations, helping buyers navigate the complexities of the market. Additionally, a detailed market analysis will be provided, showcasing trends and forecasts that are crucial for strategic planning.

By equipping buyers with actionable insights, this guide empowers organizations to identify suitable suppliers, evaluate product specifications, and ultimately optimize their procurement strategies. Whether you’re operating in consumer electronics, automotive, or telecommunications, understanding the role and selection of toroidal inductors can significantly impact your operational efficiency and product performance. Engage with this guide to unlock the potential of toroidal inductors and enhance your sourcing capabilities in the global market.

Understanding toroidal inductor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ferrite Toroidal Inductor | Made from ferrite material, excellent for high-frequency applications. | Power supplies, EMI filters, RF circuits. | Pros: High efficiency, compact size. Cons: Limited current capacity. |

| Air Core Toroidal Inductor | No magnetic core, lightweight, and ideal for low-frequency applications. | Audio equipment, RF applications. | Pros: High linearity, no saturation. Cons: Larger size, lower inductance. |

| Iron Powder Toroidal Inductor | Utilizes iron powder cores, suitable for high-power applications. | Switching power supplies, inverters. | Pros: High saturation current, cost-effective. Cons: Higher losses at high frequencies. |

| Laminated Toroidal Inductor | Constructed from laminated sheets to reduce eddy current losses. | Industrial equipment, transformers. | Pros: Improved efficiency, reduced noise. Cons: Bulkier design, higher manufacturing costs. |

| Composite Toroidal Inductor | Combines different materials for optimized performance across frequencies. | Automotive electronics, telecom equipment. | Pros: Versatile, tailored performance. Cons: Complexity in sourcing materials. |

Ferrite Toroidal Inductor

Ferrite toroidal inductors are known for their high efficiency and compact design, making them suitable for high-frequency applications. They are widely used in power supplies and EMI filters due to their ability to suppress electromagnetic interference effectively. When purchasing, buyers should consider the inductor’s rated current and frequency response, as these factors significantly impact performance in electronic circuits.

Air Core Toroidal Inductor

Air core toroidal inductors do not have a magnetic core, which makes them lightweight and ideal for low-frequency applications. They are commonly used in audio equipment and RF applications, where linearity and minimal distortion are crucial. Buyers should be mindful of the inductor’s size and inductance value, as these can affect overall circuit performance, especially in compact designs.

Iron Powder Toroidal Inductor

Iron powder toroidal inductors are particularly effective in high-power applications, such as switching power supplies and inverters. They offer high saturation current capabilities, which is beneficial for applications requiring robust performance. B2B buyers should evaluate the core material’s characteristics and the inductor’s thermal management to ensure reliability in demanding environments.

Laminated Toroidal Inductor

Laminated toroidal inductors are constructed using laminated sheets that help reduce eddy current losses, enhancing efficiency. These inductors find applications in industrial equipment and transformers, where minimizing noise and power losses is essential. Buyers should consider the trade-off between size and performance, as laminated designs can be bulkier and more expensive to manufacture.

Composite Toroidal Inductor

Composite toroidal inductors utilize a combination of materials to optimize performance across various frequencies. They are commonly found in automotive electronics and telecom equipment, where reliability and performance are paramount. When sourcing these inductors, buyers should focus on the specific application requirements, as the tailored performance can lead to enhanced functionality in diverse environments.

Key Industrial Applications of toroidal inductor

| Industry/Sector | Specific Application of toroidal inductor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | EMI suppression in electric vehicles (EVs) | Enhances reliability and performance of electronic systems | Ensure compliance with automotive standards and certifications |

| Telecommunications | Signal integrity in 5G infrastructure | Supports high-speed data transmission and reduces interference | Look for high-frequency performance and reliability |

| Consumer Electronics | Power supply filtering in compact devices | Improves efficiency and reduces size of electronic components | Prioritize miniaturization and heat management capabilities |

| Industrial Automation | Noise reduction in control systems | Enhances operational efficiency and equipment lifespan | Assess temperature range and environmental resilience |

| Renewable Energy | Energy conversion in solar inverters | Increases energy efficiency and system reliability | Source from suppliers with expertise in renewable applications |

Automotive Applications

In the automotive sector, toroidal inductors play a crucial role in electromagnetic interference (EMI) suppression, particularly in electric vehicles (EVs). By minimizing EMI, these inductors ensure that sensitive electronic systems, such as advanced driver-assistance systems (ADAS), operate reliably. Buyers in this sector should prioritize suppliers who can meet stringent automotive quality standards and certifications to guarantee product safety and performance.

Telecommunications Applications

For telecommunications, especially with the rollout of 5G networks, toroidal inductors are essential for maintaining signal integrity. They help reduce electromagnetic interference in high-frequency applications, ensuring reliable data transmission. B2B buyers need to consider sourcing inductors that are designed for high-frequency operations, as well as those that can withstand harsh environmental conditions common in telecom infrastructure.

Consumer Electronics Applications

In consumer electronics, toroidal inductors are widely used in power supply circuits to filter out noise and improve efficiency. Their compact design allows for integration into smaller devices, which is increasingly important in today’s market. Buyers should focus on suppliers who can provide miniaturized solutions that maintain high performance while managing thermal dissipation effectively.

Industrial Automation Applications

Within industrial automation, toroidal inductors are utilized to reduce noise in control systems, which enhances the overall efficiency of machinery and equipment. By improving electromagnetic compatibility, these inductors extend the lifespan of industrial components. Buyers should look for inductors that can operate under extreme conditions and offer robust performance to ensure minimal downtime in production processes.

Renewable Energy Applications

In the renewable energy sector, particularly in solar inverters, toroidal inductors are vital for energy conversion processes. They help improve the overall energy efficiency of the system, leading to better performance and reliability. When sourcing for this application, buyers should consider suppliers with a proven track record in renewable technologies and those who can provide inductors tailored to the specific demands of energy conversion applications.

Related Video: How INDUCTOR’s work & How to make your own

Strategic Material Selection Guide for toroidal inductor

When selecting materials for toroidal inductors, international B2B buyers must consider various properties and performance characteristics that align with their specific applications. Here, we analyze four common materials used in the construction of toroidal inductors: ferrite, powdered iron, silicon steel, and amorphous steel. Each material has distinct advantages and limitations that can impact the performance and suitability for different applications.

Ferrite

Key Properties: Ferrite materials exhibit high magnetic permeability and low core losses, making them ideal for high-frequency applications. They typically have a temperature rating of up to 125°C and are resistant to corrosion.

Pros & Cons: Ferrite cores are lightweight and cost-effective, which makes them suitable for mass production. However, they are brittle and can be difficult to machine, which may complicate manufacturing processes. Additionally, their performance can degrade at higher temperatures, limiting their use in high-power applications.

Impact on Application: Ferrite inductors are widely used in applications such as power supplies, RF circuits, and EMI filtering. Their ability to suppress high-frequency noise makes them essential in consumer electronics and telecommunications.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and JIS. Ferrite materials are widely available, but sourcing from reputable suppliers is crucial to guarantee quality.

Powdered Iron

Key Properties: Powdered iron cores provide good magnetic properties at low frequencies and have a higher saturation flux density compared to ferrites. They can operate effectively at temperatures up to 150°C and are more robust than ferrite materials.

Pros & Cons: These cores are less brittle and can withstand mechanical stress, making them easier to handle during manufacturing. However, they tend to have higher core losses at high frequencies, which can reduce efficiency in certain applications. The cost is generally moderate, balancing performance and affordability.

Impact on Application: Powdered iron inductors are commonly used in applications requiring low-frequency operation, such as audio transformers and power inductors in switching power supplies.

Considerations for International Buyers: Buyers should assess the availability of powdered iron cores in their regions, as sourcing may vary. Ensuring compliance with local manufacturing standards is also essential.

Silicon Steel

Key Properties: Silicon steel cores are characterized by their excellent magnetic properties and low hysteresis losses. They can operate efficiently at temperatures up to 200°C, making them suitable for high-power applications.

Pros & Cons: The durability and efficiency of silicon steel make it a preferred choice for high-frequency transformers and inductors. However, the manufacturing process can be complex, leading to higher costs. Additionally, these materials are heavier, which may not be suitable for all applications.

Impact on Application: Silicon steel is often used in power transformers and inductors where high efficiency and durability are critical. Their robust nature allows for use in industrial applications and heavy machinery.

Considerations for International Buyers: Buyers in regions with stringent energy efficiency regulations, such as Europe, should prioritize silicon steel for compliance with local standards. Understanding the supply chain for silicon steel is also important, as it may be impacted by global market fluctuations.

Amorphous Steel

Key Properties: Amorphous steel offers ultra-low core losses and high magnetic permeability. It can operate at temperatures similar to silicon steel, around 200°C, and is resistant to corrosion.

Pros & Cons: The main advantage of amorphous steel is its efficiency, particularly in applications with varying magnetic fields. However, it is more expensive to produce and can be challenging to source, which may limit its use in cost-sensitive projects.

Impact on Application: Amorphous steel is ideal for high-efficiency transformers and inductors in renewable energy systems and electric vehicles, where performance is paramount.

Considerations for International Buyers: Buyers should evaluate the total cost of ownership when considering amorphous steel, including sourcing and manufacturing complexities. Compliance with international standards is also essential for ensuring product quality.

Summary Table

| Material | Typical Use Case for toroidal inductor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Ferrite | Power supplies, RF circuits | Lightweight and cost-effective | Brittle and temperature-sensitive | Low |

| Powdered Iron | Audio transformers, power inductors | Robust and easy to handle | Higher core losses at high freq | Med |

| Silicon Steel | High-frequency transformers | Excellent efficiency and durability | Complex manufacturing process | High |

| Amorphous Steel | High-efficiency transformers | Ultra-low core losses | Expensive and challenging to source | High |

This strategic material selection guide provides B2B buyers with critical insights into the properties, advantages, and limitations of common materials used in toroidal inductors. Understanding these factors will enable informed purchasing decisions that align with specific application requirements and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for toroidal inductor

Manufacturing Processes for Toroidal Inductors

Manufacturing toroidal inductors involves several critical stages that ensure the final product meets stringent performance and quality standards. Understanding these processes is essential for B2B buyers looking to source reliable components for their electronic applications.

Material Preparation

The first step in the manufacturing process is material preparation. Toroidal inductors typically use ferrite or powdered iron cores due to their magnetic properties. The materials must be sourced from reputable suppliers who can provide raw materials that meet international quality standards.

- Material Sourcing: Buyers should verify that materials comply with relevant standards such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals).

- Processing: The materials undergo a specific processing technique, including grinding and mixing, to achieve the desired particle size and composition.

Forming

The forming stage involves shaping the prepared materials into toroidal cores. This is a critical step as the shape directly influences the inductor’s performance.

- Molding Techniques: Manufacturers typically use pressing or injection molding methods to shape the core. Pressing involves compacting the powdered material into a mold, while injection molding melts and injects the material into the mold.

- Sintering: After forming, the cores are sintered in a furnace at high temperatures. This process increases the density and magnetic properties of the core, resulting in better performance.

Assembly

Once the cores are formed, the next step is assembly, which includes winding the wire around the core and connecting terminals.

- Winding: The wire is wound around the toroidal core using automated winding machines. The number of turns and wire gauge are critical parameters that affect the inductance value.

- Terminals: After winding, terminals are attached to enable easy integration into electronic circuits. This may involve soldering or using connectors.

Finishing

The finishing stage is crucial for enhancing the performance and durability of the toroidal inductor.

- Coating: Cores may be coated with insulating materials to prevent short circuits and enhance durability. Common coatings include epoxy and varnish.

- Labeling and Packaging: Proper labeling is essential for tracking and identification. Packaging must protect the inductors during transportation, which is especially important for international shipments.

Quality Assurance in Toroidal Inductor Manufacturing

Quality assurance (QA) is a cornerstone of the manufacturing process for toroidal inductors. Implementing a robust QA system ensures that products meet both industry standards and customer expectations.

International Standards

B2B buyers should be aware of the relevant international standards that govern the quality of toroidal inductors:

- ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is applicable to all organizations. Suppliers should be ISO 9001 certified to ensure consistent product quality.

- CE Marking: For products sold in the European market, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: In industries like automotive and aerospace, adherence to API standards may be necessary, especially for inductors used in critical applications.

Quality Control Checkpoints

Quality control (QC) checkpoints throughout the manufacturing process help identify defects early and ensure the final product’s reliability:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified criteria.

- In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted to monitor production processes and product characteristics.

- Final Quality Control (FQC): Before products are shipped, a final inspection is performed to confirm that they meet all specifications and standards.

Common Testing Methods

Several testing methods are employed to validate the performance of toroidal inductors:

- Inductance Measurement: Using an LCR meter, manufacturers measure the inductance to ensure it falls within specified tolerances.

- DC Resistance Testing: This test checks for any unexpected resistance that could affect performance.

- High-Pot Test: This test determines the insulation resistance and ensures that the inductor can withstand high voltages without breakdown.

Verifying Supplier Quality Control

B2B buyers must implement strategies to verify the quality control measures of potential suppliers:

- Audits: Conducting on-site audits of the supplier’s manufacturing facilities can provide insights into their QA processes and adherence to standards.

- Quality Reports: Requesting detailed quality reports and certifications can help buyers assess the supplier’s commitment to quality.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s QC processes and product quality.

Quality Control Nuances for International Buyers

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of specific nuances when sourcing toroidal inductors:

- Cultural Differences: Understanding the cultural context of suppliers can enhance communication and negotiations. For instance, some regions may prioritize relationship-building before discussing business terms.

- Regulatory Compliance: Different regions may have varying regulatory requirements. Buyers should ensure that the products comply with local regulations in their respective markets.

- Logistics and Shipping: International shipping can introduce risks. Buyers should confirm that suppliers have robust logistics plans and quality assurance during shipping to prevent damage.

By focusing on these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing toroidal inductors, ensuring they receive high-quality products that meet their specifications and market demands.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for toroidal inductor Sourcing

When sourcing toroidal inductors, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe. This analysis provides actionable insights into the key components that influence costs and pricing, as well as strategic tips for effective procurement.

Cost Components

-

Materials: The primary cost driver in toroidal inductor manufacturing is the raw materials used, including ferrite cores and copper wire. Prices for these materials can fluctuate based on market demand and availability. Buyers should consider sourcing from suppliers with stable pricing agreements to mitigate volatility.

-

Labor: Labor costs vary significantly by region. In countries with lower labor costs, such as those in parts of Asia, manufacturers may offer more competitive pricing. However, quality should not be compromised; thus, buyers should evaluate the skill level and efficiency of the workforce.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Efficient production processes can lead to lower overhead costs, which may be passed on to buyers.

-

Tooling: Custom designs often require specific tooling, which can add to initial costs. However, investing in high-quality tooling can improve production efficiency and reduce long-term costs.

-

Quality Control (QC): Implementing stringent QC processes ensures product reliability and compliance with industry standards, which can increase costs but ultimately protect buyers from future expenses related to failures or recalls.

-

Logistics: Shipping costs can significantly impact the total cost of procurement, especially for international buyers. Factors such as distance, mode of transportation, and customs duties should be carefully analyzed to optimize logistics expenses.

-

Margin: Manufacturers will typically include a margin to cover their risks and profits. Understanding market rates for margins can help buyers negotiate better pricing.

Price Influencers

-

Volume/MOQ: Buying in larger quantities often leads to lower per-unit costs. Establishing a minimum order quantity (MOQ) can also influence pricing, so buyers should aim to meet or exceed MOQs when feasible.

-

Specifications/Customization: Custom specifications can increase costs due to the need for specialized materials or production processes. Clear communication about requirements can help in obtaining accurate quotes.

-

Quality/Certifications: Products that meet specific industry certifications (e.g., ISO, RoHS) may command higher prices due to the assurance of quality and compliance. Buyers should weigh the benefits of certification against their cost implications.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Long-standing relationships with reputable suppliers may yield better pricing and service levels.

-

Incoterms: Understanding the implications of Incoterms (International Commercial Terms) is vital for cost management. They define responsibilities for shipping, insurance, and tariffs, which can significantly impact the total landed cost.

Buyer Tips

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Leverage competitive quotes from multiple suppliers to strengthen your position.

-

Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), which includes not just the purchase price but also logistics, maintenance, and potential failure costs. This holistic view can lead to more informed purchasing decisions.

-

Pricing Nuances: Be aware that international suppliers may have different pricing structures due to local economic conditions. Understanding these nuances can help in negotiations and sourcing strategies.

-

Local Partnerships: Establishing relationships with local distributors or agents can provide insights into market pricing and help navigate logistical challenges, especially in regions like Africa and South America.

In conclusion, while the indicative prices for toroidal inductors can vary widely, a thorough understanding of the cost components, pricing influencers, and strategic procurement practices can empower international B2B buyers to make informed decisions that optimize their sourcing outcomes.

Spotlight on Potential toroidal inductor Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘toroidal inductor’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for toroidal inductor

When sourcing toroidal inductors, understanding their technical properties and the associated trade terminology is crucial for making informed purchasing decisions. Below are key specifications and terms that B2B buyers, especially from Africa, South America, the Middle East, and Europe, should be familiar with.

Key Technical Properties

-

Material Grade

– Definition: This refers to the type of material used to construct the toroidal inductor, commonly ferrite or iron powder.

– Importance: Different materials provide varying levels of magnetic permeability and saturation, impacting performance characteristics like inductance and efficiency. Selecting the appropriate material can ensure optimal performance in specific applications, such as power supplies or RF circuits. -

Inductance Value

– Definition: Measured in henries (H), this indicates the ability of the inductor to store energy in a magnetic field.

– Importance: The inductance value directly affects the inductor’s performance in filtering and energy storage applications. Buyers must ensure that the inductance value aligns with their circuit requirements to avoid inefficiencies. -

DC Resistance (DCR)

– Definition: This is the resistance of the inductor’s wire when a direct current flows through it, measured in ohms (Ω).

– Importance: A lower DCR indicates less energy loss as heat, which is crucial for high-efficiency applications. Understanding DCR helps buyers evaluate the overall efficiency of the inductors in their designs. -

Current Rating

– Definition: The maximum continuous current the inductor can handle without overheating or losing its inductance.

– Importance: This specification is vital for ensuring that the inductor can operate effectively under load without failing. Buyers should match the current rating to their application’s demands to prevent premature failure. -

Tolerance

– Definition: This represents the acceptable range of variation in inductance value, expressed as a percentage.

– Importance: Tolerance affects the precision of the inductor in a circuit. In applications where accuracy is critical, such as in communication devices, selecting components with tighter tolerances can enhance performance. -

Temperature Coefficient

– Definition: This indicates how the inductance value changes with temperature variations, typically expressed in parts per million per degree Celsius (ppm/°C).

– Importance: Understanding this property is essential for applications operating in varying temperature environments, ensuring reliable performance across conditions.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– Definition: A company that manufactures products that are sold under another company’s brand.

– Importance: OEMs often supply specialized components like toroidal inductors for larger manufacturers. Understanding this term helps buyers identify potential suppliers for custom or specific applications. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is crucial for budgeting and inventory management. Buyers must ensure that the MOQ aligns with their production needs to avoid excess inventory or shortages. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and availability for specific products.

– Importance: Submitting an RFQ allows buyers to compare prices and terms from different suppliers, facilitating better purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of rules that define the responsibilities of sellers and buyers in international transactions.

– Importance: Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risks involved in the procurement process, enabling more effective negotiation and planning. -

EMI (Electromagnetic Interference)

– Definition: Disturbance generated by an external source that affects an electrical circuit.

– Importance: Understanding EMI is vital for buyers as toroidal inductors are often used to mitigate these effects in electronic devices, ensuring reliable operation.

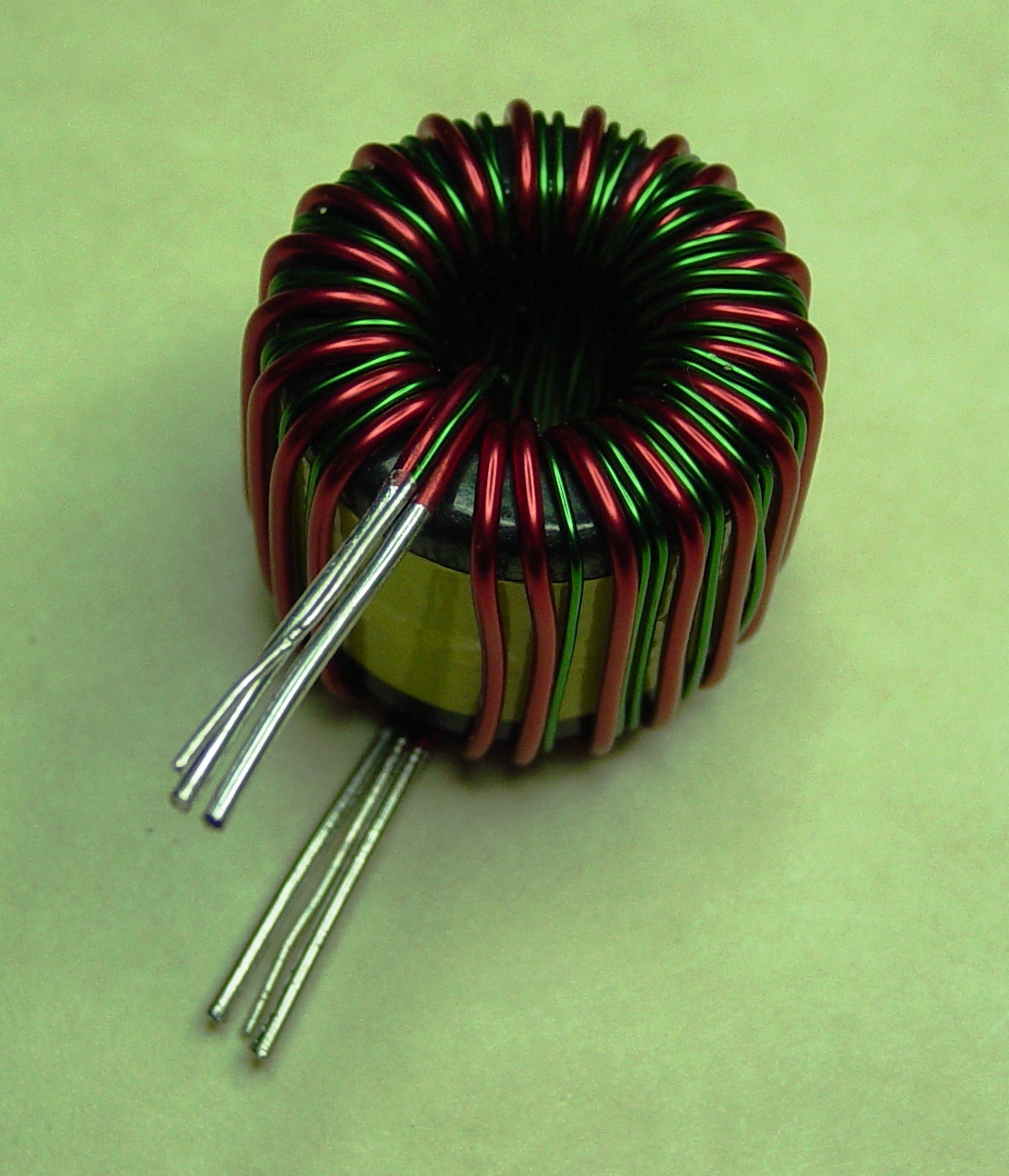

Illustrative Image (Source: Google Search)

By being equipped with knowledge of these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing toroidal inductors, ultimately leading to enhanced product performance and operational efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the toroidal inductor Sector

Market Overview & Key Trends

The global market for toroidal inductors is projected to grow significantly, driven by the increasing demand for efficient energy management solutions across various industries. In 2024, the market was valued at approximately USD 423.6 million and is expected to reach USD 625.7 million by 2032, reflecting a compound annual growth rate (CAGR) of 5.00%. Key drivers include the proliferation of electric vehicles (EVs) and advanced driver-assistance systems (ADAS) in the automotive sector, which rely heavily on high-performance inductors for electromagnetic interference (EMI) suppression.

Emerging trends indicate a shift towards miniaturization of electronic components, with a growing emphasis on compact designs for wearable technology and Internet of Things (IoT) devices. This trend is particularly relevant for international B2B buyers in regions such as Africa and South America, where technology adoption is accelerating. Additionally, the rollout of 5G networks is creating a surge in demand for reliable components that can maintain signal integrity, making toroidal inductors indispensable in telecom infrastructure.

From a sourcing perspective, buyers are encouraged to consider suppliers that offer customized solutions tailored to specific application needs. The ability to adapt designs and materials according to unique specifications is becoming a critical factor in supplier selection. As the market dynamics evolve, fostering strong partnerships with manufacturers who can provide both catalog and custom solutions is essential for maintaining a competitive edge.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal consideration for B2B buyers in the toroidal inductor sector. The environmental impact of manufacturing processes and materials used in inductors is under scrutiny, making ethical sourcing a priority. Buyers are increasingly seeking suppliers that adhere to sustainability practices, including the use of recycled materials and energy-efficient production methods. This not only reduces the carbon footprint of products but also aligns with global trends towards responsible consumption.

Certifications such as ISO 14001 for environmental management and RoHS compliance for hazardous substances are becoming critical benchmarks for assessing supplier credibility. B2B buyers should prioritize partnerships with manufacturers who are transparent about their sourcing practices and offer ‘green’ materials that contribute to sustainable product lifecycles. Moreover, engaging in supply chain audits can help ensure that ethical standards are upheld throughout the procurement process.

By focusing on sustainability, companies can not only mitigate risks associated with regulatory compliance but also enhance their brand reputation and appeal to environmentally conscious consumers. This commitment can lead to long-term cost savings and foster loyalty among customers who value sustainable practices.

Brief Evolution/History

The evolution of toroidal inductors dates back to the mid-20th century, coinciding with advancements in electronics and telecommunications. Initially designed for simple applications, these inductors have undergone significant transformations, becoming essential components in modern high-frequency circuits due to their superior performance characteristics. The toroidal shape, which minimizes electromagnetic radiation and power losses, has made them a preferred choice in various sectors, including consumer electronics, automotive, and industrial automation.

Over the years, innovations in materials science have further enhanced the efficiency and functionality of toroidal inductors, allowing them to meet the demands of increasingly complex electronic systems. Today, they are integral to the development of cutting-edge technologies, underscoring their importance in the global market landscape. As industries continue to evolve, the role of toroidal inductors will only grow, making it essential for B2B buyers to stay informed about market dynamics and sourcing trends.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of toroidal inductor

-

What should I consider when vetting suppliers for toroidal inductors?

When vetting suppliers, prioritize their industry experience, reputation, and certifications. Check for compliance with international standards such as ISO 9001, which indicates a commitment to quality management. Request references from previous clients and assess their financial stability to mitigate risks. Additionally, consider their production capabilities, lead times, and responsiveness to inquiries, as these factors can affect your supply chain efficiency. -

Can toroidal inductors be customized for specific applications?

Yes, many suppliers offer customization options for toroidal inductors to meet specific requirements. This can include variations in size, inductance values, materials, and even specific winding techniques. When discussing customization, provide detailed specifications about your application needs, such as frequency ranges and environmental conditions. Always request prototypes to evaluate performance before finalizing bulk orders. -

What are the typical minimum order quantities (MOQ) and lead times for toroidal inductors?

Minimum order quantities vary by supplier and can range from a few dozen to several thousand units. Lead times also depend on the complexity of the order and the supplier’s production capacity, typically ranging from 2 to 12 weeks. For international buyers, factor in additional time for shipping and customs clearance. Always negotiate MOQs and lead times during initial discussions to align with your project timelines. -

What payment terms are commonly accepted by suppliers?

Most suppliers accept various payment methods, including bank transfers, credit cards, and letters of credit. Payment terms can vary; some may require a deposit upfront, while others may offer payment upon delivery. For larger orders, consider negotiating favorable terms that minimize upfront costs while ensuring supplier commitment. Always clarify payment terms in the contract to avoid misunderstandings. -

How can I ensure quality assurance and certifications for toroidal inductors?

Request copies of quality certifications from potential suppliers, such as ISO certifications and RoHS compliance. It’s advisable to inquire about their quality control processes, including testing methods and inspection protocols. If possible, conduct site visits or audits to verify their quality assurance practices. Establish clear quality expectations in your purchase agreements to hold suppliers accountable. -

What logistics considerations should I keep in mind when sourcing from international suppliers?

Logistics is crucial when sourcing toroidal inductors internationally. Consider shipping methods (air freight vs. sea freight), costs, and delivery timelines. Ensure that the supplier is experienced in handling international shipments and customs documentation. Establish clear communication regarding delivery schedules and potential delays. It may also be beneficial to work with a freight forwarder to streamline the logistics process. -

How should I handle disputes with suppliers?

Disputes can arise from various issues, such as quality discrepancies or delivery delays. To mitigate this, include clear dispute resolution clauses in your contracts, specifying steps for resolution, such as mediation or arbitration. Maintain open lines of communication with your supplier to address issues promptly. Document all correspondence and agreements to support your position if disputes escalate. -

What are the current market trends affecting the toroidal inductor industry?

The toroidal inductor market is experiencing growth driven by the demand for high-efficiency components in industries like automotive and telecommunications. Trends such as the miniaturization of electronic devices and the push for sustainable manufacturing are influencing design and production processes. Additionally, advancements in materials and manufacturing techniques are enabling suppliers to offer more efficient and compact inductors, making it essential for buyers to stay informed about these developments to remain competitive.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for toroidal inductor

In conclusion, strategic sourcing of toroidal inductors is pivotal for international B2B buyers looking to enhance their product offerings and operational efficiency. By understanding the diverse applications and benefits of these components, businesses can make informed purchasing decisions that align with their specific needs, whether in automotive electronics, telecom, or industrial automation.

Key Takeaways:

– Market Growth: The ferrite toroidal coils market is projected to grow significantly, reaching USD 625.7 million by 2032, highlighting the increasing demand for these components across various sectors.

– Technological Advancements: The shift towards miniaturization and sustainable practices presents new opportunities for buyers to explore innovative solutions in their sourcing strategies.

– Regional Insights: Buyers in Africa, South America, the Middle East, and Europe should leverage local suppliers and global manufacturers to optimize costs and ensure quality.

As you navigate the complexities of sourcing toroidal inductors, consider forming strategic partnerships with reliable suppliers who can provide tailored solutions. Embrace the potential of these components to drive your business forward and stay competitive in an evolving market. The future of your supply chain depends on the decisions you make today—invest in strategic sourcing to secure a prosperous tomorrow.