Your Ultimate Guide to Sourcing D.C Motor

Introduction: Navigating the Global Market for d.c motor

In the rapidly evolving landscape of industrial technology, D.C. motors stand out as essential components that power a multitude of applications across various sectors. From automotive to manufacturing, these versatile devices offer precise control, high efficiency, and reliability, making them indispensable in modern machinery and equipment. For B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe, understanding the intricacies of D.C. motors is crucial for making informed sourcing decisions that can drive operational success.

This comprehensive guide delves into the world of D.C. motors, covering a wide range of topics essential for international buyers. It includes an exploration of various types of D.C. motors, an analysis of materials used in their manufacturing, and insights into manufacturing processes and quality control standards. Additionally, the guide provides a detailed overview of key suppliers, cost considerations, and market trends, equipping buyers with the knowledge needed to navigate the complexities of sourcing.

By empowering businesses with actionable insights and expert analysis, this guide aims to facilitate smarter purchasing decisions, ensuring that international B2B buyers can select the right D.C. motors that meet their specific operational needs. Whether you’re in Brazil looking to enhance production capabilities or in Spain seeking sustainable solutions, understanding the global D.C. motor market is your first step toward achieving greater efficiency and competitiveness.

Understanding d.c motor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Brushed DC Motor | Simple construction, uses brushes for commutation | Automotive, robotics, appliances | Pros: Cost-effective, easy to control. Cons: Limited lifespan due to brush wear. |

| Brushless DC Motor | No brushes, uses electronic controllers for commutation | HVAC systems, electric vehicles, drones | Pros: Longer lifespan, more efficient. Cons: Higher initial cost, requires complex control systems. |

| Permanent Magnet DC Motor | Uses permanent magnets for field generation | Industrial automation, conveyor systems | Pros: High efficiency, compact design. Cons: Sensitive to temperature variations. |

| Series DC Motor | High starting torque, speed varies with load | Cranes, electric traction systems | Pros: Excellent torque at low speeds. Cons: Speed control can be challenging. |

| Shunt DC Motor | Constant speed under varying loads, good for precision | Lathes, mills, and other machine tools | Pros: Stable speed, easy to control. Cons: Lower starting torque compared to series motors. |

Brushed DC Motor

Brushed DC motors are widely recognized for their straightforward design, which includes brushes that make contact with a rotating commutator. They are particularly suitable for applications where cost is a significant factor, such as in automotive components and household appliances. However, buyers should consider that while these motors are easy to control and relatively inexpensive, the brushes wear out over time, necessitating periodic maintenance and replacement.

Brushless DC Motor

Brushless DC motors eliminate the need for brushes, relying instead on electronic controllers for commutation. This design results in a longer lifespan and greater efficiency, making them ideal for applications in HVAC systems, electric vehicles, and drones. The complexity of the control systems can be a downside for some buyers, as it may require additional investment in technology and expertise to manage these motors effectively.

Permanent Magnet DC Motor

Permanent magnet DC motors utilize magnets to generate the magnetic field required for operation. This type of motor is known for its compact design and high efficiency, making it suitable for industrial automation and conveyor systems. However, potential buyers should be aware that these motors can be sensitive to temperature changes, which may affect their performance in extreme environments.

Series DC Motor

Series DC motors are characterized by their ability to provide high starting torque, making them a popular choice in applications like cranes and electric traction systems. The speed of these motors decreases as the load increases, which can be advantageous in certain scenarios. Buyers should note that while they excel at low-speed torque, controlling the speed can be more challenging compared to other motor types.

Shunt DC Motor

Shunt DC motors are designed to maintain a constant speed under varying loads, making them ideal for precision applications such as lathes and milling machines. Their easy-to-control nature allows for stable operation, which is a significant advantage in many industrial settings. However, buyers should consider that these motors typically have lower starting torque compared to series motors, which may limit their use in high-torque applications.

Related Video: Normal DC Motor VS Modified DC Motor | #shorts #dcmotor

Key Industrial Applications of d.c motor

| Industry/Sector | Specific Application of d.c motor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Electric Vehicle (EV) Powertrain | Enhanced efficiency and reduced emissions | Compatibility with existing systems and regulations |

| Manufacturing | Conveyor Systems | Increased automation and productivity | Durability and maintenance requirements |

| Agriculture | Irrigation Systems | Improved water management and efficiency | Environmental resilience and energy efficiency |

| Robotics | Robotic Arms for Assembly | Precision and speed in manufacturing processes | Integration capabilities with control systems |

| HVAC (Heating, Ventilation, Air Conditioning) | Blower Motors for Air Circulation | Energy-efficient climate control | Noise levels and energy consumption standards |

Automotive: Electric Vehicle (EV) Powertrain

D.C. motors are crucial in the powertrains of electric vehicles, providing reliable and efficient power delivery. They help in optimizing energy consumption, which is essential for extending battery life and enhancing vehicle range. For international buyers, especially in regions like Africa and South America, understanding local regulations on electric vehicles and sourcing compatible motor systems that meet those standards is vital.

Manufacturing: Conveyor Systems

In manufacturing, d.c. motors drive conveyor systems, allowing for seamless material handling and automation. This application not only boosts productivity but also minimizes manual labor costs. Buyers should consider the motor’s durability and maintenance needs, particularly in high-demand environments, ensuring long-term operational efficiency.

Agriculture: Irrigation Systems

D.C. motors are employed in irrigation systems to automate water distribution, enhancing efficiency in agricultural practices. This technology aids in optimizing water usage, which is increasingly important in arid regions of Africa and South America. Buyers must prioritize motors that can withstand harsh environmental conditions and maintain energy efficiency to reduce operational costs.

Robotics: Robotic Arms for Assembly

In robotics, d.c. motors power robotic arms that are used in assembly lines, offering precision and speed. This application is critical in sectors such as automotive and electronics manufacturing, where accuracy is paramount. B2B buyers should focus on motors that can integrate seamlessly with advanced control systems to achieve the desired performance.

HVAC: Blower Motors for Air Circulation

D.C. motors are used in HVAC systems to drive blower motors, which circulate air efficiently. This application is essential for maintaining optimal indoor climates in commercial and residential buildings. When sourcing these motors, buyers should consider energy consumption and noise levels, as these factors significantly impact overall system performance and user satisfaction.

Strategic Material Selection Guide for d.c motor

When selecting materials for direct current (d.c.) motors, international B2B buyers must consider various factors such as performance, cost, and compliance with regional standards. Below is an analysis of four common materials used in d.c. motors, along with their properties, advantages, disadvantages, and considerations for specific markets.

Copper

Key Properties:

Copper is known for its excellent electrical conductivity and thermal conductivity, making it ideal for windings in d.c. motors. It has a melting point of approximately 1,984°F (1,085°C) and exhibits good corrosion resistance.

Pros & Cons:

Copper’s high conductivity ensures efficient energy transfer, which enhances motor performance. However, it is relatively expensive compared to alternatives like aluminum. Additionally, manufacturing processes can be complex, especially for high-purity copper used in specialized applications.

Impact on Application:

Copper is particularly suitable for applications requiring high efficiency and low heat generation. Its compatibility with various media, including water and oil, makes it versatile for different environments.

Considerations for International Buyers:

Buyers should be aware of compliance with standards such as ASTM B170 for copper wire. In regions like Europe and North America, copper is widely accepted, but in emerging markets, cost considerations may lead to a preference for alternatives.

Aluminum

Key Properties:

Aluminum is lightweight and has good electrical conductivity, although it is less conductive than copper. Its melting point is around 1,221°F (660°C), and it exhibits excellent corrosion resistance, particularly when anodized.

Pros & Cons:

The primary advantage of aluminum is its lower cost and weight, making it suitable for applications where weight savings are critical. However, its lower conductivity can lead to increased energy losses in high-performance applications.

Impact on Application:

Aluminum is often used in applications where weight and cost are significant factors, such as in automotive or portable devices. Its compatibility with various cooling media enhances its usability in diverse environments.

Considerations for International Buyers:

International buyers should consider compliance with standards like ASTM B221 for aluminum extrusions. In markets such as Brazil and South Africa, aluminum’s cost-effectiveness may drive its adoption, despite its lower performance compared to copper.

Steel

Key Properties:

Steel, particularly low-carbon steel, is commonly used for motor housings and structural components. It has a high melting point (around 2,500°F or 1,370°C) and offers good strength and durability.

Pros & Cons:

Steel’s primary advantage is its strength and durability, which provides structural integrity to the motor. However, its weight can be a drawback in applications where lightweight components are preferred. Additionally, steel can be prone to corrosion unless properly treated.

Impact on Application:

Steel is suitable for applications requiring robust structural support, such as industrial motors. Its compatibility with various environmental conditions makes it a reliable choice for heavy-duty applications.

Considerations for International Buyers:

Buyers should ensure compliance with standards such as ASTM A36 for structural steel. In regions like the Middle East, where harsh environmental conditions prevail, corrosion resistance treatments are essential.

Polymer Composites

Key Properties:

Polymer composites are lightweight materials that can offer good electrical insulation and resistance to corrosion. They can withstand temperatures up to 300°F (150°C) depending on the specific type used.

Pros & Cons:

The main advantage of polymer composites is their lightweight nature and resistance to corrosion, making them ideal for applications in harsh environments. However, they may not provide the same mechanical strength as metals and can be more expensive to manufacture.

Impact on Application:

These materials are particularly useful in applications where weight reduction is crucial, such as in aerospace or automotive sectors. Their compatibility with various media enhances their versatility.

Considerations for International Buyers:

International buyers should consider compliance with standards such as ASTM D638 for tensile properties of plastics. In Europe, there is a growing trend towards using composites in automotive applications, driven by sustainability goals.

Summary Table

| Material | Typical Use Case for d.c motor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Windings | Excellent conductivity | High cost, complex manufacturing | High |

| Aluminum | Lightweight applications | Lower cost and weight | Lower conductivity | Medium |

| Steel | Structural components | High strength and durability | Heavier, prone to corrosion | Medium |

| Polymer Composites | Aerospace and automotive | Lightweight and corrosion-resistant | Lower mechanical strength | High |

This strategic material selection guide provides valuable insights for international B2B buyers in making informed decisions regarding d.c. motor components, ensuring compliance with local standards and optimizing performance for specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for d.c motor

The manufacturing process and quality assurance for direct current (D.C.) motors are critical areas that international B2B buyers need to understand. This knowledge not only helps in selecting the right suppliers but also in ensuring that the products meet the required standards and specifications. Below is a detailed overview of the typical manufacturing processes and quality assurance practices for D.C. motors, tailored for B2B buyers from Africa, South America, the Middle East, and Europe.

Manufacturing Processes

The production of D.C. motors involves several key stages, each contributing to the overall quality and performance of the motor. The main stages are material preparation, forming, assembly, and finishing.

1. Material Preparation

This initial stage involves selecting and preparing the raw materials necessary for D.C. motor production, such as:

- Copper Wire: For windings, which are critical for electrical conductivity.

- Steel Laminations: Used for the stator and rotor cores to reduce energy losses.

- Insulation Materials: Such as varnishes and plastics to ensure electrical isolation.

Proper sourcing of materials is essential, as the quality of raw materials directly impacts the motor’s efficiency and durability. Suppliers should provide documentation on material specifications and certifications.

2. Forming

In the forming stage, raw materials are shaped into the required components. Key techniques include:

- Stamping: Used for producing steel laminations for the rotor and stator.

- Winding: This involves winding copper wire around the rotor and stator cores. Automated winding machines can enhance precision and efficiency.

- Machining: Parts are machined to exact dimensions to ensure proper fit and function.

Advanced forming techniques can improve the consistency and quality of components, which is vital for overall motor performance.

3. Assembly

The assembly stage is where individual components are put together to form the complete D.C. motor. This includes:

- Mounting the Rotor and Stator: Ensuring correct alignment and spacing.

- Connecting the Windings: Proper electrical connections are made, including soldering and crimping.

- Installing Bearings and Housing: Bearings ensure smooth rotation, while the housing protects internal components.

During assembly, attention to detail is crucial. Automated assembly lines may be employed to increase efficiency and reduce human error.

4. Finishing

Finishing processes enhance the motor’s performance and longevity. This stage may include:

- Coating and Painting: Protective coatings prevent corrosion and wear.

- Balancing: Ensuring that the rotor is balanced to minimize vibrations during operation.

- Testing for Dimensions and Tolerances: Final checks to ensure components meet specified tolerances.

The finishing touches not only improve aesthetics but also play a significant role in the motor’s operational reliability.

Quality Assurance

Quality assurance is paramount in the manufacturing of D.C. motors to ensure they meet international standards and customer expectations. Key aspects include adherence to relevant standards, implementation of quality checkpoints, and common testing methods.

International Standards

B2B buyers should be aware of international quality standards such as:

- ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is applicable to any organization aiming to enhance customer satisfaction and ensure quality.

- CE Marking: In Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For motors used in the oil and gas industry, compliance with American Petroleum Institute (API) standards may be necessary.

Ensuring that suppliers adhere to these standards provides assurance of product quality and reliability.

Quality Control Checkpoints

Quality control (QC) is an ongoing process during manufacturing, with several checkpoints:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during production to catch defects early.

- Final Quality Control (FQC): A thorough inspection of the finished product before it leaves the factory.

These checkpoints help in identifying and rectifying issues at various stages, ultimately reducing the risk of defects in the final product.

Common Testing Methods

Testing methods are crucial for verifying the performance and reliability of D.C. motors. Common tests include:

- Electrical Testing: Measures parameters such as insulation resistance, winding resistance, and back EMF.

- Mechanical Testing: Evaluates the physical properties, including torque, speed, and vibration analysis.

- Thermal Testing: Assesses the motor’s performance under different temperature conditions.

Documentation of these tests should be available for buyer review to ensure transparency and trustworthiness.

Verifying Supplier Quality Control

B2B buyers must take proactive steps to verify the quality control processes of potential suppliers:

- Conduct Audits: Regular audits can help assess the supplier’s compliance with quality standards and processes.

- Request Quality Reports: Ask for detailed reports on quality checks, including IQC, IPQC, and FQC results.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality practices.

Quality Control and Certification Nuances for International Buyers

When dealing with international suppliers, particularly from regions like Africa, South America, the Middle East, and Europe, buyers should consider:

- Cultural Differences: Be aware of varying business practices and quality perceptions.

- Regulatory Compliance: Ensure that suppliers meet local and international regulations that may affect product quality.

- Logistics and Supply Chain Considerations: Understand the implications of international shipping on product quality, including potential damage during transit.

By focusing on these aspects, international B2B buyers can better navigate the complexities of sourcing D.C. motors, ensuring they receive high-quality products that meet their operational needs.

Related Video: How its made: Efficient Construction Sites & #Fabrication Factory Insights | #Manufacturing Factory

Comprehensive Cost and Pricing Analysis for d.c motor Sourcing

Understanding the Cost Structure of D.C. Motor Sourcing

When sourcing D.C. motors for international B2B applications, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The quality and type of materials used in the production of D.C. motors can significantly impact costs. Common materials include copper for windings, iron or steel for cores, and various plastics for housing. Opting for high-quality materials can enhance performance but may increase the initial purchase price.

-

Labor: Labor costs vary by region and can affect the overall pricing of D.C. motors. Regions with lower labor costs, such as parts of South America and Africa, might provide competitive pricing, while European manufacturers may offer higher quality but at a premium.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, maintenance, and factory management. Efficient manufacturing processes can help reduce these costs, which is essential for competitive pricing.

-

Tooling: Custom tooling can be a significant upfront investment, especially for specialized motor designs. Buyers should consider whether the supplier has the necessary tooling for their specifications, as this affects both lead time and costs.

-

Quality Control (QC): Implementing stringent QC measures can increase production costs. However, investing in quality assurance can lead to long-term savings by minimizing defects and enhancing product reliability.

-

Logistics: Shipping costs are influenced by the distance between the supplier and the buyer, shipping mode, and any tariffs or duties applicable. Understanding logistics is vital for accurate total cost estimation.

-

Margin: Suppliers will include a profit margin in their pricing. This margin can vary widely depending on the supplier’s market position, brand reputation, and perceived value of their products.

Price Influencers in D.C. Motor Sourcing

Several factors can influence the pricing of D.C. motors, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically lead to lower per-unit costs due to economies of scale. Establishing clear volume commitments with suppliers can help negotiate better pricing.

-

Specifications and Customization: Custom designs or specific performance requirements can significantly affect pricing. Buyers should clarify their needs upfront to avoid unexpected costs later.

-

Materials: The choice of materials not only influences performance but also impacts cost. Buyers should weigh the benefits of high-performance materials against their budget constraints.

-

Quality and Certifications: Motors that meet international quality standards or certifications (like ISO or CE) may come at a premium. However, these certifications can provide assurance of reliability and safety.

-

Supplier Factors: The reputation, reliability, and financial stability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: The terms of shipping and delivery (Incoterms) can also affect overall costs. Understanding whether costs include freight, insurance, and customs duties is essential for accurate budgeting.

Buyer Tips for Cost-Efficiency

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, consider the following strategies:

-

Negotiation: Engage in open discussions with suppliers about pricing. Leverage your purchasing volume and long-term relationship potential to negotiate better terms.

-

Total Cost of Ownership (TCO): Assess not just the purchase price but the TCO, which includes operational costs, maintenance, and potential downtime. This comprehensive view can lead to better long-term investment decisions.

-

Understand Pricing Nuances: Be aware of regional pricing differences and currency fluctuations that may impact costs when sourcing from international suppliers.

-

Request Detailed Quotes: Ensure that quotes include a breakdown of all costs, including shipping and any additional fees, to avoid surprises.

Disclaimer on Pricing

Pricing for D.C. motors can vary widely based on numerous factors, including market conditions and supplier capabilities. The figures discussed here are indicative and should be verified with suppliers for accuracy. Always conduct thorough due diligence when negotiating contracts and sourcing components.

Spotlight on Potential d.c motor Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘d.c motor’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for d.c motor

When navigating the procurement of direct current (d.c.) motors, understanding the essential technical properties and trade terminology is crucial for international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe. This knowledge not only facilitates better purchasing decisions but also enhances communication with suppliers.

Key Technical Properties of D.C. Motors

-

Voltage Rating

The voltage rating indicates the maximum voltage the motor can handle. Common ratings include 12V, 24V, and 48V. Understanding the voltage requirement is essential for ensuring compatibility with existing systems and preventing equipment damage. Buyers should assess their application needs to select motors that match these specifications. -

Torque

Torque is the rotational force the motor produces and is typically measured in Newton-meters (Nm). High torque ratings are vital for applications requiring significant mechanical work, such as in automotive or industrial machinery. Buyers should consider the torque requirements of their specific application to avoid performance issues. -

Speed (RPM)

The speed of a d.c. motor is usually specified in revolutions per minute (RPM). This property directly affects the efficiency and performance of the motor in its application. Understanding the required speed helps buyers select a motor that meets their operational needs without compromising efficiency.

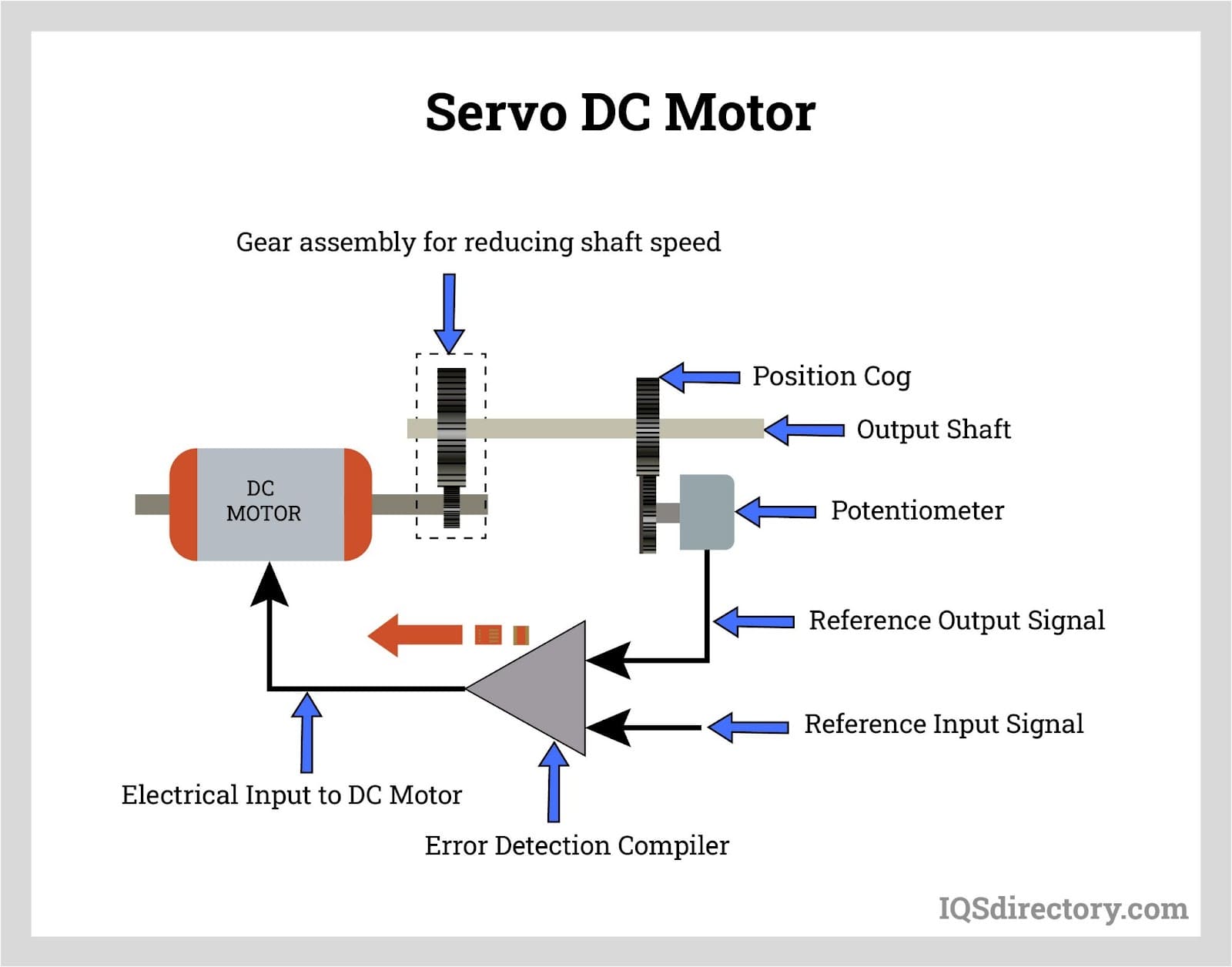

Illustrative Image (Source: Google Search)

-

Efficiency

Efficiency is a measure of how effectively the motor converts electrical energy into mechanical energy. Higher efficiency ratings lead to lower operational costs and energy consumption. Buyers should prioritize motors with high efficiency ratings to reduce long-term expenses and environmental impact. -

Material Grade

The material grade refers to the materials used in the motor’s construction, affecting durability, weight, and performance. Common materials include steel for the casing and copper for windings. Buyers should ensure that the material grades align with their operational environments to enhance reliability and longevity. -

Tolerance

Tolerance specifies the allowable variation in dimensions and performance parameters. This is critical for ensuring that the motor fits properly within its intended application and operates as expected. Buyers must evaluate tolerances to prevent fitment issues and ensure proper integration with other components.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding this term is crucial for buyers seeking to source components that meet specific standards or compatibility requirements. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it can affect inventory costs and purchasing strategies. Buyers should negotiate MOQs that align with their demand forecasts to optimize inventory levels. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. This process is essential for comparing prices and terms from multiple vendors. Buyers should prepare detailed RFQs to receive accurate and competitive quotes. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international rules that clarify the responsibilities of buyers and sellers in international trade. Familiarity with these terms helps buyers understand shipping costs, risks, and insurance responsibilities, facilitating smoother transactions. -

Lead Time

Lead time refers to the time taken from placing an order to the delivery of goods. This is a critical factor for project planning and inventory management. Buyers should consider lead times when negotiating with suppliers to ensure timely project execution. -

Warranty

Warranty is a guarantee provided by the manufacturer regarding the performance and longevity of the motor. Understanding warranty terms is vital for buyers to assess the risk associated with their investment and ensure adequate support in case of defects.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed decisions that enhance their procurement strategies for d.c. motors, ensuring they meet their operational needs effectively.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the d.c motor Sector

Market Overview & Key Trends

The global market for D.C. motors is experiencing significant growth, driven by the increasing demand for electric vehicles (EVs) and automation across various industries. Key regions, including Africa, South America, the Middle East, and Europe, are witnessing a surge in industrial applications, particularly in manufacturing and renewable energy sectors. B2B buyers should pay attention to technological advancements such as the integration of smart technologies and IoT in D.C. motors, which enhance operational efficiency and enable predictive maintenance.

Emerging sourcing trends include a shift towards localized supply chains to mitigate risks associated with global disruptions. This trend is particularly relevant for buyers in South America and Africa, where establishing local partnerships can facilitate better logistics and compliance with regional regulations. Additionally, the emphasis on modular motor designs allows for customization and flexibility in various applications, catering to specific industry needs.

International B2B buyers should also consider the impact of regulatory changes, particularly in Europe, where stringent emissions standards are influencing the design and sourcing of D.C. motors. Engaging with suppliers who are proactive in adapting to these regulations can provide a competitive advantage and enhance market positioning.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a crucial aspect of the D.C. motor supply chain, driven by both consumer demand and regulatory pressures. The environmental impact of manufacturing processes and product lifecycle must be considered by B2B buyers. D.C. motors, particularly those designed for electric vehicles, should focus on reducing energy consumption and utilizing eco-friendly materials.

Illustrative Image (Source: Google Search)

Ethical sourcing is equally important. Buyers should ensure that their suppliers adhere to responsible sourcing practices, including fair labor conditions and reduced carbon footprints. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as benchmarks for assessing supplier sustainability.

Additionally, utilizing ‘green’ materials, such as recycled metals and biodegradable components, can enhance the sustainability profile of D.C. motors. This approach not only meets regulatory compliance but also appeals to environmentally conscious consumers, thereby improving brand reputation and marketability.

Brief Evolution/History

The evolution of D.C. motors traces back to the 19th century, with significant advancements in electrical engineering paving the way for their widespread use. Initially employed in simple applications, these motors have evolved into sophisticated devices integral to modern technology. The transition from mechanical to electronic control systems has revolutionized motor performance, enhancing efficiency and precision.

In recent decades, the rise of renewable energy sources and electric vehicles has further propelled the demand for D.C. motors, emphasizing their versatility and adaptability. As industries continue to innovate, understanding the historical context of D.C. motors can provide valuable insights for international B2B buyers seeking to navigate current market dynamics and trends effectively.

Related Video: Global National: June 11, 2025 | US ambassador to Canada hints at progress on trade deal

Frequently Asked Questions (FAQs) for B2B Buyers of d.c motor

-

What criteria should I use to vet suppliers of d.c motors?

When vetting suppliers, assess their manufacturing capabilities, certifications, and industry experience. Check for ISO certifications, as they indicate adherence to quality management standards. Additionally, request references from other clients and review their track record for on-time delivery and responsiveness. Understanding their financial stability can also provide insight into their reliability. Consider visiting the supplier’s facility if possible, as this allows for a firsthand assessment of their operations. -

Can d.c motors be customized to meet specific needs?

Yes, many suppliers offer customization options for d.c motors to suit specific applications. This can include adjustments to voltage, speed, torque, and physical dimensions. Be clear about your requirements and ask potential suppliers about their customization capabilities during initial discussions. Ensure that they have the technical expertise and resources to deliver custom solutions that align with your operational needs. -

What are typical minimum order quantities (MOQs) and lead times for d.c motors?

Minimum order quantities can vary significantly by supplier, often ranging from 50 to 500 units. Lead times typically depend on the complexity of the motor and the supplier’s current production schedule, often ranging from 4 to 12 weeks. It’s crucial to discuss these details upfront and factor them into your project timelines, especially if you are working on a tight schedule. Some suppliers may also offer flexibility on MOQs for first-time orders. -

What payment terms are common when purchasing d.c motors internationally?

Payment terms can vary widely, but common practices include a partial upfront payment (30-50%) with the balance due upon delivery or after inspection. Some suppliers may offer letters of credit or escrow services for large transactions, providing additional security. Always negotiate terms that protect your interests, especially if you are dealing with a new supplier. Ensure that payment methods are secure and that all terms are clearly documented in your purchase agreement. -

How can I ensure quality assurance (QA) and certifications for my d.c motors?

To ensure quality, request documentation of the supplier’s quality management systems and certifications, such as ISO 9001. Inquire about their testing protocols, including any certifications for safety and performance standards relevant to your industry. Consider asking for samples or conducting third-party inspections before finalizing large orders. Establishing a clear QA process in your contract can help mitigate risks associated with product quality. -

What logistics considerations should I be aware of when importing d.c motors?

Logistics for importing d.c motors include understanding shipping options, customs regulations, and potential tariffs. Choose between air freight for speed or sea freight for cost-effectiveness, depending on your urgency and budget. Familiarize yourself with the import duties and taxes applicable in your country to avoid unexpected costs. Working with a freight forwarder can streamline the process, ensuring compliance with all regulations and smooth customs clearance. -

How should I handle disputes with suppliers over d.c motor orders?

Disputes can arise over quality issues, delivery delays, or contract misunderstandings. Always maintain clear communication with your supplier and document all interactions. If a dispute occurs, refer to the terms outlined in your purchase agreement regarding dispute resolution, which may include mediation or arbitration. Keeping a professional tone and focusing on resolution can help preserve the business relationship, while also ensuring that your concerns are addressed. -

What are the trends in the d.c motor market that I should be aware of?

Key trends include increasing demand for energy-efficient and environmentally friendly motors, driven by global sustainability initiatives. The shift towards electric vehicles and automation in various industries is also influencing the market. Additionally, advancements in smart motor technologies, which incorporate IoT capabilities for enhanced performance monitoring, are gaining traction. Staying informed about these trends can help you make better procurement decisions and ensure that your products remain competitive in the marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for d.c motor

In conclusion, strategic sourcing for DC motors presents an unparalleled opportunity for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. By leveraging local suppliers and fostering partnerships with manufacturers that emphasize innovation and quality, buyers can significantly enhance their operational efficiency and reduce costs. The automotive industry’s ongoing investment in research and development further underscores the importance of sourcing high-quality components that meet evolving market demands.

Key Takeaways:

– Local Sourcing: Engaging with suppliers in your region can lower logistics costs and foster stronger relationships.

– Quality Assurance: Prioritizing suppliers who invest in R&D ensures that you receive cutting-edge technology and reliable products.

– Market Trends: Keeping abreast of global trends, particularly in electric vehicle technologies, can position your business ahead of competitors.

Looking ahead, it is crucial for international buyers to remain agile and proactive in their sourcing strategies. By embracing innovative sourcing practices and forming strategic alliances, businesses can not only thrive in a competitive landscape but also contribute to the sustainable growth of their respective industries. Explore partnerships today that align with your vision for tomorrow.