Master Your Sourcing Strategy for Flat Belt Drive Pulley

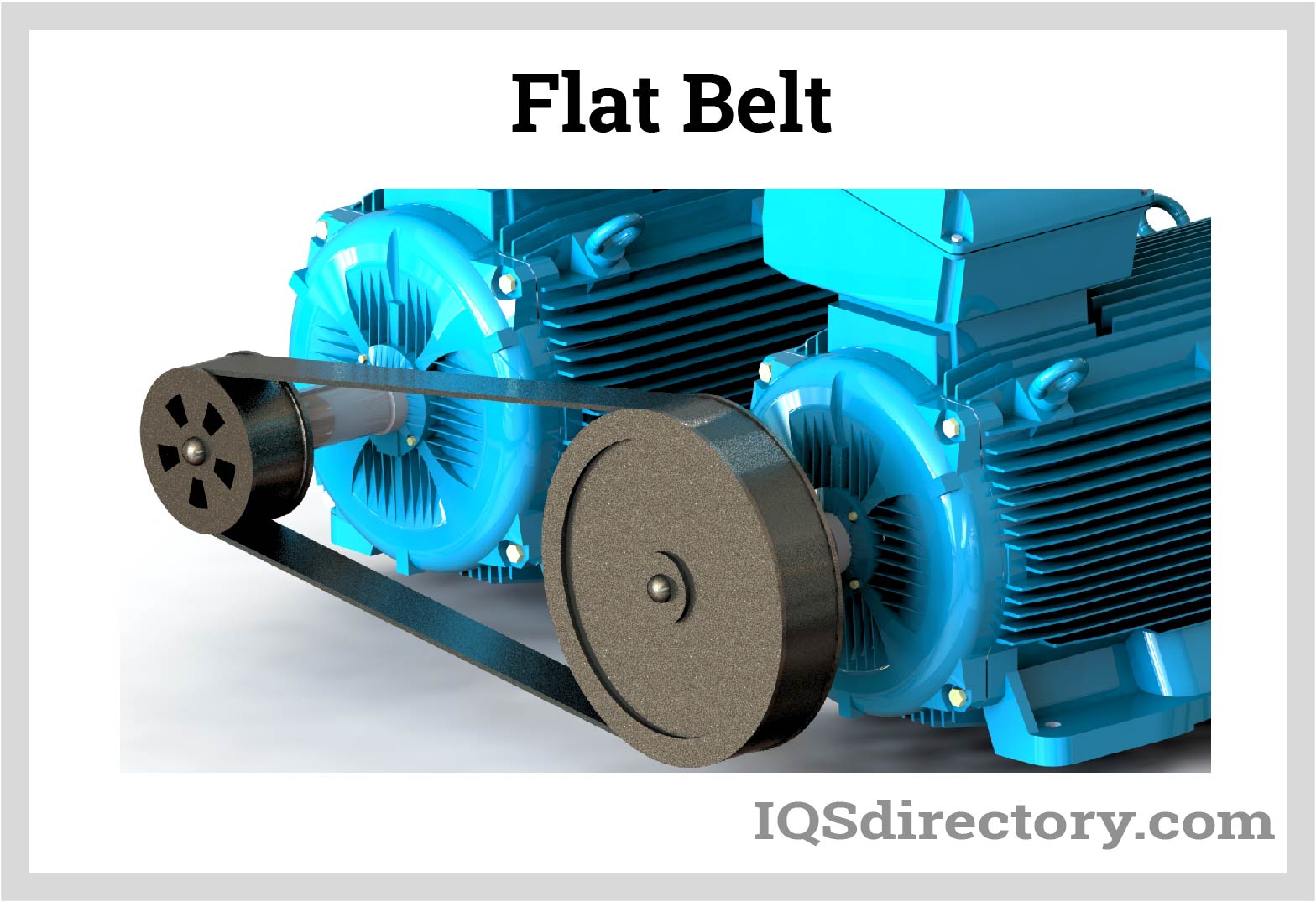

Introduction: Navigating the Global Market for flat belt drive pulley

In an increasingly interconnected global economy, flat belt drive pulleys serve as essential components across various industries, from manufacturing and agriculture to woodworking and printing. Their ability to provide smooth and efficient power transmission makes them invaluable for optimizing operational efficiency and reducing downtime. For B2B buyers in Africa, South America, the Middle East, and Europe—including key markets like Italy and Spain—understanding the intricacies of flat belt drive pulleys is crucial for making informed sourcing decisions.

This comprehensive guide explores the diverse types of flat belt drive pulleys, the materials used in their production, and the critical manufacturing and quality control processes that ensure reliability and performance. We will also delve into the supplier landscape, highlighting both established manufacturers and emerging players in the market. Additionally, key considerations regarding cost factors and market dynamics will be examined, along with a dedicated FAQ section to address common procurement challenges.

By equipping international buyers with in-depth knowledge and actionable insights, this guide empowers you to navigate the complexities of sourcing flat belt drive pulleys effectively. With a clear understanding of the market, you can enhance your procurement strategies, optimize operations, and ultimately drive business success in your respective industries.

Understanding flat belt drive pulley Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Flat Pulley | Simple design, often made from steel or aluminum | Manufacturing, conveyor systems | Pros: Cost-effective, easy to install. Cons: Limited torque capacity. |

| Adjustable Flat Pulley | Features adjustable tensioning mechanism | Textile industry, woodworking | Pros: Customizable speed and torque. Cons: More complex installation. |

| Heavy-Duty Flat Pulley | Reinforced construction for high-load applications | Agricultural machinery, industrial equipment | Pros: High durability, suitable for demanding environments. Cons: Higher cost. |

| Flat Pulley with Flanges | Includes side flanges to prevent belt slippage | Packaging, automotive assembly | Pros: Enhanced belt stability, reduced wear. Cons: Slightly more expensive. |

| Polymer Flat Pulley | Made from advanced materials like nylon or polyurethane | Food processing, pharmaceuticals | Pros: Resistant to chemicals and abrasion. Cons: Higher initial investment. |

Standard Flat Pulley

Standard flat pulleys are characterized by their straightforward design, typically constructed from materials like steel or aluminum. They are widely utilized in manufacturing and conveyor systems due to their cost-effectiveness and ease of installation. However, buyers should be aware that while they are suitable for many applications, their torque capacity may be limited, making them less ideal for high-load scenarios.

Adjustable Flat Pulley

Adjustable flat pulleys come equipped with a tensioning mechanism that allows for precise control over speed and torque. This feature makes them particularly valuable in industries such as textiles and woodworking, where variations in material and process requirements are common. While their customizability is a significant advantage, the complexity of installation may require skilled personnel, impacting labor costs.

Heavy-Duty Flat Pulley

Heavy-duty flat pulleys are designed with reinforced construction to withstand high-load applications, making them ideal for agricultural machinery and industrial equipment. Their robust design ensures longevity and reliability in demanding environments. However, the higher cost associated with these pulleys may be a consideration for budget-conscious buyers, particularly in regions where cost efficiency is a priority.

Flat Pulley with Flanges

Flat pulleys with flanges incorporate side flanges to prevent belt slippage, enhancing the stability of the belt during operation. These pulleys are commonly used in packaging and automotive assembly lines, where consistent performance is critical. While they provide improved belt stability and reduced wear, the additional features may result in a slightly higher price point, which buyers should factor into their budget.

Polymer Flat Pulley

Constructed from advanced materials like nylon or polyurethane, polymer flat pulleys offer exceptional resistance to chemicals and abrasion, making them suitable for industries such as food processing and pharmaceuticals. Their durability and longevity can lead to lower maintenance costs over time. However, the initial investment in polymer pulleys tends to be higher than traditional materials, which may affect procurement decisions for cost-sensitive buyers.

Related Video: Belt Drive | Types of Belt Drives

Key Industrial Applications of flat belt drive pulley

| Industry/Sector | Specific Application of flat belt drive pulley | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Industrial Manufacturing | Conveyor Systems | Smooth and continuous power transmission, reduced wear | Quality of materials, compatibility with existing systems |

| Woodworking | Power Transfer in Woodworking Machines | High torque transmission for precise cutting | Durability under heavy loads, ease of installation |

| Printing | Printing Press Operations | Consistent speed and tension for high-quality prints | Precision in manufacturing, noise reduction capabilities |

| Agriculture | Machinery Power Transfer | Efficient operation in harsh environments | Resistance to dust and vibrations, maintenance requirements |

| Home Appliances | Washing Machines and Vacuum Cleaners | Reliable and quiet operation | Cost-effectiveness, compatibility with various designs |

Industrial Manufacturing

In industrial manufacturing, flat belt drive pulleys are integral to conveyor systems that transport raw materials and finished products. These systems rely on smooth and continuous power transmission, which minimizes wear on components and extends service life. For international buyers, particularly in regions like Africa and South America, sourcing high-quality pulleys made from durable materials is crucial. Additionally, compatibility with existing machinery and systems is a key consideration to ensure seamless integration and efficiency.

Woodworking

In the woodworking sector, flat belt drive pulleys are used to transfer power in machines such as table saws and planers. Their ability to handle high torque makes them ideal for heavy-duty applications, ensuring precise cuts and effective operation. Buyers from Europe, especially Italy and Spain, should focus on the durability of the pulleys, as well as their ease of installation. Understanding the specific power requirements of the machinery is vital to ensure optimal performance and longevity.

Printing

Flat belt drive pulleys are essential in printing press operations, where they provide precise control over the movement of paper and printing cylinders. This precision is crucial for maintaining consistent speed and tension, thereby producing high-quality prints with minimal defects. For B2B buyers in the Middle East, sourcing pulleys that offer noise reduction capabilities can enhance the working environment. Additionally, the manufacturing precision of these components is a critical factor to consider.

Agriculture

In the agricultural sector, flat belt drive pulleys are widely used in tractors and harvesting machinery to transfer power from engines to various components. Their robustness ensures reliable operation in challenging environments filled with dust and vibrations. Buyers from regions like Africa must consider the pulleys’ resistance to harsh conditions and their maintenance requirements. Ensuring compatibility with existing agricultural machinery is also essential for efficient operations.

Home Appliances

Flat belt drive pulleys are found in everyday home appliances such as washing machines and vacuum cleaners, where they facilitate smooth power transmission. Their reliability and quiet operation are significant benefits that enhance user experience. For B2B buyers, especially those in Europe, cost-effectiveness and compatibility with various appliance designs are critical sourcing considerations. Understanding the specific application requirements can help in selecting the right pulley for optimal performance.

Related Video: Differences between Flat Belt Drive and V Belt Drive

Strategic Material Selection Guide for flat belt drive pulley

When selecting materials for flat belt drive pulleys, it is essential to consider various properties that directly impact performance, durability, and cost-effectiveness. Below is a detailed analysis of four common materials used in the manufacturing of flat belt drive pulleys, along with their implications for international B2B buyers.

1. Steel

Key Properties:

Steel pulleys exhibit high strength and rigidity, with excellent temperature resistance (up to 300°C) and pressure ratings. They are also resistant to deformation under heavy loads.

Pros & Cons:

Steel is highly durable and can withstand significant wear and tear, making it suitable for heavy-duty applications. However, it is prone to corrosion if not properly treated, which can lead to increased maintenance costs. Manufacturing complexity is moderate, as steel requires precise machining and finishing.

Impact on Application:

Steel pulleys are ideal for industrial environments where high torque and load capacities are required, such as in manufacturing and agricultural machinery. However, they may not be suitable for applications involving corrosive materials unless coated or treated.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM or DIN for material quality. Corrosion-resistant coatings may be necessary for specific environments, particularly in humid or corrosive regions.

2. Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance, with a temperature rating of around 150°C. It is also non-magnetic, which can be beneficial in certain applications.

Pros & Cons:

Aluminum pulleys are easy to manufacture and offer a good strength-to-weight ratio. They are less durable than steel, making them less suitable for heavy-duty applications. The cost is generally higher than steel due to the material’s properties and processing requirements.

Impact on Application:

Aluminum is commonly used in applications where weight reduction is critical, such as in automotive and aerospace industries. Its corrosion resistance makes it suitable for outdoor applications, but it may not handle high torque situations effectively.

Considerations for International Buyers:

Buyers in regions with stringent environmental regulations should consider aluminum’s recyclability. Compliance with standards like JIS for aluminum alloys is also critical, especially in markets like Europe and Japan.

3. Polyurethane

Key Properties:

Polyurethane offers excellent abrasion resistance and flexibility, with a temperature range of -30°C to 80°C. It is also resistant to oils and chemicals, making it versatile.

Pros & Cons:

The primary advantage of polyurethane pulleys is their durability and ability to withstand harsh conditions, making them suitable for a variety of applications. However, they are generally more expensive than metal options, and manufacturing can be complex due to the material’s properties.

Impact on Application:

Polyurethane is ideal for applications in the food processing and pharmaceutical industries, where hygiene and chemical resistance are paramount. Its flexibility allows for smooth operation in various environments.

Considerations for International Buyers:

Buyers should be aware of the specific regulations regarding food-grade materials in their regions. Compliance with standards such as FDA for food applications and ISO for quality management is essential.

4. Cast Iron

Key Properties:

Cast iron is known for its excellent wear resistance and ability to absorb vibrations. It can withstand high temperatures (up to 500°C) and has a good load-bearing capacity.

Pros & Cons:

Cast iron pulleys are very durable and can handle heavy loads, making them suitable for industrial applications. However, they are heavy and can be brittle, which may lead to breakage under extreme conditions. The manufacturing process is more complex due to the casting required.

Impact on Application:

Cast iron is often used in heavy machinery and industrial equipment where vibration dampening is necessary. However, its weight can be a disadvantage in applications requiring lightweight components.

Considerations for International Buyers:

Buyers should consider the local availability of cast iron and its compliance with international standards like ASTM A48. Understanding the specific applications and environments is crucial to ensure the right material choice.

Summary Table

| Material | Typical Use Case for flat belt drive pulley | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial applications | High strength and durability | Prone to corrosion | Medium |

| Aluminum | Automotive and aerospace applications | Lightweight and corrosion-resistant | Less durable than steel | High |

| Polyurethane | Food processing and pharmaceutical sectors | Excellent abrasion resistance | Higher cost and complex manufacturing | High |

| Cast Iron | Heavy machinery and industrial equipment | Excellent wear resistance | Heavy and brittle | Medium |

This guide provides a comprehensive overview of material selection for flat belt drive pulleys, enabling international B2B buyers to make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for flat belt drive pulley

The manufacturing processes and quality assurance protocols for flat belt drive pulleys are critical aspects that international B2B buyers must understand. This knowledge ensures that they source reliable components that meet their operational requirements and compliance standards. Below is a detailed examination of the key manufacturing stages, quality assurance practices, and how buyers can verify supplier quality.

Manufacturing Processes for Flat Belt Drive Pulleys

The manufacturing of flat belt drive pulleys involves several key stages, each essential for producing high-quality, durable products.

1. Material Preparation

The first step in the manufacturing process is the selection and preparation of materials. Common materials used for flat belt pulleys include:

– Aluminum: Lightweight and resistant to corrosion, ideal for applications requiring ease of handling.

– Steel: Offers high strength and durability, suitable for heavy-duty applications.

– Plastic Composites: Used for lighter applications where weight reduction is crucial.

Once the material is selected, it undergoes processes such as cutting and shaping to prepare it for forming. This stage may also include treatment processes to enhance properties such as strength or corrosion resistance.

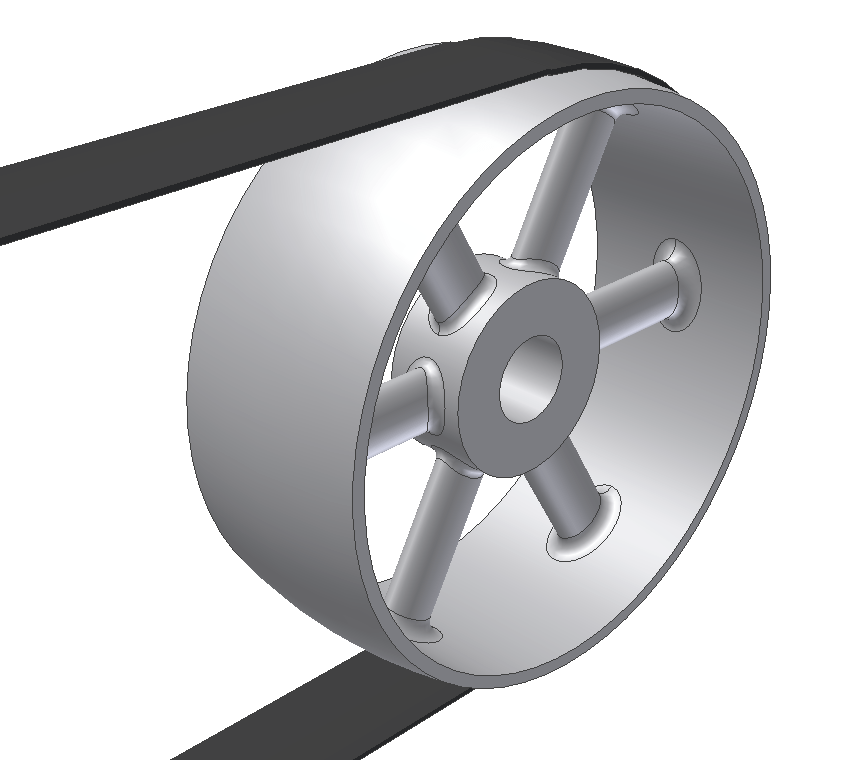

2. Forming

Forming is the next stage, which involves creating the basic shape of the pulley. Key techniques include:

– Casting: Molten material is poured into a mold to create the desired pulley shape. This method is often used for complex geometries.

– Machining: After casting, machining processes like turning, milling, and drilling refine the pulley’s dimensions and surface finish.

– Stamping: For high-volume production, stamping can be utilized to form flat belt pulleys quickly and efficiently.

Illustrative Image (Source: Google Search)

Each method has its advantages, and the choice depends on factors such as volume, complexity, and cost considerations.

3. Assembly

In cases where pulleys are part of a larger assembly (e.g., with bearings or hubs), the assembly process is critical. This stage involves:

– Inserting Bearings: Proper alignment and secure fitting of bearings ensure smooth operation.

– Attaching Hubs: Hubs may be pressed or bolted onto the pulley, depending on design specifications.

Attention to detail during assembly is vital, as misalignment can lead to premature wear and failure in operation.

4. Finishing

The final stage in manufacturing is finishing, which enhances the pulley’s performance and aesthetic appeal. Techniques include:

– Surface Treatment: Processes such as anodizing or powder coating improve corrosion resistance and provide a more durable surface.

– Balancing: Precision balancing ensures that the pulley operates smoothly at high speeds, reducing vibration and noise.

Quality Assurance Practices

Quality assurance (QA) is paramount in the production of flat belt drive pulleys, ensuring that each product meets industry standards and customer specifications.

International Standards

B2B buyers should look for suppliers who adhere to recognized international standards such as:

– ISO 9001: This standard focuses on quality management systems and ensures that organizations meet customer and regulatory requirements consistently.

– CE Marking: Indicates compliance with European safety, health, and environmental protection standards.

Additionally, industry-specific certifications like API (American Petroleum Institute) may apply for pulleys used in oil and gas applications, ensuring they meet sector-specific performance criteria.

QC Checkpoints

Quality control is typically structured around several key checkpoints:

– Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Ongoing checks during manufacturing to monitor processes and identify defects early.

– Final Quality Control (FQC): Comprehensive evaluation of the finished product, including dimensional checks and performance testing.

Common Testing Methods

B2B buyers should be aware of common testing methods used to ensure product quality:

– Dimensional Inspection: Verifying that the pulley meets specified dimensions using calipers and gauges.

– Performance Testing: Assessing the pulley’s operational efficiency under simulated working conditions.

– Fatigue Testing: Evaluating the pulley’s durability and lifespan under repeated stress conditions.

Verifying Supplier Quality

To ensure that suppliers adhere to quality assurance protocols, B2B buyers can implement several strategies:

Supplier Audits

Conducting regular audits of suppliers helps verify compliance with industry standards and internal quality processes. Audits can include:

– Facility Inspections: Assessing manufacturing capabilities and quality control measures.

– Document Review: Evaluating quality management system documentation and previous audit reports.

Quality Reports

Requesting detailed quality reports from suppliers can provide insight into their QC processes. These reports should include:

– Non-Conformance Reports: Documenting any deviations from quality standards and corrective actions taken.

– Test Results: Providing results from performance and safety tests conducted on the pulleys.

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of supplier quality. These services can perform:

– Random Sampling: Inspecting a batch of pulleys to ensure compliance with specifications.

– Certification Verification: Confirming that suppliers hold necessary certifications and adhere to international standards.

Conclusion

Understanding the manufacturing processes and quality assurance measures for flat belt drive pulleys is essential for international B2B buyers. By focusing on the key stages of production and the relevant quality control practices, buyers can make informed sourcing decisions that enhance operational efficiency and reliability. Ensuring that suppliers meet rigorous standards through audits, reports, and third-party inspections will further bolster confidence in their procurement choices, ultimately leading to successful business outcomes across regions such as Africa, South America, the Middle East, and Europe.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for flat belt drive pulley Sourcing

When sourcing flat belt drive pulleys, understanding the cost structure is crucial for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. The overall pricing of these components involves various cost components that can significantly influence the final price.

Cost Components

-

Materials: The primary material used in flat belt drive pulleys is typically steel or aluminum, with some applications utilizing composite materials for weight reduction. The choice of material impacts not only the cost but also the durability and performance of the pulley.

-

Labor: Labor costs can vary depending on the manufacturing location. For instance, countries with lower labor costs may offer competitive pricing, but this can also reflect in quality. Skilled labor is essential for ensuring precision in the manufacturing process.

-

Manufacturing Overhead: This includes expenses related to the production environment, utilities, and equipment maintenance. High-quality production facilities often incur higher overhead costs, which can be reflected in the pricing.

-

Tooling: The cost of specialized tooling for manufacturing specific pulley designs can be significant, especially for customized orders. Buyers should consider whether the tooling costs are included in the quoted price or if they will be charged separately.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the pulleys meet industry standards. Suppliers with robust QC measures may charge a premium, but this investment is crucial for reliability and performance.

-

Logistics: Shipping costs can vary significantly based on the distance between the supplier and the buyer, as well as the mode of transportation. Incoterms also play a vital role in determining who bears the shipping costs and risks.

-

Margin: Suppliers typically add a profit margin to their costs, which can vary based on market competition, demand, and the supplier’s positioning. Understanding the margin structure can help buyers negotiate better prices.

Price Influencers

Several factors can influence pricing when sourcing flat belt drive pulleys:

-

Volume/MOQ: Larger orders often lead to discounts due to economies of scale. Buyers should inquire about minimum order quantities (MOQs) to optimize costs.

-

Specifications/Customization: Custom designs can increase costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Materials: Premium materials or coatings for corrosion resistance may increase costs. Buyers need to balance performance needs with budget constraints.

-

Quality/Certifications: Suppliers with recognized quality certifications (e.g., ISO) may charge more, but this often guarantees better reliability.

-

Supplier Factors: Established suppliers may have a reputation for quality and reliability, which can justify higher prices. Newer suppliers might offer lower prices to gain market entry.

-

Incoterms: Understanding the implications of Incoterms is essential for cost calculation. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) determine who is responsible for shipping costs and risks, impacting overall pricing.

Buyer Tips

-

Negotiation: Always negotiate prices, especially for large orders. Suppliers may have room to maneuver on price, particularly if they are eager to secure a deal.

-

Cost-Efficiency: Assess the total cost of ownership rather than just the purchase price. Consider factors like maintenance, durability, and potential downtime when evaluating options.

-

Total Cost of Ownership (TCO): Include not only the purchase price but also operational costs, potential savings from improved efficiency, and any associated logistical costs.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, suppliers in Europe may have different pricing structures compared to those in Africa or South America, influenced by local market conditions and demand.

Disclaimer

While this analysis provides indicative pricing insights, actual costs may vary based on specific supplier negotiations, market conditions, and currency fluctuations. Always request detailed quotes and consider obtaining multiple bids to ensure competitive pricing.

Spotlight on Potential flat belt drive pulley Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘flat belt drive pulley’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for flat belt drive pulley

Key Technical Properties of Flat Belt Drive Pulleys

Understanding the technical properties of flat belt drive pulleys is crucial for international B2B buyers. These specifications impact performance, longevity, and overall efficiency in various applications.

-

Material Grade: Flat belt drive pulleys are typically made from materials like steel, aluminum, or high-strength plastics. The choice of material affects durability and resistance to wear. For instance, steel pulleys are favored in heavy-duty applications due to their strength, while aluminum is lighter and often used in portable machinery.

-

Diameter: The diameter of the pulley directly influences the speed and torque of the power transmission system. Larger diameters can reduce the speed of the belt while increasing torque, making them suitable for applications requiring high power transfer. Buyers must consider the required speed-torque relationship for their specific machinery.

-

Belt Width: The width of the flat belt is essential for load capacity. A wider belt can distribute the load more evenly across the pulley, reducing wear and increasing efficiency. Buyers should match belt width to the anticipated load to optimize performance and minimize maintenance costs.

-

Tolerance: This specification refers to the allowable deviation in the dimensions of the pulley. Tight tolerances ensure better alignment and performance, reducing the risk of belt slippage or misalignment. Buyers should seek manufacturers who can provide precise tolerances to enhance operational efficiency.

-

Belt Thickness: The thickness of the flat belt impacts its strength and flexibility. Thicker belts are generally more robust and can handle heavier loads but may be less flexible, impacting the speed of operation. Buyers need to balance these factors based on their specific application requirements.

Common Trade Terminology

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B landscape. Here are key terms relevant to flat belt drive pulleys:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable sources for flat belt pulleys that meet specific quality standards.

-

MOQ (Minimum Order Quantity): MOQ indicates the smallest number of units that a supplier is willing to sell. For buyers, knowing the MOQ is vital for budgeting and inventory management, especially when sourcing from international suppliers.

-

RFQ (Request for Quotation): An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. Utilizing RFQs can help buyers gather competitive offers and make informed purchasing decisions.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for managing shipping costs, risks, and delivery timelines, especially for B2B buyers engaged in global sourcing.

-

Lead Time: This refers to the time between placing an order and receiving the product. For international buyers, understanding lead times can aid in planning production schedules and inventory levels, ensuring that operations run smoothly without delays.

-

Quality Assurance: This term encompasses the processes and procedures that ensure products meet specified standards. Buyers should prioritize suppliers with robust quality assurance practices to minimize the risk of defects and ensure reliability in their operations.

By grasping these technical properties and trade terminologies, international B2B buyers can enhance their procurement strategies, optimize their supply chains, and ultimately drive better business outcomes.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the flat belt drive pulley Sector

In the competitive landscape of the flat belt drive pulley sector, understanding market dynamics and sourcing trends is crucial for international B2B buyers, especially from Africa, South America, the Middle East, and Europe.

Market Overview & Key Trends

The global market for flat belt drive pulleys is being driven by several key factors. Firstly, the continuous expansion of industrial manufacturing, particularly in automotive, textile, and woodworking sectors, is increasing the demand for reliable power transmission systems. As countries in Africa and South America ramp up their manufacturing capabilities, there is a growing need for efficient machinery, which often relies on flat belt drive pulleys for optimal performance.

Emerging technologies such as automation and IoT (Internet of Things) are reshaping the sourcing landscape. Buyers are increasingly looking for suppliers who offer smart pulleys equipped with sensors that monitor performance and maintenance needs, thereby reducing downtime and enhancing productivity. Furthermore, the focus on cost-effectiveness has led to an increase in the use of locally sourced materials, which can significantly lower transportation costs and lead times.

Market dynamics are also influenced by regulatory changes and trade agreements, particularly in Europe. For instance, the EU’s emphasis on sustainability and environmental standards is prompting manufacturers to innovate and adapt their products to meet these regulations. Consequently, buyers should actively seek suppliers who demonstrate compliance with international quality standards and offer warranties that reflect product durability and performance.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

The importance of sustainability and ethical sourcing cannot be overstated in today’s B2B environment. The flat belt drive pulley sector is not immune to the pressures of environmental responsibility. As awareness of climate change and resource depletion grows, buyers are increasingly scrutinizing the environmental impact of their supply chains. This includes evaluating the sourcing of raw materials and the production processes employed by suppliers.

For B2B buyers, it is essential to prioritize suppliers who utilize sustainable materials, such as recycled rubber or biodegradable composites, in the manufacturing of flat belt pulleys. Certifications like ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are indicators of a supplier’s commitment to sustainable practices. By choosing partners with these certifications, buyers can enhance their own sustainability profiles and appeal to environmentally conscious customers.

Additionally, ethical sourcing practices are crucial in ensuring fair labor conditions and responsible sourcing of materials. Engaging with suppliers who adhere to social responsibility standards can mitigate risks associated with supply chain disruptions and reputational damage. Buyers should actively seek transparency in their supply chains to ensure that their procurement practices align with their corporate values.

Brief Evolution/History

The flat belt drive pulley has evolved significantly since its inception during the Industrial Revolution. Initially employed in simple mechanical systems, these pulleys have undergone advancements in design and material technology, making them integral to modern manufacturing processes. The transition from leather belts to synthetic materials has improved durability and performance, allowing for better power transmission and reduced maintenance needs.

Today, the flat belt drive pulley stands as a testament to innovation in engineering, combining traditional manufacturing principles with modern technology to meet the demands of diverse industries. As the market continues to evolve, international B2B buyers must remain vigilant in their sourcing strategies, ensuring that they capitalize on emerging trends while adhering to sustainability and ethical standards.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of flat belt drive pulley

-

What factors should I consider when vetting suppliers of flat belt drive pulleys?

When vetting suppliers, prioritize their industry experience, reputation, and quality certifications. Look for suppliers with a proven track record in producing flat belt drive pulleys for your specific application. Request references and case studies to assess their reliability. Additionally, consider their capacity for customization, ability to meet your production timelines, and their willingness to provide samples. It’s also beneficial to evaluate their customer service responsiveness, as effective communication can be crucial during the sourcing process. -

Can flat belt drive pulleys be customized to fit specific applications?

Yes, many manufacturers offer customization options for flat belt drive pulleys to meet the unique requirements of various applications. Customizations may include alterations in size, material, or design features to optimize performance. When discussing customization, clearly outline your specifications and performance expectations to ensure the supplier can meet your needs. Be aware that custom orders may affect lead times and pricing, so it’s essential to discuss these factors upfront. -

What are the typical minimum order quantities (MOQs) and lead times for flat belt drive pulleys?

Minimum order quantities can vary significantly between suppliers, often ranging from a few dozen to several hundred units. Lead times typically depend on the complexity of the order and the supplier’s production capacity, averaging between 2 to 6 weeks. For custom orders, lead times may extend further. It’s advisable to clarify MOQs and lead times during initial discussions to align your procurement schedule with the supplier’s capabilities. -

What payment terms are commonly used in international transactions for flat belt drive pulleys?

Payment terms can vary, but common practices include advance payments, letters of credit, or payment upon delivery. For international transactions, consider using secure payment methods that offer buyer protection, such as PayPal or escrow services. It’s crucial to negotiate terms that provide both parties with confidence and security. Ensure you understand any potential currency exchange risks and factor them into your total cost calculations. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers will implement stringent quality assurance measures, including material testing, dimensional inspections, and performance testing of flat belt drive pulleys. Request documentation of their quality control processes and any relevant certifications, such as ISO 9001. Additionally, inquire about their return policy and warranty terms, as these are indicators of the supplier’s commitment to quality and customer satisfaction. -

How can I ensure smooth logistics and timely delivery of flat belt drive pulleys?

To ensure efficient logistics, work closely with your supplier to understand their shipping methods and timelines. Discuss the best shipping options considering your location and urgency. Utilize a reliable freight forwarder familiar with international shipping regulations to facilitate customs clearance and avoid delays. It’s also advisable to establish clear communication channels for tracking shipments and addressing any potential issues promptly. -

What steps should I take if a dispute arises with my supplier?

In the event of a dispute, maintain clear and professional communication with your supplier to resolve the issue amicably. Document all correspondence and agreements related to the transaction. If direct negotiations fail, refer to the terms outlined in your contract, which should specify dispute resolution procedures. Consider mediation or arbitration as alternative solutions before escalating to legal action, which can be costly and time-consuming. -

What certifications should I look for when sourcing flat belt drive pulleys?

Look for certifications that indicate adherence to international quality and safety standards. Common certifications include ISO 9001 for quality management and ISO 14001 for environmental management. Additionally, if your application involves food processing or pharmaceuticals, check for FDA or food safety certifications. These certifications not only assure product quality but also demonstrate the supplier’s commitment to maintaining industry standards, which can significantly reduce risks in your supply chain.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for flat belt drive pulley

In conclusion, the strategic sourcing of flat belt drive pulleys presents significant opportunities for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe. Understanding the diverse applications of flat belt pulleys—from industrial manufacturing to agricultural machinery—enables buyers to identify the most suitable solutions for their specific needs. The advantages of flat belt pulleys, such as low maintenance, ease of installation, and efficient power transmission, make them a valuable addition to various operations.

As global markets evolve, it is essential for buyers to leverage strategic sourcing practices to enhance procurement efficiency and reduce costs. Engaging with reliable suppliers and staying informed about industry trends will further empower businesses to optimize their operations.

Looking ahead, as technological advancements continue to shape the manufacturing landscape, buyers should remain proactive in adapting their sourcing strategies. By doing so, they can ensure that their operations are equipped with the most effective and innovative flat belt drive pulley solutions, ultimately driving success in their respective markets. Explore partnerships with trusted manufacturers and keep an eye on emerging trends to stay ahead in this competitive environment.