Your Ultimate Guide to Sourcing Solenoid Valve Coil

Introduction: Navigating the Global Market for solenoid valve coil

In today’s global marketplace, the solenoid valve coil stands as a vital component across various industries, enabling precise control in systems ranging from HVAC to industrial automation. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of solenoid valve coils is essential for making informed sourcing decisions that enhance operational efficiency and reliability.

This comprehensive guide aims to demystify the complexities surrounding solenoid valve coils by exploring various types and their applications, materials used in manufacturing, and quality control standards that ensure performance longevity. Additionally, it delves into the cost factors influencing procurement, identifies reputable suppliers across different regions, and addresses frequently asked questions to clarify common misconceptions.

By empowering buyers with actionable insights into the specifications and operational characteristics of solenoid valve coils, this guide facilitates smarter purchasing strategies. Whether you are a procurement officer in Germany seeking high-performance AC coils or a manufacturer in Argentina looking for reliable DC options, this resource equips you with the knowledge needed to navigate the global market effectively. With a focus on quality, compatibility, and performance, you can confidently select the right solenoid valve coils that meet your operational demands and drive business success.

Understanding solenoid valve coil Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| AC Solenoid Coils | Operate on alternating current; typically have high inrush and low holding current. | HVAC systems, industrial automation | Pros: High pull force; suitable for continuous duty. Cons: Sensitive to dirt and may require more maintenance. |

| DC Solenoid Coils | Operate on direct current; quieter and more energy-efficient. | Battery-powered systems, low-voltage applications | Pros: Quieter operation; energy-efficient. Cons: Limited voltage options; may require specific power sources. |

| Dual Voltage Coils | Can operate on both AC and DC; versatile in application. | Versatile industrial applications | Pros: Flexibility in power supply; reduces inventory costs. Cons: Rare and may not suit all applications. |

| High-Temperature Coils | Designed for high ambient temperatures; usually rated for insulation classes F and H. | Industrial settings with extreme conditions | Pros: High reliability in tough environments. Cons: Higher cost and may require specific installation conditions. |

| IP-rated Coils | Offer varying degrees of ingress protection (IP65-IP68); suitable for harsh environments. | Water treatment, outdoor automation | Pros: Enhanced durability against environmental factors. Cons: Typically more expensive than standard coils. |

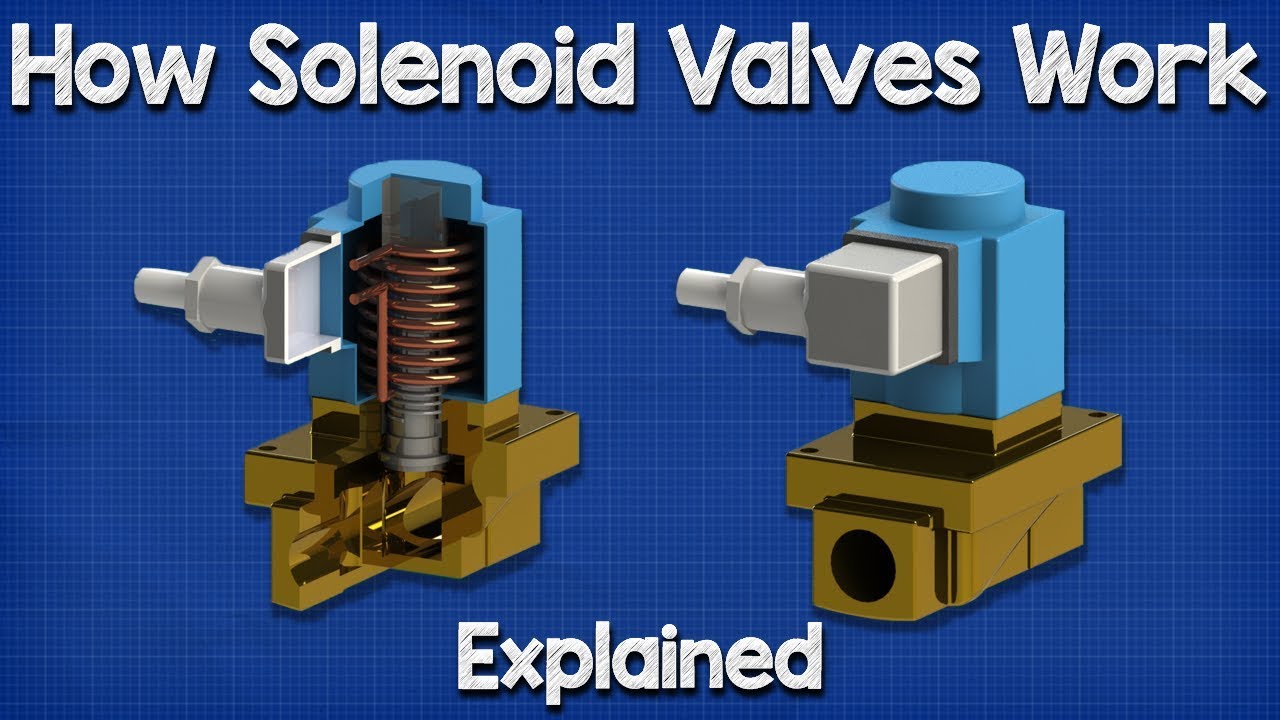

AC Solenoid Coils

AC solenoid coils are designed to operate with alternating current, making them ideal for applications requiring continuous operation. Their high inrush and low holding current characteristics allow them to generate significant pull force, which is essential for tasks like valve actuation in HVAC systems and industrial automation. However, buyers should consider that AC coils are sensitive to dirt and may require more frequent maintenance, especially in dusty or industrial environments.

Illustrative Image (Source: Google Search)

DC Solenoid Coils

DC solenoid coils utilize direct current and are known for their quieter and more energy-efficient operation compared to their AC counterparts. They are particularly suitable for battery-powered systems and low-voltage applications, making them a preferred choice for industries such as automotive and portable equipment. When purchasing, it is crucial for buyers to ensure compatibility with their power sources, as DC coils often come with limited voltage options.

Dual Voltage Coils

Dual voltage coils offer the flexibility to operate on both AC and DC power, making them versatile for various industrial applications. This adaptability allows businesses to minimize inventory costs by using the same coil type across different systems. However, buyers should be aware that dual voltage options are relatively rare and may not be suitable for all applications, necessitating careful consideration of operational requirements.

High-Temperature Coils

High-temperature solenoid coils are engineered to withstand extreme ambient conditions, typically rated under insulation classes F and H. They are essential for industrial settings where high temperatures are common, such as manufacturing or chemical processing plants. While they offer high reliability, buyers should be prepared for potentially higher costs and the need for specific installation conditions to ensure optimal performance.

IP-rated Coils

IP-rated solenoid coils provide various levels of ingress protection, making them ideal for use in harsh environments, such as water treatment facilities and outdoor automation systems. These coils are designed to resist dust and moisture, ensuring longevity and reliability. However, the added durability comes at a premium, so buyers should weigh the benefits against the higher costs associated with IP-rated products.

Related Video: Solenoid Valve Explained | Types and Application

Key Industrial Applications of solenoid valve coil

| Industry/Sector | Specific Application of solenoid valve coil | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| HVAC | Control of heating and cooling systems | Enhances energy efficiency and precise temperature control | Voltage compatibility, insulation class, and durability ratings |

| Water Treatment | Automated control of water flow and chemical dosing | Ensures consistent water quality and compliance with regulations | Corrosion resistance, size specifications, and response time |

| Industrial Automation | Actuation of machinery in production lines | Increases operational efficiency and reduces downtime | Availability of replacement parts and technical support |

| Oil and Gas | Regulation of gas flow in pipelines | Improves safety and operational reliability | High-pressure ratings, temperature tolerance, and material compatibility |

| Agricultural Irrigation | Automated irrigation systems | Optimizes water usage and enhances crop yield | Environmental ratings, voltage options, and compatibility with existing systems |

HVAC Applications

In the HVAC sector, solenoid valve coils are integral for controlling heating and cooling systems. They enable precise actuation of valves that regulate refrigerant flow, contributing to energy efficiency and maintaining desired temperatures. International buyers, especially from regions with varying climates, need to consider the voltage compatibility of coils, as well as insulation classes that can withstand high temperatures. Selecting durable coils can prevent frequent replacements and reduce maintenance costs.

Water Treatment

In water treatment facilities, solenoid valve coils automate the control of water flow and chemical dosing, ensuring the consistent quality of treated water. This is crucial for meeting health and safety regulations. Buyers in this industry must prioritize corrosion-resistant materials and verify size specifications to ensure compatibility with existing systems. Additionally, response times of solenoid valves can significantly impact overall system efficiency, making it a vital consideration during sourcing.

Industrial Automation

In industrial automation, solenoid valve coils are used to actuate machinery on production lines. This application enhances operational efficiency by enabling quick and reliable valve actuation, which is essential for maintaining workflow and reducing downtime. B2B buyers must consider the availability of replacement parts and the technical support offered by suppliers, as these factors can greatly influence production continuity. Moreover, understanding the specific power requirements and environmental conditions is critical for optimal performance.

Oil and Gas

The oil and gas industry utilizes solenoid valve coils for regulating gas flow in pipelines, a crucial application for ensuring safety and operational reliability. These coils must be able to handle high-pressure environments and various temperature conditions. International buyers should focus on sourcing coils with appropriate pressure ratings and materials that can withstand harsh environments. Compliance with safety standards is also paramount, necessitating thorough verification of product specifications.

Agricultural Irrigation

In agricultural irrigation, solenoid valve coils automate the distribution of water, optimizing usage and enhancing crop yield. This application is particularly beneficial in regions facing water scarcity. Buyers in this sector should look for environmentally rated coils that can operate efficiently under varying conditions. Additionally, compatibility with existing irrigation systems and voltage options are essential to ensure seamless integration and operation.

Related Video: How Solenoid Valves Work – Basics actuator control valve working principle

Strategic Material Selection Guide for solenoid valve coil

When selecting materials for solenoid valve coils, it is essential to consider various factors that influence performance, durability, and application suitability. Below, we analyze four common materials used in solenoid valve coils, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

Copper

Key Properties: Copper is a highly conductive material, which allows for efficient electrical flow. It has a high melting point (approximately 1,984°F or 1,085°C) and good corrosion resistance, particularly when coated or alloyed.

Pros & Cons: Copper coils are durable and provide excellent electromagnetic performance. However, they can be more expensive than alternatives like aluminum, and their manufacturing process can be complex, especially when precision winding is required. Additionally, copper is susceptible to oxidation if not properly coated.

Impact on Application: Copper coils are suitable for applications requiring high conductivity and reliability, such as HVAC systems and industrial automation. They are compatible with various media but may require protective coatings in corrosive environments.

Considerations for International Buyers: Buyers in regions like Europe and South America should ensure compliance with standards such as ASTM B187 for copper bars and rods. The demand for high-quality copper coils is increasing, particularly in industries focused on energy efficiency.

Aluminum

Key Properties: Aluminum is lightweight, has good corrosion resistance, and offers moderate conductivity compared to copper. It typically has a melting point of around 1,221°F (660°C).

Pros & Cons: The main advantage of aluminum is its lower cost and lighter weight, making it easier to handle and install. However, its lower conductivity can lead to reduced performance in high-demand applications. Additionally, aluminum coils may require more frequent maintenance due to potential corrosion.

Impact on Application: Aluminum coils are often used in less demanding applications, such as small-scale pneumatic systems or low-pressure environments. They are compatible with various fluids but may not be suitable for high-temperature applications.

Considerations for International Buyers: Compliance with standards such as ASTM B221 is crucial for ensuring quality. Buyers in Africa and the Middle East may find aluminum coils more accessible due to lower costs, but they should evaluate their specific application needs carefully.

Stainless Steel

Key Properties: Stainless steel offers excellent corrosion resistance and can withstand high temperatures (up to 1,500°F or 815°C). Its mechanical strength is significantly higher than that of copper or aluminum.

Pros & Cons: The durability and longevity of stainless steel coils make them ideal for harsh environments. However, they are more expensive to manufacture and can be heavier than other materials, which may complicate installation.

Impact on Application: Stainless steel coils are particularly suited for applications involving aggressive media, such as chemicals or high-pressure systems. They are commonly used in water treatment and gas safety systems.

Considerations for International Buyers: Buyers should pay attention to specific grades of stainless steel, such as 316L, which is known for its corrosion resistance. Compliance with international standards like ASTM A240 is essential, especially for buyers in Europe and the Middle East.

Ferrite

Key Properties: Ferrite materials are magnetic and have high permeability, which enhances the efficiency of solenoid coils. They can operate effectively at elevated temperatures but are typically less conductive than metals.

Pros & Cons: Ferrite coils are often more cost-effective and can be designed to meet specific electromagnetic requirements. However, their lower conductivity can lead to inefficiencies in high-power applications.

Impact on Application: Ferrite coils are commonly used in applications where magnetic properties are more critical than electrical conductivity, such as in certain types of sensors and relays.

Considerations for International Buyers: Buyers should consider the specific electromagnetic requirements of their applications and ensure compliance with relevant standards. Ferrite materials may be more prevalent in certain regions, such as Asia, but are gaining traction in Europe and South America.

Summary Table

| Material | Typical Use Case for solenoid valve coil | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | HVAC systems, industrial automation | Excellent conductivity and reliability | Higher cost, susceptible to oxidation | High |

| Aluminum | Small-scale pneumatic systems | Lightweight and cost-effective | Lower conductivity, more frequent maintenance | Medium |

| Stainless Steel | Water treatment, gas safety systems | High durability and corrosion resistance | Higher manufacturing costs, heavier | High |

| Ferrite | Sensors, relays | Cost-effective with good magnetic properties | Lower conductivity, less efficient in high-power applications | Low |

This analysis provides a comprehensive overview of material options for solenoid valve coils, enabling international B2B buyers to make informed decisions based on application needs, cost considerations, and compliance with relevant standards.

In-depth Look: Manufacturing Processes and Quality Assurance for solenoid valve coil

The manufacturing of solenoid valve coils involves a series of intricate processes designed to ensure high performance, reliability, and safety. For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, understanding these manufacturing processes and quality assurance measures is crucial for making informed purchasing decisions.

Manufacturing Processes

The production of solenoid valve coils typically encompasses several key stages:

1. Material Preparation

The first step in manufacturing solenoid valve coils is the selection and preparation of materials. Commonly used materials include:

- Copper Wire: The primary material for winding coils, chosen for its excellent conductivity.

- Insulation Materials: Used to prevent electrical shorting, often made from materials like PVC or polyurethane.

- Ferromagnetic Cores: Typically made from stainless steel or other ferromagnetic materials, these cores enhance the magnetic field generated by the coil.

In this stage, materials are sourced from certified suppliers to ensure compliance with international standards. Buyers should verify that suppliers use high-quality materials, as this directly impacts the performance and durability of the coils.

2. Forming

Once materials are prepared, the forming process begins. This involves:

- Winding the Coil: Automated machines wind the copper wire around the core, ensuring consistent tension and spacing. The number of turns is critical, as it determines the coil’s electromagnetic properties.

- Insulation Application: Insulation materials are applied to the wound coil to prevent electrical leakage and protect against environmental factors.

3. Assembly

After forming, the assembly stage integrates various components to create the final product. This includes:

- Connecting Leads: Depending on the design, leads are attached to the coil, either as DIN connectors or flying leads, ensuring secure electrical connections.

- Final Assembly: The coil is then assembled with other valve components, if applicable, to form a complete solenoid valve assembly.

Efficient assembly processes are vital to maintain production timelines and product consistency.

4. Finishing

The finishing stage includes several processes that enhance the coil’s performance and aesthetics:

- Coating and Protection: Coatings may be applied to protect against corrosion and environmental damage, particularly for coils intended for harsh operating conditions.

- Labeling: Each coil is labeled with specifications, including voltage ratings and compliance marks, to facilitate identification and usage.

Quality Assurance

Quality assurance is a critical aspect of solenoid valve coil manufacturing, ensuring products meet international standards and customer expectations. Key components of a robust QA process include:

International and Industry Standards

- ISO 9001: This widely recognized standard focuses on quality management systems, emphasizing continuous improvement and customer satisfaction.

- CE Marking: Particularly relevant for European markets, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For coils used in oil and gas applications, adherence to American Petroleum Institute (API) standards is essential.

Quality Control Checkpoints

To maintain product quality throughout the manufacturing process, various checkpoints are implemented:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, random checks are conducted to verify that the processes are followed correctly and that the products meet interim quality standards.

- Final Quality Control (FQC): Completed coils undergo rigorous testing to ensure they meet all specifications before shipment.

Common Testing Methods

Testing is integral to quality assurance, and several methods are employed:

- Electrical Testing: Coils are tested for electrical resistance, insulation integrity, and electromagnetic performance.

- Thermal Testing: Coils are subjected to temperature extremes to ensure they can operate within specified limits without failure.

- Mechanical Testing: This includes pull force tests to evaluate the coil’s performance under operational conditions.

Verifying Supplier Quality Control

B2B buyers can take several steps to verify the quality control practices of their suppliers:

- Audits: Conducting supplier audits helps assess compliance with quality standards and manufacturing processes.

- Quality Reports: Requesting detailed quality reports and certificates of compliance can provide insight into the supplier’s QA processes.

- Third-Party Inspections: Engaging third-party inspection services can offer unbiased evaluations of product quality.

Quality Control Nuances for International Buyers

For buyers in Africa, South America, the Middle East, and Europe, there are specific considerations to keep in mind:

- Regulatory Compliance: Ensure that suppliers understand and comply with local regulations and standards relevant to your region.

- Supply Chain Transparency: Transparency in the supply chain is crucial, as it allows buyers to trace the origin of materials and understand the manufacturing processes.

- Cultural and Communication Factors: Different regions may have varying expectations regarding quality assurance practices. Establishing clear communication channels is essential for resolving any issues that arise.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices for solenoid valve coils is vital for B2B buyers. By focusing on the manufacturing stages, quality standards, testing methods, and verification processes, buyers can make informed decisions that ensure the reliability and performance of their solenoid valve coils.

Comprehensive Cost and Pricing Analysis for solenoid valve coil Sourcing

Understanding the cost structure and pricing analysis for sourcing solenoid valve coils is crucial for international B2B buyers. This section delves into the various cost components, price influencers, and practical tips for negotiating and optimizing purchases.

Cost Components

-

Materials: The primary raw materials for solenoid valve coils include copper wire, ferromagnetic core materials, and insulation materials. The quality and sourcing of these materials can significantly affect pricing. For instance, high-purity copper and specialized insulation materials designed for high-temperature applications typically incur higher costs.

-

Labor: Labor costs vary by region and complexity of the manufacturing process. Regions with lower labor costs, such as parts of South America and Africa, may offer competitive pricing. However, the skill level required for high-quality production can also dictate labor expenses.

-

Manufacturing Overhead: This includes costs related to production facilities, utilities, and administrative expenses. Efficient manufacturing processes can minimize overhead, thereby reducing the overall cost of the coils.

-

Tooling: The initial investment in tooling can be significant, especially for custom solenoid coils. This cost is often amortized over large production runs, making it essential to consider the minimum order quantity (MOQ) to achieve cost efficiency.

-

Quality Control (QC): Ensuring that solenoid coils meet international standards and certifications can add to the cost. Rigorous testing and quality assurance processes are necessary to maintain reliability, especially in critical applications.

-

Logistics: Shipping and handling costs can vary widely based on the shipping method, distance, and chosen Incoterms. Buyers should account for potential customs duties and taxes when importing coils from different regions.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market competition and perceived value. Understanding the competitive landscape can help buyers gauge reasonable margins.

Price Influencers

-

Volume/MOQ: Pricing is often tiered based on order volume. Larger orders can lead to significant discounts, making it beneficial for buyers to consolidate their purchases.

-

Specifications/Customization: Customized coils that meet specific requirements may incur additional costs. Buyers should clearly define their specifications to avoid unforeseen expenses.

-

Materials: The choice of materials directly impacts pricing. Higher quality or specialty materials will command a premium.

-

Quality/Certifications: Coils that meet international standards or specific industry certifications (such as ISO or CE) may be priced higher due to the added value they provide.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a proven track record may charge more but offer peace of mind regarding product quality and delivery timelines.

-

Incoterms: Understanding the terms of shipment can significantly impact total costs. For instance, choosing FOB (Free on Board) may reduce risks and costs associated with shipping.

Buyer Tips

-

Negotiation: Engaging in discussions with multiple suppliers can create competitive pricing scenarios. Highlighting your order volume and long-term partnership potential can yield better terms.

-

Cost Efficiency: Consider the Total Cost of Ownership (TCO), which includes not only the purchase price but also operational costs, maintenance, and potential downtime due to coil failures. Investing in higher-quality coils may reduce long-term costs.

-

Pricing Nuances: Be aware that pricing can fluctuate based on market conditions, material costs, and geopolitical factors, especially when sourcing from different regions. Buyers should remain flexible and informed about global market trends.

-

Regional Considerations: For buyers in Africa, South America, the Middle East, and Europe, it’s essential to understand local market dynamics. Prices may vary significantly based on regional supply chains and logistical considerations.

Disclaimer

Prices mentioned in this analysis are indicative and can vary based on market fluctuations, supplier negotiations, and specific order requirements. Always consult suppliers for the most accurate and up-to-date pricing information.

Spotlight on Potential solenoid valve coil Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘solenoid valve coil’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for solenoid valve coil

Understanding the technical properties and trade terminology associated with solenoid valve coils is crucial for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This knowledge not only aids in selecting the right products but also facilitates smoother transactions and operational efficiency.

Key Technical Properties of Solenoid Valve Coils

-

Voltage Rating (AC/DC)

Voltage ratings specify the electrical supply required for the coil to operate. Common options include 6V, 12V, 24V, 110V, and 230V for both AC and DC applications. Understanding voltage ratings is essential to ensure compatibility with existing systems, preventing equipment failure and unnecessary downtime. -

Temperature Class

Solenoid coils are classified into insulation classes (E, F, H) based on their maximum operating temperature. For instance, Class F can withstand temperatures up to 155°C. Selecting the appropriate temperature class is vital for applications exposed to high heat, ensuring longevity and reliable performance under operational conditions. -

Connector Type

The type of connection, such as DIN or flying lead, impacts installation and compatibility with existing systems. DIN connectors offer fast and secure connections, while flying leads provide flexibility for custom setups. Choosing the right connector type is crucial for efficient installation and maintenance processes. -

Coil Size and Power Rating

The physical dimensions and power consumption of a solenoid coil determine its suitability for specific applications. Buyers must match the coil size with the valve specifications to ensure optimal performance. Misalignment can lead to inefficient operation or system failures. -

Electromagnetic Force

The strength of the electromagnetic force generated by the coil is critical for valve operation. A higher force ensures consistent actuation, particularly in applications requiring rapid response times. Understanding this property helps buyers assess whether a coil meets the demands of their specific operational environment. -

Protection Rating (IP Rating)

The Ingress Protection (IP) rating indicates the coil’s resistance to dust and moisture. Ratings such as IP65 or IP68 are crucial for coils used in harsh environments. Selecting a coil with an appropriate IP rating protects against operational failures due to environmental factors.

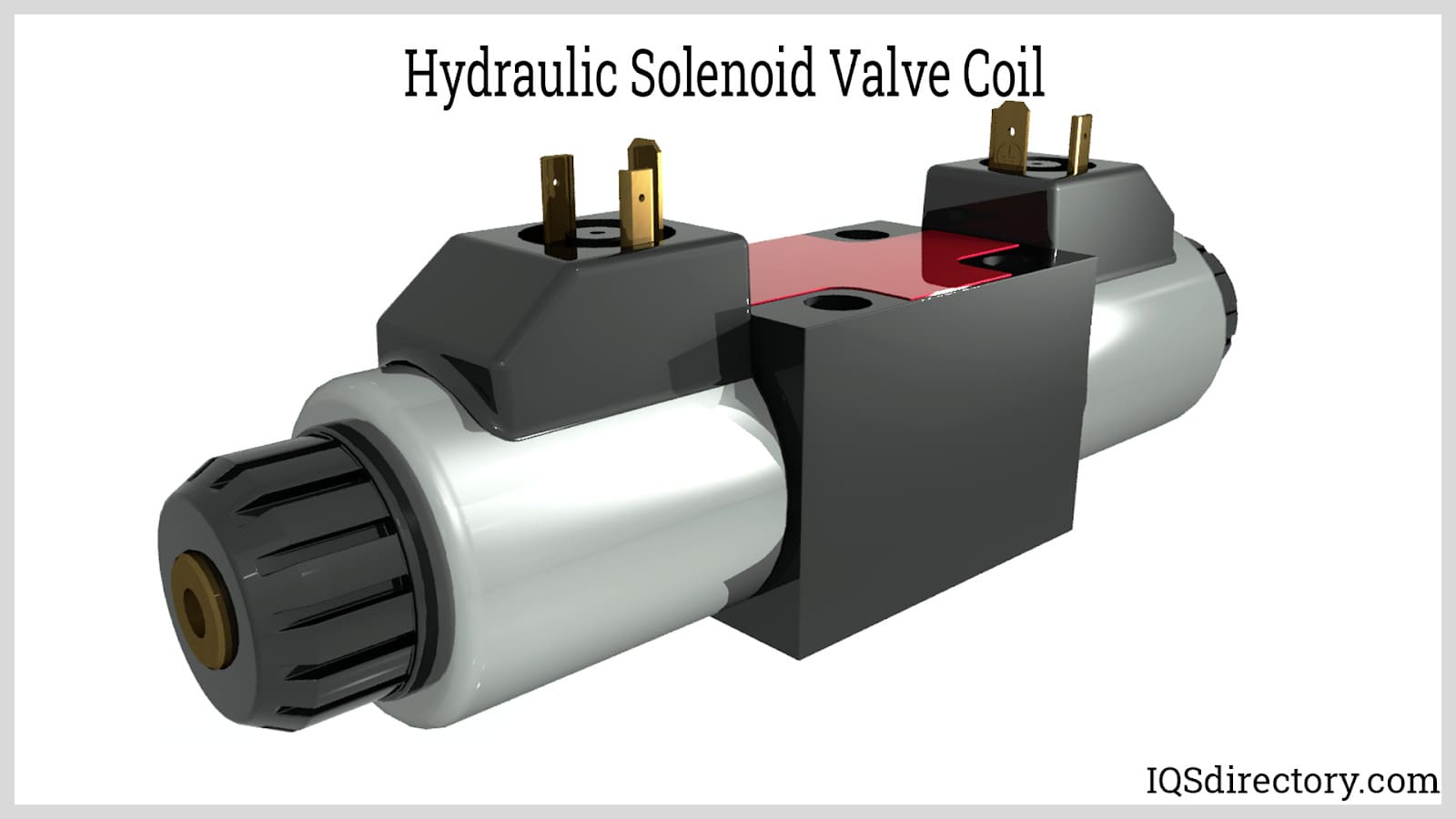

Common Trade Terms in the Solenoid Valve Coil Market

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are used in another company’s end product. Buyers should seek coils from reputable OEMs to ensure quality and compatibility with their systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ helps buyers plan their purchases efficiently and can influence pricing negotiations. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting price quotes for specific products. By issuing an RFQ, buyers can gather multiple offers, allowing them to compare prices and make informed purchasing decisions.

Illustrative Image (Source: Google Search)

-

Incoterms

International Commercial Terms (Incoterms) define the responsibilities of buyers and sellers in shipping contracts. Familiarity with Incoterms is essential for international transactions, as they clarify who is responsible for shipping costs, insurance, and risks during transport. -

Duty Cycle

Duty cycle refers to the ratio of the time a solenoid is energized to the total cycle time. Understanding the duty cycle is crucial for ensuring that the coil operates within safe limits, preventing overheating and extending its lifespan. -

Lead Time

Lead time indicates the time required from placing an order until the product is delivered. Knowing the lead time is important for planning and ensuring that operations run smoothly without delays.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing solenoid valve coils, ultimately enhancing their operational efficiency and product reliability.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the solenoid valve coil Sector

Market Overview & Key Trends

The solenoid valve coil market is witnessing significant growth driven by advancements in automation, industrialization, and the increasing demand for energy-efficient solutions. Global players are focusing on enhancing the performance and reliability of solenoid valve coils, adapting to the needs of various sectors such as HVAC, water treatment, and industrial automation. In regions like Africa and South America, growing infrastructure investments are propelling the demand for reliable solenoid systems, while Europe, particularly Germany, is leading in the adoption of high-tech, energy-efficient solutions.

Emerging trends indicate a shift towards smart solenoid systems equipped with IoT capabilities, enabling real-time monitoring and predictive maintenance. This technology not only enhances operational efficiency but also reduces downtime, which is critical for B2B buyers in competitive markets. Additionally, international buyers are increasingly looking for suppliers that offer customizable solutions, allowing them to tailor products to specific operational requirements. As the market evolves, the need for quick shipping and reliable customer support becomes paramount, particularly for buyers in regions with less established supply chains.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a crucial factor in the procurement of solenoid valve coils. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. Buyers are encouraged to partner with suppliers that prioritize eco-friendly production methods and materials. This includes the use of recyclable materials and compliance with international environmental standards.

Ethical sourcing is equally important, with businesses increasingly expected to ensure that their supply chains are free from exploitation and that they support fair labor practices. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management can serve as indicators of a supplier’s commitment to sustainability. Additionally, the use of ‘green’ materials, such as low-impact plastics and metals, can enhance the sustainability profile of solenoid valve coils, making them more attractive to environmentally conscious buyers.

Brief Evolution/History

The evolution of solenoid valve coils can be traced back to the early 19th century when the principles of electromagnetism were first harnessed. Initially used in basic applications, advancements in materials and technology have transformed solenoid coils into sophisticated components essential for automation and control systems. In recent decades, the integration of digital technologies and smart features has further enhanced their functionality, making them indispensable in modern industrial applications. As industries continue to evolve, solenoid valve coils are expected to adapt, aligning with the increasing demands for efficiency, reliability, and sustainability in the B2B landscape.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of solenoid valve coil

-

What should I consider when vetting suppliers for solenoid valve coils?

When vetting suppliers, prioritize their industry experience, reputation, and customer reviews. Verify their certifications, such as ISO 9001, which indicates adherence to quality management standards. Request samples to evaluate product quality and performance. Additionally, assess their ability to provide technical support and compatibility with your existing systems, ensuring they can meet your specific operational needs. -

Can I customize solenoid valve coils to fit my unique specifications?

Yes, many suppliers offer customization options for solenoid valve coils. When discussing your requirements, provide detailed specifications, including voltage, size, temperature ratings, and connector types. It’s also beneficial to inquire about the supplier’s design capabilities and previous custom projects to gauge their experience. Custom solutions can enhance efficiency and performance in your specific applications. -

What are the typical minimum order quantities (MOQs) and lead times for solenoid valve coils?

MOQs for solenoid valve coils can vary significantly based on the supplier and customization requirements. Generally, standard models may have lower MOQs, while customized coils may require larger quantities. Lead times can range from a few days for in-stock items to several weeks for custom orders. Always clarify these details upfront to align with your project timelines and avoid delays. -

What payment methods are typically accepted by suppliers of solenoid valve coils?

Payment methods can differ among suppliers, but common options include bank transfers, credit cards, and PayPal. Some suppliers may offer payment terms for larger orders, such as net 30 or net 60 days. Always confirm the payment terms before finalizing your order and consider discussing options that provide buyer protection, especially in international transactions. -

How can I ensure the quality of solenoid valve coils I purchase?

To ensure quality, request documentation of compliance with international standards such as CE, UL, or RoHS. Ask for test reports or certifications that verify the coils’ performance specifications. It’s also advisable to conduct periodic audits of your supplier and request samples for testing in your operational environment to confirm their reliability under real-world conditions. -

What logistical considerations should I be aware of when importing solenoid valve coils?

When importing, consider customs regulations, duties, and taxes that may apply to your shipment. Work with suppliers who have experience in international shipping to ensure compliance with local regulations. Additionally, discuss shipping options and timelines, and consider insurance for high-value orders to protect against potential losses during transit. -

What steps should I take if I encounter a dispute with a supplier?

If a dispute arises, first attempt to resolve it directly with the supplier through clear communication. Document all correspondence and agreements. If the issue remains unresolved, consider mediation or arbitration as per the terms outlined in your contract. Familiarize yourself with the legal framework governing international trade in your jurisdiction, as this may provide additional avenues for resolution. -

How important is after-sales support when sourcing solenoid valve coils?

After-sales support is crucial for ensuring the long-term performance of solenoid valve coils. A reliable supplier should offer technical assistance, warranty services, and guidance on installation and maintenance. Establishing a relationship with your supplier that includes ongoing support can enhance operational efficiency and reduce downtime caused by technical issues.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for solenoid valve coil

In conclusion, strategic sourcing of solenoid valve coils is essential for optimizing operational efficiency and ensuring long-term reliability across various industries. Key considerations for international buyers include understanding voltage specifications (AC vs. DC), ensuring compatibility with existing systems, and selecting coils based on temperature ratings and connector types. By prioritizing high-quality, certified replacements, businesses can avoid costly downtimes and enhance system performance.

As the demand for automation and control solutions grows globally, particularly in Africa, South America, the Middle East, and Europe, investing in robust sourcing strategies will be critical. Buyers should leverage local partnerships and suppliers that offer ready-to-ship options, expert support, and customized solutions to meet specific operational needs.

Looking ahead, the future of solenoid valve coils will be driven by advancements in technology and increasing focus on energy efficiency. By staying informed about market trends and innovations, international B2B buyers can position themselves for success. Engage with reputable suppliers today to ensure your operations are equipped with the best solenoid valve coils that drive performance and reliability.