Your Ultimate Guide to Sourcing Scissor Lift Mechanism

Introduction: Navigating the Global Market for scissor lift mechanism

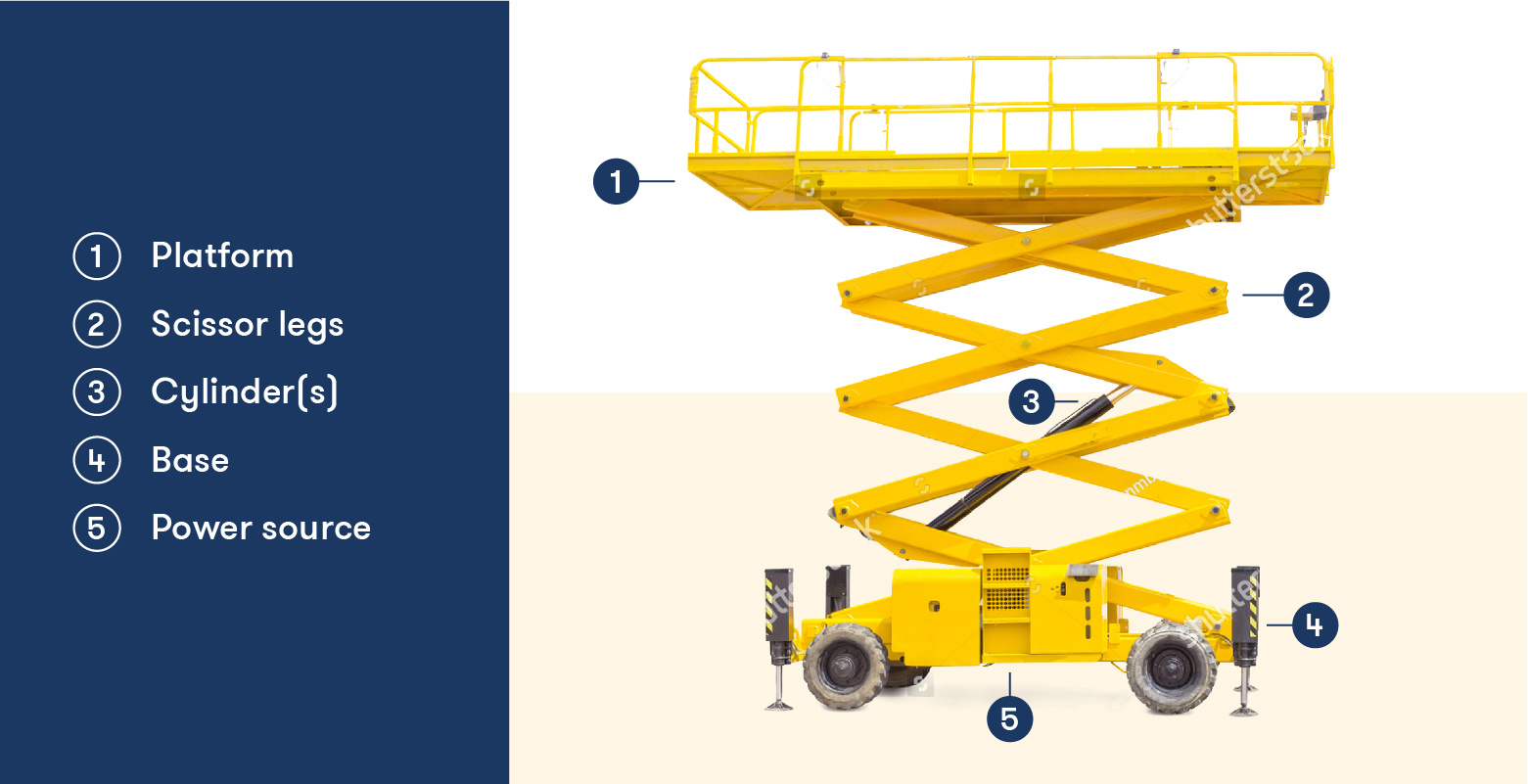

In today’s rapidly evolving global marketplace, the scissor lift mechanism stands out as an essential tool for industries ranging from construction to automotive and aerospace. These versatile lifting devices provide safe, efficient access to elevated workspaces, making them indispensable in various operational settings. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe (including countries like Indonesia and Germany) seek to optimize their supply chains and enhance productivity, understanding the intricacies of scissor lifts is crucial.

This comprehensive guide delves into the diverse types of scissor lifts available, covering key attributes such as materials, manufacturing processes, and quality control standards. It also outlines potential suppliers and the factors influencing costs, enabling buyers to make informed sourcing decisions. Furthermore, we will explore market trends and answer frequently asked questions to demystify common concerns associated with scissor lift procurement.

By equipping international buyers with actionable insights, this guide empowers organizations to navigate the complexities of sourcing scissor lift mechanisms effectively. Whether you are looking to enhance workplace safety, improve operational efficiency, or meet regulatory requirements, understanding the global landscape of scissor lifts is pivotal for successful procurement strategies.

Understanding scissor lift mechanism Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hydraulic Scissor Lift | Utilizes hydraulic cylinders for lifting; high load capacity. | Warehousing, construction, manufacturing. | Pros: High efficiency, smooth operation. Cons: Higher maintenance costs. |

| Electric Scissor Lift | Powered by electric motors; quieter operation. | Indoor maintenance, retail, and exhibitions. | Pros: Eco-friendly, low noise. Cons: Limited outdoor use due to battery dependency. |

| Mechanical Scissor Lift | Operated via mechanical means like lead screws; simple design. | Automotive repair, light industrial tasks. | Pros: Lower cost, simple maintenance. Cons: Slower operation, less lifting capacity. |

| Multi-Stage Scissor Lift | Features multiple scissor mechanisms for higher reach. | Construction sites, large warehouses. | Pros: Extended reach, versatile. Cons: More complex, potentially higher cost. |

| Portable Scissor Lift | Compact and lightweight; easy to transport. | Event setups, small-scale jobs. | Pros: Easy mobility, space-saving. Cons: Limited load capacity, less stability. |

Hydraulic Scissor Lift

Hydraulic scissor lifts are renowned for their robust lifting capabilities, making them ideal for heavy-duty applications in sectors such as warehousing and construction. These lifts operate using hydraulic cylinders, allowing for smooth and efficient elevation of loads. When considering a hydraulic scissor lift, buyers should evaluate the maximum load capacity and the required maintenance frequency, as these lifts can incur higher operational costs due to their complex hydraulic systems.

Electric Scissor Lift

Electric scissor lifts are designed for quieter, eco-friendly operation, making them suitable for indoor environments such as retail spaces and exhibitions. They run on electric motors, which provide a clean energy alternative. Buyers should consider the battery life and charging time, as these factors can impact productivity, especially in high-demand settings. While they are ideal for indoor use, their reliance on batteries can limit their outdoor functionality.

Mechanical Scissor Lift

Mechanical scissor lifts are characterized by their straightforward design, utilizing mechanical means like lead screws for operation. This type of lift is often favored in automotive repair shops and light industrial tasks due to its lower cost and ease of maintenance. However, buyers should be aware that while these lifts are budget-friendly, they may not provide the same speed or load capacity as hydraulic or electric variants, making them less suitable for heavy lifting.

Multi-Stage Scissor Lift

Multi-stage scissor lifts incorporate several scissor mechanisms, allowing for higher reaches and greater versatility in various applications, particularly in construction and large warehouses. These lifts can be an excellent investment for businesses requiring extended height capabilities. However, potential buyers should consider the complexity of the design, which may lead to increased costs and maintenance needs compared to simpler models.

Portable Scissor Lift

Portable scissor lifts are lightweight and compact, designed for easy transportation between job sites. They are particularly useful for event setups and small-scale jobs where space is a constraint. While they offer the advantage of mobility and ease of storage, buyers must keep in mind that these lifts typically have limited load capacities and may lack the stability of larger models, which could be a concern in demanding environments.

Related Video: Hydraulic Scissor Lift Mechanism In Solidworks | Project

Key Industrial Applications of scissor lift mechanism

| Industry/Sector | Specific Application of scissor lift mechanism | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Elevating workers and materials at construction sites | Increases safety and efficiency in material handling | Load capacity, height range, and stability under load |

| Manufacturing | Assembly line workstations for vehicle production | Streamlines processes and enhances worker ergonomics | Customization options, hydraulic vs. mechanical systems |

| Entertainment | Stage lifting systems for theaters and events | Facilitates complex stage setups and quick scene changes | Weight capacity, portability, and ease of operation |

| Warehousing | Loading and unloading goods from trucks and shelves | Improves logistics efficiency and reduces labor costs | Size, mobility features, and compatibility with forklifts |

| Maintenance & Repair | Access platforms for servicing machinery and vehicles | Enhances safety and accessibility for maintenance tasks | Durability, ease of setup, and compliance with safety standards |

Detailed Applications

Construction: In the construction industry, scissor lifts are pivotal for elevating workers and materials to various heights. They allow for safer access to elevated work areas, reducing the risk of falls and accidents. For international buyers, particularly in regions like Africa and South America, sourcing scissor lifts with robust load capacities and height ranges is critical. The harsh environmental conditions in some areas necessitate equipment that can withstand heavy use and maintain stability under load.

Manufacturing: Scissor lifts are extensively used in manufacturing, particularly in assembly line workstations for vehicle production. By elevating components to optimal working heights, they enhance productivity and ergonomics, allowing workers to operate more efficiently. Buyers should consider customization options that align with their specific operational needs, as well as the choice between hydraulic and mechanical systems, depending on their production environment.

Entertainment: In the entertainment sector, scissor lifts are essential for stage lifting systems used in theaters and events. They enable smooth transitions between scenes and provide safe access to high-tech equipment and lighting. When sourcing these systems, businesses should prioritize weight capacity, portability, and ease of operation to ensure quick setup and breakdown during performances, especially in regions with diverse event logistics.

Warehousing: Scissor lifts play a crucial role in warehousing operations, particularly for loading and unloading goods from trucks and shelves. They significantly improve logistics efficiency by allowing for quick and safe movement of heavy items. Buyers in Europe and the Middle East should focus on features such as size, mobility, and compatibility with existing forklifts to optimize their warehouse operations and reduce labor costs.

Maintenance & Repair: For maintenance and repair tasks, scissor lifts provide essential access platforms for servicing machinery and vehicles. They enhance safety by allowing technicians to work at height without the risk of falling. Buyers should ensure that the lifts are durable, easy to set up, and compliant with local safety standards, particularly in regions where regulations may vary significantly.

Related Video: Industrial Scissor Lift Table (The work of the lifting mechanism)

Strategic Material Selection Guide for scissor lift mechanism

When selecting materials for scissor lift mechanisms, international B2B buyers must consider various factors that influence performance, durability, and compliance with regional standards. Below is an analysis of four common materials used in scissor lift construction, focusing on their properties, advantages, disadvantages, and specific considerations for international markets.

Steel

Key Properties:

Steel is renowned for its high tensile strength and durability, making it suitable for heavy-duty applications. It can withstand high temperatures and pressures, which is essential for hydraulic systems. Additionally, steel can be treated for corrosion resistance through galvanization or coating.

Pros & Cons:

Steel’s primary advantage is its strength and load-bearing capacity, which is critical for scissor lifts that must support significant weight. However, it is heavier than other materials, which can affect mobility and require more robust lifting mechanisms. The cost of steel is moderate, but manufacturing complexity can increase with the need for additional treatments for corrosion resistance.

Impact on Application:

Steel is compatible with hydraulic fluids and can handle various environmental conditions, making it versatile for different applications. However, it may require regular maintenance to prevent rust, especially in humid environments.

Considerations for International Buyers:

Buyers should ensure compliance with standards such as ASTM A36 or DIN 17100 for structural steel. In regions like Europe and the Middle East, buyers may prefer galvanized steel for enhanced corrosion resistance.

Aluminum

Key Properties:

Aluminum is lightweight yet strong, offering excellent corrosion resistance. It has a lower melting point than steel, which can be advantageous in applications requiring thermal management.

Pros & Cons:

The primary advantage of aluminum is its weight, which improves maneuverability and reduces energy consumption. However, its lower tensile strength compared to steel may limit its use in heavy-duty applications. Aluminum is generally more expensive than steel, but its long-term durability can justify the investment.

Impact on Application:

Aluminum’s corrosion resistance makes it ideal for outdoor applications or environments with high humidity. It is compatible with various hydraulic fluids, but care must be taken to avoid galvanic corrosion when in contact with dissimilar metals.

Considerations for International Buyers:

Buyers should look for compliance with standards such as ASTM B221 or EN AW-6060. In regions like Africa and South America, where weight and portability are crucial, aluminum is often preferred.

Composite Materials

Key Properties:

Composite materials, such as fiberglass or carbon fiber, offer high strength-to-weight ratios and excellent corrosion resistance. They can be engineered to meet specific performance requirements, including thermal and chemical resistance.

Pros & Cons:

The main advantage of composites is their lightweight nature and resistance to corrosion, which can significantly reduce maintenance costs. However, they can be more expensive to manufacture and repair. Additionally, composites may not have the same load-bearing capacity as metals, limiting their use in certain applications.

Impact on Application:

Composites are suitable for environments where traditional materials may fail due to corrosion or chemical exposure. They are also non-conductive, making them ideal for electrical applications.

Considerations for International Buyers:

Buyers should ensure compliance with relevant standards such as ASTM D3039 for tensile properties. In Europe, the use of composites is growing, particularly in industries focused on innovation and sustainability.

High-Strength Steel Alloys

Key Properties:

High-strength steel alloys offer enhanced performance characteristics, including increased tensile strength and fatigue resistance. These materials can withstand extreme conditions, making them suitable for heavy-duty applications.

Pros & Cons:

The key advantage of high-strength steel alloys is their ability to reduce weight while maintaining strength, improving overall efficiency. However, they can be more expensive than standard steel and may require specialized manufacturing processes.

Impact on Application:

These alloys are ideal for applications where weight reduction is critical without compromising safety or performance. They can handle high loads and are compatible with hydraulic systems.

Considerations for International Buyers:

Compliance with standards such as ASTM A992 or EN 10025 is essential. In regions like Germany, where engineering standards are stringent, high-strength steel alloys are often the material of choice.

Summary Table

| Material | Typical Use Case for scissor lift mechanism | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial applications | High strength and load-bearing capacity | Heavier, may require corrosion treatment | Medium |

| Aluminum | Portable lifts and outdoor applications | Lightweight and corrosion-resistant | Lower tensile strength than steel | High |

| Composite Materials | Specialized environments (corrosive or electrical) | High strength-to-weight ratio | More expensive and difficult to repair | High |

| High-Strength Steel Alloys | Heavy-duty and critical load applications | Reduces weight while maintaining strength | Higher cost and specialized manufacturing | High |

This strategic material selection guide provides valuable insights for B2B buyers, enabling informed decisions that align with operational needs and compliance requirements across various regions.

In-depth Look: Manufacturing Processes and Quality Assurance for scissor lift mechanism

The manufacturing of scissor lift mechanisms involves several critical stages that ensure the final product meets quality and safety standards. B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe, must be well-versed in these processes to make informed purchasing decisions.

Manufacturing Processes

1. Material Preparation

The first stage in the manufacturing process involves selecting and preparing high-quality materials. Common materials for scissor lifts include:

- Steel: Known for its strength and durability, steel is often used for the frame and supports.

- Aluminum: Lightweight and resistant to corrosion, aluminum is preferred for portable scissor lifts.

- Hydraulic fluids and seals: Essential for the hydraulic systems that power the lifts.

Techniques:

– Material cutting (laser or plasma cutting) to achieve precise dimensions.

– Surface treatments (e.g., galvanization, powder coating) to enhance corrosion resistance.

2. Forming

The forming stage shapes the materials into the necessary components of the scissor lift.

- Bending: Steel plates are often bent into the required angles using press brakes.

- Welding: Critical for joining components, welding processes (MIG, TIG) must ensure structural integrity.

Key Techniques:

– CNC machining for high precision in producing complex parts.

– Hydroforming, which uses high-pressure fluid to shape metal into desired forms.

3. Assembly

The assembly phase combines all components into a functional unit.

- Sub-assembly: Individual components like the scissor arms, platform, and hydraulic system are assembled separately.

- Final assembly: All sub-assemblies are brought together, ensuring proper alignment and functionality.

Techniques:

– Use of jigs and fixtures to maintain accuracy during assembly.

– Torque specifications for bolts to ensure structural integrity.

4. Finishing

Finishing processes enhance the aesthetics and performance of the scissor lifts.

- Painting: Protective coatings are applied to prevent corrosion and improve appearance.

- Quality checks: Visual inspections for surface defects, alignment, and functionality.

Techniques:

– Powder coating for durability.

– Electrostatic painting to ensure even coverage.

Quality Assurance

Quality assurance in the manufacturing of scissor lifts is paramount to ensure safety, reliability, and compliance with international standards.

International Standards

- ISO 9001: This standard ensures that manufacturers maintain a consistent quality management system. Compliance indicates that a company can consistently provide products that meet customer and regulatory requirements.

- CE Marking: Required in Europe, this certification demonstrates that the product complies with EU safety, health, and environmental protection standards.

- API Certification: Relevant for lifts used in oil and gas sectors, ensuring adherence to industry-specific safety and performance standards.

Quality Control Checkpoints

B2B buyers should be aware of the following quality control checkpoints during the manufacturing process:

- Incoming Quality Control (IQC): Inspection of raw materials upon delivery to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous checks during the manufacturing process to detect any deviations from quality standards.

- Final Quality Control (FQC): Comprehensive testing of the completed product before shipment, including load testing and operational checks.

Common Testing Methods

B2B buyers should consider the following testing methods to verify the quality of scissor lifts:

- Load Testing: Ensures the lift can handle its rated capacity safely.

- Hydraulic Pressure Testing: Confirms the integrity of hydraulic systems and seals.

- Functional Testing: Assesses the operational performance of the lift, including movement and stability.

Verifying Supplier Quality Control

To ensure reliability and quality from suppliers, B2B buyers can take several steps:

- Supplier Audits: Conducting on-site audits helps assess the manufacturing processes and quality control measures in place.

- Quality Reports: Requesting detailed quality assurance reports, including testing results and compliance certifications, provides insight into the supplier’s adherence to standards.

- Third-party Inspections: Engaging independent inspectors can offer an unbiased assessment of product quality before shipment.

Quality Control and Certification Nuances for International Buyers

International buyers should be aware of the following nuances regarding quality control and certification:

- Cultural Differences: Understanding regional manufacturing practices and regulations is crucial. For instance, European standards may differ significantly from those in Africa or South America.

- Documentation Requirements: Ensure that all necessary certificates and compliance documents are provided, as these may be required for importation and local regulations.

- Local Partnerships: Collaborating with local agents or consultants can facilitate smoother transactions and compliance with regional standards.

By understanding the manufacturing processes and quality assurance mechanisms, B2B buyers can make informed decisions when sourcing scissor lift mechanisms. Adopting a thorough approach to supplier evaluation and quality verification will help mitigate risks and ensure that the purchased equipment meets operational needs and safety standards.

Related Video: Most Satisfying Factory Production Processes And Heavy-Duty Factory Machines!

Comprehensive Cost and Pricing Analysis for scissor lift mechanism Sourcing

Understanding the Cost Structure of Scissor Lift Mechanism Sourcing

When sourcing scissor lift mechanisms, international B2B buyers must grasp the intricate cost structure that influences pricing. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials include steel, aluminum, and composite materials. Higher-grade materials, while more expensive, often provide better durability and performance.

-

Labor: Labor costs vary by region, with countries in Europe generally experiencing higher labor rates compared to those in Africa and South America. Skilled labor is crucial for the assembly and quality assurance of scissor lifts.

-

Manufacturing Overhead: This encompasses indirect costs related to production, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Custom tooling may be required for unique designs or specifications, which can add to the initial investment. Buyers should factor in these costs when considering custom solutions.

-

Quality Control (QC): Ensuring the lift meets safety and operational standards necessitates rigorous testing and quality checks, contributing to the overall cost.

-

Logistics: Transportation costs can vary widely based on distance, mode of transport, and local regulations. For international buyers, understanding Incoterms is essential to manage these costs effectively.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on their market position and the competitive landscape.

Price Influencers in Scissor Lift Mechanism Sourcing

Several factors can influence the final price of scissor lift mechanisms:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs. Negotiating minimum order quantities (MOQ) can yield significant savings.

-

Specifications/Customization: Customized lifts tailored to specific needs may incur higher costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Products with higher quality materials or specific certifications (such as ISO standards) typically command higher prices. However, they may offer better reliability and longevity.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge a premium for their proven track record.

-

Incoterms: Understanding the terms of shipment and delivery can help buyers manage logistics costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly influence the total landed cost.

Buyer Tips for Cost Efficiency

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, the following strategies can enhance cost efficiency:

-

Negotiate Terms: Leverage volume and long-term relationships to negotiate better pricing and payment terms. Suppliers may offer discounts for repeat business or larger orders.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also maintenance, operational costs, and potential downtime. A higher upfront investment in a quality lift may reduce overall costs in the long run.

-

Research Market Prices: Stay informed about market trends and pricing fluctuations. This knowledge can empower negotiations and help identify fair pricing.

-

Explore Local Suppliers: Sourcing locally may reduce logistics costs and lead times. Local suppliers might also provide better support and maintenance services.

-

Be Aware of Pricing Nuances: Understand that international pricing may include tariffs, duties, and exchange rate fluctuations. Factor these into your budget when sourcing from overseas.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on the specific configurations, supplier negotiations, and market conditions. Always consult multiple suppliers for the most accurate and competitive pricing tailored to your needs.

Spotlight on Potential scissor lift mechanism Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘scissor lift mechanism’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for scissor lift mechanism

Key Technical Properties of Scissor Lift Mechanisms

Understanding the technical properties of scissor lift mechanisms is crucial for B2B buyers to ensure they select the right equipment for their operational needs. Here are some essential specifications to consider:

-

Load Capacity: This refers to the maximum weight that a scissor lift can safely lift. Typically measured in kilograms or pounds, understanding load capacity is critical for applications in construction, warehousing, and manufacturing. Buyers must evaluate their specific lifting requirements to avoid overloading, which can lead to equipment failure or safety hazards.

-

Lift Height: This specification indicates the maximum vertical reach of the lift. It is essential for operations that require access to elevated areas. Buyers should assess the height needed for their tasks to ensure the scissor lift can meet those demands.

-

Material Grade: The materials used in the construction of the scissor lift, such as steel or aluminum, impact the lift’s durability and weight. Higher-grade materials can offer better strength-to-weight ratios, improving mobility and lifespan. Buyers should consider the environmental conditions (e.g., humidity, temperature) the lift will face to select appropriate materials.

-

Platform Size: The dimensions of the lift’s platform affect the amount of space available for workers or equipment. A larger platform allows for more extensive operations but may require additional space for maneuvering. Buyers must balance platform size with their spatial constraints and operational needs.

-

Tolerance Levels: Tolerance refers to the permissible limit of variation in dimensions and weight. High tolerance levels ensure that the lift operates safely and effectively under varying loads. Buyers should seek equipment with precise tolerances to minimize operational risks.

-

Power Source: Scissor lifts can be powered by hydraulic, pneumatic, or electric systems. The choice of power source affects operational efficiency, maintenance requirements, and suitability for specific environments (e.g., indoor vs. outdoor). Buyers should consider the power source that aligns with their operational capabilities and environmental conditions.

Common Trade Terminology in the Scissor Lift Industry

Familiarity with industry jargon can facilitate smoother transactions and better communication between buyers and suppliers. Here are some common terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of scissor lifts, knowing the OEM can help buyers assess the quality and compatibility of parts.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory and costs effectively. It can also influence purchasing decisions, especially for smaller businesses.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers asking for price quotes on specific products or services. This process is vital for buyers to gather competitive pricing and understand market rates for scissor lifts.

-

Incoterms: These are international commercial terms that define the responsibilities of sellers and buyers in global transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and obligations, which is crucial for effective logistics management.

-

Lead Time: This refers to the time it takes from placing an order to receiving the product. Understanding lead times is vital for planning operations and ensuring that equipment is available when needed.

-

Warranty: A warranty is a guarantee provided by the manufacturer regarding the condition of the product and the terms of repair or replacement. Buyers should carefully review warranty terms to understand their rights and the level of support they can expect after purchase.

By understanding these essential technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing scissor lift mechanisms, ensuring they meet their operational needs while optimizing costs and efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the scissor lift mechanism Sector

Market Overview & Key Trends

The scissor lift mechanism sector is experiencing robust growth, driven by increased demand across various industries such as construction, manufacturing, and logistics. Key market drivers include the global trend towards automation and the necessity for enhanced workplace safety and efficiency. As companies seek to optimize their operations, scissor lifts offer a practical solution for elevating personnel and materials while minimizing risks associated with manual handling.

Current and Emerging Trends:

– Technological Advancements: The integration of IoT and smart technologies is transforming scissor lifts into connected devices that provide real-time data on usage, maintenance needs, and operational efficiency. This trend is particularly relevant for international buyers seeking to enhance productivity and reduce downtime.

– Customization and Versatility: Manufacturers are increasingly offering tailored solutions to meet specific industry requirements, such as specialized lifts for narrow aisles in warehouses or outdoor models for construction sites. This trend is vital for buyers in diverse markets like Africa and South America, where operational conditions can vary widely.

– Sourcing Strategies: Global supply chains are adapting to geopolitical changes and disruptions. Buyers are increasingly looking for local suppliers or regional partners to mitigate risks associated with long-distance shipping and tariffs, particularly in the Middle East and Europe.

Understanding these dynamics allows international B2B buyers to align their procurement strategies with market realities, ensuring they invest in solutions that meet both current and future operational needs.

Sustainability & Ethical Sourcing in B2B

As environmental concerns rise globally, sustainability has become a critical consideration in the procurement of scissor lift mechanisms. Buyers are increasingly aware of the environmental impact of their purchases, prompting a shift towards more sustainable practices.

Key Considerations:

– Lifecycle Analysis: Buyers should assess the entire lifecycle of scissor lifts, from manufacturing through to disposal. This includes understanding the materials used and the energy consumed during operation. Opting for lifts made from recycled or eco-friendly materials can significantly reduce environmental footprints.

– Ethical Supply Chains: Establishing transparent and ethical supply chains is essential. Buyers should prioritize manufacturers that adhere to fair labor practices and have certifications that demonstrate compliance with environmental standards. This not only supports sustainable practices but also enhances brand reputation.

– Green Certifications: Look for products that carry certifications such as ISO 14001 for environmental management or those that comply with local regulations regarding emissions and waste. These certifications can serve as a benchmark for sustainability and provide peace of mind for buyers committed to ethical sourcing.

Incorporating these sustainability principles into procurement strategies can not only help mitigate environmental impacts but also align businesses with the growing consumer preference for responsible companies.

Brief Evolution/History

The scissor lift mechanism has evolved significantly since its inception in the mid-20th century. Originally designed for simple lifting tasks, early models relied heavily on mechanical systems and manual operation. Over the decades, advancements in hydraulic technology and materials science led to the development of more efficient, powerful, and versatile lifts.

Today, the market features a wide array of scissor lifts, including electric, hydraulic, and even solar-powered models. This evolution reflects a broader trend in the manufacturing sector towards automation and enhanced safety measures. For B2B buyers, understanding this historical context is crucial, as it informs current technological capabilities and future innovations that can improve operational efficiencies and safety standards in various industries.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of scissor lift mechanism

-

How can I vet suppliers of scissor lift mechanisms?

When sourcing scissor lift mechanisms, it’s essential to conduct thorough supplier vetting. Start by checking the supplier’s credentials, including certifications (ISO, CE), industry experience, and customer reviews. Utilize platforms like Alibaba or Global Sources to find verified suppliers. Request references from previous clients, and perform on-site visits if possible. Additionally, consider suppliers with a solid track record of exporting to your region, as they will be familiar with local regulations and logistics. -

Can I customize the scissor lift to meet specific requirements?

Yes, many manufacturers offer customization options for scissor lifts. This can include adjusting the lift height, load capacity, or adding specific features such as safety guards or platform size. When discussing customization, provide detailed specifications and applications to ensure the supplier can meet your needs. It’s advisable to request prototypes or samples before finalizing your order to verify that the customizations meet your expectations. -

What are typical minimum order quantities (MOQ) and lead times?

Minimum order quantities can vary widely based on the manufacturer, ranging from a single unit for smaller suppliers to several units for larger manufacturers. Lead times typically range from 4 to 12 weeks, depending on the complexity of the order and customization requirements. Always confirm MOQs and lead times during negotiations to avoid any surprises. Consider suppliers that can accommodate smaller orders if your needs are not large-scale.

Illustrative Image (Source: Google Search)

-

What payment terms should I expect when ordering scissor lifts?

Payment terms can vary by supplier and region but generally include options such as upfront payment, letters of credit, or payment upon delivery. It’s crucial to negotiate terms that align with your cash flow and risk management strategies. International buyers may also consider using escrow services to protect their payments until the goods are received and verified. Always ensure that you have a clear agreement in writing regarding payment terms before proceeding with the order. -

What quality assurance measures should I look for?

Quality assurance is critical in ensuring the performance and safety of scissor lifts. Look for suppliers who implement rigorous quality control processes, including inspections at various stages of production. Request documentation for quality certifications and test reports for the lifts. Additionally, inquire about after-sales support and warranties, which can indicate the manufacturer’s confidence in their product quality. -

How can I handle logistics and shipping for international orders?

Managing logistics is vital for the timely delivery of scissor lifts. Coordinate with the supplier to understand their shipping capabilities, including methods (sea, air, or land) and associated costs. Be aware of customs regulations in your country and ensure that the supplier can provide the necessary documentation for smooth clearance. Consider partnering with a logistics provider experienced in handling heavy machinery to streamline the process and mitigate risks. -

What should I do in case of disputes with suppliers?

Disputes can arise over quality issues, delays, or contract misunderstandings. Establish a clear communication channel with the supplier from the outset to resolve issues swiftly. Document all correspondence and agreements. If a dispute occurs, first attempt to resolve it amicably. If necessary, refer to the contract’s terms regarding dispute resolution, which may include mediation or arbitration. Engaging legal counsel familiar with international trade laws can also be beneficial. -

What certifications and regulations should scissor lifts comply with?

Compliance with local and international safety standards is crucial for scissor lifts. Common certifications include ISO 9001 for quality management and ISO 14001 for environmental management. In Europe, CE marking is mandatory, indicating compliance with health, safety, and environmental protection standards. In Africa and South America, be aware of regional regulations that may affect your use of scissor lifts. Always request documentation confirming compliance to ensure safety and legality in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for scissor lift mechanism

As we conclude this exploration of scissor lift mechanisms, it is imperative for international B2B buyers to recognize the transformative impact of strategic sourcing. By selecting the right suppliers and equipment, businesses can enhance operational efficiency, safety, and productivity. The benefits of scissor lifts are manifold, from their versatility across various industries to their ability to facilitate complex tasks at height, making them indispensable in sectors such as construction, logistics, and manufacturing.

Illustrative Image (Source: Google Search)

When sourcing scissor lifts, consider factors such as load capacity, mechanism type (hydraulic vs. mechanical), and application-specific features. Establishing strong partnerships with reputable manufacturers can lead to better pricing, quality assurance, and ongoing support. Moreover, buyers should remain vigilant about market trends and technological advancements to leverage innovations that could further streamline operations.

Looking ahead, the demand for efficient material handling solutions is expected to rise, particularly in developing regions of Africa and South America, as well as established markets in Europe and the Middle East. Take action now: evaluate your current sourcing strategies, explore new suppliers, and invest in scissor lift technology that meets your operational needs. By doing so, you position your business not just for success today, but for a sustainable and productive future.