Your Ultimate Guide to Sourcing Bevel Gear

Introduction: Navigating the Global Market for bevel gear

Bevel gears are essential components in the machinery landscape, facilitating efficient power transmission between intersecting shafts, typically at right angles. Their unique conical design and various tooth configurations—such as straight, spiral, and Zerol—enable them to perform reliably across a range of industries, including automotive, aerospace, and heavy equipment manufacturing. For international B2B buyers, understanding the intricacies of bevel gears is crucial for making informed sourcing decisions that enhance operational efficiency and reduce costs.

This comprehensive guide delves into the multifaceted world of bevel gears, offering insights into their types, materials, and manufacturing processes. It also covers quality control measures, supplier considerations, and cost factors, providing a well-rounded perspective that empowers buyers to navigate the global market confidently. With specific attention to the needs of businesses in Africa, South America, the Middle East, and Europe, this guide aims to bridge knowledge gaps and facilitate strategic procurement.

By equipping buyers with actionable insights and essential FAQs, this resource not only clarifies the complexities of bevel gear specifications but also enhances their ability to select the right products for their unique applications. Ultimately, this guide serves as a vital tool for B2B buyers seeking to optimize their operations and drive competitive advantage in today’s dynamic marketplace.

Understanding bevel gear Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Straight Bevel Gears | Straight teeth, simple manufacturing | Machine tools, printing machines | Pros: Easy to manufacture, low cost; Cons: Limited to low speeds, can produce noise. |

| Spiral Bevel Gears | Curved teeth, smoother engagement | Automotive speed reducers, aviation | Pros: High efficiency, quieter operation; Cons: More complex to manufacture, higher cost. |

| Zerol Bevel Gears | Curved teeth with no helix angle | Robotics, precision machinery | Pros: Smoother operation than straight gears; Cons: May require specialized manufacturing processes. |

| Miter Gears | 1:1 gear ratio, equal number of teeth | Gearboxes, power transmission systems | Pros: Simple design, cost-effective; Cons: Limited load capacity, not suitable for high torque applications. |

| Hypoid Gears | Offset shafts, curved teeth | Heavy machinery, automotive differentials | Pros: Allows for greater shaft offset; Cons: More complex design, typically more expensive. |

Straight Bevel Gears

Straight bevel gears feature straight teeth that run parallel to the cone’s generators. This design makes them straightforward to manufacture and cost-effective, which is advantageous for B2B buyers looking for economical solutions in applications like machine tools and printing machines. However, they operate best at lower speeds (below 1000 rpm), and their performance can be noisy due to the design, which may require consideration in noise-sensitive environments.

Spiral Bevel Gears

Spiral bevel gears have curved teeth that allow for gradual engagement, resulting in smoother and quieter operation. They are ideal for high-speed applications such as automotive speed reducers and aviation systems, where efficiency is paramount. While they offer significant performance benefits, the complexity of their manufacturing can lead to higher costs. Buyers should weigh the long-term operational efficiency against initial investment when considering spiral bevel gears.

Zerol Bevel Gears

Zerol bevel gears combine the benefits of both straight and spiral bevel gears, featuring curved teeth without an angled helix. This unique design allows for smoother meshing and efficient power transmission, making them suitable for applications in robotics and precision machinery. However, the specialized manufacturing processes required may increase costs. B2B buyers should evaluate their specific needs for precision and smooth operation when considering these gears.

Miter Gears

Miter gears are characterized by a 1:1 gear ratio, providing a straightforward method to change the direction of rotation without altering speed or torque. Their simple design makes them affordable and easy to maintain, making them suitable for applications in power transmission systems and mechanical advantage setups. However, their limited load-carrying capacity means they are not ideal for high-torque applications. Buyers should consider the specific torque requirements of their applications before opting for miter gears.

Hypoid Gears

Hypoid gears feature an offset shaft design with curved teeth, allowing for greater flexibility in applications requiring significant shaft offset. They are commonly used in heavy machinery and automotive differentials, where robust performance is essential. While hypoid gears can provide superior performance in specific contexts, their complex design typically results in higher costs. Buyers should assess the operational requirements and budget constraints when considering hypoid gears for their applications.

Related Video: Bevel Gears Types and Terminology

Key Industrial Applications of bevel gear

| Industry/Sector | Specific Application of bevel gear | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Transmissions in vehicles | Efficient power transfer and enhanced performance | Precision specifications, material quality, and durability |

| Aerospace | Flight control systems | Reliable operation in critical environments | Compliance with industry standards and certifications |

| Heavy Machinery | Mining and construction equipment | Improved torque management and operational efficiency | Load capacity, size, and compatibility with existing systems |

| Renewable Energy | Wind turbine gearboxes | Maximized energy conversion and reduced maintenance costs | Environmental resistance, efficiency ratings, and warranties |

| Robotics | Robotic arms and automated systems | Enhanced precision and control in movement | Customization capabilities, weight considerations, and lead times |

Automotive Applications

In the automotive sector, bevel gears are integral to the transmission systems of vehicles. They facilitate the transfer of power between the engine and the wheels, allowing for smooth acceleration and deceleration. Buyers should prioritize precision specifications and material quality to ensure durability and performance, especially in regions with diverse climate conditions, like Africa and South America. Additionally, understanding the local regulatory compliance for automotive components is crucial for successful sourcing.

Aerospace Applications

Bevel gears play a vital role in aerospace applications, particularly in flight control systems. These gears must operate reliably in high-stress environments, where failure can have catastrophic consequences. For international buyers, sourcing gears that comply with stringent aerospace industry standards is essential. Factors such as weight, material strength, and precision are critical in ensuring safety and performance in flight operations, particularly for companies in the Middle East and Europe.

Heavy Machinery Applications

In heavy machinery, bevel gears are used in mining and construction equipment to manage torque effectively. They help in transferring power from engines to various operational components, enhancing efficiency and reducing energy losses. Buyers should consider load capacity and compatibility with existing machinery when sourcing bevel gears. Given the harsh working conditions in these industries, durability and resistance to wear are also important factors, particularly in South American mining operations.

Renewable Energy Applications

Bevel gears are increasingly used in wind turbine gearboxes, where they play a crucial role in converting wind energy into electrical energy. The efficiency of these gears directly affects the overall energy conversion process, making sourcing high-quality bevel gears essential for maximizing output and minimizing maintenance costs. International buyers should focus on environmental resistance and efficiency ratings, as these factors can significantly impact operational costs and performance, especially in diverse climates across Africa and Europe.

Robotics Applications

In robotics, bevel gears are utilized in robotic arms and automated systems to provide precise movement and control. They enable the efficient transfer of motion, which is critical in applications requiring high accuracy. Buyers should seek customization capabilities to meet specific operational requirements, as well as consider weight and size constraints to ensure the gears fit seamlessly into existing robotic systems. Timeliness in sourcing is also vital, given the fast-paced nature of technological advancements in robotics, particularly in European markets.

Related Video: The World’s Largest Bevel Gear CNC Machine- Modern Gear Production Line. Steel Wheel Manufacturing

Strategic Material Selection Guide for bevel gear

When selecting materials for bevel gears, international B2B buyers must consider various factors, including performance characteristics, manufacturing complexity, and compliance with industry standards. Here, we analyze four common materials used in bevel gear production: carbon steel, stainless steel, aluminum, and bronze. Each material has unique properties that impact performance and suitability for specific applications.

Carbon Steel

Key Properties:

Carbon steel is known for its high strength and hardness, making it suitable for heavy-duty applications. It typically exhibits good wear resistance and can withstand high temperatures. However, its corrosion resistance is relatively low unless it is treated or coated.

Pros & Cons:

The primary advantage of carbon steel is its durability and ability to handle high loads, which is essential for applications like automotive and industrial machinery. However, it can be more challenging to machine and may require additional processes like heat treatment to enhance its properties. The cost is generally moderate, making it a popular choice.

Impact on Application:

Carbon steel is compatible with various media, including oils and lubricants, making it ideal for mechanical systems. However, its susceptibility to corrosion means that it may not be suitable for environments with high humidity or exposure to corrosive substances.

Considerations for International Buyers:

Buyers should ensure that carbon steel gears comply with relevant standards such as ASTM A36 or DIN 17100. In regions like Africa and South America, where environmental conditions can vary, additional protective coatings may be necessary.

Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance, high strength, and good temperature stability. It is particularly advantageous in environments exposed to moisture or corrosive chemicals.

Pros & Cons:

The key advantage of stainless steel is its longevity and reliability in harsh conditions. While it is more expensive than carbon steel, its reduced maintenance needs can offset initial costs. However, stainless steel can be more difficult to machine, leading to higher manufacturing complexity.

Impact on Application:

Stainless steel is ideal for applications in food processing, pharmaceuticals, and marine environments due to its resistance to corrosion and staining. Its compatibility with various media makes it a versatile choice.

Considerations for International Buyers:

Compliance with standards like ASTM A240 or DIN 17440 is crucial, especially in Europe and the Middle East, where regulations regarding material safety and environmental impact are stringent. Buyers should also consider the availability of specific stainless steel grades.

Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has good thermal and electrical conductivity. It is often chosen for applications requiring reduced weight and improved efficiency.

Pros & Cons:

The primary advantage of aluminum is its low weight, making it suitable for applications where weight savings are critical, such as aerospace and automotive sectors. However, it has lower strength compared to steel, which may limit its use in high-load applications. Additionally, aluminum can be more costly than carbon steel.

Impact on Application:

Aluminum gears are compatible with various lubricants and are often used in environments where weight and corrosion resistance are priorities. However, their lower strength may necessitate larger gear sizes to handle the same loads as steel gears.

Considerations for International Buyers:

Buyers must ensure that aluminum gears meet relevant standards such as ASTM B221 or JIS H4000. In regions with strict environmental regulations, the recyclability of aluminum may also be a selling point.

Bronze

Key Properties:

Bronze offers excellent wear resistance, low friction, and good corrosion resistance, particularly in marine environments. It is known for its durability and ability to withstand various operating conditions.

Pros & Cons:

Bronze gears are highly durable and can operate smoothly under high loads, making them ideal for applications in marine and heavy machinery. However, bronze is generally more expensive than steel and can be more challenging to source.

Impact on Application:

Bronze is particularly suitable for applications exposed to seawater or other corrosive environments, as it resists pitting and corrosion. Its compatibility with various lubricants enhances its performance in mechanical systems.

Considerations for International Buyers:

Compliance with standards such as ASTM B271 or DIN 17660 is essential. Buyers in the Middle East and Europe should also consider the implications of sourcing bronze, as availability may vary.

Summary Table

| Material | Typical Use Case for bevel gear | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Automotive, industrial machinery | High strength and durability | Corrosion susceptibility | Medium |

| Stainless Steel | Food processing, marine applications | Excellent corrosion resistance | Higher manufacturing complexity | High |

| Aluminum | Aerospace, lightweight machinery | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

| Bronze | Marine applications, heavy machinery | Excellent wear resistance | Higher cost and sourcing challenges | High |

This guide provides a strategic overview of material selection for bevel gears, enabling international B2B buyers to make informed decisions based on their specific applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for bevel gear

Bevel gears are integral components in various industries, particularly in applications requiring the transfer of power between intersecting shafts. Understanding the manufacturing processes and quality assurance measures is crucial for international B2B buyers to ensure they procure reliable and high-performance bevel gears. This section provides a detailed look into the typical manufacturing processes, quality control measures, and relevant standards that B2B buyers should consider.

Manufacturing Processes for Bevel Gears

The manufacturing of bevel gears involves several critical stages, each contributing to the final product’s quality and performance. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation

The manufacturing process begins with material selection, typically high-carbon steels or alloy steels that offer superior strength and wear resistance. The selected material is then prepared through processes such as:

-

Cutting and Shaping: Large steel blocks are cut into manageable sizes and pre-formed into blanks. This initial shaping is crucial for subsequent processes.

-

Heat Treatment: Before machining, the material may undergo heat treatment to improve hardness and wear resistance. Common methods include quenching and tempering, which enhance the material’s structural integrity.

Forming

This stage encompasses the primary methods used to create the gear teeth and overall shape of the bevel gear:

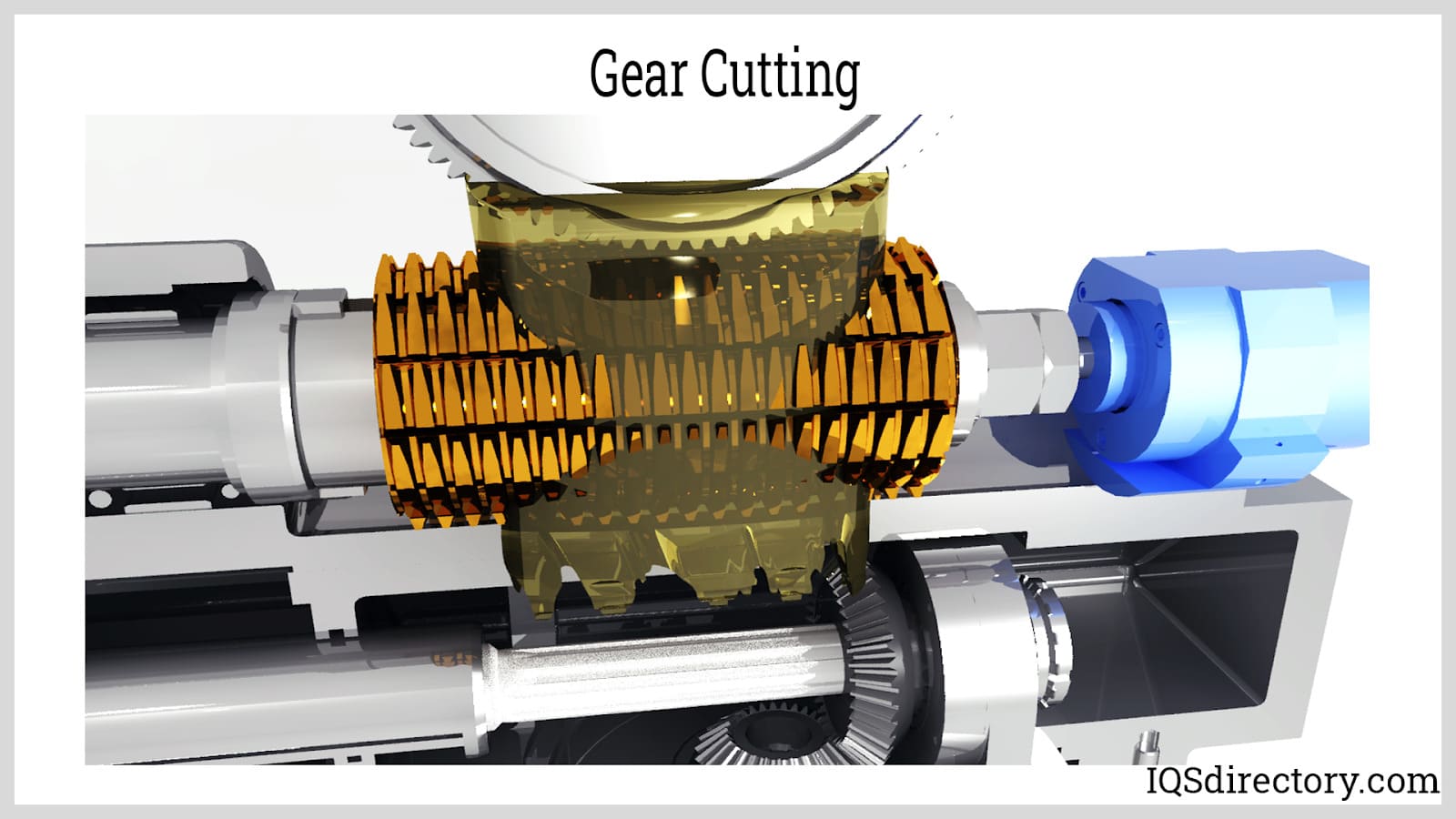

- Gear Cutting: Various techniques can be employed, including:

- Conventional Gear Cutting: Utilizing gear hobs or shapers for low to medium production runs.

- CNC Gear Cutting: Offers precision and flexibility for complex designs, suitable for high-volume production.

-

Gear Grinding: Ensures a high-quality surface finish and precise dimensions, often necessary for gears requiring tight tolerances.

-

Heat Treatment (Post-Cutting): After the teeth are cut, gears typically undergo further heat treatment, such as carburizing, to enhance surface hardness and fatigue resistance.

Assembly

Once individual components are manufactured, they must be assembled. This may involve:

- Press-Fitting: Components are fitted together under pressure, ensuring tight tolerances.

- Welding or Bolting: Depending on the design, some gears may require permanent fastening methods.

Finishing

Finishing processes enhance the gear’s performance characteristics:

- Deburring: Removal of sharp edges and burrs from the cutting process.

- Lapping: A precision process that refines the surface finish and tooth contact patterns.

- Coating: Optional surface treatments, such as plating, can be applied to improve corrosion resistance.

Quality Control Measures

Quality assurance is a fundamental aspect of bevel gear manufacturing, ensuring that products meet specified standards and performance criteria.

International Standards

B2B buyers should look for suppliers adhering to recognized international quality standards, such as:

- ISO 9001: This standard outlines criteria for a quality management system, ensuring consistent quality in products and services.

- CE Certification: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: Relevant for gears used in the oil and gas industry, ensuring they meet specific operational requirements.

Quality Control Checkpoints

Quality control processes typically include several checkpoints throughout the manufacturing lifecycle:

- Incoming Quality Control (IQC): Initial inspection of raw materials to verify that they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to catch defects early and ensure adherence to specifications.

- Final Quality Control (FQC): A comprehensive inspection of the finished product, checking dimensions, surface finish, and performance characteristics.

Common Testing Methods

B2B buyers should be familiar with the various testing methods used in quality assurance:

- Dimensional Inspection: Utilizes tools such as coordinate measuring machines (CMM) to verify gear dimensions.

- Surface Roughness Testing: Assesses the surface finish to ensure it meets operational requirements.

- Hardness Testing: Determines the hardness of the gear material, essential for assessing durability.

Verifying Supplier Quality Control

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality control is vital. Here are effective strategies:

- Supplier Audits: Conduct regular audits to assess the supplier’s adherence to quality management systems and manufacturing processes.

- Request Quality Reports: Ask for detailed quality reports that outline testing methods, results, and compliance with international standards.

- Third-Party Inspections: Engage independent inspection services to evaluate the manufacturing processes and final products, ensuring impartiality in quality assessment.

Quality Control Nuances for International Buyers

Understanding the nuances of quality control in different regions can help buyers make informed decisions:

- Cultural Differences: Be aware that quality standards and practices may vary across regions. For instance, European standards may be stricter than those in some African or South American countries.

- Regulatory Compliance: Ensure that suppliers are compliant with both local and international regulations that may impact gear performance and safety.

- Supply Chain Considerations: Evaluate the entire supply chain for potential quality issues, including logistics and transportation, which can affect the final product’s integrity.

By grasping the intricacies of bevel gear manufacturing processes and quality assurance, B2B buyers can make strategic decisions that enhance their supply chain reliability and product performance, ultimately leading to successful operational outcomes.

Comprehensive Cost and Pricing Analysis for bevel gear Sourcing

Bevel gears are essential components in various mechanical systems, and understanding their cost structure and pricing dynamics is crucial for international B2B buyers. This section provides a comprehensive analysis of the cost components, price influencers, and practical tips for sourcing bevel gears effectively.

Cost Components

-

Materials: The primary materials used in bevel gear manufacturing include high-carbon steel, alloy steel, and sometimes specialty materials for specific applications. The choice of material significantly affects the cost, with higher-grade materials typically leading to increased durability and performance but also higher prices.

-

Labor: Labor costs can vary greatly depending on the region of production. Countries with lower labor costs may offer more competitive pricing, while those with skilled labor forces, such as in Europe, may charge more due to higher wages. Skilled labor is particularly essential for precision processes like gear cutting and finishing.

-

Manufacturing Overhead: This includes costs associated with factory operations, equipment maintenance, and utilities. Overhead costs can be substantial, particularly in facilities that utilize advanced manufacturing technologies like CNC machining and automation.

-

Tooling: The initial investment in specialized tooling for bevel gear production can be high. Tooling costs may be amortized over larger production runs, so buyers should consider the scale of their order when assessing the total cost.

-

Quality Control (QC): Rigorous QC processes ensure that the bevel gears meet the required specifications and performance standards. The costs associated with testing and inspection can influence the overall price, particularly for high-precision applications.

-

Logistics: Shipping and handling costs can add significantly to the total price, especially for international orders. Factors such as distance, mode of transportation, and customs duties should be factored into the overall cost analysis.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the average margins within the industry can help buyers negotiate better deals.

Price Influencers

-

Volume/MOQ: Bulk orders usually lead to lower unit prices. Buyers should consider their Minimum Order Quantity (MOQ) requirements and negotiate for favorable pricing based on volume.

-

Specifications/Customization: Customized bevel gears tailored to specific applications may incur additional costs. The complexity of the design and the level of customization will impact the final price.

-

Materials: As previously mentioned, the choice of materials can significantly affect costs. Buyers should weigh the benefits of high-grade materials against their budget constraints.

-

Quality/Certifications: Gears that meet specific industry standards or certifications may cost more due to the additional testing and quality assurance processes involved.

-

Supplier Factors: Reputation, reliability, and historical performance of suppliers can also influence pricing. Established suppliers may charge a premium but often provide better quality assurance.

-

Incoterms: Understanding the terms of shipment and delivery can help buyers manage logistics costs effectively. Incoterms define the responsibilities of buyers and sellers, which can impact the total landed cost.

Buyer Tips

-

Negotiation: Engage in open discussions with suppliers to negotiate better prices based on volume and long-term relationships. Leveraging multiple suppliers can also provide comparative pricing.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO) rather than just the initial purchase price. This includes maintenance, durability, and potential downtime costs associated with gear failure.

-

Pricing Nuances for International Buyers: International buyers should be aware of currency fluctuations, tariffs, and regional market conditions that may affect pricing. Conducting market research in the target region can provide insights into competitive pricing.

Disclaimer

The prices discussed in this analysis are indicative and subject to change based on various factors, including market conditions, raw material costs, and supplier pricing strategies. Buyers are encouraged to conduct thorough due diligence and obtain quotes from multiple suppliers to ensure competitive pricing.

Spotlight on Potential bevel gear Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘bevel gear’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for bevel gear

Bevel gears are critical components in various mechanical systems, facilitating the transfer of power between intersecting shafts. For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, understanding the essential technical properties and trade terminology related to bevel gears is crucial for informed purchasing decisions.

Key Technical Properties of Bevel Gears

-

Material Grade

– Definition: The material grade indicates the type of material used to manufacture the bevel gear, commonly carbon steel, alloy steel, or stainless steel.

– Importance: Selecting the appropriate material affects the gear’s strength, durability, and resistance to wear and corrosion. Buyers must consider the specific application and environmental conditions when choosing the material grade. -

Tooth Profile

– Definition: The tooth profile refers to the shape and design of the gear teeth, which can be straight, spiral, or Zerol.

– Importance: Different tooth profiles impact the gear’s operational efficiency, noise levels, and load capacity. Understanding the tooth profile helps buyers select gears that meet their performance needs. -

Pitch Diameter

– Definition: Pitch diameter is the diameter of the pitch circle, where the teeth of two meshing gears effectively engage.

– Importance: This measurement is crucial for ensuring proper meshing with other gears and achieving the desired speed and torque ratios in a mechanical system. -

Tolerance

– Definition: Tolerance indicates the permissible limit of variation in a gear’s dimensions, affecting how well the gear fits with other components.

– Importance: Precise tolerances ensure optimal performance, reducing the risk of gear failure. Buyers should prioritize suppliers who adhere to stringent tolerance specifications. -

Heat Treatment

– Definition: Heat treatment processes, such as carburizing or hardening, enhance the hardness and strength of bevel gears.

– Importance: Proper heat treatment improves the gear’s wear resistance and longevity, making it vital for buyers to inquire about the heat treatment methods used in manufacturing. -

Load Capacity

– Definition: Load capacity refers to the maximum load a bevel gear can handle without failure.

– Importance: Understanding load capacity is essential for ensuring that the selected gear can withstand operational stresses in specific applications, preventing premature wear or breakage.

Illustrative Image (Source: Google Search)

Common Trade Terminology in Bevel Gear Transactions

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM produces parts and equipment that are marketed by another company.

– Relevance: Buyers often seek OEM products for reliability and compatibility with existing systems, ensuring quality and performance. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell.

– Relevance: Understanding MOQ helps buyers assess their purchasing power and negotiate better terms, particularly for bulk orders. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document issued by a buyer requesting pricing and terms from suppliers for specific products or services.

– Relevance: Submitting an RFQ allows buyers to compare offers and make informed decisions based on cost and delivery conditions. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are standardized international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

– Relevance: Familiarity with Incoterms is essential for buyers to understand their obligations and risks in the shipping process, ensuring smooth international transactions. -

Lead Time

– Definition: Lead time is the amount of time it takes from placing an order to receiving the product.

– Relevance: Understanding lead times helps buyers plan their inventory and production schedules effectively, minimizing disruptions in their operations. -

Custom Gears

– Definition: Custom gears are specially designed gears tailored to specific requirements or applications.

– Relevance: Buyers with unique operational needs may require custom gears, making it important to communicate specifications clearly with manufacturers.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of bevel gear procurement, ensuring they select the right components for their applications while fostering successful partnerships with suppliers.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the bevel gear Sector

Market Overview & Key Trends

The global bevel gear market is experiencing significant growth, driven by the increasing demand for high-performance mechanical components across various industries, including automotive, aerospace, and industrial machinery. Key market dynamics include the rapid adoption of advanced manufacturing technologies such as CNC machining and automation, which enhance production efficiency and precision. International B2B buyers, especially from Africa, South America, the Middle East, and Europe, are now prioritizing suppliers who leverage these technologies to provide high-quality and customized bevel gear solutions.

Emerging trends in sourcing include the shift towards local suppliers to reduce lead times and shipping costs, particularly in regions with developing manufacturing sectors. Buyers are also focusing on suppliers that can offer integrated solutions, combining bevel gear manufacturing with design and engineering services. This trend is particularly evident in Europe and South America, where businesses seek to streamline their supply chains and improve collaboration with manufacturers.

Moreover, the increasing emphasis on digital transformation in manufacturing, including the use of Industry 4.0 technologies, is reshaping sourcing strategies. Buyers are looking for suppliers who can provide real-time data and analytics on production processes, enabling better decision-making and inventory management. This shift not only enhances operational efficiency but also helps in mitigating risks associated with supply chain disruptions.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration for international B2B buyers in the bevel gear sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. Buyers are increasingly favoring suppliers that adopt sustainable practices, such as using energy-efficient machinery and implementing waste reduction initiatives.

Ethical sourcing is equally important, with businesses seeking to establish supply chains that prioritize fair labor practices and responsible material sourcing. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are gaining traction among buyers, as they signal a commitment to sustainability and ethical manufacturing practices.

Furthermore, the use of ‘green’ materials in bevel gear production is on the rise. Suppliers that incorporate recycled materials or sustainable alternatives into their manufacturing processes are likely to stand out in the market. Buyers can enhance their brand reputation and customer loyalty by partnering with manufacturers who prioritize sustainability and ethical sourcing, aligning with the growing consumer demand for environmentally responsible products.

Illustrative Image (Source: Google Search)

Brief Evolution/History

The evolution of bevel gears can be traced back to the early mechanical innovations of the 19th century, where their unique ability to transmit power between intersecting shafts was first recognized. Initially, bevel gears were crafted using rudimentary methods, limiting their precision and efficiency. However, with advancements in material science and manufacturing technology, particularly during the Industrial Revolution, bevel gears began to see widespread application in various industries.

In the 20th century, the introduction of CNC machining and heat treatment processes significantly enhanced the quality and performance of bevel gears. Today, manufacturers leverage advanced technologies such as 5-axis CNC machining and automated inspection systems to produce gears with exceptional accuracy and durability. This evolution not only reflects the technological advancements in manufacturing but also highlights the increasing demand for high-quality bevel gears across global markets, making them a vital component in modern mechanical systems.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of bevel gear

-

How can I effectively vet suppliers of bevel gears?

To vet suppliers, start by researching their company history, reputation, and client testimonials. Request certifications such as ISO 9001 for quality management and any industry-specific certifications. Conduct site visits if feasible, or use video conferencing to assess their facilities and capabilities. Additionally, consider their experience in your specific application area, such as automotive or industrial machinery, to ensure they understand your requirements. Lastly, ask for samples to evaluate the quality of their bevel gears firsthand. -

Can bevel gears be customized to fit specific applications?

Yes, many manufacturers offer customization options for bevel gears. This can include modifications to tooth geometry, materials, and sizes to meet unique application requirements. When discussing customization, provide detailed specifications, such as load capacities, operating conditions, and any specific design features. Be prepared for potential additional costs and longer lead times associated with customized orders. Establish clear communication with the supplier throughout the design process to ensure alignment on expectations. -

What are the typical minimum order quantities (MOQs) and lead times for bevel gear orders?

Minimum order quantities can vary significantly between suppliers, often depending on production capabilities and the complexity of the bevel gear. Typical MOQs range from 50 to 500 units, but some suppliers may accommodate lower quantities for prototypes or smaller projects. Lead times can also vary, generally ranging from 4 to 12 weeks, depending on customization, production schedules, and shipping logistics. It’s essential to discuss these factors upfront to align with your project timelines. -

What payment terms should I expect when sourcing bevel gears internationally?

Payment terms can vary by supplier, but common practices include advance payments, letters of credit, or payment upon delivery. For international transactions, it’s crucial to negotiate terms that protect your interests, such as partial payments upfront with the remainder due upon successful delivery and inspection. Always confirm the currency used for transactions and consider any potential foreign exchange risks. Establishing a clear agreement on payment terms in the contract can help avoid disputes later. -

What quality assurance processes should I look for in bevel gear manufacturing?

Look for suppliers that implement rigorous quality assurance (QA) processes throughout their manufacturing operations. This includes in-process inspections, final inspections, and testing of mechanical properties. Ask about their use of advanced measurement tools, such as coordinate measuring machines (CMM), and whether they conduct performance testing to ensure compliance with specifications. Certifications like ISO 9001 or specific industry standards are indicators of a commitment to quality. Request documentation of QA processes to review before finalizing your supplier choice. -

How do logistics and shipping impact the sourcing of bevel gears?

Logistics play a crucial role in the timely delivery of bevel gears. Consider factors such as the supplier’s location, shipping methods, and potential customs regulations that could affect delivery times. Discuss with your supplier their shipping options, costs, and expected delivery times. It may be beneficial to work with a logistics partner familiar with international shipping to navigate customs and avoid delays. Always clarify who is responsible for shipping costs and insurance to mitigate risks during transit. -

What should I do in case of a dispute with a bevel gear supplier?

In the event of a dispute, maintain clear and open communication with the supplier to resolve the issue amicably. Document all correspondence and keep records of agreements, contracts, and any relevant communications. If direct discussions do not lead to a resolution, refer to the terms outlined in your contract regarding dispute resolution mechanisms, such as mediation or arbitration. Engaging a legal expert familiar with international trade can provide guidance on your rights and options based on the jurisdiction involved. -

What certifications should I look for when sourcing bevel gears?

When sourcing bevel gears, seek suppliers with relevant certifications that indicate compliance with international quality and safety standards. Common certifications include ISO 9001 for quality management systems, ISO 14001 for environmental management, and specific industry standards like AS9100 for aerospace applications. These certifications demonstrate a supplier’s commitment to quality and reliability. Additionally, inquire about any product-specific certifications that may apply to your industry, ensuring that the gears meet necessary performance and safety requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for bevel gear

In the evolving landscape of bevel gear sourcing, strategic partnerships and informed decision-making are paramount for international B2B buyers. Understanding the complexities of bevel gear manufacturing processes—from design and engineering to cutting, heat treatment, and quality control—enables buyers to make educated choices that align with their operational needs.

Key Takeaways:

– Prioritize Quality: Engage suppliers that adhere to rigorous quality control processes to ensure high-performance gears that meet your specifications.

– Leverage Technology: Consider suppliers utilizing advanced manufacturing technologies, such as CNC machining and automation, which can enhance precision and efficiency.

– Adapt to Local Markets: Buyers from Africa, South America, the Middle East, and Europe should assess local supplier capabilities to reduce lead times and logistical costs.

As the demand for high-quality bevel gears continues to grow across industries, the importance of strategic sourcing cannot be overstated. By forging strong relationships with reliable manufacturers and staying abreast of technological advancements, international buyers can ensure they remain competitive.

Call to Action: Start evaluating your sourcing strategies today to capitalize on emerging opportunities in the bevel gear market. Your success hinges on making informed choices that drive operational excellence.