Your Ultimate Guide to Sourcing Gear Drives

Introduction: Navigating the Global Market for gear drives

In today’s competitive global marketplace, gear drives are pivotal components in numerous industries, driving efficiency and reliability in applications ranging from automotive to renewable energy. As international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of gear drives is essential for informed sourcing decisions. This guide offers a comprehensive overview of gear drives, covering various types, materials, manufacturing processes, quality control measures, and the key suppliers shaping the industry.

From the intricacies of gear design to the latest advancements in manufacturing technology, each section of this guide is tailored to empower buyers with actionable insights. For instance, knowing the differences between helical, bevel, and planetary gear drives can significantly influence your procurement strategy, ensuring alignment with specific operational requirements.

Moreover, we delve into the critical aspects of supplier selection, providing a framework for evaluating quality standards and cost-effectiveness. By addressing frequently asked questions and emerging market trends, this guide serves as a vital resource for making strategic purchasing decisions. As you navigate the complexities of sourcing gear drives, leverage this guide to enhance your understanding, minimize risks, and ultimately optimize your supply chain efficiency.

Understanding gear drives Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Helical Gear Drives | Angled teeth for smoother operation | Automotive, Industrial Machinery | Pros: High load capacity, quieter operation. Cons: More complex manufacturing, higher cost. |

| Bevel Gear Drives | Conical shape for angular motion transfer | Marine, Aerospace, Automotive | Pros: Efficient power transmission at angles. Cons: Requires precise alignment, can be bulky. |

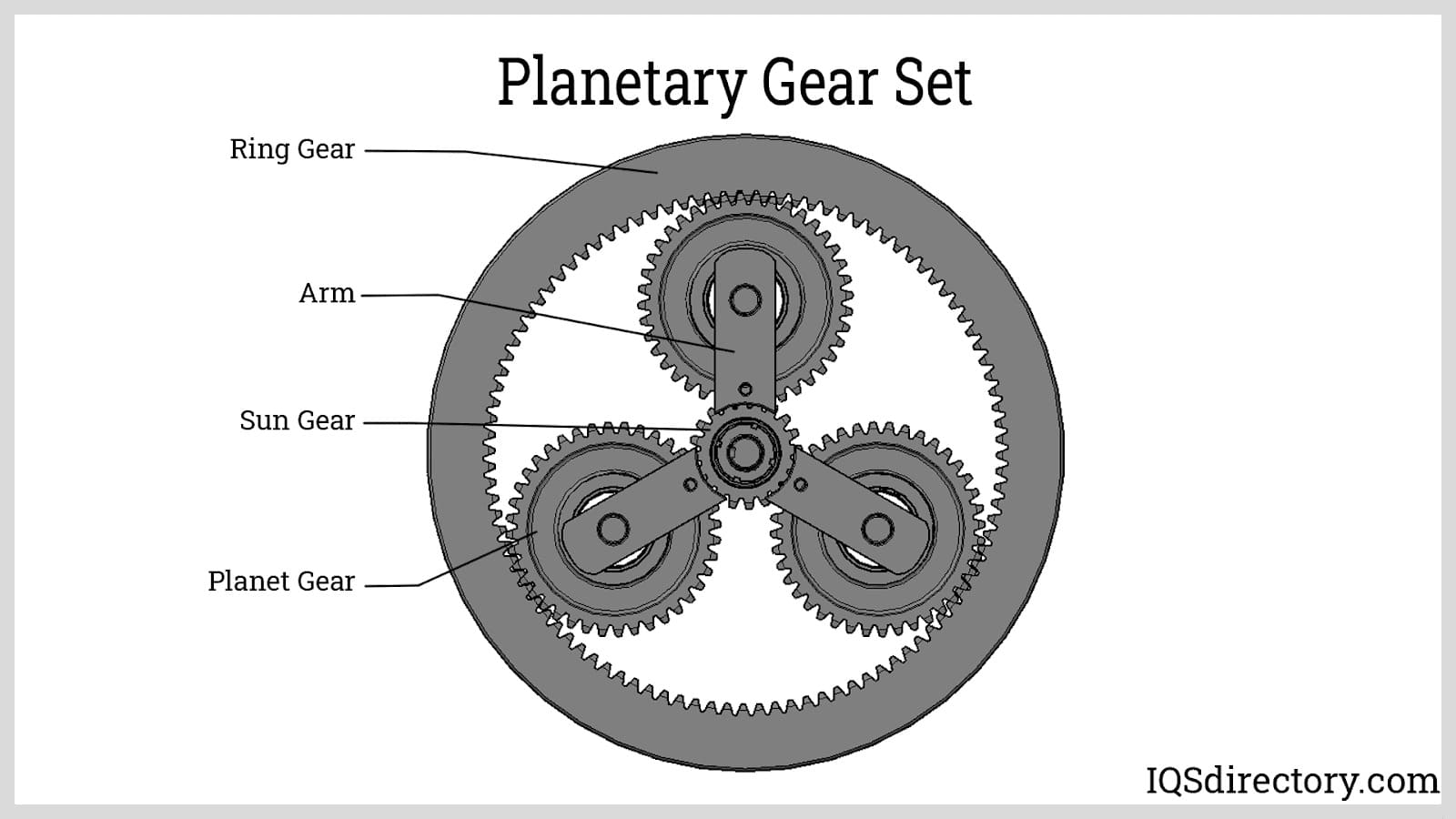

| Planetary Gear Drives | Multiple gears orbiting around a central gear | Robotics, Wind Turbines, Automotive | Pros: Compact design, high torque density. Cons: More complex assembly, higher initial cost. |

| Spur Gear Drives | Straight teeth parallel to the gear axis | General Manufacturing, Conveyors | Pros: Simple design, easy to manufacture. Cons: Noisy operation, limited load capacity. |

| Worm Gear Drives | Worm and worm wheel for high torque applications | Lifts, Conveyors, Heavy Machinery | Pros: High reduction ratios, self-locking feature. Cons: Less efficient, higher friction losses. |

Helical Gear Drives

Helical gear drives feature teeth that are cut at an angle, allowing for gradual engagement of the gear teeth. This design results in smoother and quieter operation compared to spur gears. They are commonly used in automotive and industrial machinery applications where high load capacity and reduced noise are critical. When purchasing helical gears, buyers should consider the specific load requirements and operating conditions, as well as the potential for increased manufacturing costs due to their complexity.

Bevel Gear Drives

Bevel gear drives are characterized by their conical shape, enabling the transfer of motion between shafts that are at right angles to each other. They are widely utilized in marine and aerospace applications, as well as in automotive systems. While bevel gears offer efficient power transmission, their alignment is crucial for optimal performance, and buyers must ensure precision in installation to avoid premature wear or failure.

Planetary Gear Drives

Planetary gear drives consist of multiple gears that revolve around a central sun gear, allowing for high torque density in a compact design. This type of gear drive is prevalent in robotics, wind turbines, and automotive applications, where space and weight constraints are significant. Buyers should be aware of the complexity involved in assembly and maintenance, as well as the potentially higher initial investment, which can be offset by long-term performance benefits.

Spur Gear Drives

Spur gear drives are the simplest type of gear, with straight teeth that are aligned parallel to the gear axis. They are widely used in general manufacturing and conveyor systems due to their ease of manufacturing and straightforward design. While spur gears are cost-effective, they can produce more noise and have limitations in load capacity. Buyers should weigh the simplicity and affordability against the operational noise and performance needs of their applications.

Worm Gear Drives

Worm gear drives utilize a worm and worm wheel configuration to provide high torque and significant speed reduction. They are often found in applications such as lifts and heavy machinery, where a self-locking feature is advantageous. Although worm gears can achieve high reduction ratios, they tend to be less efficient due to friction losses. Buyers should assess the specific torque and speed requirements for their applications, keeping in mind the trade-offs in efficiency and operational costs.

Related Video: Porsche Models Explained ( All Porsche Cars 2021 ) | Let Me Explain

Key Industrial Applications of gear drives

| Industry/Sector | Specific Application of gear drives | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Drivetrain systems for electric and hybrid vehicles | Enhanced efficiency and performance | Supplier’s experience with electric drivetrains and customization capabilities |

| Renewable Energy | Gear drives in wind turbine systems | Increased energy output and reliability | Compliance with industry standards and local regulations, particularly in emerging markets |

| Industrial Machinery | Gear drives in conveyor systems | Improved operational efficiency and uptime | Quality certifications and ability to provide technical support |

| Mining and Heavy Industry | Custom gearboxes for heavy-duty applications | Tailored solutions for extreme conditions | Supplier’s ability to provide robust designs and remote monitoring options |

| Aerospace | Precision gear systems for aircraft | Critical for safety and performance | Supplier’s adherence to stringent aerospace standards and track record in precision engineering |

Automotive

In the automotive sector, gear drives are integral to the drivetrain systems of electric and hybrid vehicles. They facilitate smooth power transmission while optimizing energy efficiency, which is crucial as manufacturers strive for greener technologies. International buyers should seek suppliers with expertise in electric drivetrains, as these require specialized gear configurations to handle high torque and variable speeds. Additionally, customization capabilities are essential to meet specific vehicle performance requirements.

Renewable Energy

In the renewable energy sector, particularly in wind turbine systems, gear drives play a vital role in converting mechanical energy into electrical energy. They enhance the efficiency and reliability of energy output, which is critical for meeting renewable energy targets. Buyers from Africa and South America, where renewable projects are rapidly expanding, must ensure that suppliers comply with local industry standards and regulations. Understanding the supplier’s experience with large-scale projects can also provide assurance of product reliability.

Industrial Machinery

Gear drives are extensively used in conveyor systems within industrial machinery to facilitate the movement of materials. These systems require high reliability and operational efficiency to minimize downtime. For international buyers, especially in Europe, sourcing from suppliers with quality certifications (like ISO) ensures adherence to best practices. Additionally, the ability of suppliers to offer technical support is crucial for maintaining system performance and addressing any operational challenges.

Mining and Heavy Industry

In mining and heavy industries, custom gearboxes are essential for handling extreme conditions, such as high loads and harsh environments. Gear drives in this sector are designed to be robust and durable, providing tailored solutions for specific applications. Buyers should prioritize suppliers with proven capabilities in delivering heavy-duty designs and options for remote monitoring, which can significantly enhance maintenance and reduce operational risks.

Aerospace

Precision gear systems are critical in the aerospace industry, where safety and performance are paramount. Gear drives must meet stringent aerospace standards, ensuring they can operate reliably under extreme conditions. International buyers should focus on suppliers with a strong track record in precision engineering and compliance with regulatory requirements. Understanding the supplier’s experience in producing aerospace components can significantly influence sourcing decisions, ensuring that the end products meet all necessary performance criteria.

Related Video: Gear Types, Design Basics, Applications and More – Basics of Gears

Strategic Material Selection Guide for gear drives

When selecting materials for gear drives, international B2B buyers must consider various factors including performance, cost, and application suitability. Below is an analysis of four common materials used in gear drive manufacturing, focusing on their key properties, advantages, disadvantages, and specific considerations for buyers in Africa, South America, the Middle East, and Europe.

Steel Alloys

Key Properties:

Steel alloys, particularly carbon and alloy steels, are known for their excellent strength, toughness, and wear resistance. They can withstand high temperatures and pressures, making them suitable for heavy-duty applications.

Pros & Cons:

Steel gears are durable and have a long service life, but they can be prone to corrosion if not properly treated. Manufacturing complexity is moderate, as processes like heat treatment and surface hardening are often required to enhance performance.

Impact on Application:

Steel gears are compatible with a wide range of lubricants and can be used in various environments, including automotive and industrial machinery.

Considerations for Buyers:

Buyers should ensure compliance with international standards such as ASTM and DIN for material specifications. Corrosion-resistant coatings may be necessary for applications in humid or corrosive environments, particularly in tropical regions.

Cast Iron

Key Properties:

Cast iron is characterized by its good machinability, excellent wear resistance, and vibration-damping properties. It can handle moderate loads and has a high resistance to deformation.

Pros & Cons:

While cast iron is cost-effective and easy to manufacture, it is relatively brittle compared to steel, which can limit its use in high-stress applications. The weight of cast iron components can also be a disadvantage in weight-sensitive designs.

Impact on Application:

Cast iron gears are often used in applications where noise reduction is essential, such as in gearboxes for industrial machinery.

Considerations for Buyers:

Buyers should consider the local availability of cast iron grades that meet specific mechanical properties. Compliance with local standards and regulations is crucial, especially in regions with strict manufacturing guidelines.

Plastics (Polymer Gears)

Key Properties:

Plastics such as nylon and acetal are lightweight, corrosion-resistant, and can operate at lower noise levels. They also have good chemical resistance, making them suitable for various environments.

Pros & Cons:

Plastic gears are cost-effective and easy to manufacture, but they typically have lower load-bearing capacities compared to metals. They may also have limitations in high-temperature applications.

Impact on Application:

These materials are ideal for applications in consumer electronics, automotive, and light machinery where weight and noise reduction are priorities.

Considerations for Buyers:

International buyers should verify that the selected plastic materials comply with relevant standards for mechanical properties and environmental impact. Understanding the thermal and chemical compatibility with the intended application is essential.

Composite Materials

Key Properties:

Composite materials, such as fiber-reinforced plastics, offer high strength-to-weight ratios and excellent resistance to wear and corrosion. They can be engineered for specific applications, providing tailored performance characteristics.

Pros & Cons:

While composites can be more expensive and complex to manufacture, they provide significant advantages in terms of performance and longevity. They are also lighter than metals, which can be beneficial in many applications.

Impact on Application:

Composite gears are suitable for high-performance applications in aerospace and automotive sectors, where weight and efficiency are critical.

Considerations for Buyers:

Buyers should assess the availability of composite materials that meet their specific needs and ensure compliance with industry standards. Understanding the long-term performance characteristics and potential environmental impacts is also crucial.

Summary Table

| Material | Typical Use Case for gear drives | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel Alloys | Heavy-duty machinery | High strength and durability | Prone to corrosion | High |

| Cast Iron | Industrial machinery | Cost-effective and good machinability | Brittle under high stress | Medium |

| Plastics | Consumer electronics, light machinery | Lightweight and corrosion-resistant | Lower load-bearing capacity | Low |

| Composite Materials | Aerospace, automotive | High strength-to-weight ratio | Higher manufacturing complexity | High |

This strategic material selection guide provides crucial insights for international B2B buyers, enabling them to make informed decisions based on performance requirements and local market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for gear drives

Gear drives are integral to various industrial applications, necessitating a comprehensive understanding of their manufacturing processes and quality assurance protocols. This section delves into the main stages of gear drive manufacturing, key techniques involved, and the quality assurance measures that B2B buyers must consider when sourcing these critical components.

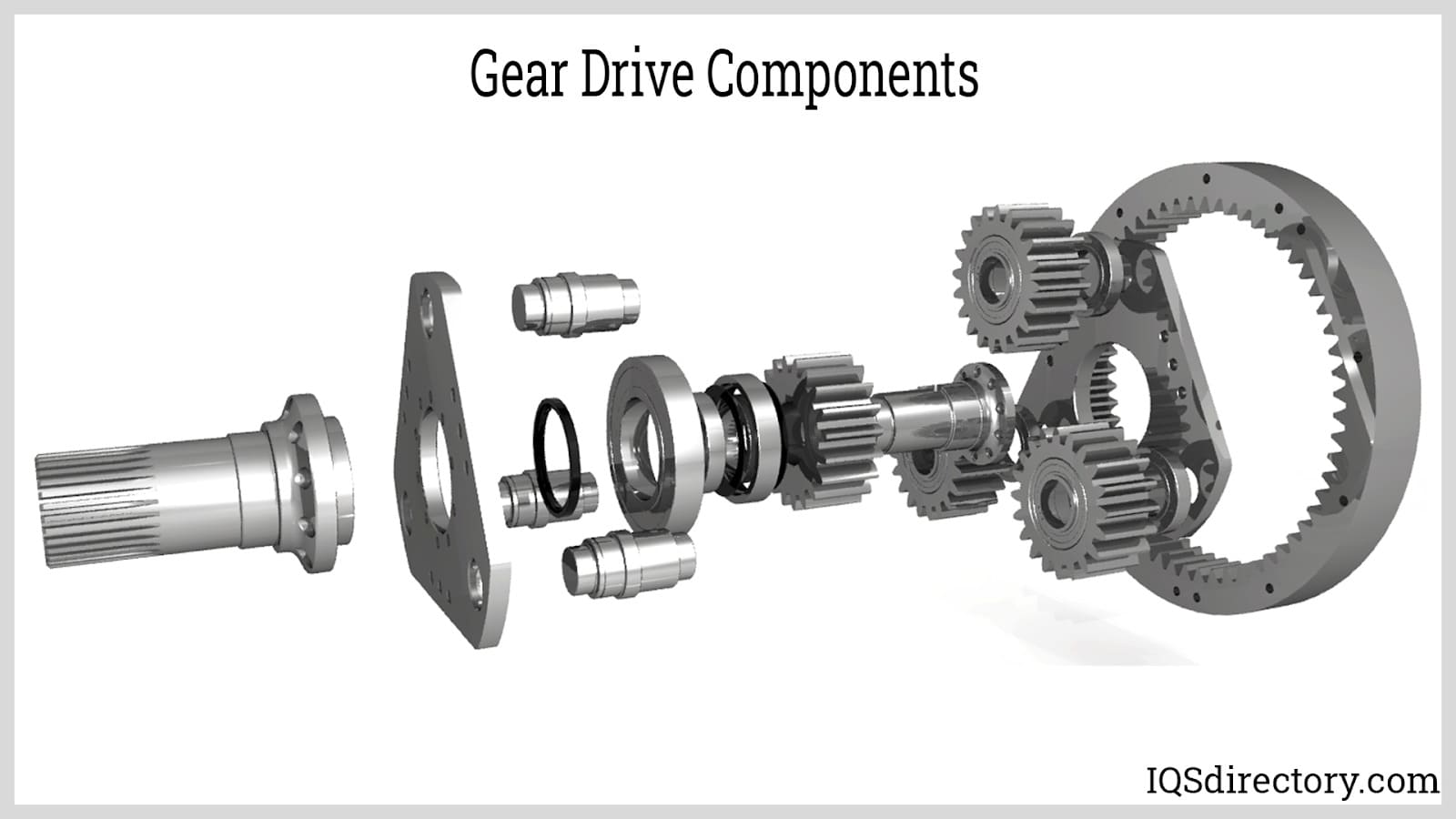

Manufacturing Processes for Gear Drives

The manufacturing of gear drives involves several key stages, each critical to ensuring the final product meets industry standards and customer specifications. The main stages include:

-

Material Preparation

– Selection of Materials: Common materials for gear drives include carbon steel, alloy steel, and sometimes non-ferrous metals like aluminum or bronze, depending on the application. The choice of material impacts the strength, weight, and corrosion resistance of the gear.

– Heat Treatment: Prior to forming, materials may undergo heat treatment to enhance their mechanical properties, such as hardness and wear resistance. -

Forming

– Forging: Gear blanks are typically created through forging processes, which can be hot die forging or free forging. This step improves the metal’s density and grain structure, leading to higher strength and fatigue resistance.

– Machining: After forming, rough machining is performed to shape the gear blanks into their preliminary forms. CNC lathes and machining centers are commonly used to achieve the necessary geometric accuracy.

– Tooth Cutting: This critical process involves generating the gear teeth through methods like hobbing, shaping, or broaching. The choice of method affects the precision and surface finish of the teeth. -

Assembly

– Component Integration: In multi-part gear drives, components such as shafts and bearings are assembled. Precision during assembly is crucial to ensure proper alignment and functionality.

– Lubrication Application: Proper lubrication is applied to reduce friction and wear during operation, which can significantly extend the lifespan of the gear drive. -

Finishing

– Heat Treatment: Post-machining heat treatment may be applied to improve hardness and wear characteristics further. This often includes processes like quenching and tempering.

– Surface Finishing: Techniques such as grinding, honing, or shot peening are used to achieve the required surface finish and dimensional tolerances. This stage is vital for ensuring operational efficiency and reliability.

Quality Assurance in Gear Drive Manufacturing

Quality assurance is paramount in gear drive manufacturing, with several international and industry-specific standards guiding the process. Key aspects include:

International Standards

- ISO 9001: This standard is critical for ensuring quality management systems are in place. It focuses on consistent product quality and customer satisfaction.

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards, particularly relevant for buyers in Europe.

- API Standards: For gear drives used in the oil and gas industry, API standards provide guidelines for quality and performance.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards. This includes material certifications and physical inspections.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process ensures that any deviations from specifications are identified and corrected promptly.

- Final Quality Control (FQC): The completed gear drives undergo rigorous testing, including dimensional checks, performance testing, and surface quality inspections.

Common Testing Methods

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or magnetic particle inspection are used to detect internal defects without damaging the component.

- Load Testing: Gear drives are subjected to operational loads to verify performance under real-world conditions.

- Vibration Analysis: This method assesses the health of gear drives by monitoring vibrations, which can indicate misalignment or wear.

Verifying Supplier Quality Control

B2B buyers must take proactive steps to ensure their suppliers maintain high-quality standards. Effective strategies include:

- Supplier Audits: Conducting regular audits of suppliers’ manufacturing processes and quality control systems can provide insights into their operational capabilities and compliance with standards.

- Reviewing Quality Reports: Requesting detailed quality reports and certificates can help validate the supplier’s adherence to international standards and internal quality benchmarks.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an impartial assessment of the supplier’s quality control practices and product reliability.

Quality Control and Certification Nuances for International Buyers

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges regarding quality control and certification:

- Regulatory Variations: Different regions may have varying regulatory requirements, making it essential for buyers to understand local standards and ensure suppliers comply.

- Cultural Differences: Communication styles and business practices can differ widely, impacting quality assurance processes. Building strong relationships with suppliers can facilitate better quality management.

- Logistical Considerations: International shipping may introduce risks such as damage during transit. Buyers should consider suppliers that offer robust packaging and shipping protocols to mitigate these risks.

In conclusion, a thorough understanding of manufacturing processes and quality assurance practices is essential for international B2B buyers seeking reliable gear drives. By focusing on quality standards, engaging in proactive verification methods, and understanding the nuances of international trade, buyers can secure high-quality products that meet their operational needs.

Related Video: BMW Car PRODUCTION ⚙️ ENGINE Factory Manufacturing Process

Comprehensive Cost and Pricing Analysis for gear drives Sourcing

Understanding the cost and pricing dynamics of gear drives is crucial for international B2B buyers, particularly those sourcing from regions like Africa, South America, the Middle East, and Europe. The complexity of gear drive components, combined with varying market conditions, necessitates a thorough analysis of the cost structure and price influencers.

Cost Components of Gear Drives

-

Materials: The choice of materials significantly impacts the overall cost. Common materials include steel, aluminum, and composites, each varying in price based on market conditions and quality. High-strength alloys can increase costs but may offer better durability and performance.

-

Labor: Labor costs are influenced by the region of manufacturing. Countries with higher labor costs may produce gear drives at a premium, while regions with lower labor costs can offer more competitive pricing. However, the skill level of the workforce can also affect the quality of the product.

-

Manufacturing Overhead: This includes expenses related to plant operation, utilities, and administrative costs. Efficient manufacturing processes can help reduce overhead, leading to more competitive pricing.

-

Tooling: The initial investment in tooling can be substantial, particularly for custom gear drives. Tooling costs are often amortized over production runs, so larger orders can reduce the per-unit cost.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes adds to the cost but is essential for preventing defects and ensuring reliability. Certifications (e.g., ISO) can also influence pricing.

-

Logistics: Transportation costs can vary significantly based on distance, mode of transport, and shipping conditions. Incoterms play a crucial role in defining who bears the logistics costs and risks, impacting the final pricing.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on market competition, brand reputation, and the perceived value of the product.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) and bulk purchasing can lead to significant discounts. Suppliers are often willing to negotiate prices for larger orders.

-

Specifications/Customization: Customized gear drives tailored to specific applications usually come at a higher price point. Buyers should evaluate whether the added cost aligns with their operational needs.

-

Quality/Certifications: Higher-quality products with recognized certifications may command premium prices. However, investing in quality can reduce long-term operational costs due to increased reliability and lower failure rates.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality and service may charge higher prices but offer greater peace of mind.

-

Incoterms: Understanding the implications of Incoterms is critical for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the final landed cost of gear drives.

Buyer Tips

-

Negotiation: Leverage volume purchases and long-term contracts to negotiate better prices. Building a relationship with suppliers can also facilitate more favorable terms.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also installation, maintenance, and operational costs over the product’s lifespan.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, suppliers in Europe may have different pricing structures compared to those in Africa or South America due to varying labor and material costs.

-

Quality vs. Cost: Balance the trade-off between cost and quality. Investing in higher-quality gear drives can lead to lower failure rates and maintenance costs, ultimately saving money in the long run.

Disclaimer

Prices for gear drives can fluctuate based on market conditions, material availability, and supplier pricing strategies. Therefore, it is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Illustrative Image (Source: Google Search)

Spotlight on Potential gear drives Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘gear drives’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for gear drives

Key Technical Properties of Gear Drives

When evaluating gear drives, understanding the technical properties is essential for ensuring performance, reliability, and compatibility with specific applications. Here are critical specifications that B2B buyers should consider:

-

Material Grade

– Definition: The classification of materials used in manufacturing gears, often specified in terms of strength, wear resistance, and fatigue limits.

– Importance: Selecting the right material grade ensures that the gear can withstand operational stresses and environmental conditions, impacting the longevity and functionality of the machinery. -

Tooth Profile

– Definition: The shape and design of the gear teeth, including parameters like pressure angle and tooth pitch.

– Importance: The tooth profile affects the gear’s efficiency, noise levels, and load capacity. A well-designed tooth profile minimizes wear and enhances performance, which is critical for high-precision applications. -

Tolerance

– Definition: The permissible limit of variation in dimensions and shapes of the gear components.

– Importance: Tight tolerances are crucial for ensuring proper meshing between gears, reducing backlash, and enhancing operational smoothness. This is especially important in applications requiring high precision, such as automotive and aerospace. -

Surface Finish

– Definition: The texture of the gear’s surface, which can influence friction and wear characteristics.

– Importance: A fine surface finish can reduce friction, improve load-bearing capacity, and extend the gear’s service life. It is particularly vital in high-speed applications where heat generation can be a concern. -

Load Capacity

– Definition: The maximum load that a gear drive can handle without failure.

– Importance: Understanding load capacity helps buyers match gear drives to their specific application requirements, ensuring that the gears can perform optimally under expected operational loads. -

Efficiency Rating

– Definition: A measure of how effectively a gear drive transmits power, typically expressed as a percentage.

– Importance: Higher efficiency ratings indicate less energy loss during operation, which can lead to cost savings and improved overall performance, particularly in energy-intensive industries.

Common Trade Terminology

Familiarity with industry jargon is essential for effective communication and negotiation in gear drive procurement. Here are several key terms B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that manufactures products that are then sold under another company’s brand.

– Relevance: OEMs are critical in the supply chain as they provide the components needed for assembling complete machinery. Buyers should ensure they are sourcing from reputable OEMs to guarantee quality. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units that a supplier is willing to sell.

– Relevance: Understanding MOQ is vital for budgeting and inventory planning. Buyers should negotiate MOQs based on their specific needs to avoid excess inventory or stock shortages. -

RFQ (Request for Quotation)

– Definition: A formal document requesting price quotes from suppliers for specific products or services.

– Relevance: An RFQ allows buyers to compare pricing and terms from multiple suppliers, facilitating informed purchasing decisions.

Illustrative Image (Source: Google Search)

-

Incoterms (International Commercial Terms)

– Definition: A set of predefined commercial terms published by the International Chamber of Commerce that outline the responsibilities of buyers and sellers in international trade.

– Relevance: Familiarity with Incoterms is crucial for understanding shipping responsibilities, risks, and costs, which can significantly affect the total landed cost of gear drives. -

Lead Time

– Definition: The amount of time it takes from placing an order until the goods are delivered.

– Relevance: Knowing the lead time helps buyers plan their production schedules and manage inventory levels effectively, which is essential for maintaining operational continuity. -

Certification

– Definition: Documentation that confirms a product meets specific industry standards or regulations.

– Relevance: Certifications ensure that the gear drives comply with safety and performance standards, which is critical for international trade and regulatory compliance.

By understanding these essential technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing gear drives, ultimately enhancing operational efficiency and reliability in their applications.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the gear drives Sector

Market Overview & Key Trends

The gear drives sector is experiencing significant transformation driven by several global factors. Increased demand for energy-efficient solutions, particularly in automotive and renewable energy applications, is pushing manufacturers to innovate. As industries strive for greater efficiency, B2B buyers are increasingly looking for high-precision gear drives that enhance operational performance while minimizing energy consumption.

Emerging technologies such as Industry 4.0, digital twins, and IoT are reshaping sourcing trends. These advancements allow for real-time monitoring and predictive maintenance, reducing downtime and improving overall equipment effectiveness. For international buyers, particularly in Africa, South America, the Middle East, and Europe, understanding the integration of these technologies into gear manufacturing is crucial. Buyers should seek suppliers that leverage advanced manufacturing processes, such as CNC machining and additive manufacturing, to ensure they receive high-quality, custom-engineered solutions that meet their specific needs.

Additionally, sustainability is becoming a key market driver. Companies that prioritize sustainable practices in their manufacturing processes are gaining a competitive edge. Buyers should look for suppliers that not only comply with international environmental regulations but also actively pursue certifications such as ISO 14001, which demonstrates a commitment to effective environmental management.

Sustainability & Ethical Sourcing in B2B

Sustainability and ethical sourcing are increasingly critical in the gear drives sector. The environmental impact of manufacturing processes, including carbon emissions and resource depletion, necessitates a shift towards greener practices. B2B buyers are encouraged to prioritize suppliers that implement sustainable manufacturing techniques, such as energy-efficient machinery and waste reduction strategies.

Moreover, ethical supply chains are essential in today’s global marketplace. Buyers should conduct thorough due diligence to ensure their suppliers adhere to fair labor practices and responsible sourcing of raw materials. Certifications such as the Forest Stewardship Council (FSC) for wood-based components or the Global Recycled Standard (GRS) for recycled materials can serve as benchmarks for suppliers’ commitments to sustainability.

Incorporating ‘green’ materials into gear drives, such as biodegradable lubricants and recycled metals, not only reduces environmental impact but also enhances the brand reputation of buyers. By aligning with suppliers who prioritize sustainability, international buyers can contribute to a more sustainable future while also potentially reducing costs through improved efficiency and resource management.

Brief Evolution/History

The evolution of gear drives dates back to ancient civilizations, where basic gears were utilized in simple machines. Over the centuries, gear technology has advanced significantly, paralleling the rise of the industrial revolution in the 18th and 19th centuries. The introduction of precision engineering led to the mass production of gears, enhancing their reliability and performance.

In the 20th century, the development of advanced materials and manufacturing techniques, such as heat treatment and CNC machining, revolutionized the gear drives sector. Today, manufacturers are not only focused on creating durable gear systems but also on integrating digital technologies to enhance performance and efficiency. This evolution reflects a broader trend in manufacturing, where innovation and sustainability are increasingly intertwined, making it essential for B2B buyers to stay informed and adaptable in their sourcing strategies.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of gear drives

-

What criteria should I use to vet suppliers of gear drives?

When vetting suppliers, consider their industry reputation, years of experience, and specialization in gear drives. Check for certifications such as ISO 9001, which indicates quality management systems. Request references from previous clients to gauge customer satisfaction and reliability. Analyze their production capabilities and technology used, as well as their adherence to sustainability practices. Finally, assess their financial stability to ensure they can fulfill orders over the long term. -

Can gear drives be customized to meet specific application needs?

Yes, many manufacturers offer customization options for gear drives to fit specific application requirements. When discussing customization, provide detailed specifications regarding size, material, load capacity, and environmental conditions. Inquire about the supplier’s design capabilities and their experience with custom solutions. Ensure that they have a well-defined process for prototyping and testing customized gear drives, which can help minimize risks in performance. -

What are the typical minimum order quantities (MOQs) and lead times for gear drives?

Minimum order quantities can vary widely among suppliers, ranging from a few units to several hundred, depending on the complexity of the gear drives and the supplier’s production capabilities. Lead times generally range from 4 to 12 weeks, influenced by factors such as customization, materials availability, and production schedules. Always discuss MOQs and lead times upfront to align expectations and avoid delays in your project timelines. -

What payment terms are common when sourcing gear drives internationally?

Common payment terms include upfront deposits (typically 30% to 50%), with the balance due upon delivery or after inspection. Some suppliers may offer net 30 or net 60 terms for established clients. For international transactions, consider using secure payment methods such as letters of credit or escrow services to mitigate risks. Always clarify payment terms in the contract and ensure they are mutually agreed upon to avoid disputes. -

How do I ensure quality assurance and certifications for gear drives?

To ensure quality, request documentation of certifications such as ISO 9001 and any industry-specific standards that may apply. Inquire about the supplier’s quality control processes, including in-process inspections and final testing procedures. If possible, arrange for third-party audits or inspections of the manufacturing facility. Establish clear quality expectations in your contract, including acceptable tolerances and testing methods, to protect your interests. -

What logistics considerations should I be aware of when importing gear drives?

Logistics can significantly impact your supply chain. Assess shipping options based on cost, transit time, and reliability. Understand customs regulations and tariffs that apply to importing gear drives into your region. Collaborate with experienced freight forwarders to navigate potential challenges. Additionally, consider warehousing solutions to manage inventory effectively and reduce lead times once the products arrive. -

How should disputes with suppliers be handled?

Disputes can arise from quality issues, delivery delays, or contract misunderstandings. Establish a clear dispute resolution process in your contract, including mediation or arbitration clauses. Document all communications and agreements to provide a clear record in case of a dispute. Engage legal counsel familiar with international trade laws to assist with complex issues, ensuring that your rights are protected under the applicable jurisdiction. -

What factors can impact the pricing of gear drives?

Pricing for gear drives is influenced by several factors, including material costs, complexity of design, manufacturing processes, and order volume. Customization can also lead to increased costs due to additional design and testing requirements. Keep an eye on global market trends affecting raw materials and production technologies. Negotiate pricing based on long-term purchasing commitments or bulk orders to achieve better rates.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for gear drives

In conclusion, the strategic sourcing of gear drives presents an invaluable opportunity for international B2B buyers to enhance operational efficiency and gain a competitive edge. As the demand for high-precision gear solutions continues to rise across diverse sectors such as automotive, renewable energy, and industrial automation, selecting the right suppliers is crucial. Focus on manufacturers who integrate digital tools, sustainability practices, and advanced production techniques, as these factors contribute significantly to product quality and lifecycle management.

Key takeaways for B2B buyers include:

-

Evaluate Supplier Capabilities: Assess potential suppliers based on their technological innovations, such as digital twins and automation, which can enhance production efficiency and accuracy.

-

Prioritize Quality Assurance: Ensure that suppliers adhere to strict quality control measures throughout the manufacturing process, from forging to finishing, to guarantee durability and performance stability.

-

Leverage Global Networks: Utilize international partnerships to access cutting-edge gear technologies and support systems, particularly from leading manufacturers in Europe and Asia.

Looking ahead, as global supply chains evolve, B2B buyers from Africa, South America, the Middle East, and Europe should embrace strategic sourcing as a means to not only meet current demands but also to anticipate future trends. Engage with innovative manufacturers and invest in long-term relationships that foster collaboration and mutual growth in the gear drive sector.