Your Ultimate Guide to Sourcing Hinge Spring

Introduction: Navigating the Global Market for hinge spring

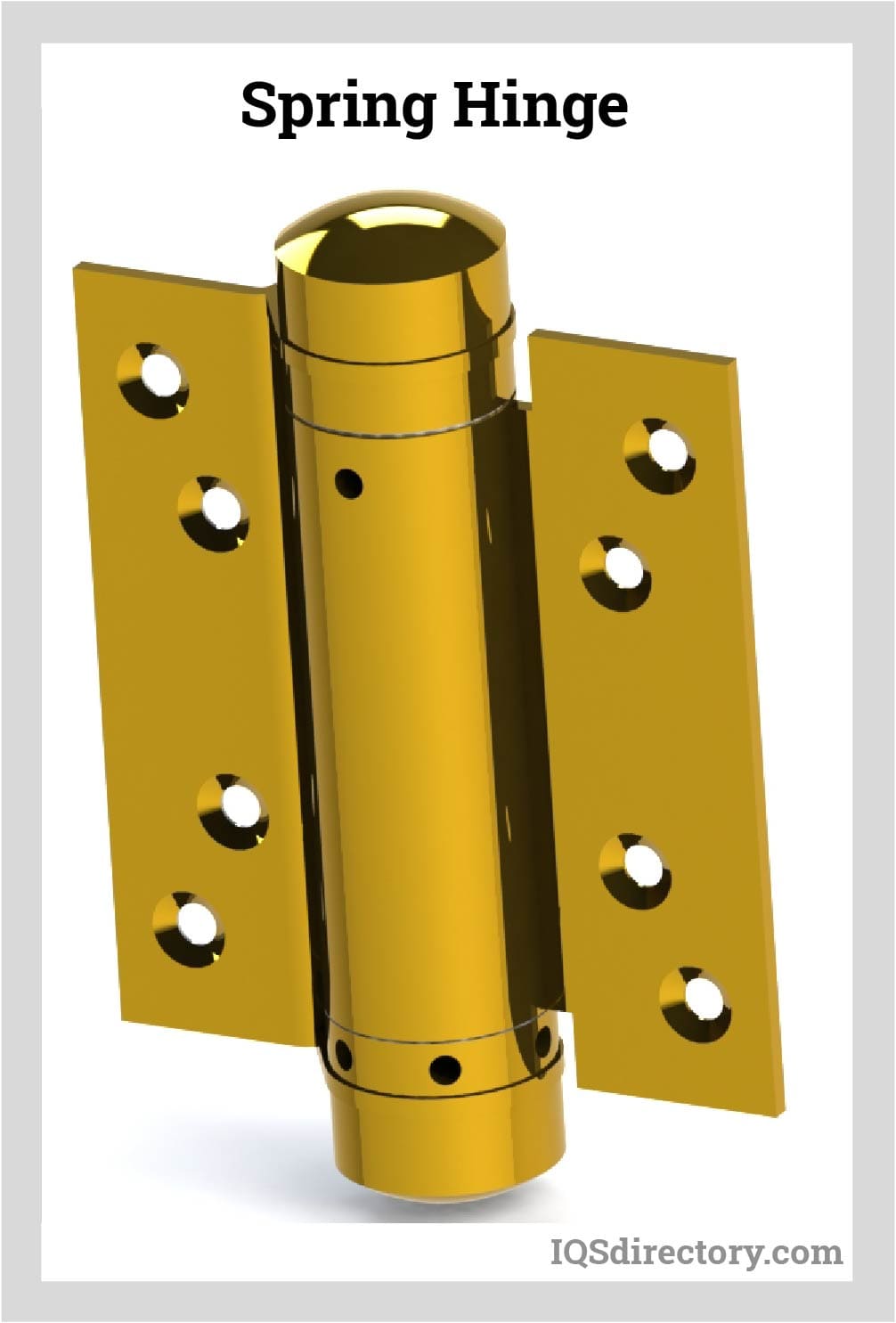

Navigating the complexities of the global market for hinge springs is crucial for international B2B buyers seeking reliable and efficient components for their operations. Hinge springs serve as vital components in various applications, from industrial machinery and medical devices to everyday consumer products. Their primary function—to facilitate the automatic closing and opening of doors and lids—enhances operational efficiency and safety, making them indispensable in numerous sectors.

This comprehensive guide aims to empower B2B buyers from Africa, South America, the Middle East, and Europe, including key markets like France and Thailand, with the knowledge necessary for informed sourcing decisions. We will explore a variety of hinge spring types, including adjustable and concealed options, and delve into the materials used, such as stainless steel and brass, which influence durability and performance.

Additionally, we will cover manufacturing and quality control processes, essential for ensuring the reliability of these components. Buyers will also find valuable insights into selecting reputable suppliers, understanding cost structures, and analyzing market trends to optimize procurement strategies.

Finally, the guide will address frequently asked questions to clarify any uncertainties and facilitate a smooth purchasing experience. With this resource, international buyers can confidently navigate the hinge spring market, ensuring they choose the right products for their specific needs and applications.

Understanding hinge spring Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Concealed Spring Hinge | Hidden installation, aesthetically pleasing design | Residential doors, cabinets, office furniture | Pros: Clean look, space-saving; Cons: More complex installation, potentially higher cost. |

| Adjustable Spring Hinge | Spring tension can be modified | Heavy doors, industrial applications | Pros: Customizable performance; Cons: Requires periodic adjustments, may need tools for adjustment. |

| Self-Closing Spring Hinge | Automatically closes after being opened | Commercial entry doors, gates | Pros: Enhances security, reduces energy costs; Cons: May require more maintenance over time. |

| Heavy-Duty Spring Hinge | Designed for high load capacities | Industrial machinery, large gates | Pros: Robust and durable; Cons: Bulkier design, higher initial investment. |

| Friction Spring Hinge | Provides controlled resistance to movement | Display cases, cabinetry | Pros: Allows for adjustable holding positions; Cons: Less effective for heavy doors, limited load capacity. |

Concealed Spring Hinge

Concealed spring hinges are designed for a clean and modern aesthetic, as they are installed within the door or frame. This type is ideal for residential applications, such as doors and cabinets, where visual appeal is important. Buyers should consider the complexity of installation and the potential higher costs associated with these hinges. They are particularly suitable for projects where aesthetics and space-saving are priorities.

Adjustable Spring Hinge

Adjustable spring hinges allow users to modify the spring tension according to specific requirements. This feature makes them ideal for heavy doors and industrial applications where load capacity can vary. When purchasing adjustable hinges, buyers should assess the frequency of adjustments required and ensure they have the appropriate tools for maintenance. This flexibility can lead to enhanced performance in diverse operational environments.

Self-Closing Spring Hinge

Self-closing spring hinges are engineered to automatically close doors after they are opened, making them popular in commercial settings for entry doors and gates. They enhance security and can contribute to energy efficiency by preventing drafts. Buyers should be aware that while these hinges offer significant advantages, they may require more maintenance to ensure reliable operation over time.

Heavy-Duty Spring Hinge

Heavy-duty spring hinges are built to handle substantial loads and are commonly used in industrial machinery and large gates. Their robust construction ensures durability and longevity, making them a smart investment for businesses with heavy-use applications. Buyers should consider the bulkier design and higher initial investment, but the long-term benefits often outweigh these drawbacks.

Friction Spring Hinge

Friction spring hinges provide controlled resistance, allowing for adjustable holding positions. They are commonly used in display cases and cabinetry where precise positioning is required. While they offer versatility, buyers should note their limitations in terms of load capacity, making them less suitable for heavier doors. Understanding the specific application needs is crucial when selecting this type of hinge.

Related Video: Justor Double Action Spring Hinge Installation

Key Industrial Applications of hinge spring

| Industry/Sector | Specific Application of hinge spring | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Self-closing doors in vehicles | Enhances user convenience and safety; reduces wear on door components. | Consider load capacity and environmental resistance; ensure compliance with automotive standards. |

| Manufacturing | Automated machinery covers | Improves operational efficiency; reduces downtime by ensuring covers close automatically. | Evaluate compatibility with machinery specifications; prioritize durability and ease of maintenance. |

| Healthcare | Medical equipment access panels | Facilitates quick access for maintenance; enhances patient safety by preventing accidental openings. | Look for hygiene compliance; materials should withstand sterilization processes. |

| Construction | Industrial doors in commercial buildings | Ensures security and energy efficiency by maintaining controlled access. | Assess weight tolerance and weather resistance; consider local regulations for installation. |

| Consumer Electronics | Laptop and device casings | Provides seamless user experience; protects internal components from accidental exposure. | Focus on size compatibility and aesthetic design; ensure reliable performance under frequent use. |

Automotive Applications

In the automotive sector, hinge springs are integral to the functionality of self-closing doors. This application not only enhances user convenience but also contributes to safety by ensuring doors close securely after use. For international B2B buyers, especially in regions like Africa and South America, it’s crucial to consider the load capacity of these hinges and their resistance to environmental factors such as humidity and temperature fluctuations. Compliance with automotive industry standards is also a key factor in sourcing.

Manufacturing Applications

In manufacturing, hinge springs are commonly used in automated machinery covers. These springs allow covers to close automatically, which reduces downtime and improves operational efficiency. Buyers in the Middle East and Europe should evaluate the compatibility of hinge springs with their specific machinery requirements and prioritize durability to withstand continuous use. Ease of maintenance is another significant consideration, as it impacts overall productivity.

Healthcare Applications

Healthcare settings utilize hinge springs in access panels of medical equipment. These springs facilitate quick access for maintenance while ensuring that panels close securely to enhance patient safety. For B2B buyers in Europe and Africa, sourcing hinges that comply with hygiene standards is essential, as is ensuring that materials can withstand sterilization processes. The ability to meet these specific requirements is critical in maintaining operational integrity in healthcare environments.

Illustrative Image (Source: Google Search)

Construction Applications

In the construction industry, hinge springs are used in industrial doors for commercial buildings. These hinges ensure secure and energy-efficient operations by maintaining controlled access. Buyers, particularly in regions with varying climates, should assess the weight tolerance of these hinges and their resistance to weather conditions. Additionally, local regulations regarding installation and safety standards should be taken into account during the sourcing process.

Consumer Electronics Applications

In the consumer electronics sector, hinge springs are applied in laptop and device casings to provide a seamless user experience. They protect internal components from accidental exposure while allowing for easy access. For international B2B buyers, focusing on size compatibility and aesthetic design is crucial, along with ensuring reliable performance under frequent use. Understanding market trends in different regions can also inform better sourcing decisions.

Strategic Material Selection Guide for hinge spring

When selecting materials for hinge springs, international B2B buyers must consider various factors that influence performance, durability, and application suitability. Here, we analyze four common materials used in hinge spring manufacturing: stainless steel, carbon steel, brass, and plastic composites. Each material presents unique properties, advantages, and limitations that can significantly impact the end product’s performance.

Stainless Steel

Key Properties: Stainless steel is renowned for its excellent corrosion resistance, high tensile strength, and ability to withstand extreme temperatures. It typically performs well in environments with moisture or exposure to chemicals.

Pros & Cons: The durability of stainless steel makes it a preferred choice for applications requiring longevity and reliability. However, it tends to be more expensive than other materials, which can affect overall project costs. Manufacturing complexity is moderate, as stainless steel requires specific techniques for bending and shaping.

Impact on Application: Stainless steel hinge springs are ideal for outdoor applications or environments with high humidity, such as in marine or industrial settings. They maintain performance under varying loads and conditions.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM A313 or DIN 17224. In regions like Europe and the Middle East, stainless steel grades may vary, so familiarity with local regulations is essential.

Carbon Steel

Key Properties: Carbon steel offers high strength and excellent load-bearing capabilities. However, it is less resistant to corrosion compared to stainless steel, making it suitable for dry environments.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness, making it a popular choice for budget-sensitive projects. However, its susceptibility to rust and corrosion can limit its application in humid or corrosive environments, necessitating protective coatings.

Impact on Application: Carbon steel hinge springs are commonly used in indoor applications where moisture exposure is minimal. They are effective in heavy-duty applications, such as industrial doors or machinery.

Considerations for International Buyers: Buyers should consider the need for protective coatings or treatments to enhance corrosion resistance. Compliance with standards like ASTM A228 is also important, especially in regions with stringent quality requirements.

Brass

Key Properties: Brass is a copper-zinc alloy known for its excellent corrosion resistance and aesthetic appeal. It has good mechanical properties and is relatively easy to machine.

Pros & Cons: The primary advantage of brass is its resistance to tarnishing and corrosion, making it suitable for decorative applications. However, it is less durable than stainless steel and carbon steel under heavy loads. Additionally, brass can be more expensive than carbon steel.

Impact on Application: Brass hinge springs are often used in applications requiring a combination of aesthetics and functionality, such as in cabinetry or high-end fixtures.

Considerations for International Buyers: Buyers should be aware of the varying standards for brass alloys in different regions (e.g., JIS in Japan or EN in Europe). Understanding local preferences for finishes and aesthetics can also guide selection.

Plastic Composites

Key Properties: Plastic composites are lightweight and resistant to corrosion, making them suitable for various applications. They can also be engineered to meet specific performance requirements, such as flexibility and strength.

Pros & Cons: The key advantage of plastic composites is their low weight and resistance to environmental factors. However, they may not withstand high temperatures or heavy loads as effectively as metal options, limiting their use in certain applications.

Impact on Application: Plastic composite hinge springs are often used in consumer products, such as electronics and lightweight doors, where corrosion resistance and weight savings are critical.

Considerations for International Buyers: Buyers should evaluate the specific composite materials used, as performance can vary widely. Compliance with international standards for plastics, such as ISO 9001, is also essential for ensuring quality.

Summary Table

| Material | Typical Use Case for hinge spring | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Outdoor applications, industrial doors | Excellent corrosion resistance | Higher cost | High |

| Carbon Steel | Indoor heavy-duty applications | Cost-effective | Susceptible to corrosion | Low |

| Brass | Decorative cabinetry, fixtures | Aesthetic appeal, corrosion resistant | Less durable under heavy loads | Medium |

| Plastic Composites | Electronics, lightweight doors | Lightweight, corrosion resistant | Limited load-bearing capability | Medium |

This strategic material selection guide enables international B2B buyers to make informed decisions based on application requirements, environmental conditions, and cost considerations, ensuring optimal performance and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for hinge spring

Manufacturing Processes for Hinge Springs

The manufacturing of hinge springs involves several critical stages that ensure the final product meets industry standards for performance and durability. Understanding these processes can help B2B buyers evaluate potential suppliers and their capabilities.

1. Material Preparation

The first stage in the manufacturing process is material preparation. Hinge springs are typically made from high-carbon steel, stainless steel, or specialized alloys, depending on the required properties like tensile strength and corrosion resistance. The selected materials undergo several processes:

- Material Sourcing: Suppliers should be evaluated for their sourcing practices. High-quality raw materials are essential for producing durable hinge springs.

- Cutting and Shaping: Raw materials are cut into specific lengths and widths based on design specifications. This can involve techniques such as shearing or laser cutting, which ensure precision.

2. Forming

After material preparation, the next step is forming. This is where the raw materials are transformed into the desired spring shape through various techniques:

- Cold Coiling: This is a common method where wire is wound into the shape of a spring at room temperature. This technique helps maintain the material’s hardness and elasticity.

- Hot Coiling: For heavier-duty applications, wire may be heated before coiling. This allows for the creation of larger springs but can alter the material properties, requiring additional heat treatment.

3. Assembly

Once formed, the individual components of the hinge spring must be assembled. This stage includes:

- Joining Techniques: Depending on the design, components may be welded, bolted, or riveted together. The choice of joining method impacts the strength and durability of the final product.

- Alignment and Testing: During assembly, precise alignment is critical to ensure the spring functions as intended. Testing at this stage can include functional tests to ensure the spring returns to its original position after compression.

4. Finishing

The finishing stage enhances both the aesthetic and functional properties of hinge springs. Key processes include:

- Surface Treatment: Techniques like galvanizing, powder coating, or anodizing are applied to improve corrosion resistance and durability. This is particularly important for products intended for outdoor use or in corrosive environments.

- Final Inspection: Before the products are packaged, a thorough inspection is conducted to verify that they meet specifications. This often involves visual inspections and measurements to ensure compliance with design tolerances.

Quality Assurance in Manufacturing

Quality assurance (QA) is a fundamental aspect of the hinge spring manufacturing process. For international B2B buyers, understanding the QA measures in place can significantly affect purchasing decisions.

International Standards

Manufacturers often adhere to recognized international standards to ensure product quality. Notable standards include:

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements.

- CE Marking: Required for products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Spec Q1: For products used in the oil and gas sector, compliance with API specifications ensures that the products meet industry-specific quality requirements.

Quality Control Checkpoints

Quality control (QC) checkpoints are established throughout the manufacturing process to catch defects early:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards before processing begins.

- In-Process Quality Control (IPQC): During production, ongoing inspections are conducted to monitor the manufacturing process and catch any deviations from quality standards.

- Final Quality Control (FQC): Once manufacturing is complete, a final inspection ensures that all products meet the required specifications before they are shipped.

Common Testing Methods

Various testing methods are employed to verify the quality and performance of hinge springs:

- Tensile Testing: This measures the strength of the spring material and its ability to withstand forces without breaking.

- Fatigue Testing: This assesses how many cycles a spring can endure before failure, which is crucial for ensuring long-term performance.

- Dimensional Inspection: Using tools like calipers and gauges, manufacturers check that the springs conform to specified dimensions.

Verifying Supplier Quality Control

For B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are actionable steps to ensure supplier reliability:

- Conduct Audits: Regular audits of suppliers can help verify compliance with quality standards and reveal insights into their manufacturing processes.

- Request Documentation: Buyers should request quality assurance documents, including certifications and inspection reports, to validate compliance with international standards.

- Third-party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the manufacturer’s quality control processes and product integrity.

Nuances for International Buyers

International buyers must also consider certain nuances when dealing with suppliers:

- Cultural Differences: Understanding local business practices and cultural norms can help facilitate better communication and collaboration with suppliers.

- Regulatory Compliance: Buyers should be aware of the regulatory landscape in their own country and ensure that suppliers comply with these regulations, especially for imports.

- Logistics and Supply Chain: Consideration of logistics, shipping times, and costs is essential when sourcing from international suppliers. This includes understanding tariffs and trade agreements that may affect pricing.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for hinge springs can empower B2B buyers to make informed decisions. By focusing on supplier capabilities, international standards, and effective verification methods, buyers can secure high-quality products that meet their specific needs.

Related Video: The Process of Manufacturing Giant Springs A Spring Factory in China

Comprehensive Cost and Pricing Analysis for hinge spring Sourcing

When sourcing hinge springs, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. This analysis focuses on the key cost components, price influencers, and actionable buyer tips that can help organizations optimize their purchasing strategies.

Cost Components

-

Materials: The primary raw materials used in hinge springs typically include stainless steel, brass, and other alloys. Prices can fluctuate based on market conditions, availability, and the specific grades of materials chosen. For instance, stainless steel offers superior corrosion resistance but may come at a premium compared to standard steel.

-

Labor: Labor costs vary widely depending on the manufacturing location. In regions with higher labor costs, such as Europe, the overall price of hinge springs may increase. Conversely, sourcing from areas with lower labor costs, such as certain parts of Africa or South America, can result in cost savings.

-

Manufacturing Overhead: This includes expenses related to utilities, rent, and equipment maintenance. Manufacturers often factor these costs into their pricing models, leading to variations based on the operational efficiency of the production facility.

-

Tooling: Custom tooling for specific hinge designs can be a significant upfront investment. This cost is often amortized over the production run, meaning higher volumes can lead to lower per-unit costs.

-

Quality Control (QC): Ensuring that hinge springs meet specific quality standards involves rigorous testing and inspection processes. High-quality certifications can add to costs but are essential for applications where reliability is critical.

-

Logistics: Shipping and handling costs can vary based on the chosen Incoterms and the distance from the supplier to the buyer. International shipping can introduce additional costs related to customs duties and tariffs, particularly for buyers in Africa and South America.

-

Margin: Suppliers typically apply a markup to cover their costs and profit. This margin can vary significantly based on the supplier’s market position, relationship with the buyer, and overall demand.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQ) can greatly influence pricing. Larger orders generally result in lower per-unit prices due to economies of scale. However, buyers should balance volume with their actual needs to avoid excess inventory costs.

-

Specifications/Customization: Custom-designed hinge springs will incur additional costs related to design and production. Clear specifications can aid suppliers in providing accurate quotes.

-

Quality and Certifications: Products with recognized quality certifications (e.g., ISO) may command higher prices but ensure reliability and compliance with industry standards.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with a track record of quality may charge a premium, but they often provide better service and reliability.

-

Incoterms: Understanding and negotiating Incoterms is crucial for controlling logistics costs. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can impact the total landed cost of hinge springs.

Buyer Tips

-

Negotiation: Engage in open discussions with suppliers regarding pricing, especially if you are placing large orders. Leverage competition among suppliers to negotiate better terms.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO), which includes not just the purchase price but also maintenance, logistics, and potential downtime costs. This holistic view can help identify the best overall value.

-

Pricing Nuances: Buyers from regions like Africa and South America should be aware of additional costs related to import duties and tariffs, which can significantly affect the final price. Understanding local regulations can help avoid unexpected expenses.

-

Market Research: Regularly review market trends and supplier pricing strategies. This knowledge can empower buyers to make informed decisions and anticipate price changes.

Disclaimer

Prices for hinge springs can vary significantly based on the factors outlined above. The information provided is indicative and should be validated through direct supplier engagement and market research.

Spotlight on Potential hinge spring Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘hinge spring’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for hinge spring

Key Technical Properties of Hinge Springs

Understanding the technical properties of hinge springs is crucial for international B2B buyers, particularly those involved in industries such as construction, manufacturing, and electronics. Here are some essential specifications to consider:

-

Material Grade: Hinge springs are typically made from various materials, including stainless steel, brass, and carbon steel. The material grade affects durability, corrosion resistance, and overall performance. For instance, stainless steel is preferred in humid or corrosive environments due to its resistance to rust and oxidation, making it ideal for outdoor or marine applications.

-

Load Capacity: This specification indicates the maximum weight a hinge spring can support without failing. It is vital for ensuring that the hinge can handle the intended application, such as heavy doors or industrial machinery. Buyers should always verify load ratings to prevent premature wear or malfunction.

-

Tension Adjustment Range: Many hinge springs come with adjustable tension settings, allowing users to modify the spring force according to specific operational requirements. This feature is particularly important in applications where the weight of the door or lid may vary, providing flexibility in installation and use.

-

Tolerance: Tolerance refers to the allowable deviation in dimensions and performance characteristics of hinge springs. High tolerance standards are crucial for ensuring that the hinge fits properly and operates smoothly. Poor tolerance can lead to misalignment, which may cause increased wear and potential failure.

-

Finish and Coating: The surface treatment of hinge springs, such as galvanizing or powder coating, enhances their resistance to environmental factors. A good finish prevents corrosion and extends the lifespan of the product, which is particularly important in regions with extreme weather conditions.

-

Cycle Life: This property measures the number of open-close cycles a hinge spring can endure before failure. A higher cycle life indicates better durability and reliability, making it essential for applications requiring frequent use, such as in commercial doors or machinery.

Common Trade Terminology

Familiarity with industry jargon can enhance communication and facilitate smoother transactions. Here are some key terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Buyers should ensure that the hinge springs they procure meet OEM specifications to guarantee compatibility and performance.

-

MOQ (Minimum Order Quantity): This is the smallest number of units that a supplier is willing to sell. Understanding MOQ is vital for budgeting and inventory management, especially for small to medium-sized enterprises (SMEs) that may not require large quantities.

-

RFQ (Request for Quotation): An RFQ is a document sent by buyers to suppliers asking for price quotes for specific products or services. This process is essential for obtaining competitive pricing and understanding the terms of supply.

-

Incoterms: Short for International Commercial Terms, these are predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities.

-

Lead Time: This term refers to the time taken from placing an order to its delivery. Understanding lead times is critical for planning and inventory management, particularly for international purchases that may involve longer shipping durations.

-

Certifications: Various industry standards and certifications (like ISO or CE) indicate compliance with specific quality and safety standards. Buyers should look for these certifications to ensure that the hinge springs meet necessary regulatory requirements for their region.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions and ensure they procure hinge springs that meet their specific operational needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the hinge spring Sector

Market Overview & Key Trends

The global hinge spring market is experiencing significant growth, driven by increasing demand across various sectors, including construction, automotive, and consumer electronics. As B2B buyers in Africa, South America, the Middle East, and Europe look to source high-quality hinge springs, it is essential to understand the current dynamics shaping the market. Key drivers include the rise of automation in industrial applications, where self-closing mechanisms enhance efficiency and safety. Furthermore, the growing trend toward smart manufacturing is leading to innovations in hinge design, integrating IoT technology for real-time monitoring and maintenance.

Emerging sourcing trends indicate a shift towards digital platforms and e-commerce for procurement. B2B buyers are leveraging online marketplaces to access a broader range of suppliers, enabling them to compare products and pricing more effectively. Additionally, the focus on customization is gaining momentum, as businesses seek tailored solutions that meet specific operational requirements. This trend is particularly relevant in regions with diverse industrial needs, such as the Middle East and South America, where localized production can offer competitive advantages.

Moreover, the market is witnessing a shift towards sustainable practices. Buyers are increasingly prioritizing suppliers who demonstrate commitment to environmental responsibility, reflecting a broader global trend toward sustainability in manufacturing. Understanding these dynamics will empower B2B buyers to make informed sourcing decisions that align with their operational goals and values.

Sustainability & Ethical Sourcing in B2B

The environmental impact of hinge spring production is a critical concern for today’s B2B buyers. The manufacturing processes involved often contribute to carbon emissions and waste generation. As a response, the industry is moving toward greener practices, including the use of sustainable materials and energy-efficient production techniques. Buyers should seek suppliers who have implemented eco-friendly practices, such as using recycled metals or biodegradable lubricants, to minimize their carbon footprint.

Ethical sourcing is equally important. B2B buyers must consider the transparency of their supply chains and the ethical implications of their sourcing decisions. This includes ensuring fair labor practices and responsible sourcing of raw materials. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical practices. By prioritizing suppliers with these credentials, buyers can contribute to a more sustainable and responsible supply chain.

Furthermore, incorporating ‘green’ certifications into sourcing criteria not only enhances a company’s sustainability profile but can also lead to cost savings in the long run. For instance, energy-efficient hinges can reduce operational costs, while products made from sustainable materials often have lower disposal costs. By focusing on sustainability and ethical sourcing, B2B buyers can align their procurement strategies with their corporate social responsibility goals.

Brief Evolution/History

The hinge spring, as a mechanical device, has evolved significantly over the years. Initially designed for basic applications, these hinges have transformed into sophisticated components that enhance functionality across various industries. The introduction of materials like stainless steel and advanced composites has improved durability and performance.

In the industrial sector, the demand for self-closing and adjustable spring hinges emerged in the mid-20th century, responding to the need for efficiency and safety in manufacturing environments. As technology progressed, manufacturers began integrating innovative features, such as adjustable spring tension and concealed designs, catering to modern aesthetic preferences and functional requirements. This evolution reflects the industry’s adaptability to changing market demands, positioning hinge springs as essential components in contemporary applications.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of hinge spring

-

What should I look for when vetting suppliers of hinge springs?

When vetting suppliers, consider their experience in the industry, reputation, and customer reviews. Verify their certifications such as ISO 9001 to ensure quality management. Request references from other B2B clients, and assess their financial stability to avoid potential disruptions. Additionally, inquire about their production capabilities, technology used, and ability to meet specific requirements for hinge springs. A reliable supplier should also be transparent about their sourcing of materials and environmental practices. -

Can hinge springs be customized to meet specific requirements?

Yes, many manufacturers offer customization options for hinge springs. You can specify dimensions, materials, load capacities, and spring tension based on your application needs. When discussing customization, provide detailed specifications and any relevant design drawings. It’s essential to establish clear communication with the supplier to ensure they understand your requirements. Always request samples before committing to a large order to evaluate the quality and performance of the customized products. -

What are the typical minimum order quantities (MOQ) and lead times for hinge springs?

MOQs for hinge springs can vary widely depending on the supplier and the complexity of the product. Generally, they range from 100 to 1,000 units. Lead times typically range from 2 to 8 weeks, influenced by factors such as the type of customization, production capacity, and shipping logistics. It’s advisable to discuss your requirements with the supplier upfront to understand their capabilities and negotiate favorable terms based on your purchasing needs. -

What payment terms should I expect when sourcing hinge springs internationally?

Payment terms can differ by supplier and region, but common practices include a 30% deposit upon order confirmation and the balance before shipment. Some suppliers may offer payment via letters of credit or escrow services for added security. Be aware of any additional fees related to currency conversion or international transactions. Establishing clear payment terms in the contract is crucial to avoid disputes and ensure both parties are aligned on financial expectations. -

How do I ensure quality assurance and certifications for hinge springs?

To ensure quality assurance, request documentation of the supplier’s quality management systems and relevant certifications, such as ISO 9001 or industry-specific standards. Ask for test reports and compliance certificates that demonstrate adherence to international quality standards. It’s also beneficial to conduct factory audits or inspections if feasible. Establishing a quality assurance plan that outlines expectations for inspections, testing, and reporting can further safeguard against quality issues. -

What logistics considerations should I be aware of when importing hinge springs?

Logistics for importing hinge springs include selecting the right shipping method (air vs. sea), understanding customs regulations, and ensuring proper documentation for international shipping. Consider working with a freight forwarder to navigate the complexities of cross-border logistics. Be aware of potential tariffs and duties that may apply to your shipment. Additionally, plan for possible delays in transit and ensure that your supplier can provide tracking information throughout the shipping process.

Illustrative Image (Source: Google Search)

-

How should I handle disputes with suppliers?

When disputes arise, begin by communicating directly with the supplier to address the issue. Document all correspondence and agreements related to the dispute. If the matter cannot be resolved amicably, refer to the terms outlined in your contract regarding dispute resolution, which may include mediation or arbitration. Engaging a legal professional with experience in international trade can be beneficial if the situation escalates. Maintaining a professional demeanor throughout the process is essential for a constructive resolution. -

What are the best practices for maintaining a long-term relationship with hinge spring suppliers?

To foster a long-term relationship with suppliers, prioritize open communication and transparency regarding your needs and expectations. Regularly provide feedback on their products and service quality. Consider scheduling periodic reviews to discuss performance, product improvements, and market trends. Building trust through consistent orders and timely payments can also strengthen your partnership. Additionally, collaborating on product development or sharing insights can enhance mutual growth and innovation.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for hinge spring

In summary, the strategic sourcing of hinge springs is crucial for international B2B buyers seeking reliable and efficient solutions for their operations. Key takeaways include understanding the diverse applications of spring hinges, the importance of selecting the right materials, and the value of sourcing from reputable manufacturers that meet industry standards. Buyers should prioritize suppliers that offer customization options, as this can enhance the functionality of hinges in specific applications.

Moreover, the benefits of spring hinges extend beyond mere convenience; they significantly improve operational efficiency, reduce noise, and enhance safety. As global markets continue to evolve, staying informed about advancements in hinge technology and material science will be vital for making informed purchasing decisions.

Looking ahead, international B2B buyers from Africa, South America, the Middle East, and Europe should actively engage with manufacturers and suppliers to explore innovative solutions tailored to their unique needs. By leveraging strategic sourcing practices, businesses can not only optimize their supply chains but also position themselves for growth in an increasingly competitive landscape. Embrace this opportunity to strengthen partnerships and enhance your operational capabilities with high-quality hinge springs.