Master the Sourcing Process for Membrane Switch Keyboards

Introduction: Navigating the Global Market for membrane switch keyboard

In today’s fast-paced global market, the demand for reliable and efficient user interfaces has never been higher, making the membrane switch keyboard an essential component across various industries. These keyboards combine durability, versatility, and a sleek design, making them ideal for applications ranging from medical devices to industrial machinery. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the intricacies of membrane switch keyboards can significantly impact your sourcing decisions.

This comprehensive guide delves into the critical aspects of membrane switch keyboards, covering a wide array of topics such as types and materials, manufacturing processes, quality control measures, supplier selection, cost considerations, and market trends. Each section is designed to equip you with actionable insights, enabling you to navigate the complexities of sourcing effectively.

By exploring the nuances of different materials and designs, you can tailor your procurement strategies to meet specific operational needs, ensuring that the products you choose align with your quality and performance expectations. Moreover, understanding the manufacturing landscape and identifying reputable suppliers will empower you to mitigate risks, control costs, and enhance overall operational efficiency.

Prepare to make informed decisions that will elevate your product offerings and strengthen your competitive edge in the global marketplace.

Understanding membrane switch keyboard Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Membrane Switch | Simple design with graphic overlays and printed circuits | Consumer electronics, appliances | Pros: Cost-effective, lightweight. Cons: Limited durability in harsh conditions. |

| Tactile Membrane Switch | Provides tactile feedback, often with raised buttons | Medical devices, industrial machinery | Pros: Enhanced user experience, reduces errors. Cons: More expensive than standard types. |

| Backlit Membrane Switch | Integrated LED backlighting for visibility | Control panels, automotive applications | Pros: Improved visibility in low light. Cons: Higher power consumption, increased complexity. |

| Custom Membrane Switch | Tailored designs with specific features and functions | Specialized equipment, niche markets | Pros: Fully customizable, meets specific needs. Cons: Higher costs, longer lead times. |

| Sealed Membrane Switch | Waterproof and dustproof designs | Outdoor equipment, medical devices | Pros: High durability, suitable for harsh environments. Cons: Typically more expensive, limited design options. |

Standard Membrane Switch

The Standard Membrane Switch is characterized by its straightforward design, featuring graphic overlays and printed circuits. It is commonly used in consumer electronics and household appliances due to its cost-effectiveness and lightweight nature. However, buyers should consider its limited durability in harsh environments, as it may not withstand exposure to moisture or extreme temperatures.

Tactile Membrane Switch

The Tactile Membrane Switch stands out for providing tactile feedback, often incorporating raised buttons to enhance user interaction. This type is particularly suitable for medical devices and industrial machinery, where precision and user experience are crucial. While it offers a more engaging experience that can reduce operational errors, it typically comes at a higher price point compared to standard options.

Backlit Membrane Switch

Backlit Membrane Switches feature integrated LED lighting, making them ideal for control panels and automotive applications where visibility is essential. This type enhances user interaction in low-light conditions, but buyers should be aware of its higher power consumption and the increased complexity in design and manufacturing.

Custom Membrane Switch

For specialized applications, the Custom Membrane Switch allows for tailored designs that can incorporate specific features and functions. This flexibility makes it a popular choice in niche markets and specialized equipment. However, it often involves higher costs and longer lead times, necessitating careful planning and budgeting by B2B buyers.

Sealed Membrane Switch

Sealed Membrane Switches are designed to be waterproof and dustproof, making them suitable for outdoor equipment and medical devices. Their high durability is a significant advantage in harsh environments. However, buyers should be prepared for typically higher costs and potentially limited design options due to the sealing requirements.

Illustrative Image (Source: Google Search)

Key Industrial Applications of membrane switch keyboard

| Industry/Sector | Specific Application of Membrane Switch Keyboard | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical Devices | Control panels for diagnostic equipment | Enhances usability and hygiene, supporting quick response times | Compliance with health regulations, durability against cleaning agents |

| Industrial Machinery | Operator interfaces for heavy machinery | Increases operational efficiency and safety in harsh environments | Resistance to temperature and moisture, robust adhesive options |

| Consumer Electronics | Remote controls for smart home devices | Provides intuitive user experience and compact design | Customization options for branding, tactile feedback features |

| Automotive | Dashboard controls and infotainment systems | Improves user interaction and aesthetic appeal | Ability to withstand vibrations, UV resistance, and easy integration |

| Aerospace | Cabin control panels and in-flight entertainment systems | Ensures reliability and functionality in extreme conditions | Lightweight materials, compliance with aviation standards, and safety certifications |

Medical Devices

In the medical sector, membrane switch keyboards are essential for control panels in diagnostic equipment such as ultrasound machines and patient monitors. Their design allows for easy cleaning and disinfecting, addressing hygiene concerns critical in healthcare settings. Buyers from Africa, South America, and the Middle East should ensure that their suppliers comply with health regulations and provide materials resistant to common cleaning agents. The longevity and durability of these keyboards also help minimize downtime in critical healthcare environments.

Industrial Machinery

Membrane switch keyboards are widely used in operator interfaces for industrial machinery, where they facilitate control over complex processes. Their robustness allows them to function effectively in harsh environments, such as factories or outdoor settings. For international buyers, especially in Europe and the Middle East, sourcing keyboards that can withstand temperature fluctuations and moisture is vital. Additionally, the choice of adhesive used in installation must be compatible with the machinery’s surface to ensure longevity.

Consumer Electronics

In the consumer electronics industry, membrane switch keyboards are commonly found in remote controls for smart home devices. Their compact and lightweight design allows for seamless integration into various products, enhancing user experience. Buyers should focus on customization options that align with their branding and consider tactile feedback features to improve usability. This is particularly important for buyers in regions like South America, where user experience can significantly influence product acceptance.

Automotive

Membrane switch keyboards serve as dashboard controls and infotainment systems in the automotive sector. Their ability to provide a sleek and intuitive interface improves user interaction and enhances the overall aesthetic of vehicle interiors. Buyers need to ensure that the keyboards are designed to withstand vibrations, UV exposure, and other automotive-specific challenges. Sourcing from ISO-certified manufacturers can guarantee compliance with industry standards, which is crucial for buyers in Europe and the Middle East.

Aerospace

In the aerospace industry, membrane switch keyboards are utilized in cabin control panels and in-flight entertainment systems. They must meet stringent reliability and functionality standards due to the extreme conditions encountered during flight. Buyers from Africa and Europe should prioritize lightweight materials and ensure that their suppliers provide components that comply with aviation safety regulations. Additionally, sourcing from vendors with a proven track record in aerospace applications can mitigate risks associated with product failure.

Related Video: Advantages and Uses of ICT devices || Applications of ICT devices || Computer Basics

Strategic Material Selection Guide for membrane switch keyboard

When selecting materials for membrane switch keyboards, international B2B buyers must consider various factors that influence product performance, durability, and suitability for specific applications. Below, we analyze four common materials used in the construction of membrane switch keyboards, highlighting their properties, advantages, disadvantages, and considerations for buyers in diverse regions such as Africa, South America, the Middle East, and Europe.

Polyester Film

Key Properties:

Polyester film is known for its excellent dimensional stability, high tensile strength, and resistance to moisture and chemicals. It typically has a temperature rating of up to 120°C (248°F), making it suitable for various environments.

Pros & Cons:

The durability of polyester film is a significant advantage, as it can withstand repeated use without degrading. However, it may be more expensive compared to other materials like PVC. Manufacturing complexity is moderate, as it requires precise printing techniques to ensure the quality of the graphic overlay.

Impact on Application:

Polyester film is compatible with a wide range of cleaning solutions and is often used in medical devices and industrial applications where hygiene is paramount.

Considerations for International Buyers:

Buyers should ensure that the polyester film complies with local regulations, such as RoHS in Europe. Understanding the material’s compatibility with specific media and cleaning agents is crucial for applications in diverse environments.

Polycarbonate Film

Key Properties:

Polycarbonate film offers high impact resistance and can withstand temperatures ranging from -40°C to 120°C (-40°F to 248°F). It is also resistant to UV light, making it suitable for outdoor applications.

Pros & Cons:

The primary advantage of polycarbonate is its toughness, which makes it ideal for high-traffic environments. However, it can be more costly than polyester and may require additional coatings for enhanced scratch resistance.

Impact on Application:

Due to its durability, polycarbonate is often used in applications that demand high performance under physical stress, such as control panels in industrial machinery.

Considerations for International Buyers:

Buyers should verify compliance with international standards such as ASTM and ISO. Additionally, understanding the specific environmental conditions where the product will be used is essential for ensuring longevity.

PVC (Polyvinyl Chloride)

Key Properties:

PVC is a cost-effective material with good chemical resistance and a temperature range of -10°C to 70°C (14°F to 158°F). It is flexible and can be easily molded into various shapes.

Pros & Cons:

The low cost of PVC makes it an attractive option for budget-conscious projects. However, its lower durability compared to polyester and polycarbonate can be a drawback, especially in demanding applications. Manufacturing processes are relatively straightforward, which can reduce lead times.

Impact on Application:

PVC is suitable for applications where cost is a primary concern, but it may not perform well in extreme conditions or where high durability is required.

Considerations for International Buyers:

Buyers should be aware of environmental regulations concerning PVC, particularly in Europe where restrictions may apply. Understanding local preferences for material safety and sustainability can influence purchasing decisions.

Silicone

Key Properties:

Silicone is highly flexible and can withstand extreme temperatures ranging from -60°C to 200°C (-76°F to 392°F). It is also resistant to moisture, chemicals, and UV light.

Pros & Cons:

Silicone’s flexibility and durability make it an excellent choice for applications requiring tactile feedback. However, it is generally more expensive than other materials, and the manufacturing process can be complex due to the need for specialized molds.

Impact on Application:

Silicone is often used in applications where user interaction is critical, such as consumer electronics and medical devices, due to its excellent tactile properties.

Considerations for International Buyers:

Buyers should ensure that silicone components meet relevant safety standards and certifications in their region. Understanding the specific tactile requirements of the target market can also guide material selection.

Summary Table

| Material | Typical Use Case for membrane switch keyboard | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester Film | Medical devices, industrial applications | High durability | Higher cost compared to PVC | Medium |

| Polycarbonate Film | Control panels in industrial machinery | Excellent impact resistance | Higher cost, requires coatings | High |

| PVC | Budget-sensitive applications | Cost-effective | Lower durability in extreme conditions | Low |

| Silicone | Consumer electronics, medical devices | Excellent tactile feedback | Higher cost, complex manufacturing | High |

This strategic material selection guide serves as a foundational resource for international B2B buyers, aiding in informed decision-making for membrane switch keyboards tailored to specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for membrane switch keyboard

The manufacturing of membrane switch keyboards involves a series of carefully orchestrated processes that ensure quality, functionality, and reliability. As B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe evaluate potential suppliers, understanding these processes will empower them to make informed decisions.

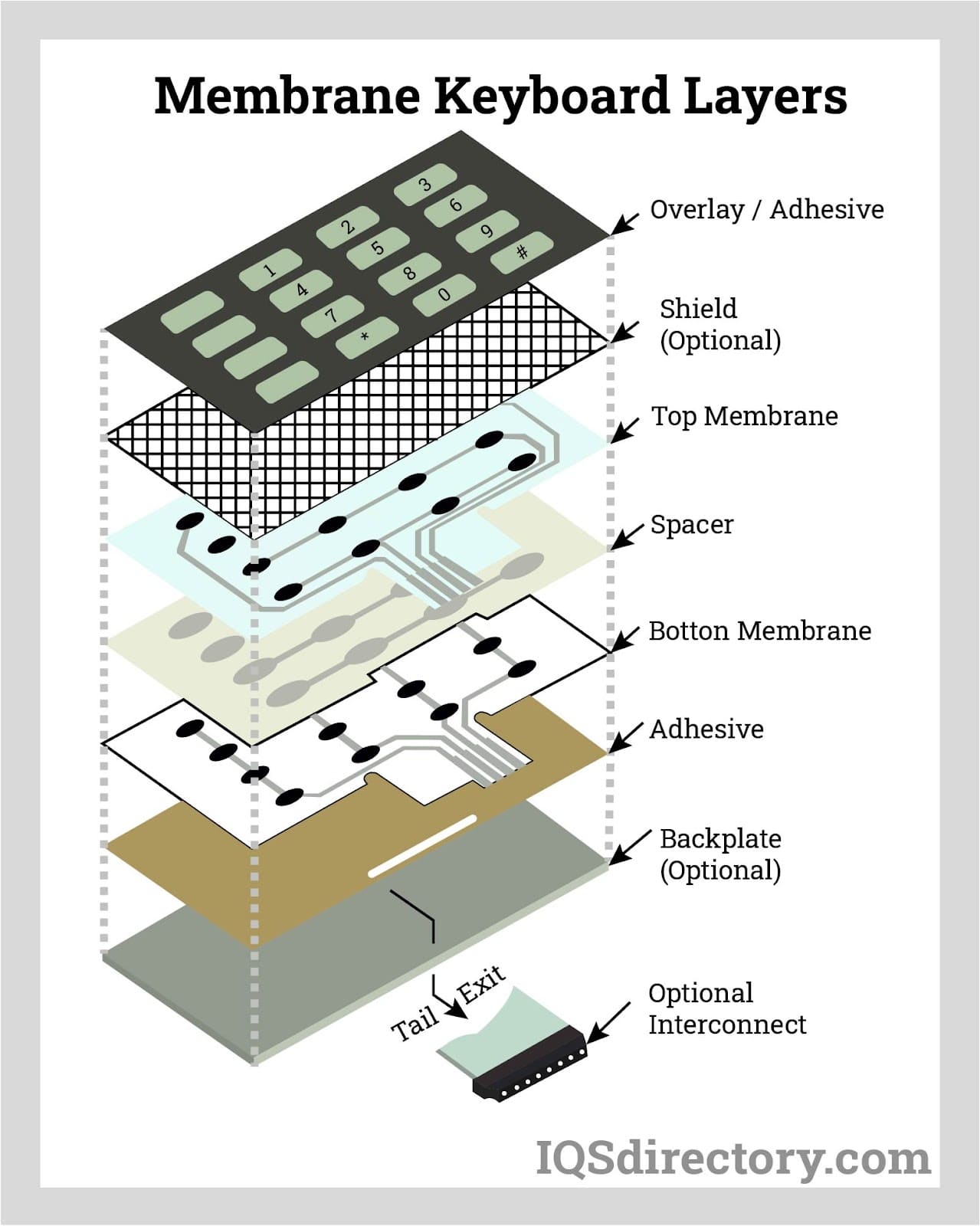

Manufacturing Processes

Material Preparation

The first step in manufacturing membrane switch keyboards is selecting and preparing high-quality materials. Typically, these keyboards are made from layers of polyester or polycarbonate films, conductive inks, adhesives, and graphic overlays. The choice of materials significantly impacts the keyboard’s durability and performance. B2B buyers should seek suppliers who use premium materials that are resistant to moisture, chemicals, and temperature fluctuations, ensuring that the final product meets operational demands.

Key Techniques:

– Conductive Ink Printing: The conductive inks, often silver or carbon-based, are printed onto the substrate using techniques like screen printing or digital printing. This process requires precision to ensure that the circuits function correctly.

– Adhesive Selection: The choice of adhesive is critical. Depending on the surface type (high-energy vs. low-energy), the correct adhesive must be selected to ensure proper bonding.

Forming

Once the materials are prepared, the next phase is forming the various components of the membrane switch. This includes cutting the layers to size and creating any necessary embossing for tactile feedback.

Key Techniques:

– Die Cutting: This technique is often used to create precise shapes and sizes for each layer of the membrane switch. This ensures that all components align perfectly during assembly.

– Embossing: This process adds texture to the graphic overlay, providing tactile cues for users and enhancing the keyboard’s usability in low-light conditions.

Assembly

The assembly process involves layering the components and securing them together. Each layer must be aligned accurately to ensure proper functionality.

Key Techniques:

– Layer Registration: This step is crucial for ensuring that the conductive paths align correctly with the graphic overlay. Advanced machinery is often used to achieve high precision.

– Adhesive Application: The appropriate adhesive is applied to bond the layers together effectively. The method of application may vary based on the adhesive type and design specifications.

Finishing

The final stage involves quality checks and finishing touches. This includes any additional features, such as backlighting or protective coatings, that enhance the keyboard’s functionality and aesthetic appeal.

Key Techniques:

– Coating Application: A protective coating may be applied to the surface to enhance durability and resistance to wear and tear.

– Final Inspection: This is a critical step where each unit undergoes a thorough examination to ensure it meets the specified standards.

Quality Assurance

Quality assurance is paramount in the manufacturing of membrane switch keyboards. B2B buyers should prioritize suppliers who adhere to international and industry-specific standards to ensure product reliability.

Relevant International Standards

- ISO 9001: This standard focuses on quality management systems and ensures that suppliers have processes in place to consistently meet customer requirements and enhance satisfaction.

- CE Marking: This indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: For applications in industrial settings, adherence to API standards can be crucial, particularly for products used in oil and gas or related industries.

QC Checkpoints

To ensure that the manufacturing process meets quality standards, several checkpoints are typically established:

- Incoming Quality Control (IQC): This involves the inspection of raw materials before production. Suppliers should have rigorous protocols to verify that all materials meet specified standards.

- In-Process Quality Control (IPQC): Continuous checks during the manufacturing process help to identify defects early, reducing waste and ensuring that issues are addressed promptly.

- Final Quality Control (FQC): This is the last line of defense, where finished products are inspected for functionality, durability, and compliance with specifications.

Common Testing Methods

B2B buyers should inquire about the specific testing methods employed by suppliers, which may include:

- Functional Testing: Verifying that all keys respond correctly and that the conductive paths are intact.

- Environmental Testing: Assessing the keyboard’s performance under various conditions, such as exposure to moisture, chemicals, and extreme temperatures.

- Durability Testing: Simulating prolonged use to ensure that graphic overlays and components do not degrade.

Verifying Supplier Quality Control

To ensure that a potential supplier maintains high-quality standards, B2B buyers should consider the following verification strategies:

- Supplier Audits: Conducting on-site audits can provide insight into a supplier’s manufacturing processes, quality control measures, and overall operational integrity.

- Requesting Quality Reports: Suppliers should be willing to share their quality reports, which outline their adherence to standards and any corrective actions taken.

- Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased assessment of the supplier’s quality control practices.

QC/Cert Nuances for International B2B Buyers

When dealing with international suppliers, especially from regions such as Africa, South America, and the Middle East, buyers should be aware of the following nuances:

- Regulatory Compliance: Different countries may have varying regulatory requirements. Buyers should ensure that their suppliers are compliant with both local and international standards.

- Cultural Considerations: Communication styles and business practices may vary significantly. Establishing clear lines of communication and setting expectations upfront can help mitigate misunderstandings.

- Supply Chain Transparency: Understanding the entire supply chain process, including sourcing of materials and production methods, can help buyers evaluate the overall quality and reliability of the supplier.

By gaining a comprehensive understanding of the manufacturing processes and quality assurance protocols, B2B buyers can make informed decisions when selecting suppliers for membrane switch keyboards. This diligence not only helps ensure product quality but also fosters long-term partnerships that are beneficial for both parties.

Related Video: Mechanical Keyboard Factory Production Process【2022】

Comprehensive Cost and Pricing Analysis for membrane switch keyboard Sourcing

Understanding the cost structure and pricing dynamics of membrane switch keyboards is crucial for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. Here’s a comprehensive analysis that outlines the key cost components, price influencers, and strategic buyer tips to enhance procurement efficiency.

Cost Components

-

Materials: The primary materials for membrane switch keyboards include polyester or polycarbonate films, conductive inks (silver or carbon), adhesives, and graphic overlays. Material costs can vary significantly based on quality and sourcing regions. High-quality materials enhance durability and performance but also increase costs.

-

Labor: Labor costs can fluctuate based on the manufacturing location. Regions with lower labor costs may provide initial savings, but they could compromise quality. It’s essential to assess the skill level of the workforce, especially in specialized tasks like printing and assembly.

-

Manufacturing Overhead: This includes expenses related to production facilities, utilities, equipment maintenance, and administrative costs. Efficient manufacturing processes can reduce overhead, impacting the final product price.

-

Tooling: Tooling costs encompass the creation of molds and dies necessary for custom designs. These costs can be substantial for bespoke keyboard designs but are often amortized over larger production runs.

-

Quality Control (QC): Ensuring product reliability through rigorous QC processes is vital, especially for applications in critical environments like medical or industrial settings. These costs should be factored into the total pricing, as they directly influence product longevity and customer satisfaction.

Illustrative Image (Source: Google Search)

-

Logistics: Shipping costs can vary widely based on the origin of manufacturing and the destination market. Factors such as Incoterms, transportation mode, and customs duties must be considered to avoid unexpected expenses.

-

Margin: Supplier margins will vary based on market demand, competition, and the supplier’s operational efficiency. Understanding the typical margin in the industry can help in negotiating better pricing.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Larger orders typically reduce per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their demand forecasts.

-

Specifications/Customization: Highly customized keyboards with unique features (e.g., backlighting, specialized adhesives) will incur higher costs. Clear communication of specifications at the outset can prevent costly revisions later.

-

Materials: The choice of materials impacts durability and performance. Premium materials may increase initial costs but can reduce the total cost of ownership by minimizing replacements.

-

Quality/Certifications: Suppliers with ISO certifications or other quality assurances may charge higher prices but offer greater reliability. Investing in certified suppliers can mitigate risks associated with product failures.

-

Supplier Factors: Factors such as supplier reputation, responsiveness, and geographical proximity can influence pricing. Local suppliers might offer better logistics and support, whereas overseas suppliers could provide lower base costs.

-

Incoterms: The choice of Incoterms affects shipping costs and responsibilities. Buyers should choose terms that minimize risk and ensure clarity regarding who bears the cost and responsibility at each stage of transport.

Buyer Tips

-

Negotiation: Engage in open discussions with suppliers about costs and potential savings. Highlighting long-term partnerships can motivate suppliers to offer better pricing.

-

Cost-Efficiency: Analyze the total cost of ownership rather than just the initial purchase price. Consider factors like maintenance, durability, and potential replacement costs.

-

Pricing Nuances for International Buyers: Be aware of exchange rates, tariffs, and import duties that can affect overall costs. Building relationships with local suppliers can sometimes yield better pricing and support.

-

Disclaimer for Indicative Prices: Prices for membrane switch keyboards can vary widely based on the factors mentioned above. Always seek detailed quotations tailored to specific requirements to avoid budget overruns.

By understanding these components and strategies, international B2B buyers can make informed decisions, ensuring they secure high-quality membrane switch keyboards at competitive prices tailored to their unique needs.

Spotlight on Potential membrane switch keyboard Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘membrane switch keyboard’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for membrane switch keyboard

When considering membrane switch keyboards for your business needs, understanding their essential technical properties and industry terminology is crucial for making informed purchasing decisions. Below are key specifications and commonly used terms that will aid international B2B buyers, particularly in Africa, South America, the Middle East, and Europe.

Key Technical Properties

-

Material Grade

The material grade refers to the type of substrate used in the membrane switch, commonly polyester or polycarbonate. Higher-grade materials offer better durability, resistance to chemicals, and environmental factors. Selecting the right material is vital for applications that may face harsh conditions, such as industrial or medical environments. -

Tactile Feedback

Tactile feedback is the sensation provided to the user when a button is pressed. This can be achieved through the use of dome switches or embossing techniques. For B2B buyers, ensuring adequate tactile feedback can enhance user experience and minimize operational errors, particularly in high-use settings. -

Ingress Protection (IP) Rating

The IP rating indicates the level of protection against dust and moisture. For instance, an IP65 rating signifies that the device is dust-tight and can withstand water jets. Understanding the IP rating is essential for buyers in industries such as healthcare and manufacturing, where exposure to contaminants is a concern. -

Operating Temperature Range

This specification defines the temperature limits within which the membrane switch can function effectively. A wider operating temperature range allows for versatility in various environments, making it a critical factor for industries operating in extreme conditions. -

Circuit Layer Configuration

The configuration of the circuit layer, which includes the type of conductive inks used (e.g., silver or carbon), directly impacts the reliability and responsiveness of the keyboard. Buyers should assess the circuit design based on their specific application requirements to ensure optimal performance. -

Adhesive Type

The adhesive used for mounting the membrane switch to its application surface can significantly affect durability. Understanding whether a high-surface energy or low-surface energy adhesive is required based on the application surface is crucial. This can prevent premature failure and enhance longevity.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is important for buyers looking for customized solutions, as it can affect pricing, quality, and lead times. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory management, especially for smaller businesses or those testing new products. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and other details for specified products. B2B buyers should be familiar with this process as it helps in comparing offers from multiple vendors, ensuring competitive pricing and terms. -

Incoterms (International Commercial Terms)

Incoterms are standardized international shipping terms that define the responsibilities of buyers and sellers regarding the delivery of goods. Understanding these terms is crucial for B2B transactions, as they clarify who bears the risk and costs at various stages of the shipping process. -

Customization Options

This term refers to the ability to alter various aspects of the membrane switch, such as size, design, and functionality, to meet specific customer needs. Buyers should explore customization options to ensure the product aligns with their branding and operational requirements. -

Lead Time

Lead time is the duration from placing an order to its delivery. Understanding lead times is essential for planning and inventory management, especially in industries where timely delivery is critical for production schedules.

By familiarizing yourself with these technical properties and trade terms, you can enhance your procurement strategy for membrane switch keyboards, ensuring that your selections meet both operational requirements and market expectations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the membrane switch keyboard Sector

Market Overview & Key Trends

The membrane switch keyboard market is witnessing robust growth driven by advancements in technology and increasing demand for user-friendly interfaces in various industries. Global factors such as digital transformation, automation, and the rise of IoT devices are reshaping how businesses approach sourcing these products. Particularly for B2B buyers from Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed decisions.

Emerging trends include a shift towards customization, where manufacturers offer tailored solutions to meet specific end-user requirements. This is particularly relevant in sectors such as healthcare, automotive, and industrial machinery, where the durability and functionality of membrane keyboards are paramount. Additionally, the adoption of advanced materials like polycarbonate and polyester films is on the rise, enhancing the performance characteristics such as moisture resistance and longevity.

Furthermore, the market is seeing increased integration of smart technology, with features like backlighting and tactile feedback becoming standard. This aligns with the demand for enhanced user experience, particularly in environments that require quick and efficient operation. As international B2B buyers navigate these trends, it’s essential to partner with suppliers who are not only technologically adept but also responsive to market changes and customer needs.

Sustainability & Ethical Sourcing in B2B

As businesses increasingly prioritize sustainability, the membrane switch keyboard sector is no exception. The environmental impact of manufacturing processes and materials used is under scrutiny, prompting buyers to seek suppliers committed to ethical sourcing and eco-friendly practices. This includes the use of green certifications and sustainable materials that reduce carbon footprints and waste.

B2B buyers should look for suppliers that utilize recyclable materials and implement waste reduction strategies in their production processes. Certifications such as ISO 14001 (Environmental Management) can serve as a benchmark for assessing a manufacturer’s commitment to sustainability. Additionally, opting for suppliers who provide transparency in their supply chain can help mitigate risks associated with unethical labor practices.

The emphasis on sustainability also extends to product design. Membrane switch keyboards designed with longevity in mind not only reduce the need for frequent replacements but also contribute to lower overall environmental impact. By aligning procurement strategies with sustainable practices, international buyers can enhance their corporate responsibility profiles while ensuring compliance with increasing regulatory demands related to environmental stewardship.

Brief Evolution/History

The membrane switch keyboard has evolved significantly since its inception in the 1960s. Originally developed for basic applications, the technology has advanced to accommodate a wide range of industries requiring durable and versatile user interfaces. Early models were primarily used in consumer electronics, but as industries like healthcare and industrial automation grew, so did the complexity and functionality of membrane switches.

Today, advancements in printing technologies, materials science, and design capabilities have transformed membrane keyboards into sophisticated interfaces that offer tactile feedback, moisture resistance, and customizable aesthetics. This evolution is particularly relevant for B2B buyers, as it underscores the importance of selecting manufacturers who not only understand these advancements but can also leverage them to meet specific business needs effectively.

Related Video: Global Trends Tutorial: Chapter 3: IPE

Frequently Asked Questions (FAQs) for B2B Buyers of membrane switch keyboard

-

What should I consider when vetting a supplier for membrane switch keyboards?

When vetting suppliers, focus on their experience and expertise in your specific application area. Check for ISO certification, which indicates adherence to quality standards. Request samples to assess quality and ensure they understand your requirements for materials, design, and functionality. Evaluate their responsiveness and customer service through initial communications. Additionally, review their production capabilities, including technology used and lead times, to confirm they can meet your demands efficiently. -

How customizable are membrane switch keyboards, and what options should I explore?

Membrane switch keyboards are highly customizable. You can choose materials for the graphic overlay, such as polyester or polycarbonate, and incorporate features like backlighting or embossing for tactile feedback. Discuss options for printed circuit materials, adhesive types, and surface finishes with your supplier. Consider your brand’s design needs, including colors and shapes, as well as the keyboard’s functional requirements to ensure it meets your application’s specific demands. -

What are the typical minimum order quantities (MOQs) and lead times for membrane switch keyboards?

MOQs for membrane switch keyboards can vary significantly based on the supplier and the complexity of your design. Generally, expect MOQs to range from 100 to 1,000 units for custom orders. Lead times typically range from 4 to 12 weeks, depending on factors such as complexity, material availability, and the supplier’s production capacity. Always confirm these details with your supplier to align your production schedule and inventory needs. -

What payment terms are common for international purchases of membrane switch keyboards?

Payment terms can vary by supplier and region but often include options such as partial upfront payments, letters of credit, or payment upon delivery. For international transactions, it’s advisable to use secure payment methods like PayPal, wire transfers, or escrow services to protect your investment. Clarify any additional costs, such as shipping fees and customs duties, to avoid surprises and ensure smooth financial transactions. -

How can I ensure quality assurance (QA) and certifications for my membrane switch keyboards?

To ensure quality, request documentation of the supplier’s QA processes and relevant certifications, such as ISO 9001 or ISO 13485. Inquire about their testing procedures for durability, moisture resistance, and electrical performance. Some suppliers may offer third-party testing reports as proof of compliance. Establish clear acceptance criteria and conduct regular quality audits during production to maintain standards and address any issues promptly. -

What logistical considerations should I keep in mind when sourcing membrane switch keyboards?

When planning logistics, consider shipping methods (air freight vs. sea freight) based on urgency and cost. Factor in customs clearance times and potential tariffs for imports into your country. Collaborate with your supplier to determine the best shipping options, and ensure they have experience with international shipping regulations. Tracking shipments and establishing clear communication channels can help prevent delays and manage expectations. -

How should I handle disputes with suppliers when sourcing membrane switch keyboards?

To minimize disputes, establish clear contracts detailing specifications, timelines, payment terms, and quality expectations before production begins. In the event of a disagreement, maintain open communication with the supplier to discuss the issue directly. If necessary, consider mediation or arbitration as a formal resolution method. Always document all interactions and agreements to support your position in any disputes that may arise. -

What are the best practices for integrating membrane switch keyboards into my products?

Successful integration involves understanding the keyboard’s operating environment and ensuring compatibility with your device. Collaborate closely with your supplier during the design phase to address factors such as surface adhesion, electrical connectivity, and user interface design. Conduct thorough testing after integration to ensure functionality and durability. Consider user feedback for further improvements and iterate on the design as necessary to enhance user experience.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for membrane switch keyboard

In conclusion, strategic sourcing of membrane switch keyboards is pivotal for international B2B buyers aiming to enhance product reliability and functionality. By focusing on experienced manufacturers who understand specific applications, buyers can avoid common pitfalls such as material mismatches and unexpected costs. Key considerations include assessing adhesive quality, ensuring robust metal fabrication capabilities, and prioritizing ISO-certified suppliers to guarantee product integrity.

Moreover, responsive communication with suppliers fosters collaboration, ensuring that the final product meets all requirements. As the demand for durable and customizable interfaces rises across various sectors—from medical devices to industrial machinery—investing in high-quality membrane switch keyboards becomes increasingly critical.

Looking ahead, international buyers from Africa, South America, the Middle East, and Europe should leverage the growing global network of suppliers to secure innovative solutions that not only meet but exceed user expectations. By actively engaging in strategic sourcing, companies can position themselves at the forefront of technological advancements, driving success in their respective markets. Now is the time to explore partnerships that align with your operational goals and elevate your product offerings.