Top 30 Sun and Planet Gear Manufacturers You Should Know

Are you tired of sifting through countless suppliers for your sun and planet gear needs? It can be overwhelming to find a manufacturer that offers quality, reliability, and innovation. But don’t worry—you’re not alone! Choosing the right supplier is crucial for ensuring your projects run smoothly and efficiently. The best manufacturers provide not just superior products but also exceptional support and expertise to help your business thrive.

Imagine having access to a list of the top 30 factories that can elevate your gear production. This guide will save you time and help you make informed decisions. Ready to discover the best in the business? Dive into our comprehensive comparison and find your perfect manufacturing partner today!

Top 30 Sun And Planet Gear Manufacturers

The Engineers Post – Planetary Gear Solutions

Domain: theengineerspost.com

Registered: 2018 ( 7 years )

Introduction: Planetary gears, also known as epicyclic gears, are used in various applications requiring high torque density, operational efficiency, and durability.

Engineering Cheatsheet – Planetary Gear Systems Solutions

Domain: engineeringcheatsheet.com

Registered: 2021 ( 4 years )

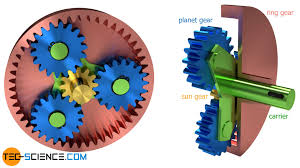

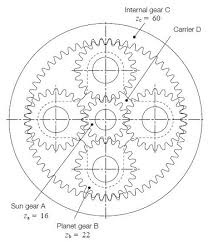

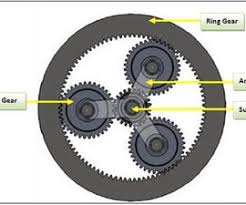

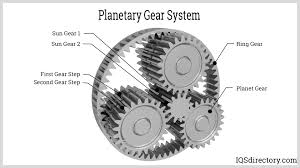

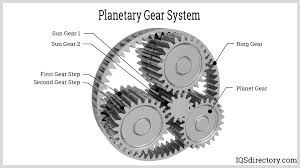

Introduction: Planetary gear systems, also known as epicyclic gearing, are compact mechanical systems that consist of a central sun gear, multiple planet gears, and an internal ring gear, used primarily in automatic transmissions.

Tec Science – Epicyclic Planetary Gear Solutions

Domain: tec-science.com

Registered: 2017 ( 8 years )

Introduction: The company offers planetary gears, specifically epicyclic gears where multiple planet gears mesh with a central sun gear, providing various transmission ratios and compact design.

Sunplanetgear – Planetary Gear Solutions

EngineerExcel – High Efficiency Planetary Gear Systems

Domain: engineerexcel.com

Registered: 2015 ( 10 years )

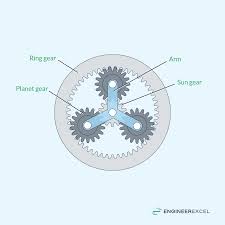

Introduction: Planetary gear systems designed for high efficiency, compactness, and high power-to-weight ratios.

Brighthubengineering – Gear Solutions for Mechanical Applications

Domain: brighthubengineering.com

Registered: 2012 ( 13 years )

Introduction: Sun and planetary gear arrangements for mechanical applications.

Gear Motions – Custom Gear Manufacturing Solutions

Domain: gearmotions.com

Registered: 1997 ( 28 years )

Introduction: Gear Motions specializes in the manufacturing of various types of gears and gear systems, including planetary gear systems, custom gears, spur gears, helical gears, bevel gears, worm gears, and gearboxes.

Khkgears – Precision Planetary Gear Systems

Domain: khkgears.net

Registered: 2015 ( 10 years )

Introduction: The company offers planetary gear systems, hypocycloid mechanisms, and constrained gear systems that provide compact size and high reduction ratios.

Iqsdirectory – Planetary Gear Systems Solutions

Domain: iqsdirectory.com

Registered: 2004 ( 21 years )

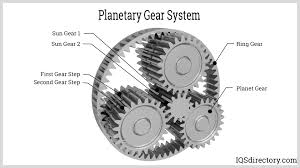

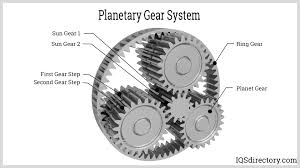

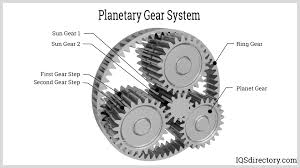

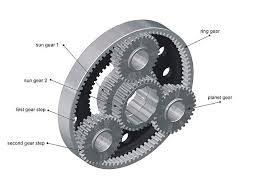

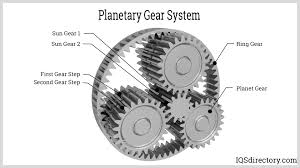

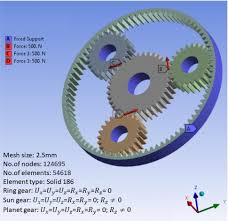

Introduction: Planetary gears, also known as epicyclic gear systems, are engineered mechanisms used to convert reciprocating motion into rotary motion. They consist of a central sun gear, multiple planet gears, an outer ring gear, and a planet carrier.

Rohloff – Bicycle Gear Systems

Domain: rohloff.de

Registration year: Not available

Introduction: Rohloff AG offers a planetary gear system, specifically the Speedhub 500/14, which is designed for bicycles to provide a wide range of gear ratios and high mechanical efficiency.

Drivetrainhub – Planetary Geartrain Solutions

Thecatalystis – Precision Gear Systems Solutions

Domain: thecatalystis.com

Registered: 2011 ( 14 years )

Introduction: The company offers gear systems that include sun gears, planet gears, and ring gears, designed for various mechanical applications.

Instructables – Data Collection and Analytics Solutions

Domain: instructables.com

Registered: 2005 ( 20 years )

Introduction: The company offers various data collection and analytics services through multiple platforms to enhance user experience and site performance.

Gearsolutions – Epicyclic Gearing Systems

Domain: gearsolutions.com

Registered: 2008 ( 17 years )

Introduction: The company offers epicyclic gearing systems, including simple planetary, compound epicyclic, and coupled epicyclic sets, designed for efficiency and compactness in various applications.

Zhuanlan – Smart Home Solutions

Domain: zhuanlan.zhihu.com

Registered: 2007 ( 18 years )

Introduction: The company primarily offers a range of smart home devices, including smart lighting, security cameras, and home automation systems.

Mentored Engineer – Gear Design Master Class & Tools

Domain: mentoredengineer.com

Registered: 2018 ( 7 years )

Introduction: Mentored Engineer offers a Comprehensive Gear Design Master Class and a Planetary Gear Calculator to help users design and specify gearboxes for various applications.

Machinedesign – High Torque Planetary Gear Solutions

Domain: machinedesign.com

Registered: 1995 ( 30 years )

Introduction: Planetary gears that provide high torque and high-speed reduction in a compact design.

Lancereal – Planetary Gearbox Solutions

Domain: lancereal.com

Registered: 2000 ( 25 years )

Introduction: Lancereal offers three types of planetary gearboxes: wheel drive, shaft output, and spindle output, with options for single, double, or triple stages.

Link – Gear Mechanism Solutions

Go4Trans – Planetary Gears for Automatic Transmissions

Domain: go4trans.com

Registered: 2016 ( 9 years )

Introduction: Planetary gears used in automatic transmissions for efficient power transfer and seamless gear shifting.

Mechanicalboost – Planetary Gearbox Solutions

Domain: mechanicalboost.com

Registered: 2020 ( 5 years )

Introduction: Planetary gearboxes, also known as epicyclic gear trains, are compact gear systems designed to transfer maximum torque in limited space, featuring input and output shafts aligned with each other.

Quizlet – Educational Flashcards and Learning Tools

Domain: quizlet.com

Registered: 2004 ( 21 years )

Introduction: Planetary gears operation flash cards for educational purposes.

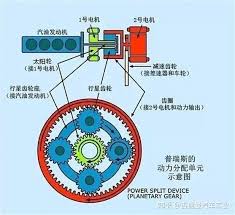

Benchtophybrid – Planetary Gearset Solutions

Domain: benchtophybrid.com

Registered: 2013 ( 12 years )

Introduction: Planetary gearsets that provide versatile input-output configurations for various applications, including hybrid powertrains.

Howtomechatronics – 3D Printed Planetary Gearboxes

Domain: howtomechatronics.com

Registered: 2015 ( 10 years )

Introduction: 3D printed planetary gearbox designed for NEMA17 stepper motors, featuring a 16:1 reduction ratio.

Roymech – Epicyclic Gearbox Solutions

Domain: roymech.org

Registered: 2019 ( 6 years )

Introduction: Epicyclic gearboxes (planetary gearboxes) consisting of one or more planet gears rotating around a central sun gear, meshed with an internal ring gear.

Britannica – Mechanical Motion Transmission Solutions

Domain: britannica.com

Registered: 1995 ( 30 years )

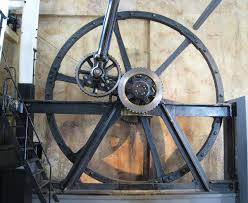

Introduction: Sun and planet gears are mechanical devices used to transmit motion and power in various machinery.

Learnmech – Epicyclic Gear Train Solutions

Domain: learnmech.com

Registered: 2017 ( 8 years )

Introduction: Epicyclic gear trains, also known as planetary gear systems, which are used for power transmission and speed reduction.

Mysite – Sun and Planet Gear Solutions

Domain: mysite.ku.edu.tr

Registered: 2000 ( 25 years )

Introduction: Sun and Planet Gear Wheels designed for converting vertical motion to rotary motion.

Wallace Racing – Planetary Gear Sets for Transmissions

Domain: wallaceracing.com

Registered: 1999 ( 26 years )

Introduction: Planetary gear sets for automotive applications, specifically for 3-speed automatic transmissions like TH 350/400.

Neugart – High-Precision Epicyclic Gear Units

Domain: neugart.com

Registered: 1997 ( 28 years )

Introduction: Neugart specializes in the development and manufacturing of high-precision epicyclic gear units, which are designed for various applications in automation and robotics.

Category Information

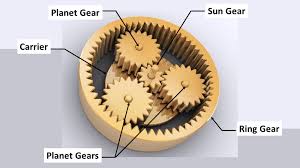

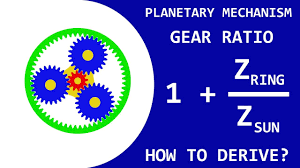

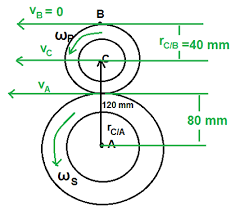

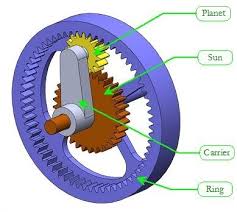

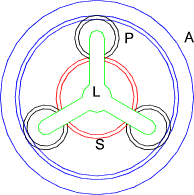

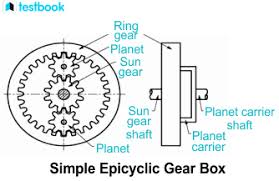

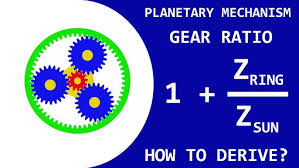

Sun and planet gears are a type of gear mechanism commonly used in mechanical systems to achieve specific motion and torque characteristics. This gear arrangement consists of a central “sun” gear, which is surrounded by one or more “planet” gears that rotate around it. The planet gears are typically mounted on a movable carrier, allowing them to orbit the sun gear while also engaging with an outer ring gear, creating a complex interplay of motion.

These systems are significant in various applications, including automotive transmissions, robotics, and aerospace engineering, where space and efficiency are critical. Sun and planet gear mechanisms provide high torque output in a compact design, making them ideal for applications that require reliable power transmission and precise control of movement. Their ability to handle heavy loads while maintaining smooth operation underscores their importance in modern engineering solutions.

Application Information

Sun and planet gears are integral components in various industries due to their unique ability to transmit motion and torque efficiently. One primary application area is in automotive engineering, where they are used in automatic transmissions to facilitate gear changes and optimize power delivery. Their compact design allows for smooth operation and increased efficiency in power transfer. Another significant application is in industrial machinery, particularly in gearboxes for conveyor systems and heavy equipment.

These gears can handle high loads while maintaining a smaller footprint, making them ideal for manufacturing and material handling processes. Additionally, aerospace utilizes sun and planet gears in flight control systems and actuators, where precision and reliability are critical. Overall, their versatility makes them suitable for a wide range of mechanical systems requiring efficient motion transfer.

Production Process Information

The production of sun and planet gear systems involves several key steps that ensure precision and functionality. First, the design phase is crucial, where engineers create detailed blueprints based on specific performance requirements. This includes determining gear ratios and sizes to ensure the system operates efficiently. Next, material selection comes into play. Manufacturers typically choose durable materials like steel or aluminum to withstand stress and wear. After materials are selected, the machining process begins.

This involves cutting, shaping, and finishing the gear components using specialized equipment to achieve the required precision. Finally, assembly and testing are performed. The individual components are carefully put together to form the complete gear system, followed by rigorous testing to ensure everything functions correctly. This process ensures that the sun and planet gear products are reliable and meet industry standards.

Related Video

Frequently Asked Questions (FAQs)

How do I start finding sun and planet gear manufacturers?

Begin your search by researching online directories and industry-specific websites that list manufacturers. You can also attend trade shows, join relevant industry groups, and seek recommendations from peers in the field. Networking can lead to valuable connections and insights about reputable suppliers.

What should I consider when evaluating a manufacturer?

Look for factors such as production capacity, quality control processes, certifications, and experience in producing sun and planet gears. It’s also essential to assess their customer service, delivery times, and pricing. Request samples to evaluate their product quality firsthand.

Are there minimum order quantities I should be aware of?

Yes, many manufacturers have minimum order quantities (MOQs), which can vary widely. It’s important to ask about MOQs upfront, as they can impact your budget and inventory management. Some manufacturers may be flexible, especially for first-time orders, so it’s worth discussing.

How can I ensure the quality of the gears produced?

Request detailed information about the manufacturer’s quality assurance processes. Ask for certifications and standards they adhere to, such as ISO. Additionally, consider conducting an on-site inspection or third-party audit to verify their production capabilities and quality control measures.

What are the typical lead times for production?

Lead times can vary based on the manufacturer, order size, and complexity of the gears. Generally, expect anywhere from a few weeks to several months. Always confirm lead times before placing an order, and consider discussing expedited options if you have urgent needs.

![Planetary Gear: Design, Parts, Function, Ratio & Uses [PDF] - sun and planet gear](https://www.fobindustry.info/wp-content/uploads/2025/06/theengineerspostcom-sun-and-planet-gear-image.jpg)