Master Sourcing Heat Elements: Key Insights for B2B Buyers

Introduction: Navigating the Global Market for heat elements

In today’s competitive industrial landscape, the role of heat elements cannot be overstated. These critical components are essential for a wide range of applications, from metal processing and glass manufacturing to precise temperature control in laboratories. For international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, understanding the intricacies of heat elements is vital for optimizing operational efficiency and ensuring product quality.

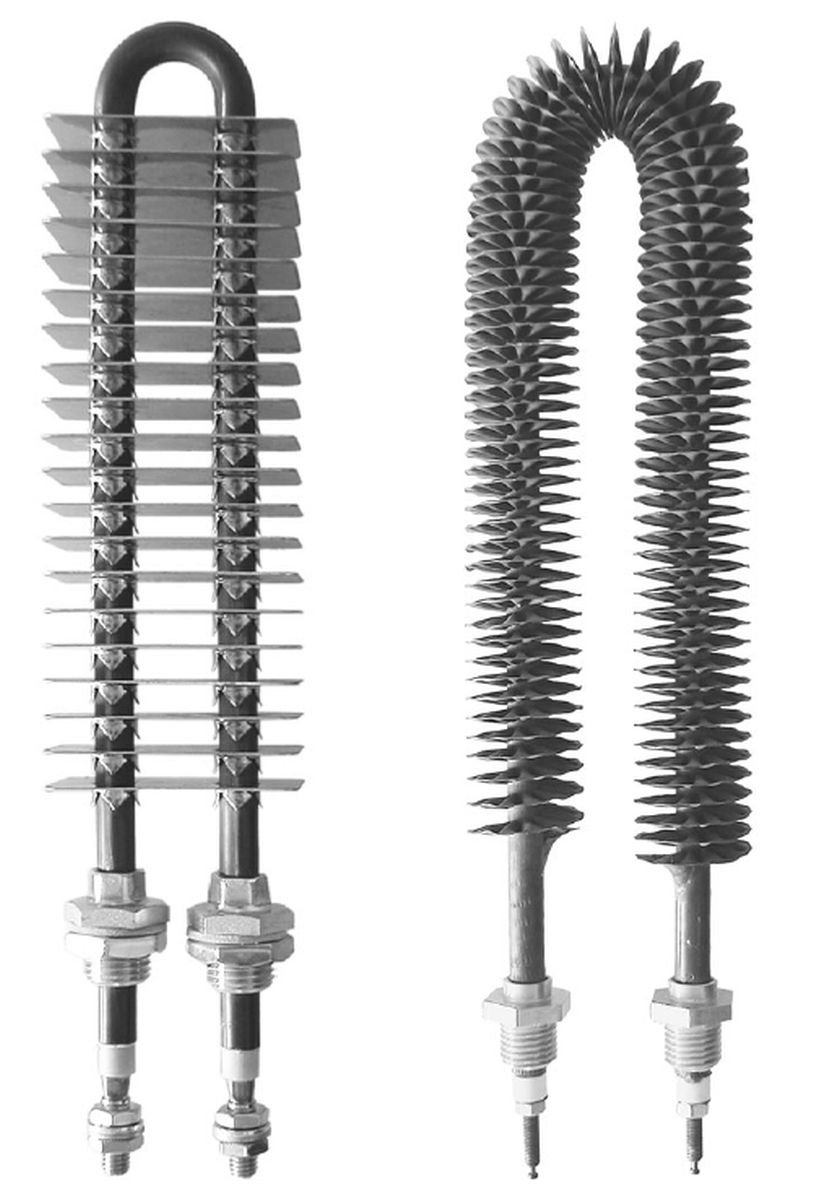

Illustrative Image (Source: Google Search)

This comprehensive guide delves into the diverse types of heating elements available, including their materials, manufacturing processes, and quality control measures. Buyers will find valuable insights into the most suitable heating element options for their specific needs, as well as a deep dive into supplier selection, cost considerations, and market trends. The guide also addresses frequently asked questions, empowering decision-makers with the knowledge needed to navigate the complexities of sourcing.

By equipping B2B buyers with critical information, this resource enables informed decisions that enhance productivity and reduce operational costs. With a focus on best practices and actionable strategies, this guide is an indispensable tool for those looking to harness the full potential of heat elements in their industrial processes. Whether you are a seasoned buyer or new to the market, the insights provided herein will help streamline your sourcing efforts and elevate your competitive edge.

Understanding heat elements Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Silicon Carbide Elements | High-temperature resistance, oxidation resistance | Ceramics, metal processing, glass manufacturing | Pros: Long lifespan, excellent thermal conductivity. Cons: Higher initial cost. |

| Molybdenum Disilicide | Capable of extreme temperatures, oxidation resistance | High-temperature furnaces, glass manufacturing | Pros: Durable, ideal for continuous use. Cons: Limited to specific high-temp applications. |

| Metallic Heating Elements | Quick heating, energy-efficient | Electric ovens, dryers, heating systems | Pros: Cost-effective, versatile. Cons: Not suitable for very high temperatures. |

| Cartridge Heaters | Compact design, versatile installation options | Plastics processing, food equipment, medical devices | Pros: Space-saving, customizable. Cons: Limited heat distribution area. |

| Tubular Heating Elements | Flexible design, good thermal efficiency | HVAC, industrial ovens, water heating | Pros: Adaptable to various shapes, good for uniform heating. Cons: Installation can be complex. |

Silicon Carbide Elements

Silicon Carbide heating elements are renowned for their ability to withstand extreme temperatures while maintaining durability. They are particularly suitable for industries such as ceramics and glass manufacturing, where high thermal resistance is crucial. When purchasing, B2B buyers should consider the initial investment against the long-term savings provided by their longevity and efficiency.

Molybdenum Disilicide

Molybdenum Disilicide heating elements excel in high-temperature applications, often exceeding 2000°C. They are ideal for use in high-temperature furnaces and glass manufacturing processes. Buyers should evaluate the specific thermal requirements of their applications, as these elements provide exceptional durability but may not be necessary for lower temperature needs.

Metallic Heating Elements

Metallic heating elements are characterized by their rapid heating capabilities and energy efficiency, making them a popular choice for electric ovens and dryers. They are cost-effective and versatile, suitable for a wide range of industrial applications. Buyers should assess the temperature limitations, as these elements are less effective in extremely high-temperature settings.

Cartridge Heaters

Cartridge heaters feature a compact design that allows for versatile installation in various applications, including plastics processing and food equipment. Their ability to be customized for specific heating needs makes them an attractive option for B2B buyers. However, it is essential to consider their limited heat distribution area when selecting for applications requiring uniform heating.

Tubular Heating Elements

Tubular heating elements are known for their flexibility and good thermal efficiency, making them suitable for HVAC systems, industrial ovens, and water heating applications. Their adaptability to various shapes allows for uniform heating across different surfaces. Buyers should be aware that while they are versatile, installation can be complex, requiring careful planning to integrate into existing systems.

Related Video: What Are The Different Atomic Models? Dalton, Rutherford, Bohr and Heisenberg Models Explained

Key Industrial Applications of heat elements

| Industry/Sector | Specific Application of Heat Elements | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Metal Processing | Heat treatment and forging | Ensures optimal material properties and durability | Temperature tolerance, material compatibility |

| Glass Manufacturing | Melting and molding processes | High efficiency in production with reduced energy costs | High-temperature resistance, oxidation resistance |

| Ceramics Production | Firing in high-temperature kilns | Enhances product quality and consistency | Thermal stability, energy efficiency |

| Food Processing | Cooking and drying processes | Improves product quality and safety | Compliance with health standards, energy efficiency |

| Laboratories | Precise temperature control in experiments | Enables accurate data and reliable results | Customization options, durability under varying conditions |

Metal Processing

In the metal processing industry, heat elements are critical for processes such as heat treatment and forging. These applications require precise temperature control to achieve desired mechanical properties and enhance material durability. International buyers, especially from regions like Africa and South America, should prioritize sourcing elements that can withstand high temperatures and are compatible with various metal types. Additionally, understanding local regulations regarding material safety and performance standards is essential for compliance.

Glass Manufacturing

Heat elements play a vital role in glass manufacturing, specifically in melting and molding processes. Molybdenum Disilicide heating elements are preferred for their ability to maintain high temperatures efficiently, thereby reducing overall energy costs. For buyers from the Middle East and Europe, sourcing elements that offer excellent oxidation resistance is crucial, as they enhance the longevity of the equipment. Furthermore, aligning with suppliers who can provide technical support and maintenance services can significantly improve operational efficiency.

Ceramics Production

In ceramics production, heat elements are utilized for firing products in high-temperature kilns. Silicon Carbide heating elements are particularly effective due to their high thermal stability and durability under extreme conditions. Buyers from Europe and South America should focus on sourcing elements that not only meet high-temperature requirements but also ensure energy efficiency to minimize operational costs. Additionally, understanding the specific thermal profiles required for different ceramics can guide optimal sourcing decisions.

Food Processing

In the food processing sector, heat elements are essential for cooking and drying processes. They contribute to improving product quality and safety by providing uniform heating. B2B buyers in Africa and South America must ensure that the heating elements comply with health and safety standards, which can vary by region. Sourcing energy-efficient options can also help reduce operational costs, making it a crucial consideration for businesses looking to optimize their production processes.

Laboratories

Heat elements in laboratories are used for precise temperature control during experiments and material testing. This application is vital for obtaining accurate data and reliable results. International buyers, particularly from Europe and the Middle East, should consider sourcing customizable heating elements that can adapt to different experimental setups. Durability under varying conditions is also a key requirement, as it ensures long-term reliability and reduces the need for frequent replacements.

Related Video: Double Pipe Heat Exchanger Basics Explained – industrial engineering

Strategic Material Selection Guide for heat elements

When selecting heating elements for industrial applications, understanding the properties, advantages, and limitations of different materials is crucial. This guide analyzes four common materials used in heating elements, providing actionable insights for international B2B buyers.

Nickel-Chromium Alloys

Key Properties: Nickel-Chromium alloys are known for their high heat resistance and excellent corrosion resistance. They can typically withstand temperatures up to 1200°C, making them suitable for high-temperature applications.

Pros & Cons: The primary advantage of Nickel-Chromium alloys is their durability and long service life, even in harsh environments. However, they tend to be more expensive than other materials, which can impact overall project costs. Manufacturing complexity can also be a concern, as these alloys require precise control during production to ensure quality.

Impact on Application: These alloys are ideal for applications that involve high-temperature processes, such as metal forging and glass manufacturing. They are compatible with various media but may not be suitable for environments with extreme oxidation.

Considerations for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should ensure compliance with international standards such as ASTM and DIN. Additionally, understanding regional preferences for material performance can influence purchasing decisions.

Silicon Carbide

Key Properties: Silicon Carbide heating elements exhibit exceptional high-temperature resistance, capable of operating at temperatures exceeding 2700°C. They also offer excellent thermal shock resistance and oxidation resistance.

Pros & Cons: The main advantage of Silicon Carbide is its ability to maintain performance under extreme conditions, making it ideal for industrial furnaces and kilns. However, the cost of Silicon Carbide elements is relatively high, and they can be brittle, which may pose challenges during handling and installation.

Impact on Application: Silicon Carbide is particularly effective in ceramics and glass production, where high temperatures are necessary for melting and shaping materials. Its compatibility with various media ensures versatility across applications.

Considerations for International Buyers: Buyers should be aware of the need for specific certifications and compliance with local regulations regarding high-temperature materials. Additionally, understanding the supply chain and sourcing capabilities in different regions is vital.

Molybdenum Disilicide

Key Properties: Molybdenum Disilicide heating elements are designed to withstand extreme temperatures, often exceeding 2000°C. They form a protective oxide layer that enhances durability and oxidation resistance.

Pros & Cons: The key advantage of Molybdenum Disilicide is its long-term reliability in high-temperature environments, making it a preferred choice for glass manufacturing and industrial furnaces. However, the high cost and specific manufacturing requirements can limit its use in lower-budget projects.

Impact on Application: This material is particularly suited for applications requiring continuous heating at high temperatures, ensuring consistent performance and efficiency.

Considerations for International Buyers: Buyers should consider the availability of Molybdenum Disilicide in their region, as sourcing can be more complex. Compliance with international standards and local regulations is also essential to ensure safe usage.

Stainless Steel

Key Properties: Stainless steel is known for its corrosion resistance and mechanical strength, typically rated for temperatures up to 800°C. It is widely used in various heating applications due to its versatility.

Pros & Cons: The primary advantage of stainless steel is its cost-effectiveness and ease of manufacturing, making it a popular choice for many applications. However, its performance may not be suitable for extreme high-temperature applications compared to specialized materials like Silicon Carbide or Molybdenum Disilicide.

Impact on Application: Stainless steel heating elements are commonly used in food processing, HVAC systems, and general industrial applications, where moderate temperatures are sufficient.

Considerations for International Buyers: Buyers should ensure that the stainless steel grade meets local standards and regulations, particularly in food-related applications. Understanding the differences in grades (e.g., 304 vs. 316) can influence material selection based on corrosion resistance needs.

Summary Table

| Material | Typical Use Case for heat elements | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nickel-Chromium Alloys | High-temperature industrial applications | Excellent durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Silicon Carbide | Ceramics and glass production | Exceptional high-temperature resistance | Brittle and expensive | High |

| Molybdenum Disilicide | High-temperature furnaces and kilns | Long-term reliability in extreme conditions | High cost and specific sourcing challenges | High |

| Stainless Steel | Food processing and general heating | Cost-effective and versatile | Limited performance in extreme temperatures | Medium |

This strategic material selection guide provides insights that can help international B2B buyers make informed decisions when sourcing heating elements for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for heat elements

Manufacturing heat elements involves several critical stages, each designed to ensure that the final product meets the required performance standards and safety regulations. This section outlines the typical manufacturing processes, quality assurance measures, and international standards relevant to B2B buyers, particularly those from Africa, South America, the Middle East, and Europe.

Manufacturing Processes

Material Preparation

The first step in manufacturing heat elements is material preparation. The choice of materials—such as nickel-chromium alloys, silicon carbide, or molybdenum disilicide—depends on the intended application and operating conditions. Key activities during this stage include:

- Material Sourcing: Selecting high-quality raw materials from reliable suppliers. B2B buyers should verify the provenance of these materials to ensure compliance with industry standards.

- Testing and Analysis: Conducting initial tests on raw materials for chemical composition and physical properties to ensure they meet specifications. This may involve spectroscopic analysis or tensile testing.

Forming

Once materials are prepared, the next stage involves shaping the materials into the desired form. This can include:

- Wire Drawing: For resistive materials, wire drawing is used to produce heating elements of specific diameters. The process requires precision to ensure consistent electrical properties.

- Molding and Casting: For materials like silicon carbide, molding techniques are employed to form components that can withstand high temperatures.

- Machining: Components may undergo machining processes such as drilling or milling to achieve precise dimensions and tolerances.

Assembly

After forming, the components are assembled into the final heating element. This stage includes:

- Insulation Application: Insulating materials like magnesium oxide or ceramics are applied to ensure safety and efficiency. Proper insulation is crucial for preventing heat loss and electrical short circuits.

- Joining Techniques: Techniques such as welding or soldering are used to connect leads and connectors securely. The integrity of these joints is vital for reliable electrical performance.

- Final Assembly: All components are brought together, ensuring that every part is securely fitted and meets design specifications.

Finishing

The final stage of manufacturing involves finishing processes that enhance the performance and durability of the heating elements. Key activities include:

- Surface Treatment: Applying coatings or treatments to improve corrosion resistance and thermal conductivity. This can include anodizing or applying protective layers.

- Quality Checks: Conducting visual inspections and dimensional checks to ensure conformity to specifications.

Quality Assurance

Quality assurance (QA) is essential in the manufacturing of heat elements, ensuring that products meet both internal and external standards. The following are key components of a robust QA framework.

International Standards

B2B buyers should be aware of various international standards that govern the quality of heating elements:

- ISO 9001: This standard outlines the requirements for a quality management system (QMS). Manufacturers adhering to ISO 9001 demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

- CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For heating elements used in oil and gas applications, compliance with American Petroleum Institute (API) standards ensures that products can withstand harsh operational conditions.

Quality Control Checkpoints

Quality control (QC) involves systematic processes to check the quality at various stages of manufacturing:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specifications before they are used in production.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process help identify defects early. Techniques such as statistical process control (SPC) can be employed to monitor variations.

- Final Quality Control (FQC): After assembly, a comprehensive inspection is conducted to verify that the final product meets all specifications and standards.

Common Testing Methods

Various testing methods are employed to ensure the performance and safety of heat elements:

- Electrical Testing: This includes insulation resistance tests and continuity tests to ensure that the electrical properties meet specifications.

- Thermal Testing: Testing the heating elements under simulated operational conditions helps verify performance at specified temperatures.

- Mechanical Testing: Assessing the structural integrity of components, including tensile and fatigue tests, ensures durability under operational stresses.

Verifying Supplier Quality Control

For international B2B buyers, particularly from diverse regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are several actionable strategies:

- Supplier Audits: Conduct regular audits of suppliers to assess their manufacturing processes, quality management systems, and compliance with international standards. This can include both on-site inspections and document reviews.

- Quality Reports: Request and review quality assurance reports from suppliers. These documents should detail their QC processes, test results, and any certifications achieved.

- Third-Party Inspections: Engage third-party inspection services to evaluate the quality of products before shipment. This provides an additional layer of assurance that the products meet specified standards.

QC and Certification Nuances for International Buyers

B2B buyers must also navigate various certification nuances when sourcing heat elements internationally:

- Regional Regulations: Different regions may have specific regulations regarding the use of heating elements, particularly in safety-critical applications. Understanding these regulations is essential for compliance.

- Certification Bodies: Familiarize yourself with the relevant certification bodies in your industry. For instance, UL (Underwriters Laboratories) in the United States or TUV in Europe may provide certification that is recognized globally.

- Documentation: Ensure that suppliers provide complete documentation for certifications, including test reports and compliance certificates. This documentation is vital for customs clearance and regulatory compliance.

By understanding the manufacturing processes and quality assurance practices associated with heat elements, international B2B buyers can make informed decisions that enhance their operational efficiency and safety. Prioritizing suppliers who adhere to recognized quality standards will help mitigate risks and ensure product reliability.

Related Video: How Things Are Made | An Animated Introduction to Manufacturing Processes

Comprehensive Cost and Pricing Analysis for heat elements Sourcing

Understanding the cost structure and pricing dynamics of heat elements is crucial for international B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe. By grasping the various cost components and price influencers, buyers can make informed decisions that enhance their procurement strategies.

Cost Components

-

Materials: The choice of materials significantly impacts cost. Common materials include nickel-chromium alloys, silicon carbide, and molybdenum disilicide. Each material has its unique pricing based on market demand and availability. For instance, high-performance materials like molybdenum disilicide typically command higher prices due to their superior properties and applications in extreme environments.

-

Labor: Labor costs vary by region and supplier. Manufacturers in countries with higher labor rates may have elevated production costs. Buyers should consider the implications of labor costs when sourcing from different geographic locations.

-

Manufacturing Overhead: This includes costs related to factory operations such as utilities, maintenance, and administrative expenses. Efficient manufacturing processes can help mitigate these costs, but buyers should be aware that suppliers with advanced technologies may charge a premium.

-

Tooling: Custom tooling for specialized heating elements can be a significant upfront cost. This cost is often amortized over large production runs, making it critical for buyers to evaluate their order volumes carefully.

-

Quality Control (QC): Stringent QC processes ensure product reliability and compliance with industry standards, particularly for applications in critical sectors like aerospace and automotive. This adds to the overall cost but is necessary for maintaining product integrity.

-

Logistics: Shipping costs can vary dramatically based on the distance from the supplier, shipping methods, and the mode of transport chosen. For international transactions, understanding Incoterms is essential to clarify who bears the costs at different stages of the supply chain.

-

Margin: Supplier margins can vary based on brand reputation, service levels, and market competition. Buyers should anticipate a range of margins and negotiate based on their purchasing power and volume.

Price Influencers

Several factors influence the pricing of heat elements:

-

Volume/MOQ: Minimum order quantities can dictate pricing structures. Higher volumes typically lead to lower per-unit costs due to economies of scale.

-

Specifications/Customization: Customization in size, shape, or material can lead to increased costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Quality/Certifications: Compliance with international standards (e.g., ISO, CE) can affect pricing. Higher quality and certified products often come with a premium but can reduce long-term operational risks.

-

Supplier Factors: The supplier’s reputation, experience, and reliability can impact both cost and pricing. Established suppliers may charge more but offer better assurance of quality and service.

-

Incoterms: Understanding the implications of Incoterms (e.g., FOB, CIF) is crucial for managing logistics costs and responsibilities effectively.

Buyer Tips

-

Negotiation: Leverage volume purchasing and long-term relationships to negotiate better terms. Suppliers are often more flexible with loyal customers.

-

Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), which includes initial purchase price, maintenance, and operational costs. A lower upfront cost may not always equate to savings in the long run.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, sourcing from local suppliers in Africa or South America may yield logistical savings, while European suppliers might offer advanced technologies at a higher price.

-

Market Research: Stay informed about market trends and material costs, as fluctuations can impact pricing. Utilize industry reports and supplier insights to anticipate changes.

-

Supplier Diversity: Engage multiple suppliers to compare costs and capabilities. This strategy not only fosters competition but also provides fallback options if one supplier cannot meet demand.

Disclaimer

The prices mentioned in any procurement discussions should be viewed as indicative and subject to change based on market conditions, order specifications, and supplier negotiations. Always conduct thorough market research and supplier evaluations to obtain the most accurate and favorable pricing.

Spotlight on Potential heat elements Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘heat elements’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for heat elements

Understanding the essential technical properties and trade terminology related to heat elements is crucial for international B2B buyers. This knowledge not only facilitates informed purchasing decisions but also enhances communication with suppliers. Below are critical specifications and industry terms that every buyer should be familiar with.

Key Technical Properties of Heat Elements

-

Material Grade

– Definition: Material grade refers to the specific classification of the materials used in the manufacturing of heating elements, such as nickel-chromium alloys or molybdenum disilicide.

– Importance: The material grade affects the heating element’s performance, including its resistance to heat, corrosion, and overall longevity. Selecting the right grade ensures compatibility with your application requirements and enhances operational efficiency. -

Temperature Rating

– Definition: This specification indicates the maximum temperature that a heating element can safely reach without failing.

– Importance: Understanding the temperature rating is essential for applications that involve extreme conditions. Choosing a heating element with an appropriate temperature rating prevents premature failure and reduces maintenance costs. -

Resistance Value

– Definition: The resistance value (measured in ohms) quantifies the electrical resistance of the heating element.

– Importance: This property is critical for calculating energy consumption and efficiency. A lower resistance value typically results in faster heating times, which can be advantageous for production timelines. -

Tolerance

– Definition: Tolerance refers to the allowable deviation in the heating element’s dimensions or performance characteristics.

– Importance: In industries where precision is key, selecting heating elements with appropriate tolerances ensures that they fit correctly within the equipment and operate as intended. This minimizes the risk of malfunctions or inefficiencies. -

Insulation Type

– Definition: Insulation type pertains to the materials used to insulate the heating element, such as magnesium oxide or ceramic.

– Importance: Proper insulation is vital for safety and efficiency. It prevents heat loss, reducing energy costs and protecting the surrounding environment from heat damage. -

Sheath Material

– Definition: The sheath material encases the resistive element, providing protection from environmental factors.

– Importance: The choice of sheath material impacts durability and thermal conductivity. For instance, stainless steel is often favored for its corrosion resistance, making it suitable for various industrial applications.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer.

– Significance: Understanding the role of OEMs is crucial when sourcing heating elements, as it helps identify reliable suppliers who can provide components that meet specific performance standards. -

MOQ (Minimum Order Quantity)

– Definition: MOQ refers to the smallest quantity of a product that a supplier is willing to sell.

– Significance: Knowing the MOQ can help buyers plan their inventory and budget. It may affect purchasing decisions, especially for smaller businesses that may not require large quantities. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document sent to suppliers requesting a price quote for specific products or services.

– Significance: Using RFQs effectively can lead to better pricing and terms. It allows buyers to compare offers from multiple suppliers, ensuring they get the best deal. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a set of international rules that define the responsibilities of sellers and buyers in international transactions.

– Significance: Familiarity with Incoterms is essential for understanding shipping and delivery responsibilities, which can impact overall costs and timelines in cross-border transactions. -

Lead Time

– Definition: Lead time is the time it takes from placing an order to receiving the product.

– Significance: Understanding lead times helps buyers manage their production schedules and inventory levels effectively. It is crucial for industries that rely on just-in-time manufacturing practices. -

Certification Standards

– Definition: Certification standards refer to industry benchmarks that products must meet to ensure safety and performance.

– Significance: Being aware of relevant certification standards (such as ISO or CE marking) can help buyers choose high-quality heating elements that comply with safety regulations and industry best practices.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions, streamline their procurement processes, and enhance their operational efficiency when sourcing heat elements.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the heat elements Sector

Market Overview & Key Trends

The global heat elements market is experiencing a transformative phase driven by several key factors. Increased demand for efficient heating solutions across various industries, including manufacturing, automotive, and food processing, is propelling market growth. The rise of automation and smart technologies is influencing B2B sourcing trends, with manufacturers increasingly seeking advanced heating elements that integrate seamlessly with IoT devices for enhanced performance monitoring and energy management.

In particular, international buyers from Africa, South America, the Middle East, and Europe are prioritizing suppliers who can offer customized solutions tailored to specific industrial needs. This trend is significant for markets like Mexico and the UK, where regulatory frameworks increasingly emphasize energy efficiency and safety standards. Furthermore, the transition towards renewable energy sources is reshaping the landscape, as companies seek heating solutions compatible with sustainable practices.

Emerging technologies, such as advanced materials and 3D printing, are also making waves in the heat elements sector. These innovations not only enhance the performance and durability of heating elements but also enable manufacturers to reduce waste and streamline production processes. As a result, international buyers should stay informed about these technological advancements to make strategic sourcing decisions that align with their operational goals.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical consideration for B2B buyers in the heat elements sector. The environmental impact of manufacturing processes, particularly regarding carbon emissions and resource consumption, is under increasing scrutiny. Buyers are now prioritizing suppliers that adhere to sustainable practices and demonstrate a commitment to reducing their ecological footprint.

Ethical sourcing plays a vital role in this context. Companies are encouraged to collaborate with suppliers that maintain transparent supply chains and prioritize fair labor practices. Certifications such as ISO 14001 (Environmental Management) and other green certifications are becoming essential benchmarks for evaluating suppliers. Utilizing materials like recycled metals and eco-friendly insulation not only supports sustainability goals but also enhances a company’s brand reputation in a market increasingly focused on corporate responsibility.

Moreover, the adoption of energy-efficient heating elements can significantly reduce operational costs while minimizing environmental impact. By investing in technologies that optimize energy consumption, B2B buyers can achieve a dual benefit: lowering expenses and contributing to a more sustainable industrial ecosystem.

Brief Evolution/History

The evolution of heat elements can be traced back to the industrial revolution, where basic resistive heating technologies were developed to meet the growing demands of manufacturing. Early heating elements were primarily made from simple metallic materials, but as industries advanced, the need for more efficient and durable solutions led to innovations in material science.

In recent decades, the introduction of advanced materials such as silicon carbide and molybdenum disilicide has revolutionized the sector. These materials offer exceptional thermal resistance and longevity, making them ideal for high-temperature applications. The integration of digital technologies and automation has further transformed heat element manufacturing, allowing for greater precision and efficiency in industrial processes. Today, the focus is on sustainability and ethical sourcing, reflecting broader societal values and regulatory pressures shaping the future of the industry.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of heat elements

-

What criteria should I use to vet suppliers of heating elements?

When vetting suppliers, focus on their industry experience, reputation, and certifications. Look for suppliers who have a proven track record in your specific application area. Verify their compliance with international standards, such as ISO and CE certifications. It’s also beneficial to request customer references and case studies. Additionally, assess their financial stability and production capacity to ensure they can meet your demand, especially for larger orders. -

Can heating elements be customized to meet specific needs?

Yes, many suppliers offer customization options for heating elements. This can include variations in size, shape, material, and performance specifications tailored to your operational requirements. When discussing customization, provide detailed specifications and any relevant application data. Ensure that the supplier has the capability to produce prototypes for testing before placing a bulk order, which will help mitigate risks associated with performance issues. -

What are the typical minimum order quantities (MOQs) and lead times for heating elements?

MOQs for heating elements can vary significantly based on the supplier and the type of product. Generally, they can range from a few units for standard products to several hundred for customized solutions. Lead times can also differ, typically ranging from 2 to 12 weeks, depending on factors such as order complexity and supplier location. When negotiating, clarify these terms upfront to align your production schedules with their capabilities. -

What payment terms are common for international B2B transactions involving heating elements?

Payment terms vary by supplier, but common practices include partial payment upfront (20-50%) with the balance due upon delivery or after inspection. Some suppliers may also offer credit terms based on your business relationship and creditworthiness. It’s advisable to use secure payment methods, such as letters of credit or escrow services, to protect against potential disputes, especially when dealing with international transactions.

Illustrative Image (Source: Google Search)

-

How can I ensure quality assurance and certifications for heating elements?

To ensure quality, request detailed documentation of the heating elements, including material certifications, test reports, and compliance with relevant industry standards. Suppliers should provide quality assurance protocols, such as ISO 9001 certification. Additionally, consider arranging for third-party inspections during production or prior to shipment, especially for large or critical orders, to confirm that the products meet your specifications and quality expectations. -

What logistics considerations should I keep in mind when sourcing heating elements internationally?

Logistics are crucial in international sourcing. Confirm the supplier’s capability to manage shipping and customs clearance. Discuss shipping options (air, sea, or land) based on your budget and urgency. Understand the Incoterms (e.g., FOB, CIF) to clarify responsibilities for costs and risks during transport. Additionally, factor in potential delays due to customs regulations and ensure you have the necessary documentation for smooth transit. -

What steps should I take in case of a dispute with a supplier?

In the event of a dispute, start by reviewing the contract terms and any correspondence related to the issue. Open a dialogue with the supplier to attempt a resolution, as many disputes can be settled through communication. If necessary, escalate the issue to a formal mediation process. Ensure you document all interactions and agreements. For significant disputes, consider legal avenues, but this can be costly and time-consuming, so weigh the pros and cons carefully. -

How can I stay informed about market trends and innovations in heating elements?

Staying updated on market trends involves actively engaging with industry publications, attending trade shows, and participating in webinars or conferences focused on industrial heating technologies. Networking with industry professionals and joining relevant associations can also provide insights into emerging trends and innovations. Additionally, subscribe to newsletters from leading manufacturers and suppliers to receive updates on new products and technologies in the heating element sector.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for heat elements

In the rapidly evolving landscape of industrial heating solutions, strategic sourcing of heat elements is essential for optimizing operational efficiency and cost-effectiveness. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe must prioritize understanding the diverse materials and types of heating elements available. Key considerations include the specific temperature requirements, material compatibility, and energy efficiency of heating elements tailored to their unique industrial applications.

The value of strategic sourcing lies in its ability to enhance reliability and performance while reducing total ownership costs. By fostering relationships with reputable suppliers and staying informed about the latest advancements in heating technology, businesses can secure high-quality products that meet their operational demands.

Looking ahead, it is crucial for buyers to remain proactive in their sourcing strategies. Engaging with suppliers who demonstrate innovation and sustainability will not only ensure a competitive edge but also contribute to long-term success in their industries. As global markets continue to evolve, now is the time to invest in the right heating solutions that will drive efficiency and support growth in your operations. Take action today to secure your supply chain and elevate your business to new heights.