Master Electrical Plug Sourcing: Essential Insights for B2B

Introduction: Navigating the Global Market for electrical plug

In the ever-evolving landscape of global trade, the electrical plug stands as a crucial component in the connectivity and functionality of electronic devices. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek to optimize their sourcing strategies, understanding the intricacies of electrical plugs becomes paramount. These seemingly simple devices are not only essential for powering everyday appliances but also serve as a gateway to ensuring safety, compliance, and interoperability across diverse markets.

This comprehensive guide delves into the multifaceted world of electrical plugs, covering various types, materials, and manufacturing processes. It provides insights into quality control measures that ensure product reliability and safety, alongside practical advice on identifying reputable suppliers. Buyers will find detailed analyses of cost factors that influence purchasing decisions, as well as an overview of current market trends shaping the electrical plug industry.

By equipping B2B buyers with the knowledge to make informed sourcing decisions, this guide empowers organizations to navigate the complexities of international procurement. Whether you are in Colombia or the UK, understanding the specifications and standards of electrical plugs can lead to significant operational efficiencies and enhanced market competitiveness. Embrace the opportunity to enhance your sourcing strategy and ensure that your business is connected to the right products in a global marketplace.

Understanding electrical plug Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type A | Two flat parallel pins, ungrounded | North America, Central America, Japan | Pros: Widely available; Cons: Not suitable for high-power devices due to lack of grounding. |

| Type C | Two round pins, often used with adapters | Europe, South America, Asia | Pros: Compatible with many devices; Cons: May require adapters for non-European outlets. |

| Type D | Three large round pins in a triangular configuration | India, Nepal, some African countries | Pros: Sturdy and reliable; Cons: Limited compatibility outside specific regions. |

| Type G | Three rectangular pins in a triangular layout, fused | UK, Ireland, some Middle Eastern countries | Pros: High safety standards; Cons: Bulky design may not fit all sockets. |

| Type I | Two flat pins in a V-shape, with a grounding pin | Australia, New Zealand, China | Pros: Safe for high-power applications; Cons: Less common globally, may require adapters. |

Type A

Type A plugs are characterized by their two flat parallel pins and are primarily used in North America, Central America, and Japan. They are suitable for devices that do not require grounding, making them ideal for low-power applications like chargers and small appliances. When purchasing Type A plugs, buyers should consider the availability of compatible sockets in their target market, as well as the potential need for adapters when operating in regions with different plug types.

Type C

Type C plugs feature two round pins and are commonly used across Europe, South America, and parts of Asia. These plugs are versatile and can accommodate a wide range of devices, making them a popular choice for international trade. B2B buyers should evaluate the compatibility of Type C plugs with their product lines and consider the need for adapters when dealing with markets that use different plug types. The ease of integration into existing electrical systems is a significant purchasing factor.

Type D

The Type D plug is distinguished by its three large round pins arranged in a triangular configuration. It is primarily used in India, Nepal, and certain African countries. This plug type is known for its robustness and reliability, making it suitable for heavy-duty applications. Buyers should assess the regional demand for Type D plugs and ensure that their products are compatible with local electrical standards. Additionally, understanding local safety regulations is crucial for B2B transactions in these markets.

Type G

Type G plugs have three rectangular pins arranged in a triangular formation and are commonly found in the UK, Ireland, and some Middle Eastern countries. They are designed with a fuse for added safety, making them ideal for high-power devices. B2B buyers should consider the safety benefits of Type G plugs, especially for products intended for consumer use. However, the bulkiness of this plug type may pose challenges in terms of compatibility with compact devices, which should be evaluated during the purchasing process.

Type I

Type I plugs, featuring two flat pins in a V-shape along with a grounding pin, are widely used in Australia, New Zealand, and China. They are suitable for high-power applications, providing a safe connection for devices that require grounding. When considering Type I plugs, buyers should take into account their prevalence in target markets and the possibility of needing adapters for compatibility with other systems. The reliability and safety of Type I plugs make them a solid choice for B2B transactions involving high-demand electrical equipment.

Related Video: Types of Electrical Outlets & How They Work | Mr. Electric

Key Industrial Applications of electrical plug

| Industry/Sector | Specific Application of electrical plug | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Powering machinery and equipment | Ensures operational efficiency and reduces downtime | Compliance with local electrical standards and plug compatibility |

| Construction | Temporary power supply for tools and lighting | Enhances safety and productivity on job sites | Durability and weather resistance; local voltage requirements |

| Healthcare | Connecting medical devices and equipment | Critical for patient safety and operational reliability | Certification and compliance with health regulations |

| Hospitality | Powering appliances in hotels and restaurants | Improves guest experience and operational effectiveness | Aesthetic design and compatibility with existing infrastructure |

| Telecommunications | Equipment connectivity for network infrastructure | Supports reliable communication and service delivery | Scalability and adaptability to various network technologies |

Manufacturing

In the manufacturing sector, electrical plugs are essential for powering various machinery and equipment. They facilitate the connection of heavy-duty machines, ensuring seamless operations and minimizing downtime. For international B2B buyers, it is crucial to consider local electrical standards, such as voltage and frequency, to avoid compatibility issues. Additionally, sourcing plugs that meet safety certifications can prevent operational disruptions and enhance workplace safety.

Construction

Within the construction industry, electrical plugs are used for temporary power supply to tools and lighting systems on job sites. This application is vital for maintaining productivity and ensuring safety during construction activities. Buyers should prioritize sourcing durable plugs that can withstand harsh environmental conditions, such as moisture and dust. Furthermore, understanding local voltage requirements is critical to avoid equipment damage and ensure compliance with safety regulations.

Healthcare

In healthcare settings, electrical plugs connect medical devices and equipment, making them indispensable for patient care. The reliability of these connections is paramount, as any disruption could compromise patient safety. B2B buyers in this sector must ensure that the plugs they source comply with stringent health regulations and standards. Additionally, compatibility with various medical equipment types is essential to support the diverse technological landscape in healthcare facilities.

Hospitality

The hospitality industry relies heavily on electrical plugs for powering appliances in hotels, restaurants, and other establishments. These plugs enhance guest experiences by ensuring that amenities such as air conditioning, lighting, and kitchen equipment operate smoothly. Buyers should consider the aesthetic design of plugs to match the interior decor while also ensuring compatibility with existing electrical infrastructure. Additionally, energy-efficient options can provide long-term cost savings for businesses.

Telecommunications

In telecommunications, electrical plugs are crucial for connecting equipment that supports network infrastructure, including routers and switches. Reliable connectivity is essential for maintaining communication services and ensuring customer satisfaction. B2B buyers should focus on sourcing plugs that offer scalability to adapt to evolving network technologies. Furthermore, understanding the specific electrical requirements of different telecommunications equipment will ensure seamless integration and optimal performance.

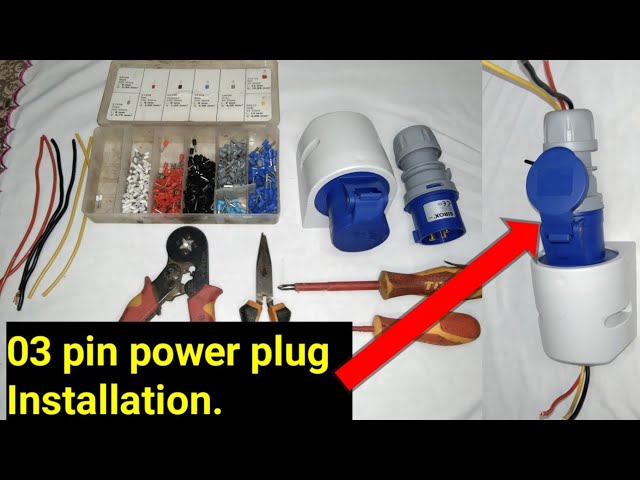

Related Video: ANDELI Industrial Plug Installation And Use Demonstration

Strategic Material Selection Guide for electrical plug

When selecting materials for electrical plugs, it is essential to consider various factors that influence performance, durability, and compliance with international standards. Below is an analysis of four common materials used in electrical plug manufacturing, highlighting their properties, advantages, disadvantages, and implications for international B2B buyers.

Polyvinyl Chloride (PVC)

Key Properties:

PVC is a widely used thermoplastic that offers excellent insulation properties and resistance to moisture, chemicals, and abrasion. It can withstand temperatures ranging from -15°C to 60°C, making it suitable for various environments.

Pros & Cons:

PVC is cost-effective and easy to mold, which simplifies manufacturing processes. However, it can become brittle over time, especially when exposed to UV light or extreme temperatures, potentially leading to failure in outdoor applications.

Impact on Application:

PVC is compatible with a range of electrical applications, particularly in residential and light commercial settings. However, its limitations in high-temperature environments may restrict its use in industrial applications.

Considerations for International Buyers:

Buyers in regions like Africa and South America should ensure that PVC plugs comply with local electrical safety standards, such as IEC 60884-1. Understanding the environmental regulations regarding PVC use is also crucial, as some countries are moving towards more sustainable alternatives.

Thermoplastic Elastomers (TPE)

Key Properties:

TPE combines the properties of rubber and plastic, offering excellent flexibility, resilience, and temperature resistance (typically from -40°C to 100°C). It also provides good electrical insulation.

Pros & Cons:

The primary advantage of TPE is its durability and ability to maintain performance across a wide temperature range. However, TPE can be more expensive than traditional plastics and may complicate the manufacturing process due to its unique properties.

Impact on Application:

TPE is particularly suitable for applications requiring flexibility, such as in portable electrical devices. Its resistance to wear and tear makes it ideal for plugs used in dynamic environments.

Considerations for International Buyers:

Buyers should verify that TPE materials meet relevant standards like ASTM D624 for rubber properties. Additionally, understanding the supply chain for TPE in regions like Europe is essential, as sourcing can impact costs.

Polycarbonate (PC)

Key Properties:

Polycarbonate is a high-performance thermoplastic known for its impact resistance and transparency. It can withstand temperatures from -40°C to 120°C and offers good electrical insulation properties.

Pros & Cons:

The durability of polycarbonate makes it suitable for high-stress applications, while its transparency allows for visual inspection of internal components. However, it is more expensive than PVC and can be challenging to process due to its high melting point.

Impact on Application:

PC is ideal for industrial plugs that require high durability and resistance to impact. Its ability to function in extreme temperatures makes it suitable for outdoor applications.

Considerations for International Buyers:

Compliance with standards such as UL 94 for flammability is essential. Buyers should also consider the sourcing of polycarbonate, as availability may vary between regions, impacting lead times and costs.

Metal (e.g., Brass or Copper)

Key Properties:

Metals like brass and copper are often used for electrical contacts due to their excellent conductivity and durability. They can handle high temperatures and pressures, making them suitable for heavy-duty applications.

Pros & Cons:

Metal contacts ensure reliable electrical connections and longevity. However, they can be susceptible to corrosion, especially in humid environments, which may require additional coatings or treatments.

Impact on Application:

Metals are commonly used in industrial plugs where high current and durability are required. Their performance can be significantly affected by environmental conditions, necessitating careful selection based on application.

Considerations for International Buyers:

Understanding corrosion resistance standards, such as ASTM B117 for salt spray testing, is crucial for ensuring longevity in various environments. Buyers should also be aware of local regulations regarding the use of metals in electrical applications.

Summary Table

| Material | Typical Use Case for electrical plug | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyvinyl Chloride (PVC) | Residential and light commercial | Cost-effective and easy to mold | Can become brittle over time | Low |

| Thermoplastic Elastomers (TPE) | Portable electrical devices | Excellent flexibility and durability | More expensive and complex manufacturing | Medium |

| Polycarbonate (PC) | Industrial plugs | High impact resistance and durability | Higher cost and challenging processing | High |

| Metal (Brass/Copper) | Heavy-duty industrial applications | Reliable electrical connections | Susceptible to corrosion | Medium |

This guide provides a strategic overview of material selection for electrical plugs, tailored for international B2B buyers. Understanding these materials’ properties and implications will facilitate informed purchasing decisions that align with regional standards and application requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for electrical plug

The manufacturing process for electrical plugs involves several critical stages, each ensuring that the final product meets safety, functionality, and regulatory standards. For international B2B buyers, understanding these processes and the accompanying quality assurance protocols is essential for making informed procurement decisions.

Manufacturing Processes

1. Material Preparation

The first step in the manufacturing process is the preparation of materials. This typically involves selecting high-quality raw materials such as thermoplastic for the casing and copper for the conductors. Buyers should ensure that suppliers source materials compliant with international standards, such as IEC 60884 for electrical plugs.

- Key Techniques:

- Material Testing: Conducting tests for electrical conductivity and thermal resistance to ensure the materials meet specifications.

- Supplier Verification: Requesting certifications for materials from suppliers to confirm they meet necessary quality and safety standards.

2. Forming

After material preparation, the next stage is forming, where the raw materials are shaped into the components of the plug. This includes the manufacturing of prongs, casings, and internal components.

- Key Techniques:

- Injection Molding: Commonly used for producing plastic casings, ensuring precise dimensions and surface finishes.

- Stamping: Utilized for metal parts, ensuring uniformity and efficiency in prong production.

3. Assembly

In the assembly stage, the various components are brought together. This involves the insertion of prongs into the casing and the connection of internal wiring.

- Key Techniques:

- Automated Assembly Lines: These can enhance efficiency and reduce human error, which is vital for maintaining quality.

- Manual Assembly: In certain cases, especially for complex designs, skilled labor may be used to ensure precision.

4. Finishing

The finishing stage includes quality checks and surface treatments. This step is crucial for ensuring the durability and aesthetic appeal of the plugs.

- Key Techniques:

- Surface Treatment: Processes such as plating or coating may be applied to enhance corrosion resistance.

- Final Inspection: Visual and functional checks are conducted to confirm that the plugs meet design specifications.

Quality Assurance

Quality assurance (QA) in the manufacturing of electrical plugs is integral to ensuring safety and compliance with international standards. For B2B buyers, understanding the QA processes can help mitigate risks associated with product failures.

Relevant International Standards

- ISO 9001: This standard focuses on quality management systems and is crucial for ensuring that the manufacturing processes are consistent and continuously improved.

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

- API Standards: Relevant for plugs used in industrial applications, ensuring they meet specific operational criteria.

Quality Control Checkpoints

Quality control (QC) checkpoints are established throughout the manufacturing process to identify and address defects early.

- Incoming Quality Control (IQC): Involves checking raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing process to ensure that any deviations from standards are corrected immediately.

- Final Quality Control (FQC): Comprehensive testing of the finished products to ensure they meet all regulatory and quality requirements.

Common Testing Methods

B2B buyers should be aware of the common testing methods employed in the QC process:

- Electrical Testing: Verifying insulation resistance, dielectric strength, and current-carrying capacity.

- Mechanical Testing: Assessing the physical robustness of the plug through stress tests and drop tests.

- Environmental Testing: Ensuring the plugs can withstand various environmental conditions, such as humidity and temperature extremes.

Verifying Supplier Quality Control

To ensure that suppliers maintain high standards of quality assurance, B2B buyers can take several steps:

- Supplier Audits: Conducting on-site audits to evaluate the manufacturing processes, QC measures, and overall compliance with international standards.

- Quality Reports: Requesting detailed reports from suppliers that outline their QC processes, testing results, and any corrective actions taken.

- Third-Party Inspections: Engaging third-party inspection services to conduct independent evaluations of the products before shipment.

Quality Control Nuances for International Buyers

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, it is crucial to understand the nuances of quality control that may vary by region:

- Regulatory Differences: Different countries may have unique regulatory requirements for electrical products. It is essential to verify that suppliers are compliant with local regulations in addition to international standards.

- Cultural Considerations: Understanding cultural differences in business practices can facilitate better communication with suppliers and ensure smoother transactions.

- Logistics and Supply Chain: Consider the logistics involved in shipping products internationally. Ensure that suppliers have robust supply chain management practices to avoid delays and ensure product integrity upon arrival.

By familiarizing themselves with the manufacturing processes and quality assurance protocols for electrical plugs, international B2B buyers can make informed decisions, mitigate risks, and establish reliable supplier relationships.

Related Video: 3 Pin Plug Manufacturing Process || JPI High Quality Three pin Shoe | Electric Plug Manufacturing |

Comprehensive Cost and Pricing Analysis for electrical plug Sourcing

Understanding the cost structure and pricing dynamics for electrical plug sourcing is crucial for international B2B buyers, especially in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis will break down the primary cost components and pricing influencers, offering actionable insights for buyers.

Cost Components

-

Materials: The cost of raw materials, including plastics, metals, and insulation components, typically represents a significant portion of the total cost. Prices can fluctuate based on market conditions and sourcing regions.

-

Labor: Labor costs vary widely depending on the location of manufacturing. Countries with lower wage structures may offer competitive pricing, but it’s essential to balance this with quality and compliance standards.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and administrative expenses. Efficient production processes can help mitigate these costs.

-

Tooling: Initial tooling costs can be substantial, especially for customized plugs. Buyers should consider whether to share tooling expenses with suppliers or absorb them entirely.

-

Quality Control (QC): Implementing stringent QC measures is vital for ensuring product reliability. While this incurs additional costs, it can prevent costly returns and reputational damage.

-

Logistics: Shipping and handling costs can vary significantly depending on the Incoterms agreed upon and the distance from the supplier. Buyers should factor in both domestic and international shipping costs.

-

Margin: Suppliers will typically add a profit margin to their costs, which can vary based on competition, demand, and supplier reputation.

Price Influencers

-

Volume/MOQ: Minimum Order Quantities (MOQs) can greatly influence pricing. Higher order volumes usually lead to discounts, while smaller orders may incur higher per-unit costs.

-

Specifications/Customization: Customized plugs tailored to specific requirements will generally cost more than standard models. Buyers should evaluate if customization is necessary for their application.

-

Materials: The choice of materials not only affects the cost but also the durability and compliance of the product. Higher quality materials may lead to higher upfront costs but can offer long-term savings.

-

Quality/Certifications: Products that meet international standards and certifications may cost more upfront but are often more reliable and can reduce costs related to compliance and returns.

-

Supplier Factors: Supplier reputation, reliability, and historical performance can impact pricing. Established suppliers may charge a premium due to their proven track record.

-

Incoterms: The chosen Incoterms can significantly affect total costs. Buyers should be clear about who bears the risks and costs at each stage of transportation to avoid unexpected expenses.

Buyer Tips

-

Negotiation: Leverage your purchasing power by negotiating terms that benefit both parties. Don’t hesitate to ask for better pricing based on volume commitments or long-term partnerships.

-

Cost-Efficiency: Assess the Total Cost of Ownership (TCO) rather than just the initial price. Consider factors like longevity, energy efficiency, and maintenance needs.

-

Pricing Nuances: Be aware of pricing trends in different regions. For instance, European manufacturers may have stricter regulatory costs, while suppliers in Africa or South America may offer lower labor costs.

-

Quality Assurance: Invest in suppliers who provide quality assurance and certifications. This will save costs associated with defects and returns in the long run.

-

Local Partnerships: Consider partnering with local distributors who understand the market nuances and can provide insights on cost-effective sourcing.

Disclaimer

Prices can vary widely based on market conditions, supplier negotiations, and specific buyer requirements. Always seek multiple quotations and conduct thorough due diligence to ensure you are making informed purchasing decisions.

Spotlight on Potential electrical plug Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘electrical plug’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for electrical plug

When sourcing electrical plugs for B2B transactions, understanding critical technical properties and industry terminology is essential for making informed decisions. Here’s a breakdown of the key specifications and terminology that international buyers, particularly from Africa, South America, the Middle East, and Europe, should consider.

Key Technical Properties

-

Material Grade

– Electrical plugs are typically made from thermoplastic, thermosetting plastic, or metal. The choice of material affects durability, heat resistance, and electrical conductivity. For instance, high-grade thermoplastics provide better insulation and resistance to impact, making them ideal for industrial applications. Selecting the right material ensures compliance with safety standards and enhances product longevity. -

Current Rating

– This specification indicates the maximum current (in amperes) that the plug can safely carry. It is crucial for ensuring that the plug can handle the electrical load without overheating or failing. Buyers should match the current rating of the plug with the devices it will power to prevent electrical hazards. -

Voltage Rating

– Voltage rating signifies the maximum voltage the plug can handle. It’s important for compatibility with the electrical systems in different countries. For example, plugs used in Europe typically operate at 230V, whereas those in the USA operate at 120V. Understanding voltage ratings helps buyers avoid purchasing plugs that are incompatible with their local electrical systems. -

Pin Configuration

– The arrangement and size of the pins vary by region (e.g., Type A, Type C). Different countries have specific standards for pin shapes and sizes, which directly affects compatibility with electrical outlets. Buyers should be aware of the pin configuration required in their target markets to ensure usability. -

Tolerance Levels

– Tolerance refers to the permissible limits of variation in dimensions and performance characteristics of the plug. High tolerance levels ensure a snug fit in sockets, which is vital for safety and effective electrical connection. Inaccurate tolerances can lead to loose connections, potentially causing electrical fires. -

Certifications and Compliance

– Certifications such as CE (Europe), UL (USA), and SABS (South Africa) indicate that the plugs meet specific safety and performance standards. Compliance with these standards not only ensures product safety but also enhances marketability in different regions. Buyers should always verify that the plugs they intend to purchase are certified for their respective markets.

Common Trade Terms

- OEM (Original Equipment Manufacturer)

– This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking to source plugs that will be branded under their name or incorporated into their products.

Illustrative Image (Source: Google Search)

-

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is vital for budgeting and inventory management. Buyers should negotiate MOQs to ensure that they can meet their operational needs without overcommitting resources. -

RFQ (Request for Quotation)

– An RFQ is a document that a buyer sends to suppliers to solicit price quotes for specific products. It is a key step in the procurement process, allowing buyers to compare prices and terms before making purchasing decisions. -

Incoterms (International Commercial Terms)

– These are a series of pre-defined commercial terms published by the International Chamber of Commerce, which clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms helps buyers manage shipping costs, risk, and logistics more effectively. -

Lead Time

– This refers to the time it takes from placing an order to receiving the goods. Knowing the lead time is essential for inventory planning and ensuring that production schedules are met. Buyers should factor in lead times when negotiating contracts and placing orders. -

Warranty and Return Policy

– Warranty conditions and return policies outline the terms under which a product can be returned or replaced. Familiarity with these policies is essential for risk management and ensuring product satisfaction.

By grasping these technical properties and industry terms, international B2B buyers can navigate the complexities of sourcing electrical plugs more effectively, ensuring compliance with regional standards and enhancing operational efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the electrical plug Sector

Market Overview & Key Trends

The electrical plug market is witnessing significant transformation driven by several global factors. The surge in renewable energy adoption, particularly in Africa and South America, is fostering demand for efficient and sustainable electrical solutions. Additionally, the increasing penetration of electric vehicles (EVs) across Europe and the Middle East is reshaping plug design and compatibility standards, creating a need for innovation among suppliers.

Emerging B2B tech trends include the integration of smart technology into electrical plugs, facilitating connectivity and energy management. International buyers are increasingly looking for suppliers that offer IoT-enabled products, which can enhance energy efficiency and provide real-time data analytics. Furthermore, there is a growing emphasis on modular design, allowing businesses to customize solutions based on specific operational requirements, particularly important in diverse markets like Colombia and the UK.

Market dynamics are also influenced by regulatory changes aimed at improving electrical safety and environmental standards. For instance, compliance with the International Electrotechnical Commission (IEC) standards is becoming essential for suppliers targeting international markets. Buyers should keep an eye on evolving regulations that may affect sourcing decisions, ensuring they partner with manufacturers who are proactive in compliance and innovation.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a cornerstone of business strategy in the electrical plug sector. The environmental impact of electrical components, especially in terms of energy consumption and material sourcing, is under increasing scrutiny. Buyers are encouraged to prioritize suppliers who employ eco-friendly materials, such as recycled plastics and biocompatible compounds, which significantly reduce the carbon footprint associated with manufacturing.

Moreover, ethical sourcing is crucial for maintaining brand integrity and consumer trust. Suppliers that adhere to fair labor practices and transparency in their supply chains are increasingly favored. Certifications such as ISO 14001 (Environmental Management) and the Responsible Business Alliance (RBA) code of conduct provide assurance to buyers about the ethical practices of their suppliers.

Investing in ‘green’ certifications not only enhances a company’s reputation but can also lead to cost savings through energy-efficient product designs. Buyers should actively seek suppliers who can demonstrate their commitment to sustainability through certifications and detailed sustainability reports, fostering a long-term partnership that aligns with global sustainability goals.

Brief Evolution/History

The electrical plug has evolved significantly since its inception in the late 19th century. Initially designed for basic connectivity, the modern plug has adapted to meet the growing demands for safety, efficiency, and interoperability. The introduction of standardized plug types, such as Type C in Europe and Type N in Brazil, has facilitated international trade and consumer convenience.

In recent years, the evolution has accelerated with the shift towards smart technologies and renewable energy solutions. This transition is not only reshaping product designs but also influencing supply chain dynamics, as businesses now seek suppliers who can provide innovative, sustainable solutions. The historical trajectory of the electrical plug reflects broader trends in technology and environmental awareness, making it a pivotal component in the global push towards a more connected and sustainable future.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of electrical plug

-

What criteria should I use to vet potential suppliers for electrical plugs?

When vetting suppliers, prioritize their certifications (e.g., ISO, CE, UL) to ensure compliance with international safety standards. Verify their production capacity and reliability by reviewing client testimonials and case studies. It’s also beneficial to assess their financial stability and experience in exporting to your region. Conducting site visits or audits can provide further assurance of their operational capabilities and quality control processes. -

Can I customize electrical plugs to meet specific requirements?

Yes, many manufacturers offer customization options for electrical plugs. This may include variations in design, voltage specifications, and material selection. When discussing customization, ensure you clearly communicate your needs and verify the supplier’s ability to accommodate these requirements without compromising safety standards. Always request samples to evaluate the quality of the customized product before placing a bulk order. -

What are the typical minimum order quantities (MOQs) and lead times for electrical plugs?

MOQs can vary significantly by supplier and product type, often ranging from 1,000 to 10,000 units for electrical plugs. Lead times typically depend on the complexity of the order and the supplier’s production capacity, generally falling between 4 to 12 weeks. To avoid delays, discuss your requirements upfront and ensure that the supplier can meet your delivery timelines, especially if you have specific project deadlines. -

What payment terms should I expect when sourcing electrical plugs internationally?

Payment terms can vary; however, most suppliers will request a deposit (usually 30-50%) before production, with the balance due upon completion or prior to shipping. Common payment methods include wire transfers, letters of credit, and online payment platforms. It’s essential to negotiate favorable terms that protect your interests and consider using escrow services for large transactions to mitigate risk. -

How can I ensure quality assurance and compliance with certifications?

Request copies of the relevant certifications from your supplier to confirm compliance with international standards. Implement a quality assurance process that includes pre-production samples, in-line inspections, and final audits. Consider third-party quality control services to conduct inspections at various stages of production, ensuring that the products meet your specifications and international safety standards. -

What logistics considerations should I keep in mind when importing electrical plugs?

Logistics can significantly impact your supply chain. Ensure you understand the shipping methods available (air, sea, or land) and choose the one that aligns with your budget and timeline. Familiarize yourself with customs regulations in your country to avoid delays. Work with experienced freight forwarders who can handle documentation, tariffs, and import duties, ensuring a smooth transition through customs. -

How should I handle disputes with suppliers?

To manage disputes effectively, establish clear terms and conditions in your contract that outline responsibilities, quality standards, and recourse options. Maintain open communication with your supplier to address issues promptly. If a dispute arises, consider mediation or arbitration as alternatives to litigation, as they can be more cost-effective and faster. Always document communications and agreements to support your position if necessary. -

What are the common challenges in sourcing electrical plugs internationally, and how can I mitigate them?

Common challenges include varying safety standards, communication barriers, and logistics issues. To mitigate these, invest time in researching local regulations and standards for electrical plugs in your target market. Establish a strong line of communication with your supplier, possibly using bilingual staff if necessary. Lastly, maintain a flexible logistics strategy that accommodates potential delays or changes in shipping routes, ensuring you can adapt to unforeseen circumstances.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for electrical plug

In conclusion, strategic sourcing for electrical plugs is not just about cost savings; it’s about fostering long-term partnerships that drive innovation and enhance supply chain resilience. By prioritizing quality, compliance with international standards, and supplier reliability, B2B buyers can significantly reduce risks associated with procurement. International buyers from Africa, South America, the Middle East, and Europe should leverage local market insights and supplier capabilities to ensure a competitive edge.

Key takeaways include the importance of thorough supplier evaluation, the need for ongoing communication to adapt to changing market conditions, and the potential for sustainable sourcing practices that resonate with increasingly eco-conscious consumers. As you navigate the complexities of sourcing electrical plugs, consider establishing criteria that align with your business goals and values.

Looking ahead, the electrical plug market is poised for innovation driven by technology and sustainability trends. Now is the time to engage with suppliers who can offer not only competitive pricing but also cutting-edge solutions that meet your future needs. Take action today to secure partnerships that will empower your business in this evolving landscape.