Master Chiller Glycol Sourcing: Key Insights for B2B Buyers

Introduction: Navigating the Global Market for chiller glycol

Navigating the complexities of the global market for chiller glycol is essential for businesses aiming to optimize their cooling systems. Chiller glycol, a critical component in industrial cooling applications, enhances efficiency by lowering freezing points and improving heat transfer in various settings, from food processing to pharmaceuticals. Understanding the diverse types, materials, and manufacturing quality controls is vital for making informed procurement decisions.

This comprehensive guide delves into the multifaceted world of chiller glycol, offering insights into its various applications, including industrial and commercial uses. Buyers will find detailed information on the different types of chiller glycol, the materials used in their production, and the rigorous quality control processes that ensure reliability and performance. Additionally, the guide highlights reputable suppliers, pricing strategies, and market trends that are shaping the industry landscape.

By equipping international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, with actionable insights, this guide empowers them to make strategic sourcing decisions. Whether you’re based in Kenya, Saudi Arabia, or elsewhere, understanding the nuances of chiller glycol procurement will not only streamline your operations but also drive cost efficiencies and enhance product quality. Engage with this guide to unlock the potential of chiller glycol in your business today.

Understanding chiller glycol Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ethylene Glycol | High heat transfer efficiency, low freezing point | HVAC systems, food processing, chemical plants | Pros: Excellent cooling capacity; Cons: Toxicity concerns for food applications. |

| Propylene Glycol | Non-toxic, biodegradable, moderate freezing point | Food and beverage, pharmaceuticals, HVAC | Pros: Safe for food processing; Cons: Lower efficiency compared to ethylene glycol. |

| Water-Glycol Mixture | Customizable ratios for specific applications | Industrial chillers, HVAC systems | Pros: Flexible performance; Cons: Requires careful formulation to avoid inefficiencies. |

| Brine Solutions | High viscosity, effective at low temperatures | Ice rinks, refrigeration systems | Pros: Excellent for low-temp applications; Cons: Higher maintenance due to viscosity. |

| Glycol-Based Heat Transfer Fluids | Enhanced thermal properties and stability | Data centers, industrial processes | Pros: Optimized for specific thermal needs; Cons: Higher initial cost than standard glycol. |

Ethylene Glycol

Ethylene glycol is the most commonly used chiller glycol due to its high heat transfer efficiency and low freezing point. It is particularly suitable for HVAC systems, food processing, and chemical plants. When considering purchasing ethylene glycol, buyers should evaluate its toxicity, especially in applications involving food. While it offers superior cooling capabilities, regulatory compliance regarding its use in food-related environments is essential.

Propylene Glycol

Propylene glycol is a non-toxic alternative that is biodegradable, making it ideal for food and beverage applications, pharmaceuticals, and HVAC systems. Its moderate freezing point means it can be used in a variety of climates. Buyers should consider the lower heat transfer efficiency compared to ethylene glycol, but its safety profile often outweighs this drawback, particularly in sensitive applications.

Water-Glycol Mixture

A water-glycol mixture allows for customizable ratios, providing flexibility to meet specific cooling needs. This type is commonly utilized in industrial chillers and HVAC systems. Buyers should consider that achieving the right formulation is crucial, as improper ratios can lead to inefficiencies. The adaptability of this mixture makes it a popular choice for varying operational conditions.

Brine Solutions

Brine solutions, often composed of salt and water, are characterized by their high viscosity and effectiveness at low temperatures. They are primarily used in ice rinks and refrigeration systems. Buyers must be aware that while brine is excellent for low-temperature applications, its higher viscosity can lead to increased maintenance needs and potential pump wear.

Glycol-Based Heat Transfer Fluids

Glycol-based heat transfer fluids are engineered for enhanced thermal properties and stability, making them suitable for data centers and various industrial processes. They are designed to optimize thermal management in critical applications. While they can be more expensive than standard glycol options, the investment may be justified by improved performance and reliability in demanding environments. Buyers should assess their specific thermal needs and budget constraints when considering these fluids.

Key Industrial Applications of chiller glycol

| Industry/Sector | Specific Application of chiller glycol | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Temperature control in refrigeration systems | Ensures food safety and quality by maintaining precise temperatures during storage and processing | Look for glycol with food-grade certification and compatibility with existing systems. |

| Pharmaceutical | Reactor temperature control | Maintains optimal conditions for chemical reactions, ensuring product efficacy and safety | Verify glycol purity levels and compliance with industry regulations. |

| Automotive | Cooling in manufacturing processes | Enhances production efficiency by preventing overheating of machinery and tools | Assess the glycol’s thermal conductivity and viscosity at various temperatures. |

| Plastics and Polymers | Injection molding process cooling | Improves product quality and reduces cycle times, leading to cost savings | Choose a glycol that minimizes mold sweating and maximizes cooling efficiency. |

| Data Centers | Cooling systems for server equipment | Prevents overheating, ensuring uninterrupted operations and longevity of equipment | Consider glycol’s thermal stability and compatibility with cooling systems. |

Food Processing

In the food processing industry, chiller glycol is essential for maintaining the required low temperatures in refrigeration systems. This prevents bacterial growth and preserves the quality of food products. For international buyers, especially in regions with varying climate conditions like Africa and the Middle East, sourcing food-grade glycol that meets local health regulations is crucial. Additionally, buyers should ensure that the glycol is compatible with existing refrigeration systems to avoid costly retrofitting.

Pharmaceutical

Chiller glycol plays a vital role in pharmaceutical manufacturing, particularly in reactor temperature control. It ensures that chemical reactions occur under optimal conditions, which is critical for the efficacy and safety of drugs. Buyers in this sector must prioritize high-purity glycol that complies with stringent industry standards. Understanding the specific thermal requirements of their processes is essential for selecting the right glycol formulation.

Automotive

In the automotive industry, chiller glycol is used for cooling during various manufacturing processes, including machining and welding. It helps prevent overheating, which can lead to equipment failure and production downtime. For B2B buyers, particularly from regions like South America and Europe, it is important to evaluate the thermal conductivity and viscosity of the glycol to ensure it meets the demands of high-performance machinery. Additionally, sourcing glycol from reliable suppliers who can guarantee consistent quality is essential.

Plastics and Polymers

Chiller glycol is utilized in the injection molding process to control the temperature of molds, which is crucial for producing high-quality plastic parts. By maintaining the right temperature, manufacturers can reduce cycle times and improve product consistency. Buyers in this sector should focus on glycol formulations that minimize mold sweating and enhance cooling efficiency. Understanding the specific cooling requirements of their molds will aid in selecting the most effective glycol solution.

Data Centers

In data centers, chiller glycol is critical for cooling server equipment, preventing overheating, and ensuring the reliability of IT operations. The use of glycol in cooling systems enhances the thermal management of data centers, which is vital for maintaining performance and extending the lifespan of equipment. B2B buyers must consider the thermal stability of the glycol and its compatibility with existing cooling technologies. Additionally, sourcing from suppliers who can provide robust technical support is beneficial for optimizing system performance.

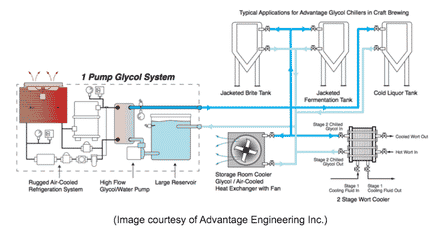

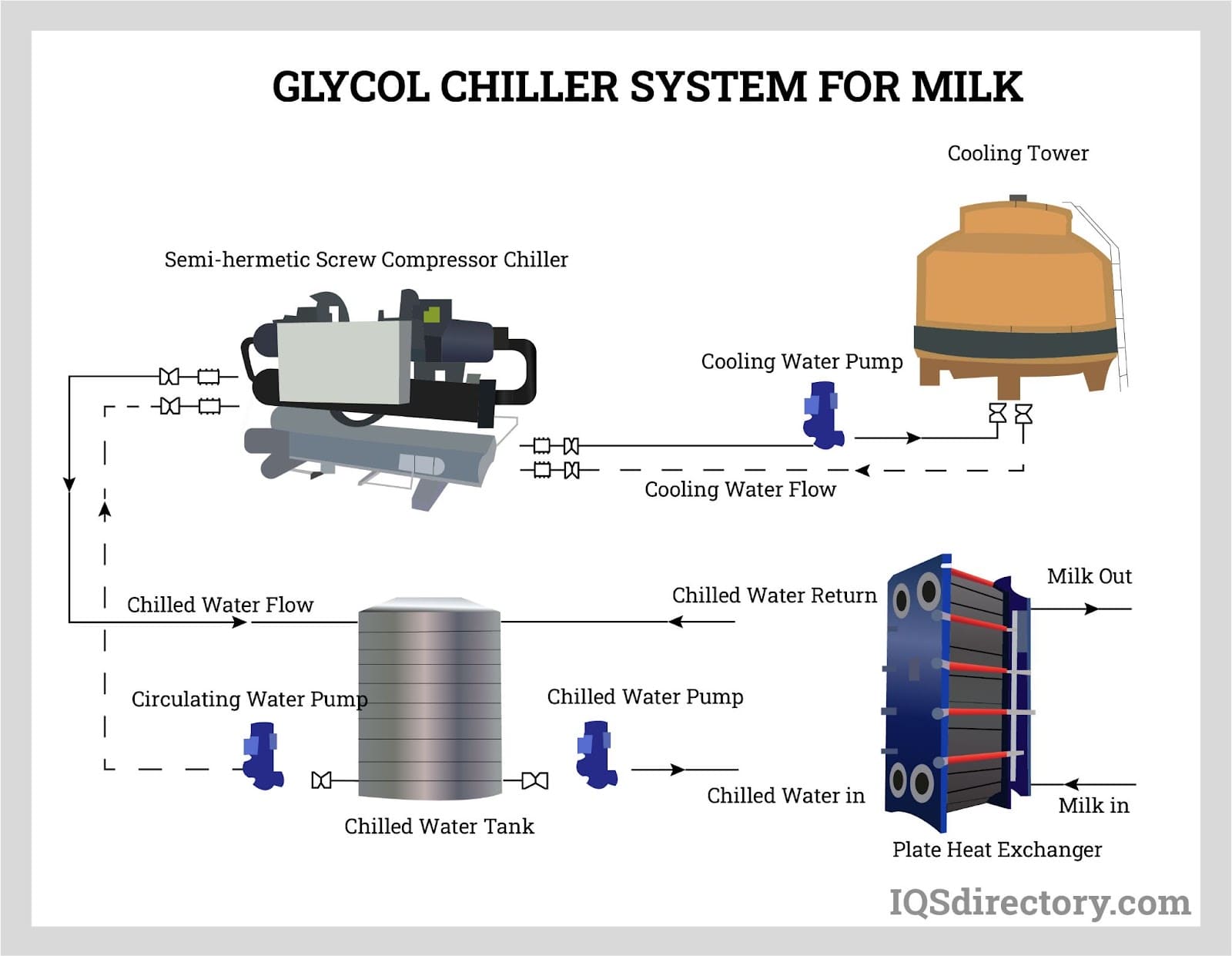

Related Video: Micromatic glycol chiller and system overview

Strategic Material Selection Guide for chiller glycol

When selecting materials for chiller glycol, international B2B buyers must consider various factors that can significantly impact performance, durability, and compliance with regional standards. Below is an analysis of four common materials used in chiller glycol applications, highlighting their properties, pros and cons, and specific considerations for buyers from regions such as Africa, South America, the Middle East, and Europe.

Ethylene Glycol

Key Properties:

Ethylene glycol has a low freezing point and a high boiling point, making it suitable for a wide range of operating temperatures. It is compatible with many metals and has good thermal conductivity.

Pros & Cons:

Ethylene glycol is relatively inexpensive and widely available, making it a cost-effective choice for many applications. However, it can be toxic, which raises safety concerns during handling and disposal. Additionally, it may require corrosion inhibitors to prevent damage to metal components.

Impact on Application:

Due to its low freezing point, ethylene glycol is often used in environments subject to freezing temperatures, particularly in colder climates. However, its toxicity limits its use in food processing applications.

Specific Considerations:

Buyers must ensure compliance with local regulations regarding the handling and disposal of toxic materials. In regions like Europe, adherence to REACH regulations is crucial.

Propylene Glycol

Key Properties:

Propylene glycol has a higher boiling point than ethylene glycol and is less toxic, making it a safer alternative. It exhibits good thermal stability and is hygroscopic, absorbing moisture from the air.

Pros & Cons:

The primary advantage of propylene glycol is its non-toxic nature, making it suitable for food and beverage applications. However, it is generally more expensive than ethylene glycol and may have lower thermal efficiency.

Impact on Application:

This material is ideal for applications in the food and pharmaceutical industries where safety is paramount. Its hygroscopic nature can lead to increased maintenance needs due to moisture absorption.

Specific Considerations:

International buyers should verify that propylene glycol meets local food safety standards. For instance, in the Middle East, certification from relevant health authorities may be required.

Glycerin

Key Properties:

Glycerin is a biodegradable and non-toxic substance with a high boiling point and excellent thermal stability. It is also hygroscopic and can serve as a good heat transfer fluid.

Pros & Cons:

Glycerin’s non-toxic nature makes it an environmentally friendly option. However, it is more viscous than other glycols, which can affect pump efficiency and increase energy costs.

Impact on Application:

Glycerin is suitable for applications requiring a non-toxic coolant, particularly in sensitive environments like food processing. Its higher viscosity may limit its use in systems requiring rapid fluid movement.

Specific Considerations:

Buyers in Europe and South America should check for compliance with environmental regulations regarding biodegradable materials. Certifications may be necessary for specific applications.

Calcium Chloride Solution

Key Properties:

Calcium chloride is highly effective at lowering the freezing point of water, making it an excellent choice for de-icing and cooling applications. It has good thermal conductivity and is less corrosive than other salts.

Pros & Cons:

This material is cost-effective and readily available. However, it can be corrosive to certain metals and may require additional inhibitors to protect equipment.

Impact on Application:

Calcium chloride is often used in industrial cooling systems and HVAC applications where low temperatures are required. Its corrosive nature necessitates careful material selection for system components.

Specific Considerations:

Buyers should consider local corrosion standards and ensure that materials used in conjunction with calcium chloride are compatible. In regions like Africa, where infrastructure may be less robust, this is particularly important.

Summary Table

| Material | Typical Use Case for chiller glycol | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Ethylene Glycol | HVAC systems, industrial cooling | Cost-effective and widely available | Toxicity raises safety concerns | Low |

| Propylene Glycol | Food and beverage processing | Non-toxic and safe for sensitive applications | Higher cost and lower thermal efficiency | Med |

| Glycerin | Environmentally sensitive applications | Biodegradable and non-toxic | Higher viscosity may increase energy costs | Med |

| Calcium Chloride Solution | Industrial cooling and de-icing | Highly effective at lowering freezing point | Corrosive to certain metals | Low |

This strategic material selection guide should assist international B2B buyers in making informed decisions regarding chiller glycol, ensuring compliance with local regulations while optimizing performance and cost-effectiveness.

In-depth Look: Manufacturing Processes and Quality Assurance for chiller glycol

The manufacturing of chiller glycol involves a series of critical processes and quality assurance measures that ensure the final product meets the necessary performance and safety standards. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these processes is essential for making informed purchasing decisions.

Manufacturing Processes for Chiller Glycol

1. Material Preparation

The first step in the manufacturing process is the selection and preparation of raw materials. Chiller glycol, typically composed of propylene glycol or ethylene glycol, requires high-purity formulations to ensure optimal thermal conductivity and freeze protection. Key considerations during this stage include:

– Sourcing Quality Raw Materials: Establish relationships with reputable suppliers who can provide certified, high-quality glycol. Look for suppliers who can furnish Material Safety Data Sheets (MSDS) and certificates of analysis (COA) for their products.

– Storage Conditions: Ensure that raw materials are stored in controlled environments to prevent contamination and degradation.

2. Forming

Once the raw materials are prepared, the next stage is the mixing and formulation of the glycol. This involves:

– Mixing: The raw materials are mixed in precise ratios using automated systems to ensure consistency. This stage may also include the addition of inhibitors to prevent corrosion and improve thermal stability.

– Temperature Control: Maintaining optimal temperature during mixing is crucial. Overheating can lead to chemical breakdown, while inadequate temperatures can result in incomplete mixing.

3. Assembly and Packaging

After the glycol is formulated, it undergoes assembly and packaging:

– Quality Control Checks: At this stage, intermediate products are sampled for quality checks. This includes viscosity testing and freeze point analysis.

– Packaging: Chiller glycol is typically packaged in bulk containers or smaller drums, depending on customer requirements. Packaging must be done in a manner that prevents contamination and ensures ease of transport.

4. Finishing

The final stage of the manufacturing process involves:

– Final Quality Assurance: Conducting thorough tests on the finished product to ensure it meets industry specifications.

– Labeling: Proper labeling is crucial for compliance and safety. Labels should include hazard information, usage instructions, and compliance certifications.

Quality Assurance Measures

Quality assurance (QA) is paramount in the production of chiller glycol to ensure that the product is safe, effective, and compliant with international standards.

Relevant International Standards

B2B buyers should be familiar with the following standards:

– ISO 9001: This standard focuses on quality management systems and is crucial for ensuring that manufacturing processes are consistently monitored and improved.

– CE Marking: For products sold within the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards.

– API Standards: For specific applications, especially in the oil and gas industry, adherence to American Petroleum Institute (API) standards is essential.

Quality Control Checkpoints

Quality control typically encompasses several key checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified quality standards.

– In-Process Quality Control (IPQC): During manufacturing, samples are taken at various stages to monitor consistency and performance.

– Final Quality Control (FQC): This final checkpoint involves comprehensive testing of the finished glycol product. Common tests include:

– Viscosity Testing: Ensures the glycol flows correctly under operating conditions.

– Freeze Point Analysis: Confirms the glycol will perform adequately in low-temperature conditions.

– Corrosion Testing: Assesses the glycol’s ability to protect equipment from corrosion.

Verifying Supplier Quality Control

B2B buyers can take several steps to verify a supplier’s quality control measures:

– Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control systems firsthand.

– Requesting Quality Reports: Suppliers should be able to provide detailed reports of their quality assurance processes, including test results and compliance certifications.

– Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality standards.

Navigating QC/CERT Nuances for International Buyers

International buyers, especially from regions such as Africa, South America, the Middle East, and Europe, should be aware of the following nuances:

– Regulatory Compliance: Different countries have varying regulations concerning chemical products. Ensure that the supplier is compliant with local and international regulations applicable to your market.

– Documentation: Maintain a thorough documentation trail for all quality assurance processes. This is crucial for compliance audits and in the event of disputes.

– Cultural Considerations: Understanding the cultural context of suppliers can help in negotiations and establishing strong business relationships.

Conclusion

Manufacturing chiller glycol is a complex process that necessitates meticulous attention to detail at every stage. B2B buyers must prioritize quality assurance to ensure that the products they source meet the required standards for safety and performance. By understanding the manufacturing processes and implementing effective quality control measures, buyers can make informed decisions that support their operational needs and enhance their overall business performance.

Related Video: Organic Fertilizer Manufacturing Process.

Comprehensive Cost and Pricing Analysis for chiller glycol Sourcing

To effectively analyze the costs associated with sourcing chiller glycol, it’s essential to break down the various components that contribute to the overall pricing structure. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of these elements to make informed purchasing decisions.

Cost Components

-

Materials: The primary component of chiller glycol pricing is the raw materials used in its production. Ethylene glycol and propylene glycol are the most common bases, and fluctuations in petrochemical prices can significantly impact costs. Buyers should monitor market trends for these materials to anticipate changes in pricing.

-

Labor: Labor costs vary by region and can influence the final price of chiller glycol. In countries with higher labor costs, such as those in Europe, the production expenses will be reflected in the pricing. Conversely, sourcing from regions with lower labor costs can provide more competitive pricing.

-

Manufacturing Overhead: This includes utilities, maintenance of equipment, and factory costs. Efficient manufacturing processes can help keep overhead low, but buyers should inquire about production practices to ensure they are not overpaying for these costs.

Illustrative Image (Source: Google Search)

-

Tooling: Initial setup costs for manufacturing equipment can be substantial, especially for custom formulations. Buyers seeking specialized glycol mixtures may face higher costs due to the necessary tooling and setup adjustments.

-

Quality Control (QC): Ensuring that the glycol meets industry standards requires robust QC processes. Suppliers who invest in quality assurance may charge higher prices, but the investment in quality can lead to lower operational issues and costs in the long run.

-

Logistics: Shipping and handling costs can significantly affect the total price, especially for international buyers. Factors such as distance, shipping methods, and local import duties should be considered in the logistics cost.

-

Margin: Suppliers will typically add a profit margin to cover their expenses and generate profit. Understanding the typical margin in the industry can help buyers gauge whether they are receiving a fair price.

Price Influencers

Several factors can influence the pricing of chiller glycol:

-

Volume/MOQ: Purchasing in larger quantities often leads to discounts. Buyers should negotiate minimum order quantities (MOQ) to optimize their costs.

-

Specifications/Customization: Custom formulations or specific quality certifications can increase costs. Buyers should clearly define their requirements to avoid unnecessary expenses.

-

Quality/Certifications: Higher quality glycol, especially those with certifications (e.g., ISO, NSF), often comes at a premium. While these certifications can ensure safety and performance, buyers should weigh the benefits against the additional costs.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a track record may charge more due to their reliability and service levels.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can affect the final price, as they determine who is responsible for shipping, insurance, and tariffs. Understanding these terms is crucial for cost calculation.

Buyer Tips

-

Negotiation: Always negotiate pricing and terms with suppliers. Leverage market insights and competitor quotes to secure better deals.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO) rather than just the initial purchase price. This includes maintenance, operational efficiency, and the potential costs of product failures.

-

Pricing Nuances: International buyers should be aware of currency fluctuations, international shipping costs, and local tariffs that can affect the final price of chiller glycol.

-

Research and Comparison: Conduct thorough research on different suppliers and their pricing structures. This can provide leverage in negotiations and help identify the best value.

By understanding these cost components, price influencers, and actionable tips, B2B buyers can navigate the complexities of sourcing chiller glycol more effectively, ensuring they make informed decisions that align with their operational needs and budget constraints.

Disclaimer: Prices are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with multiple suppliers to get accurate pricing tailored to your needs.

Spotlight on Potential chiller glycol Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘chiller glycol’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for chiller glycol

Key Technical Properties of Chiller Glycol

Understanding the essential technical properties of chiller glycol is crucial for international B2B buyers. These specifications not only determine the performance and efficiency of glycol chillers but also influence purchasing decisions and operational costs.

-

Material Grade: Chiller glycol is typically formulated with ethylene glycol or propylene glycol. The material grade affects thermal conductivity and viscosity, which are vital for efficient heat transfer. Buyers should ensure that the glycol meets industry standards suitable for their specific applications, particularly in sectors like food processing where propylene glycol is preferred due to its non-toxic nature.

-

Freezing Point: This property indicates the temperature at which the glycol will solidify. A lower freezing point allows for effective cooling in colder climates or applications. Buyers should select a glycol with a freezing point appropriate for their geographic location and operational conditions to avoid system failures.

-

Boiling Point: The boiling point of chiller glycol influences its ability to operate efficiently at high temperatures. It is essential for applications where high heat loads are present. Understanding the boiling point helps in determining whether the glycol will remain effective under varying operational conditions.

-

Viscosity: This refers to the fluid’s resistance to flow. The viscosity of chiller glycol affects the efficiency of the pumping system and the overall heat transfer performance. Buyers need to consider viscosity at both low and high temperatures, as it can impact energy consumption and system performance.

-

Corrosion Inhibition: Many chiller glycol formulations include additives to prevent corrosion within the cooling system. Understanding the corrosion resistance of a glycol is essential, especially in regions with aggressive water chemistry. Buyers should inquire about the specific inhibitors used and their compatibility with system materials.

-

Concentration Ratio: The concentration of glycol in the solution affects its thermal properties and freezing point. A higher concentration typically provides better freeze protection but may reduce heat transfer efficiency. Buyers should evaluate the balance required for their specific applications to optimize performance.

Common Trade Terminology

Familiarity with trade terminology is essential for effective communication and negotiation in B2B transactions involving chiller glycol.

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers source compatible glycol chillers and components that ensure optimal system performance.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to plan their inventory and budget effectively, especially in regions with fluctuating demand.

-

RFQ (Request for Quotation): An RFQ is a document used to solicit price proposals from suppliers for specific products or services. Buyers should prepare detailed RFQs to ensure they receive accurate and competitive pricing for chiller glycol, reflecting their operational needs.

-

Incoterms: These are international commercial terms that define the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms helps buyers understand shipping costs, risk management, and delivery responsibilities, which is particularly relevant when sourcing from different continents.

-

Lead Time: This term refers to the amount of time it takes for an order to be fulfilled after it is placed. Knowing lead times is vital for buyers to synchronize their supply chain and ensure timely availability of chiller glycol for their operations.

-

Certification: Many buyers require specific certifications (like ISO or ASTM) to ensure the quality and safety of the glycol. Understanding the importance of these certifications can assist buyers in selecting reliable suppliers and ensuring compliance with industry standards.

By familiarizing themselves with these properties and terms, international B2B buyers can make informed decisions, optimize their procurement processes, and enhance operational efficiency in their glycol cooling applications.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the chiller glycol Sector

Market Overview & Key Trends

The chiller glycol market is experiencing notable growth driven by increasing industrial applications and the rising demand for energy-efficient cooling solutions. Key global drivers include the expansion of industries such as food processing, pharmaceuticals, and automotive manufacturing, particularly in regions like Africa, South America, the Middle East, and Europe. As these regions develop, the need for reliable cooling systems that maintain product integrity and operational efficiency becomes paramount.

Emerging trends in B2B technology are shaping sourcing strategies for international buyers. Digital transformation, including the adoption of IoT and AI technologies, is revolutionizing chiller systems, enabling real-time monitoring and predictive maintenance. This shift not only enhances operational efficiency but also reduces downtime, making it a critical consideration for buyers. Furthermore, the trend towards modular and portable chiller systems is gaining traction, providing flexibility in various applications and allowing companies to scale operations swiftly.

International buyers should also be aware of the evolving regulatory landscape. Stricter environmental regulations are prompting manufacturers to innovate and offer products that comply with sustainability standards. As a result, sourcing from suppliers who prioritize compliance and invest in advanced technologies will be crucial for companies looking to maintain a competitive edge.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a non-negotiable aspect of business operations, particularly in the chiller glycol sector. The environmental impact of traditional glycol products, which often rely on petroleum-based materials, has led to increased scrutiny from consumers and regulators alike. Consequently, there is a growing demand for biodegradable and renewable alternatives, prompting suppliers to innovate in the formulation of chiller fluids.

Ethical sourcing practices are equally vital. Buyers are encouraged to partner with suppliers who demonstrate transparency in their supply chains and adhere to ethical labor practices. Certifications such as ISO 14001 for environmental management systems and NSF certifications for food-grade products serve as indicators of a supplier’s commitment to sustainability. By prioritizing these certifications, international buyers can ensure that their sourcing aligns with both environmental standards and corporate social responsibility objectives.

Investing in sustainable products not only mitigates environmental risks but can also enhance brand reputation and customer loyalty, particularly in regions where consumers are increasingly eco-conscious. As markets evolve, buyers who prioritize sustainability will likely see long-term benefits in both operational efficiency and market position.

Brief Evolution/History

The evolution of chiller glycol systems dates back to the early 20th century when refrigeration technology began to advance significantly. Initially, glycol was used primarily in the food and beverage industry for its antifreeze properties. Over the decades, the applications of chiller glycol expanded to various industrial sectors, including pharmaceuticals, chemical processing, and HVAC systems.

With the advent of modern environmental regulations in the late 20th century, the industry saw a shift towards more eco-friendly formulations. This transformation has continued into the present day, as manufacturers increasingly focus on developing biodegradable and sustainable glycol solutions. The ongoing evolution reflects not only technological advancements but also a broader commitment to sustainability and responsible sourcing practices within the B2B landscape.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of chiller glycol

-

What should I consider when vetting suppliers for chiller glycol?

When vetting suppliers, prioritize their industry experience, reputation, and production capabilities. Request references from previous clients and check online reviews. It’s also crucial to verify their certifications, such as ISO standards, which indicate compliance with international quality standards. Engage in direct communication to assess their responsiveness and willingness to customize solutions. For international transactions, ensure they have experience with export regulations and logistics in your region, particularly in Africa, South America, the Middle East, or Europe. -

Can chiller glycol be customized to meet specific requirements?

Yes, many suppliers offer customization options for chiller glycol formulations. This includes adjusting the concentration of glycol, additives for corrosion resistance, or specific temperature ranges. Communicate your specific needs clearly and request samples to test before committing to a larger order. Additionally, inquire about the supplier’s ability to scale production based on your requirements and whether they can accommodate custom labeling or packaging for branding purposes. -

What are typical minimum order quantities (MOQs) and lead times for chiller glycol?

MOQs can vary significantly based on the supplier, the formulation of glycol, and your location. Typically, you might find MOQs ranging from 200 to 1,000 liters. Lead times generally range from 2 to 6 weeks, depending on production schedules and shipping logistics. Always confirm these details upfront and ask about the potential for lower MOQs for trial orders or if you are willing to pay higher costs per liter for smaller quantities.

Illustrative Image (Source: Google Search)

-

What payment methods are commonly accepted by suppliers?

Suppliers typically accept various payment methods, including wire transfers, letters of credit, and sometimes digital payment platforms. For international transactions, a letter of credit is often preferred as it provides additional security for both parties. Ensure to discuss payment terms, including deposits and balances, as well as any currency exchange considerations. It’s also wise to establish a payment schedule that aligns with your project timelines and order quantities. -

How can I ensure quality assurance and certifications from suppliers?

Request documentation that verifies the supplier’s quality assurance processes and certifications, such as ISO 9001 or ISO 14001. Ask for material safety data sheets (MSDS) and test reports that detail the properties of the chiller glycol. Regular audits and inspections can also be arranged if you are placing large orders. Building a relationship with suppliers who have a transparent QA process will help ensure the product meets your specifications consistently. -

What logistics considerations should I keep in mind when sourcing chiller glycol?

Logistics for chiller glycol involve understanding shipping methods, costs, and timelines. Confirm whether the supplier offers shipping services or if you need to arrange your own logistics. Ensure that they are familiar with customs procedures in your country, particularly if you’re importing from regions like China or Europe. Additionally, consider the storage requirements upon arrival, as glycol needs to be stored in appropriate conditions to maintain its efficacy. -

How should I handle disputes or issues with suppliers?

Establish clear communication channels and a formal contract that outlines terms, delivery expectations, and quality standards. In the event of a dispute, document all correspondence and issues as evidence. Start by discussing the issue directly with the supplier to seek a resolution. If necessary, involve a third-party mediator or refer to the contract terms regarding dispute resolution. Understanding the legal framework for international trade in your region can also provide guidance on how to proceed. -

What are the environmental considerations when sourcing chiller glycol?

When sourcing chiller glycol, consider suppliers that adhere to environmental regulations and sustainability practices. Ask about the biodegradability of their products and any measures they take to minimize environmental impact during production. Suppliers with eco-friendly certifications can help ensure that your sourcing aligns with environmental standards. Additionally, inquire about disposal methods for used glycol to ensure compliance with local environmental laws and regulations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for chiller glycol

As the demand for efficient cooling solutions continues to grow across industries, understanding the strategic sourcing of chiller glycol becomes increasingly vital for international B2B buyers. Key takeaways emphasize the importance of selecting high-quality glycol solutions that not only enhance system performance but also ensure longevity and reliability in diverse environmental conditions. By leveraging strategic sourcing practices, buyers can optimize costs, mitigate supply chain risks, and secure a competitive advantage in the marketplace.

Value of Strategic Sourcing: Engaging with reliable suppliers, conducting thorough market research, and fostering long-term partnerships are essential strategies that can lead to significant cost savings and improved service delivery. As industries in Africa, South America, the Middle East, and Europe evolve, aligning sourcing strategies with technological advancements and sustainability goals will be crucial.

Looking ahead, international B2B buyers are encouraged to proactively explore innovative glycol solutions and engage with reputable suppliers to stay ahead of market trends. By prioritizing strategic sourcing, organizations can not only meet their operational needs but also contribute to a more sustainable future in the cooling industry. Take the initiative now to assess your sourcing strategies and ensure they align with your long-term business objectives.