Master the Selection of Types of Couplings for Optimal

Introduction: Navigating the Global Market for types of couplings

Industrial couplings are critical components in the machinery landscape, serving as the vital link between rotating shafts to ensure seamless power transmission. In today’s global market, understanding the various types of couplings—ranging from flexible to rigid, and fluid to magnetic—is essential for optimizing operational efficiency and minimizing downtime. This guide delves into the nuances of couplings, highlighting their importance across diverse industries, including manufacturing, energy, and automotive sectors.

B2B buyers from regions like Africa, South America, the Middle East, and Europe (including countries such as Spain and France) face unique challenges in sourcing the right couplings. This comprehensive resource covers essential topics such as types of couplings, materials used, manufacturing and quality control processes, and supplier selection criteria. Additionally, it addresses cost considerations and provides insights into the current market trends.

By leveraging this guide, international buyers can make informed sourcing decisions that align with their operational needs. With a focus on actionable insights and practical tips, it empowers businesses to enhance their procurement strategies, ensuring they select couplings that not only meet technical specifications but also provide long-term reliability and performance. Whether you are looking to upgrade existing systems or invest in new technology, understanding the landscape of couplings is the first step toward achieving operational excellence.

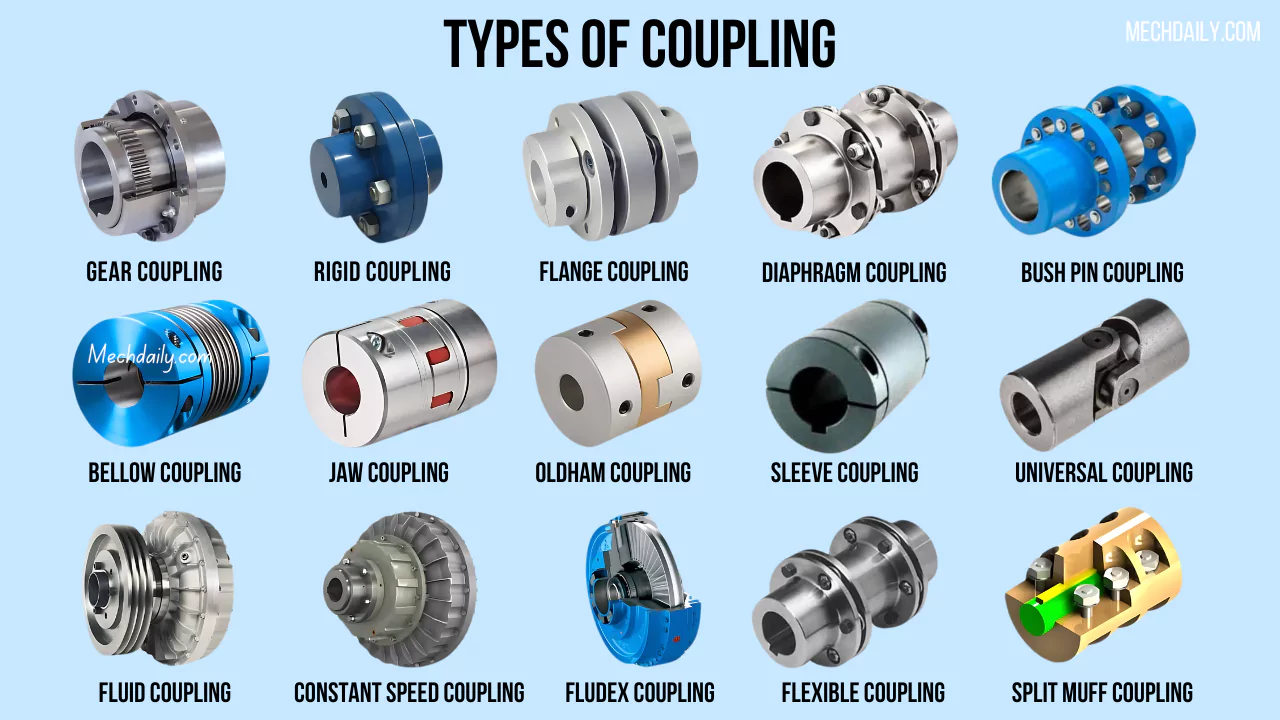

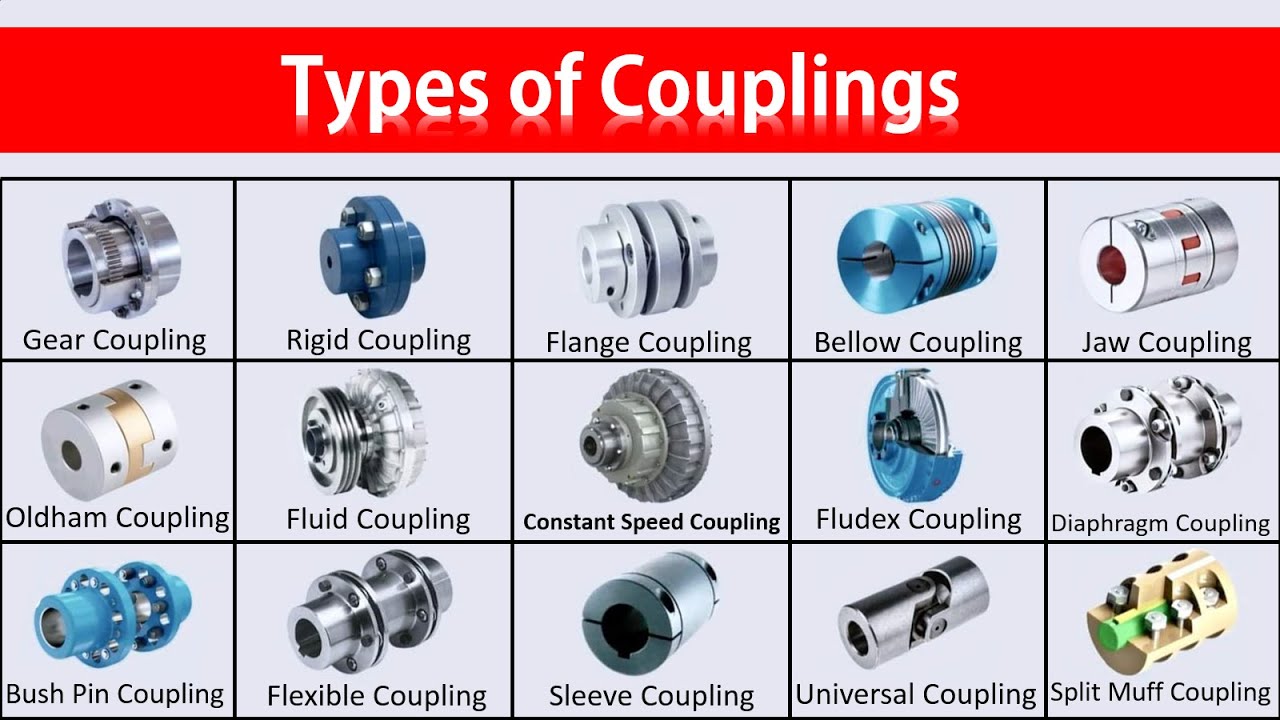

Understanding types of couplings Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flexible Coupling | Accommodates misalignment; absorbs shock and vibration | Pumps, compressors, turbines | Pros: Reduces wear, enhances lifespan. Cons: May require more maintenance. |

| Rigid Coupling | Requires precise alignment; no flexibility | Motor and generator connections | Pros: Simple design, cost-effective. Cons: Not suitable for misaligned shafts. |

| Fluid Coupling | Uses hydraulic fluid to transmit power; smooth operation | Heavy machinery, automotive applications | Pros: Reduces wear, protects against overloads. Cons: More complex and expensive. |

| Gear Coupling | Employs gear teeth for torque transmission; high strength | Heavy-duty applications, industrial machinery | Pros: High torque capacity. Cons: Limited to specific alignment. |

| Universal Coupling | Allows for angular misalignment; versatile design | Automotive driveshafts, agricultural machinery | Pros: Adaptable to various applications. Cons: Can be bulkier and more costly. |

Flexible Coupling

Flexible couplings are designed to accommodate angular, parallel, and axial misalignment between shafts. They are essential in applications such as pumps, compressors, and turbines where vibration reduction and shock absorption are critical. When purchasing, consider the specific type of flexible coupling (e.g., jaw, gear, or elastomeric) that best meets your operational needs, as each type offers unique advantages in terms of durability and maintenance requirements.

Rigid Coupling

Rigid couplings are used when shafts are perfectly aligned, making them suitable for applications like motor and generator connections. Their straightforward design often results in lower costs, but they lack the flexibility to accommodate any misalignment. Buyers should ensure that their equipment meets alignment specifications before opting for this type, as improper installation can lead to increased wear and potential failure.

Fluid Coupling

Fluid couplings use hydraulic fluid to transmit power, providing a smooth operation and excellent shock absorption. This type is commonly found in heavy machinery and automotive applications, where protecting components from overload is essential. While fluid couplings can be more complex and expensive, they offer significant benefits in terms of reducing wear and extending equipment lifespan, making them a worthwhile investment for high-demand applications.

Gear Coupling

Gear couplings utilize gear teeth to transmit torque, making them ideal for heavy-duty applications in industrial machinery. They provide high torque capacity and can handle significant loads, but they are limited to specific alignment conditions. Buyers should evaluate their torque requirements and ensure that the selected gear coupling aligns well with their operational parameters to maximize efficiency and reliability.

Universal Coupling

Universal couplings are versatile devices that allow for angular misalignment between shafts, making them suitable for various applications, including automotive driveshafts and agricultural machinery. Their adaptability is a significant advantage, but they can be bulkier and more costly than other coupling types. When considering a universal coupling, it’s essential to assess the space constraints and budget to ensure it aligns with your operational needs.

Related Video: 6 different coupling types explained by Coupling Tips

Key Industrial Applications of types of couplings

| Industry/Sector | Specific Application of types of couplings | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Connecting motors to conveyor systems | Ensures smooth operation and minimizes downtime | Material compatibility, load capacity, and maintenance requirements |

| Oil & Gas | Coupling pumps in drilling operations | Enhances efficiency and reliability under extreme conditions | Temperature ratings, corrosion resistance, and flexibility |

| Automotive | Power transmission in electric and hybrid vehicles | Improves energy efficiency and reduces emissions | Weight, size constraints, and alignment capabilities |

| Agriculture | Connecting machinery in irrigation systems | Increases operational efficiency and reduces wear | Durability, adaptability to environmental conditions, and cost-effectiveness |

| Mining | Coupling equipment in mineral processing plants | Enhances safety and performance in harsh environments | Resistance to shock loads, ease of installation, and serviceability |

Manufacturing

In the manufacturing sector, couplings are crucial for connecting motors to conveyor systems. This application ensures that power is effectively transmitted, allowing for continuous operation of assembly lines. The use of flexible couplings helps accommodate any misalignment that may occur due to thermal expansion or mechanical wear, thus minimizing downtime. Buyers in this sector should focus on sourcing couplings that offer high durability and low maintenance costs to enhance operational efficiency.

Oil & Gas

In the oil and gas industry, couplings are often used to connect pumps in drilling operations. This application demands couplings that can withstand extreme temperatures and pressures while providing reliable power transmission. The ability to absorb shock loads is also critical, as it protects equipment from damage during operation. Buyers should prioritize sourcing couplings with high corrosion resistance and the capability to operate under variable loads, ensuring long-term reliability in challenging environments.

Automotive

The automotive industry utilizes couplings for power transmission in electric and hybrid vehicles. These couplings play a vital role in enhancing energy efficiency and reducing emissions by ensuring optimal power transfer from the motor to the wheels. Buyers should consider lightweight materials that meet specific size constraints while maintaining performance standards. Additionally, compatibility with existing systems and alignment capabilities are key factors that influence sourcing decisions.

Agriculture

In agriculture, couplings are essential for connecting machinery in irrigation systems. This application helps to improve operational efficiency and reduce wear on equipment by allowing for slight misalignments without compromising performance. Buyers should look for couplings that are durable and adaptable to various environmental conditions, as agricultural machinery often operates in harsh settings. Cost-effectiveness is also a significant consideration, as farmers seek to maximize their return on investment.

Mining

In the mining sector, couplings are used to connect equipment in mineral processing plants. This application is critical for enhancing safety and performance in environments characterized by heavy loads and harsh conditions. Couplings that can resist shock loads and provide ease of installation are highly valued. Buyers should focus on sourcing products that are serviceable and designed for longevity, as equipment downtime can lead to substantial financial losses in mining operations.

Related Video: Types of couplings | Function of Coupling | Rigid coupling | Flexible coupling | Muff coupling

Strategic Material Selection Guide for types of couplings

When selecting materials for couplings, international B2B buyers must consider several factors, including the specific application requirements, environmental conditions, and regulatory compliance. Below, we analyze four common materials used in coupling manufacturing, focusing on their properties, advantages, disadvantages, and implications for global markets.

1. Steel

Key Properties:

Steel couplings offer high strength and durability, with excellent temperature and pressure ratings. They can withstand extreme conditions, making them suitable for heavy-duty applications.

Pros & Cons:

The primary advantage of steel is its robustness and ability to handle high torque loads. However, steel is susceptible to corrosion, particularly in humid or chemically aggressive environments, which can limit its lifespan unless adequately treated.

Impact on Application:

Steel couplings are ideal for applications involving heavy machinery, such as in the automotive and manufacturing sectors. However, they may not be suitable for corrosive media without protective coatings.

Considerations for International Buyers:

Buyers from regions like Africa and South America should ensure that steel couplings comply with local standards (e.g., ASTM or ISO). In Europe, adherence to DIN standards is crucial for market acceptance.

2. Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance, with moderate strength and temperature ratings. It is often used in applications where weight reduction is critical.

Pros & Cons:

The lightweight nature of aluminum is a significant advantage, especially in aerospace and automotive applications. However, its lower strength compared to steel can be a limitation in high-torque scenarios.

Impact on Application:

Aluminum couplings are suitable for applications where weight savings are essential, such as in portable machinery and vehicles. They are also compatible with a wide range of media, making them versatile.

Considerations for International Buyers:

Aluminum couplings must meet specific standards for quality and performance. Buyers in Europe should check for compliance with EN standards, while those in the Middle East may need to consider local regulations regarding material specifications.

3. Plastic (e.g., Nylon, Polypropylene)

Key Properties:

Plastic couplings are lightweight and resistant to corrosion and chemical attack. They have lower temperature and pressure ratings than metals but are often sufficient for many applications.

Pros & Cons:

The main advantage of plastic couplings is their excellent resistance to chemicals and moisture, making them ideal for use in harsh environments. However, they may not handle high torque loads as effectively as metal couplings.

Impact on Application:

Plastic couplings are commonly used in the food and beverage industry, as well as in chemical processing, where corrosion resistance is essential. They are also suitable for applications involving non-critical load-bearing.

Considerations for International Buyers:

Buyers should ensure that plastic couplings comply with food safety standards (e.g., FDA regulations in the U.S. or EU regulations in Europe). Additionally, understanding the specific chemical compatibility of the plastic material is crucial for applications in the chemical industry.

4. Composite Materials

Key Properties:

Composite couplings combine materials like fiberglass or carbon fiber with resin, providing high strength-to-weight ratios and excellent corrosion resistance.

Pros & Cons:

The key advantage of composites is their ability to perform well in extreme conditions while being lightweight. However, they can be more expensive and complex to manufacture compared to traditional materials.

Impact on Application:

Composite couplings are particularly beneficial in aerospace and advanced engineering applications where weight and strength are critical. They also offer good performance in corrosive environments.

Considerations for International Buyers:

International buyers should be aware of the certifications required for composite materials, as these can vary significantly between regions. Compliance with aerospace standards (e.g., AS9100) in Europe and the U.S. is often necessary for applications in that sector.

Summary Table

| Material | Typical Use Case for types of couplings | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery, automotive | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Aerospace, automotive | Lightweight | Lower strength than steel | Medium |

| Plastic | Food & beverage, chemical processing | Corrosion and chemical resistance | Limited torque capacity | Low |

| Composite | Aerospace, advanced engineering | High strength-to-weight ratio | Higher cost and manufacturing complexity | High |

This strategic material selection guide provides B2B buyers with essential insights into the characteristics and implications of various coupling materials, enabling informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for types of couplings

Manufacturing industrial couplings involves a series of well-defined processes and stringent quality assurance protocols. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these processes can help in making informed decisions and ensuring the reliability of the products procured. Below is a detailed overview of the manufacturing processes and quality assurance measures typically employed in the production of couplings.

Manufacturing Processes

The manufacturing of couplings generally follows several key stages: material preparation, forming, assembly, and finishing. Each stage involves specific techniques and technologies to ensure the final product meets industry standards.

1. Material Preparation

The choice of materials is crucial in coupling manufacturing. Common materials include:

- Steel: Often used for its strength and durability.

- Aluminum: Lightweight and corrosion-resistant, suitable for specific applications.

- Plastic: Used in lightweight or low-stress applications.

Key Techniques:

– Material Testing: Before production, raw materials undergo tensile and hardness testing to ensure they meet specifications.

– Cutting: Materials are cut to size using CNC machines or laser cutting for precision.

2. Forming

This stage involves shaping the raw materials into the desired coupling forms, which can vary widely based on the type of coupling being produced (e.g., rigid, flexible, fluid).

Key Techniques:

– Machining: Components are machined using lathes and milling machines to achieve precise dimensions and tolerances.

– Forging: For high-strength applications, components may be forged, which enhances the material’s properties.

– Casting: Some couplings are produced through casting, allowing for complex shapes and designs.

3. Assembly

The assembly process is critical, especially for multi-part couplings.

Key Techniques:

– Alignment and Fitting: Components are aligned and fitted together, often using jigs to ensure consistency.

– Welding/Bolting: Depending on the design, components may be welded or bolted together to create a robust coupling.

4. Finishing

Finishing processes enhance the coupling’s durability and aesthetic quality.

Key Techniques:

– Surface Treatment: Coatings such as galvanization or powder coating are applied to prevent corrosion.

– Polishing: Some applications may require polishing to reduce friction and improve appearance.

– Quality Check: Final inspections ensure that dimensions and surface finishes meet specified requirements.

Quality Assurance

Quality assurance in coupling manufacturing is essential to ensure reliability and compliance with international standards. Key aspects include adherence to relevant standards, quality control checkpoints, and testing methods.

Relevant International Standards

B2B buyers should be aware of the following standards that influence coupling quality:

- ISO 9001: A globally recognized quality management standard that emphasizes consistent quality and customer satisfaction.

- CE Marking: Indicates compliance with EU safety, health, and environmental protection standards.

- API Standards: Particularly relevant for couplings used in the oil and gas industry, ensuring they meet specific operational requirements.

Quality Control Checkpoints

Quality control processes are typically divided into several checkpoints:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before entering production.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, regular checks are performed to monitor dimensions and tolerances.

- Final Quality Control (FQC): Before shipping, finished couplings undergo thorough testing to ensure they meet quality standards.

Common Testing Methods

B2B buyers should be familiar with various testing methods used in the industry:

- Dimensional Inspection: Uses tools like calipers and micrometers to verify that components meet specified dimensions.

- Mechanical Testing: Involves tensile tests, impact tests, and fatigue tests to assess material strength and durability.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic or magnetic particle testing are employed to detect internal flaws without damaging the product.

Verifying Supplier Quality Control

For international B2B buyers, particularly those operating in diverse markets, verifying a supplier’s quality control processes is crucial. Here are some actionable steps:

- Supplier Audits: Conduct regular audits of suppliers to assess their manufacturing processes and quality control systems.

- Request Quality Reports: Suppliers should provide detailed quality assurance reports, including results from IQC, IPQC, and FQC.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures.

Quality Certification Nuances for International B2B Buyers

When sourcing couplings, buyers from different regions should be aware of specific certification requirements:

- Africa: Buyers should consider local standards that may differ from international ones, ensuring compliance with regional safety and performance expectations.

- South America: Many countries have unique import regulations; thus, certifications like ISO may be required for compliance with local market needs.

- Middle East: The Gulf Cooperation Council (GCC) often mandates specific quality standards for mechanical components, including couplings.

- Europe (e.g., Spain, France): Strict adherence to CE marking and other EU directives is essential for market entry, emphasizing the need for thorough documentation and quality assurance.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions that align with their operational needs and compliance requirements, ensuring the selection of high-quality couplings for their applications.

Related Video: What is Production? Types of Production, Factors of Production

Comprehensive Cost and Pricing Analysis for types of couplings Sourcing

Understanding the cost structure and pricing dynamics of industrial couplings is essential for international B2B buyers aiming to optimize their sourcing strategies. This analysis will break down the key cost components, price influencers, and actionable tips for buyers, particularly from regions like Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary cost driver for couplings is the raw materials used, which can vary significantly based on the type of coupling (e.g., rigid, flexible, fluid). Common materials include steel, aluminum, and various polymers. Buyers should consider the specific material properties required for their applications, as higher-grade materials often come at a premium.

-

Labor: Labor costs encompass the workforce involved in manufacturing and assembling the couplings. These costs can vary by region, with labor being more expensive in developed countries compared to emerging markets. Understanding the labor market dynamics can provide insights into potential cost savings.

-

Manufacturing Overhead: This includes costs associated with factory operations, such as utilities, maintenance, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs, which in turn can lower the overall pricing of couplings.

-

Tooling: Tooling costs refer to the investment in machinery and equipment necessary for production. Custom tooling for specialized couplings can increase costs, making it crucial for buyers to assess their needs carefully.

-

Quality Control (QC): Implementing stringent QC measures is vital for ensuring product reliability and performance. While this adds to the overall cost, it can prevent costly failures and downtime in the field.

-

Logistics: Transportation costs, including shipping, handling, and tariffs, play a significant role in the total cost of ownership. Buyers should consider the proximity of suppliers and transportation options to minimize these costs.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary widely based on market conditions, competition, and the perceived value of the coupling’s features and benefits.

Price Influencers

-

Volume/MOQ: Purchasing in bulk can often lead to significant discounts. Suppliers may offer lower prices for larger orders, incentivizing buyers to consolidate their purchasing.

-

Specifications/Customization: Custom-designed couplings tailored to specific applications can increase costs due to additional engineering and production time. Buyers should weigh the benefits of customization against potential cost increases.

-

Quality/Certifications: Couplings that meet international quality standards (e.g., ISO, API) may command higher prices but offer greater reliability. Buyers should consider the long-term implications of quality versus upfront costs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a track record of quality may charge more, but they also reduce risks associated with poor performance.

-

Incoterms: The terms of delivery (e.g., FOB, CIF) can affect the final price due to variations in shipping responsibilities and costs. Understanding these terms is critical for accurate budgeting.

Buyer Tips

-

Negotiation: Engage in proactive negotiation with suppliers to secure better pricing, especially for larger orders. Highlighting long-term relationships or potential future orders can strengthen your bargaining position.

-

Cost-Efficiency: Look beyond the initial purchase price and consider the Total Cost of Ownership (TCO), which includes maintenance, downtime, and potential replacement costs. Investing in higher-quality couplings may yield savings over time.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import tariffs, and regional market conditions that can affect pricing. Establishing contracts that account for these factors can protect against unexpected cost increases.

-

Disclaimer for Indicative Prices: Prices for couplings can vary widely based on the aforementioned factors. It is advisable for buyers to obtain multiple quotes and conduct thorough market research to ensure they are making informed purchasing decisions.

By understanding these components and influencers, international B2B buyers can make strategic decisions that enhance their operational efficiency while optimizing costs.

Spotlight on Potential types of couplings Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘types of couplings’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for types of couplings

Understanding the essential technical properties and common trade terminology associated with industrial couplings is crucial for international B2B buyers. This knowledge enables better decision-making and enhances communication with suppliers, especially in diverse markets like Africa, South America, the Middle East, and Europe.

Key Technical Properties of Couplings

-

Material Grade

– The material grade of a coupling determines its strength, durability, and resistance to wear and corrosion. Common materials include stainless steel, cast iron, and aluminum. Selecting the right material is vital for ensuring the coupling can withstand specific operational conditions, such as temperature fluctuations and exposure to chemicals. -

Torque Capacity

– This specification indicates the maximum torque the coupling can transmit without failure. It is essential for ensuring that the coupling can handle the load requirements of the application. Buyers should match torque capacity with the machinery’s specifications to prevent premature wear or catastrophic failure. -

Misalignment Tolerance

– Couplings must accommodate various types of misalignment (angular, parallel, and axial) to maintain operational efficiency. Understanding the misalignment tolerance helps buyers select the appropriate coupling type for their machinery, ensuring smooth operation and reducing the risk of damage. -

Speed Rating

– The speed rating refers to the maximum rotational speed at which a coupling can operate safely. It is crucial for applications involving high-speed machinery. Buyers should consider this property to ensure that the selected coupling will not fail under the operational conditions.

-

Vibration Dampening Capability

– Some couplings are designed to absorb vibrations, which can protect connected equipment from damage. This property is particularly important in applications with high dynamic loads. Buyers should assess vibration dampening capabilities to enhance machinery longevity and reduce maintenance costs. -

Size and Dimensions

– The physical dimensions of a coupling affect its compatibility with the shafts it connects. Accurate sizing ensures proper fit and function, which is essential for optimal performance. Buyers need to consider shaft diameters and the overall space available in their machinery.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications can help buyers ensure they are sourcing high-quality components that meet the original design standards. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This is a critical consideration for buyers, particularly those in emerging markets where initial investments may be limited. Knowing the MOQ helps in planning procurement strategies effectively.

Illustrative Image (Source: Google Search)

-

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. For B2B buyers, issuing RFQs is a strategic way to gather competitive pricing and terms, facilitating informed purchasing decisions. -

Incoterms

– International Commercial Terms (Incoterms) are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping, insurance, and risk management, thus avoiding potential disputes. -

Lead Time

– Lead time is the period from placing an order to receiving the product. For B2B buyers, understanding lead times is essential for inventory management and production planning, ensuring that operations run smoothly without delays. -

Certification Standards

– Certification standards, such as ISO or ANSI, indicate that a product meets specific quality and safety criteria. Buyers should prioritize sourcing couplings that adhere to relevant certification standards to ensure reliability and compliance with industry regulations.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, enhance supplier negotiations, and ultimately improve their operational efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the types of couplings Sector

Market Overview & Key Trends

The global couplings market is experiencing significant growth driven by the increasing demand for efficient power transmission across various industries, such as manufacturing, automotive, and energy. Key factors contributing to this trend include the rise in automation, technological advancements in coupling designs, and a growing emphasis on machinery reliability. International B2B buyers, especially from Africa, South America, the Middle East, and Europe, should take note of the increasing adoption of smart coupling technologies that integrate IoT capabilities for real-time monitoring and predictive maintenance. This trend not only enhances operational efficiency but also reduces downtime, which is crucial for competitive markets.

Another notable trend is the shift towards flexible couplings due to their ability to accommodate misalignment and absorb shocks. This adaptability is particularly important in regions with varied infrastructure challenges, as seen in many African and South American markets. Additionally, the demand for customized coupling solutions is rising, enabling businesses to tailor products to specific operational needs. Buyers should prioritize suppliers who offer bespoke solutions alongside standard products to ensure optimal performance.

Moreover, the focus on local sourcing is gaining traction, particularly in response to geopolitical uncertainties and supply chain disruptions. Buyers in Europe, for instance, are increasingly looking to source couplings from within the EU to mitigate risks associated with international shipping and tariffs. Understanding these dynamics is essential for making informed purchasing decisions and maintaining a competitive edge in the marketplace.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration in the couplings sector, driven by regulatory pressures and consumer demand for environmentally responsible practices. The environmental impact of production processes, including energy consumption and waste generation, is under scrutiny. B2B buyers are encouraged to seek suppliers who prioritize sustainable manufacturing practices, such as using recycled materials and minimizing emissions.

Ethical sourcing is equally important, as companies increasingly recognize the value of transparent supply chains. Buyers should consider suppliers who can demonstrate compliance with international labor standards and environmental regulations. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as indicators of a supplier’s commitment to sustainability.

In terms of materials, the use of “green” alternatives in coupling production, such as biodegradable polymers or sustainably sourced metals, is gaining popularity. Buyers should inquire about these materials when sourcing couplings, as they not only reduce environmental impact but can also enhance brand reputation. By prioritizing sustainability and ethical sourcing, businesses can contribute to a more responsible industry while fulfilling their operational needs.

Brief Evolution/History

The coupling industry has evolved significantly since its inception, transitioning from basic mechanical connections to sophisticated devices designed for high efficiency and reliability. Early couplings, primarily rigid types, were limited in their application due to their inability to accommodate misalignment. The introduction of flexible couplings in the mid-20th century marked a pivotal point, allowing for greater tolerance in industrial applications.

As technology advanced, the development of specialized couplings, such as fluid and magnetic types, expanded the market’s offerings. Today, the focus is not only on functionality but also on integrating smart technology and sustainable practices. This evolution reflects the industry’s responsiveness to changing market demands and technological advancements, providing B2B buyers with a diverse range of options tailored to modern operational challenges. Understanding this history can help buyers appreciate the innovations that continue to shape the couplings market today.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of types of couplings

-

What factors should I consider when vetting suppliers for couplings?

When vetting suppliers, prioritize their industry experience, reputation, and certifications. Look for suppliers who have a proven track record in manufacturing the specific type of coupling you need. Request references from previous clients and evaluate customer feedback. Ensure they comply with international quality standards, such as ISO certifications, and confirm their ability to provide documentation for traceability. Additionally, consider their production capacity and flexibility in meeting your specific requirements, as this will impact lead times and reliability. -

Can I customize couplings according to my specific application needs?

Yes, many manufacturers offer customization options for couplings to meet specific application requirements. You can request modifications in dimensions, materials, and design features based on the operational environment and load conditions. When discussing customization, provide detailed specifications and any relevant performance criteria to the supplier. Ensure that the supplier has the engineering capabilities to deliver the desired modifications while maintaining product integrity and compliance with industry standards. -

What are the typical minimum order quantities (MOQs) and lead times for couplings?

Minimum order quantities can vary significantly based on the supplier and the type of coupling. Generally, MOQs can range from a few units for standard products to several hundred for custom designs. Lead times also depend on the complexity of the order, with standard couplings often shipped within 2-4 weeks, while customized solutions may take 6-12 weeks or longer. Always clarify these details with the supplier upfront to ensure they align with your project timelines and inventory needs. -

What payment terms are commonly accepted when sourcing couplings internationally?

Payment terms can differ by supplier and region. Common methods include letters of credit, bank transfers, and online payment platforms. Many suppliers require a deposit (e.g., 30-50%) upfront, with the balance due upon delivery or prior to shipment. It is crucial to negotiate terms that safeguard your interests, especially when dealing with new suppliers. Be aware of currency exchange rates and transaction fees, which can impact overall costs. -

How can I ensure the quality of couplings I purchase?

To ensure quality, request certifications and compliance documentation from suppliers, such as ISO or ASTM standards. Ask for samples before placing a large order to evaluate material quality and performance. Implement a quality assurance process that includes inspections at various production stages and final testing. Establish clear communication about quality expectations, and consider using third-party inspection services, especially for international shipments, to verify that products meet your specifications. -

What logistics considerations should I be aware of when importing couplings?

Logistics is crucial when importing couplings, particularly regarding shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder experienced in handling industrial goods. Understand the customs regulations of your country to avoid delays, and ensure all documentation (invoices, certificates of origin) is accurate and complete. Additionally, plan for potential delays due to weather or port congestion, and consider insurance options for high-value shipments to protect against loss or damage. -

What steps can I take to resolve disputes with suppliers?

To resolve disputes, maintain clear and open communication with your supplier from the outset. Document all agreements, specifications, and correspondence to establish a clear record. If issues arise, address them promptly and professionally, seeking to understand the supplier’s perspective. Many suppliers will have dispute resolution processes in place, such as mediation or arbitration. If necessary, consult legal counsel familiar with international trade laws to guide you through more complex issues. -

What certifications should I look for when sourcing couplings?

When sourcing couplings, look for certifications that demonstrate compliance with international quality and safety standards. Common certifications include ISO 9001 for quality management systems, ISO 14001 for environmental management, and industry-specific certifications such as API (American Petroleum Institute) or ASME (American Society of Mechanical Engineers). These certifications indicate that the supplier adheres to rigorous production practices, enhancing the reliability and performance of the couplings you purchase.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for types of couplings

In conclusion, understanding the diverse range of coupling types is essential for international B2B buyers seeking to enhance operational efficiency and reliability. Strategic sourcing is vital, allowing businesses to select couplings that not only meet specific technical requirements but also align with budgetary constraints and supply chain considerations. Buyers from Africa, South America, the Middle East, and Europe must prioritize partnerships with reputable suppliers that offer quality products and robust support.

As the global market evolves, the demand for innovative coupling solutions will continue to rise. Emphasizing flexibility, durability, and advanced technology will be crucial in meeting the needs of various industries, including manufacturing, automotive, and energy sectors.

To stay competitive, B2B buyers should actively engage with suppliers to explore emerging trends, such as sustainable coupling materials and smart technology integration. By investing in the right coupling solutions today, businesses can secure a more efficient and resilient operational future. Take the initiative to reassess your coupling strategies and leverage the insights gained from this guide to optimize your sourcing decisions and drive long-term success.

Illustrative Image (Source: Google Search)