Your Ultimate Guide to Sourcing Helical Gearbox

Introduction: Navigating the Global Market for helical gearbox

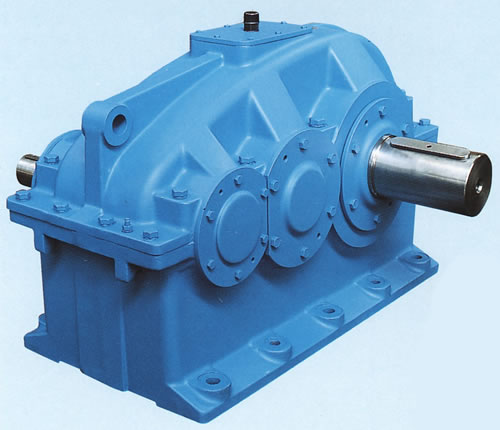

In today’s fast-evolving industrial landscape, helical gearboxes play a pivotal role in optimizing machinery performance across various sectors, including automotive, manufacturing, and renewable energy. These gear systems are renowned for their efficiency, smooth operation, and ability to transmit high torque, making them essential components in heavy-duty applications. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the intricacies of helical gearboxes is vital for informed sourcing decisions.

This guide offers a comprehensive exploration of helical gearboxes, detailing types, materials, and manufacturing quality control processes. It also highlights key considerations for selecting reliable suppliers, factors influencing cost, and prevailing market trends. By addressing frequently asked questions, we aim to demystify the complexities surrounding these critical components.

Equipped with this knowledge, buyers can navigate the global market with confidence, ensuring they choose the right products that align with their operational needs and budget constraints. As industries increasingly seek to enhance productivity and reduce downtime, understanding helical gearboxes becomes an indispensable asset for achieving competitive advantage. Empower your sourcing strategy with insights that drive efficiency and innovation in your operations.

Understanding helical gearbox Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single Stage Helical Gearbox | Simple design, high efficiency, compact size | Automotive, conveyors, industrial machinery | Pros: High torque capacity, quiet operation. Cons: Limited gear ratio range. |

| Double Stage Helical Gearbox | Increased gear reduction, enhanced torque output | Heavy machinery, mining, oil & gas | Pros: Greater torque and efficiency. Cons: Larger size and weight. |

| Helical Bevel Gearbox | Combines helical and bevel gear designs, allows for angular power transmission | Aerospace, automotive, robotics | Pros: Versatile design for space-saving. Cons: More complex and potentially higher cost. |

| Parallel Shaft Helical Gearbox | Multiple shafts aligned parallel, allows for high torque transmission | Industrial applications, material handling | Pros: High load capacity, efficient power transfer. Cons: Requires more space. |

| High-Performance Helical Gearbox | Advanced materials and designs for extreme conditions | Renewable energy, aerospace, automotive | Pros: Superior durability and efficiency. Cons: Higher initial investment. |

Single Stage Helical Gearbox

Single stage helical gearboxes are designed for applications requiring moderate torque and speed. Their compact design makes them ideal for automotive and conveyor systems, where space is a premium. Buyers should consider the specific torque requirements and the desired gear ratio, as this type offers limited options in that regard. Their quiet operation and high efficiency make them a popular choice, but their simplicity might not suffice for heavy-duty applications.

Double Stage Helical Gearbox

Double stage helical gearboxes provide increased gear reduction, making them suitable for applications that demand high torque output, such as in heavy machinery or the oil and gas sector. While they offer enhanced performance, buyers should be aware of their larger size and weight, which could impact installation and space considerations. The ability to achieve higher efficiency and torque makes them a valuable investment for industries that operate under heavy loads.

Helical Bevel Gearbox

This variant combines the benefits of helical gears with bevel gears, allowing for angular power transmission. Helical bevel gearboxes are particularly suitable for applications in aerospace, automotive, and robotics, where space constraints are often a concern. Buyers should evaluate the complexity of the system and potential costs, as these gearboxes can be more expensive due to their intricate design. However, their versatility and compact nature make them an attractive option for many B2B applications.

Parallel Shaft Helical Gearbox

Parallel shaft helical gearboxes are known for their ability to handle high loads and provide efficient power transfer. They are commonly used in industrial applications and material handling systems. Buyers should consider the physical space available for installation, as these gearboxes require more room compared to others. Their robust construction and high load capacity make them a reliable choice for industries with demanding operational requirements.

High-Performance Helical Gearbox

Designed for extreme conditions, high-performance helical gearboxes utilize advanced materials and technology to deliver superior durability and efficiency. These gearboxes are ideal for renewable energy applications, aerospace, and automotive sectors where performance is critical. While the initial investment may be higher, the long-term benefits in terms of reduced maintenance and operational efficiency can justify the cost. Buyers should assess their specific performance needs against the financial implications of choosing this advanced option.

Related Video: Type of gearbox | Helical gearbox | Bevel gearbox | Worm gearbox | Planetary gearbox |

Key Industrial Applications of helical gearbox

| Industry/Sector | Specific Application of Helical Gearbox | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Conveyor Systems | Enhanced efficiency and reduced maintenance downtime. | Quality assurance, lead time, and compatibility with existing systems. |

| Automotive | Transmission Systems | Improved torque transmission and smoother operation. | Certification standards, material quality, and supplier reliability. |

| Oil & Gas | Pumping Equipment | Increased operational reliability and energy efficiency. | Compliance with industry regulations and ruggedness for harsh environments. |

| Renewable Energy | Wind Turbines | Higher energy conversion efficiency and lower maintenance costs. | Supplier experience in renewable applications and adaptability to local conditions. |

| Construction | Heavy Machinery | Enhanced power transfer and operational stability. | Customization options and availability of technical support. |

Manufacturing

In the manufacturing sector, helical gearboxes are often used in conveyor systems, where they facilitate the smooth and efficient movement of materials. These gearboxes help in minimizing operational downtime by providing a reliable power transmission solution, which is crucial for maintaining productivity levels. For international buyers, especially from Africa and South America, sourcing high-quality helical gearboxes that comply with local standards and offer robust performance in varying environmental conditions is essential. Considerations such as lead time and compatibility with existing machinery are also critical.

Automotive

In the automotive industry, helical gearboxes play a vital role in transmission systems, where they enhance torque transmission and ensure smoother vehicle operation. This is particularly relevant as the industry shifts towards electric vehicles, which demand advanced gear solutions for efficiency. B2B buyers need to focus on suppliers that adhere to strict certification standards and offer high-quality materials to withstand the rigors of automotive applications. Reliability and supplier reputation are paramount, especially in regions like Europe and the Middle East, where regulations are stringent.

Oil & Gas

The oil and gas sector utilizes helical gearboxes in pumping equipment to ensure increased operational reliability and energy efficiency. These gearboxes are designed to withstand harsh environments and provide consistent performance over time, which is crucial for minimizing operational disruptions. Buyers in this sector must prioritize compliance with industry regulations and seek suppliers that can provide gearboxes specifically engineered for durability and performance in extreme conditions, particularly in regions like the Middle East and Africa, where operational challenges are prevalent.

Renewable Energy

In renewable energy applications, particularly wind turbines, helical gearboxes are essential for converting rotational energy into usable electrical energy. Their design allows for higher energy conversion efficiency and lower maintenance costs, making them an attractive option for energy producers. B2B buyers should look for suppliers with experience in renewable applications and the ability to adapt to local environmental conditions. Additionally, understanding the technical specifications that align with the specific demands of wind energy projects is crucial for successful implementation.

Construction

In the construction industry, helical gearboxes are commonly found in heavy machinery, where they enhance power transfer and provide operational stability. This is vital for equipment such as excavators and cranes, which require reliable performance under heavy loads. When sourcing helical gearboxes, buyers should consider customization options to meet specific machinery requirements and ensure the availability of technical support from suppliers. This is particularly relevant for international buyers in regions like Africa and South America, where equipment may need to be tailored to local operational conditions.

Related Video: Helical Bevel Gearbox vs Worm Gearbox | Supplied by John Brooks

Strategic Material Selection Guide for helical gearbox

When selecting materials for helical gearboxes, international B2B buyers must consider various factors, including mechanical properties, manufacturing complexities, and application-specific requirements. Below is an analysis of four common materials used in helical gearboxes, providing insights into their performance, advantages, and drawbacks.

Steel

Key Properties:

Steel is known for its high tensile strength and durability, making it suitable for high-load applications. It typically has excellent wear resistance and can withstand high temperatures and pressures.

Pros & Cons:

Steel helical gears are highly durable and can handle significant stress, making them ideal for heavy machinery. However, they are relatively heavy, which can be a disadvantage in applications where weight is a critical factor. Additionally, the manufacturing process can be complex and costly, especially for precision machining.

Impact on Application:

Steel gears are compatible with various media, including oils and lubricants, which are essential for reducing friction in high-load conditions. They are commonly used in automotive and industrial machinery.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM and DIN for quality assurance. In regions like Africa and South America, sourcing steel may involve navigating fluctuating prices and availability.

Cast Iron

Key Properties:

Cast iron offers good wear resistance and excellent damping properties, which help reduce vibration in gear systems. It also has a relatively high compressive strength.

Pros & Cons:

The primary advantage of cast iron is its cost-effectiveness and ease of manufacturing. However, it is more brittle than steel, making it less suitable for applications that require high tensile strength. Additionally, cast iron may have limited corrosion resistance unless treated.

Impact on Application:

Cast iron gears are suitable for applications where shock loads are minimal, such as in certain manufacturing processes. They are often used in lower-speed applications.

Considerations for International Buyers:

Buyers should be aware of the material’s brittleness and ensure that it meets local standards for mechanical properties. In Europe, for instance, compliance with EN standards is crucial.

Plastic (Polymer Composites)

Key Properties:

Plastic gears are lightweight and exhibit good corrosion resistance. They can operate effectively at lower noise levels, making them suitable for applications where noise reduction is important.

Pros & Cons:

The lightweight nature of plastic gears makes them advantageous in applications where reducing weight is critical. However, they typically have lower load-bearing capacities compared to metals, which limits their use in high-stress environments.

Impact on Application:

Plastic gears are often used in consumer electronics and automotive applications where noise and weight are critical factors. They are compatible with a variety of lubricants, although some plastics may degrade in the presence of certain chemicals.

Considerations for International Buyers:

Buyers should verify that the plastics used meet relevant standards (e.g., ISO) for durability and performance. In regions like the Middle East, where temperatures can be high, thermal stability of the plastic should be considered.

Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance, making it suitable for various applications. It also has decent strength-to-weight ratios and thermal conductivity.

Pros & Cons:

The main advantage of aluminum is its lightweight nature, which is beneficial for applications where weight savings are essential. However, it is generally less durable than steel and can be more expensive due to the cost of raw materials and processing.

Impact on Application:

Aluminum gears are often used in aerospace and automotive applications where weight is a critical factor. They can handle moderate loads and are compatible with various lubricants.

Considerations for International Buyers:

B2B buyers should ensure that aluminum components meet the relevant standards, such as ASTM and ISO, particularly for applications in the aerospace sector. Additionally, understanding local supply chains for aluminum can aid in cost management.

Summary Table

| Material | Typical Use Case for helical gearbox | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery, automotive | High durability and strength | Heavy and complex manufacturing | High |

| Cast Iron | Manufacturing processes | Cost-effective and easy to manufacture | Brittle, limited corrosion resistance | Medium |

| Plastic | Consumer electronics, automotive | Lightweight and low noise | Lower load capacity | Low |

| Aluminum | Aerospace, automotive | Lightweight and corrosion resistant | Less durable than steel | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers in making informed decisions regarding helical gearbox materials, ensuring performance, compliance, and cost-effectiveness in their applications.

In-depth Look: Manufacturing Processes and Quality Assurance for helical gearbox

Manufacturing Processes for Helical Gearboxes

The production of helical gearboxes involves a series of meticulous manufacturing processes designed to ensure durability, efficiency, and high performance. Below are the main stages of manufacturing, along with key techniques employed in the industry.

Illustrative Image (Source: Google Search)

1. Material Preparation

The first step in manufacturing helical gearboxes is selecting and preparing the right materials. Typically, high-quality steel is used due to its strength and durability. The material preparation process includes:

- Material Selection: Choosing the appropriate grade of steel or alternative materials based on application requirements, such as load capacity and environmental conditions.

- Cutting and Shaping: Raw materials are cut into manageable sizes using techniques like plasma cutting or water jet cutting. This ensures precision in the dimensions needed for subsequent processes.

2. Forming

Forming is a crucial stage where the raw material is transformed into the helical gears. This process involves several techniques:

- Machining: This is one of the primary methods used to create helical gears. CNC (Computer Numerical Control) machines are commonly employed for high precision in shaping gears. Machining processes include:

- Hobbing: A widely used method for creating the gear tooth profile. It is efficient and produces gears with high accuracy.

-

Shaping: This process involves using a shaping machine to form the tooth profile, especially for larger gears where hobbing might not be feasible.

-

Heat Treatment: After machining, gears undergo heat treatment processes like quenching and tempering to enhance their hardness and wear resistance. This is vital for ensuring the longevity of the gearbox under heavy loads.

3. Assembly

The assembly stage involves bringing together all the components of the helical gearbox. Key considerations during this stage include:

- Component Inspection: Each component is inspected for quality and adherence to specifications before assembly. This reduces the risk of failure in the final product.

- Alignment and Fitting: Precision alignment of gears and other components is critical to minimize friction and wear. This may involve the use of jigs and fixtures to maintain accuracy.

- Lubrication Application: Proper lubrication is applied to reduce friction and improve the efficiency of the gearbox. This is often done before the final assembly.

4. Finishing

The finishing stage ensures that the helical gearbox meets the required aesthetic and functional standards. This stage involves:

- Surface Treatment: Processes such as grinding, polishing, or coating are applied to improve surface finish and prevent corrosion.

- Final Assembly Checks: A thorough inspection is conducted to ensure that all components are securely assembled and that the gearbox operates smoothly.

Quality Assurance in Manufacturing Helical Gearboxes

Quality assurance (QA) is an integral part of the manufacturing process for helical gearboxes. International and industry-specific standards guide these quality processes, ensuring that products meet rigorous performance criteria.

International Standards

- ISO 9001: This standard outlines the requirements for a quality management system (QMS). Compliance ensures that manufacturers consistently produce products that meet customer and regulatory requirements.

- CE Marking: For products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

Industry-Specific Standards

- API (American Petroleum Institute): For gearboxes used in the oil and gas sector, adherence to API standards ensures that products can withstand harsh operating conditions.

Quality Control Checkpoints

Effective quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): Ongoing inspections are conducted during the manufacturing process to catch defects early. This includes monitoring machining tolerances and alignment during assembly.

- Final Quality Control (FQC): A comprehensive inspection of the finished product occurs before it leaves the manufacturing facility. This may include performance testing under simulated operational conditions.

Common Testing Methods

To ensure the reliability and performance of helical gearboxes, various testing methods are employed:

- Load Testing: Gearboxes are subjected to simulated operational loads to assess their performance and durability.

- Vibration Analysis: This technique detects imbalances and misalignments that could lead to premature failure.

- Noise Testing: Ensures that the gearbox operates within acceptable noise limits, particularly important in applications where noise reduction is critical.

Verifying Supplier Quality Control

B2B buyers must ensure that their suppliers maintain high-quality standards. Here are several strategies for verification:

- Supplier Audits: Conduct regular audits of potential suppliers to assess their manufacturing processes, quality control measures, and compliance with international standards.

- Requesting Quality Reports: Suppliers should provide detailed quality reports, including results from IQC, IPQC, and FQC, along with certifications demonstrating compliance with relevant standards.

- Third-Party Inspections: Engaging third-party inspection agencies can provide unbiased assessments of the supplier’s quality assurance processes.

Quality Control Nuances for International B2B Buyers

For buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential:

- Cultural Differences: Different regions may have varying standards of quality and business practices. It’s crucial for buyers to communicate their expectations clearly and understand the supplier’s capabilities.

- Regulatory Compliance: Buyers should be familiar with local regulations and standards that may affect the purchase and use of helical gearboxes in their respective markets.

- Supply Chain Risks: Be aware of potential disruptions due to geopolitical tensions, which could impact the consistency and reliability of supply. Establishing relationships with multiple suppliers can mitigate these risks.

By understanding the manufacturing processes and quality assurance standards for helical gearboxes, international B2B buyers can make informed decisions that enhance their operational efficiency and reduce risks associated with supplier variability.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for helical gearbox Sourcing

Understanding the Cost Structure for Helical Gearbox Sourcing

When sourcing helical gearboxes, international B2B buyers need to understand the comprehensive cost structure involved in their procurement. This structure typically comprises several components:

-

Materials: The primary materials used in helical gearboxes are high-strength steel, cast iron, and sometimes advanced composites. The choice of material significantly impacts cost, as high-grade materials offer enhanced durability and performance but at a premium price.

-

Labor: Labor costs vary by region and can be influenced by the skill level required for manufacturing. In countries with a skilled workforce, such as those in Europe, labor costs may be higher, while regions with lower labor costs, such as parts of Africa and South America, may offer more competitive pricing.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and administrative costs. Efficient manufacturing processes can help mitigate these costs, so buyers should consider suppliers with optimized production capabilities.

-

Tooling: Tooling costs can be substantial, especially for custom designs. Buyers should inquire about tooling fees and whether these costs are amortized over large orders to reduce per-unit costs.

-

Quality Control (QC): Implementing rigorous QC processes ensures the reliability of the helical gearboxes. While these processes add to the cost, they can save money in the long run by reducing failures and warranty claims.

-

Logistics: Transportation costs can vary widely based on distance, shipping method, and the chosen Incoterms. For international transactions, consider the total logistics costs, including duties and taxes, which can significantly affect the overall price.

-

Margin: Suppliers will typically include a margin that reflects their operating costs and profit expectations. Margins can vary based on market competition and supplier reputation.

Key Price Influencers in Helical Gearbox Sourcing

Several factors influence the pricing of helical gearboxes, and understanding these can lead to better purchasing decisions:

-

Volume/MOQ: Larger orders often benefit from lower per-unit costs due to economies of scale. Buyers should assess their needs and negotiate minimum order quantities (MOQs) to secure better pricing.

-

Specifications/Customization: Custom gearboxes designed to specific requirements may incur higher costs. Buyers should clearly define their needs to avoid unnecessary customization that can inflate prices.

-

Materials: The choice of materials directly impacts the cost. Buyers should balance the need for durability with budget constraints, considering alternatives if necessary.

-

Quality/Certifications: Certifications such as ISO or specific industry standards can add to the cost but are essential for ensuring product reliability and compliance with regulations.

-

Supplier Factors: Established suppliers may charge higher prices due to their reputation and reliability. However, they often provide better support and quality assurance, which can justify the higher cost.

-

Incoterms: The chosen Incoterms can affect pricing by defining the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Buyers should choose terms that align with their logistical capabilities and cost expectations.

Buyer Tips for Cost-Efficiency

-

Negotiate: Always engage in negotiations to secure the best possible pricing. Leverage information about competitor prices and market trends to strengthen your position.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term operational costs, including maintenance and potential downtime. A higher-quality gearbox may have a higher upfront cost but lower TCO.

-

Research Suppliers: Take the time to investigate various suppliers, especially those in your region. Local suppliers may offer competitive pricing and reduced shipping costs.

-

Be Aware of Pricing Nuances: International buyers should stay informed about currency fluctuations, trade tariffs, and geopolitical factors that could influence costs. Understanding these nuances can aid in better financial planning.

-

Request Samples: Before committing to large orders, request samples to assess quality firsthand. This can prevent costly mistakes and ensure that the products meet your specifications.

Disclaimer on Indicative Prices

It is essential to note that prices for helical gearboxes can vary significantly based on the factors discussed above. This analysis serves as a guideline; actual prices may differ based on market conditions and supplier negotiations. Always conduct thorough research and obtain multiple quotes to ensure the best possible value.

Spotlight on Potential helical gearbox Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘helical gearbox’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for helical gearbox

When considering the procurement of helical gearboxes, understanding the essential technical properties and industry terminology is crucial for making informed decisions. Below are key specifications and trade terms that international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should familiarize themselves with.

Key Technical Properties

-

Material Grade

– Definition: The material grade refers to the type and quality of materials used in manufacturing the gearbox, commonly including steel, cast iron, or composite materials.

– Importance: Material grade directly influences the strength, durability, and performance of the gearbox under various loads. Buyers should ensure the material aligns with their operational requirements to avoid premature failure. -

Gear Ratio

– Definition: Gear ratio is the ratio of the number of teeth on the driven gear to the number of teeth on the driving gear.

– Importance: This property affects the output speed and torque of the gearbox. Understanding gear ratios helps buyers select gearboxes that meet their specific application needs, whether for high-speed or high-torque scenarios. -

Load Capacity

– Definition: Load capacity indicates the maximum weight or force the gearbox can handle without failure.

– Importance: This specification is critical for ensuring that the selected gearbox can operate safely within the limits of the application. Exceeding load capacity can lead to mechanical failures and costly downtime. -

Efficiency Rating

– Definition: Efficiency rating measures the gearbox’s ability to transmit power without excessive energy loss, typically expressed as a percentage.

– Importance: A higher efficiency rating indicates less energy waste, which translates to lower operational costs and improved performance. Buyers should prioritize gearboxes with high efficiency, especially in energy-sensitive applications. -

Tolerance

– Definition: Tolerance specifies the permissible limit or limits of variation in a physical dimension, such as gear teeth spacing or shaft diameter.

– Importance: Proper tolerances ensure that components fit together correctly, minimizing wear and improving lifespan. Precision in tolerances is vital for high-performance applications. -

Noise Level

– Definition: Noise level indicates the amount of sound produced during the operation of the gearbox.

– Importance: Low noise levels are often required in environments where sound pollution must be minimized, such as in residential or healthcare settings. Understanding this property aids in compliance with local regulations and improves user comfort.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Buyers should consider OEM products for reliability and compatibility, as they are often designed to meet specific standards required for particular applications. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest number of units a supplier is willing to sell.

– Importance: Understanding the MOQ helps buyers negotiate better pricing and manage inventory effectively. It also influences purchasing strategies, especially for smaller businesses. -

RFQ (Request for Quotation)

– Definition: An RFQ is a business document sent to suppliers to invite them to bid on specific products or services.

– Importance: Submitting an RFQ allows buyers to compare prices and terms from multiple suppliers, ensuring they get the best deal and understand the market landscape. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions.

– Importance: Familiarity with Incoterms is crucial for understanding shipping costs, risks, and responsibilities, ensuring smooth logistics and compliance in international trade. -

Lead Time

– Definition: Lead time refers to the amount of time taken from placing an order to delivery.

– Importance: Knowing the lead time helps buyers plan their projects and manage operational schedules, reducing the risk of delays in production. -

Warranty

– Definition: A warranty is a guarantee provided by the manufacturer regarding the condition of the product and its lifespan.

– Importance: A robust warranty reflects the manufacturer’s confidence in their product’s quality and provides buyers with protection against defects, which is essential for long-term investments.

By understanding these technical properties and trade terms, international B2B buyers can make more informed decisions when selecting helical gearboxes, ultimately leading to better operational efficiency and cost-effectiveness.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the helical gearbox Sector

Market Overview & Key Trends

The global helical gearbox market is poised for significant growth, driven by the increasing demand for automation across various industries. With a projected market valuation of approximately $40 billion in 2024 and a compound annual growth rate (CAGR) of around 5.8% through 2034, the sector is witnessing robust investment and innovation. Key drivers include the rising adoption of advanced manufacturing technologies such as IoT-enabled gear systems and additive manufacturing, which enhance operational efficiency and performance.

Emerging trends in sourcing include a shift towards digital platforms for procurement and supply chain management. B2B buyers are increasingly utilizing online marketplaces to compare suppliers, streamline the purchasing process, and gain access to a wider range of products. Furthermore, collaborative sourcing is becoming popular, where companies pool resources to negotiate better terms and access specialized suppliers, particularly in regions like Africa and South America where local suppliers may have limitations.

For international B2B buyers, understanding regional market dynamics is critical. In Africa and South America, the focus is on enhancing local manufacturing capabilities to reduce dependency on imports, while in Europe and the Middle East, there is a push for high-efficiency solutions that meet stringent regulatory requirements. Buyers should also be aware of geopolitical factors that could influence supply chains, including fluctuating raw material prices and potential trade barriers.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming an integral part of the helical gearbox sector, with increasing pressure from stakeholders to adopt environmentally friendly practices. The environmental impact of traditional manufacturing processes necessitates a shift towards sustainable production methods. This includes the use of recyclable materials and energy-efficient manufacturing techniques that minimize waste and carbon emissions.

Ethical sourcing is equally important, as buyers are increasingly scrutinizing their supply chains for compliance with labor standards and environmental regulations. Suppliers that demonstrate a commitment to sustainability through certifications—such as ISO 14001 for environmental management—are gaining a competitive edge. B2B buyers should seek out suppliers who utilize green materials and practices, such as utilizing recycled steel or bio-based lubricants in their gearboxes.

Moreover, the adoption of circular economy principles is reshaping sourcing strategies. Companies are exploring options for remanufacturing and refurbishing helical gearboxes, thereby extending product life cycles and reducing resource consumption. This trend not only meets environmental goals but also offers cost savings for buyers.

Illustrative Image (Source: Google Search)

Brief Evolution/History

The helical gearbox has evolved significantly since its inception in the early industrial age. Originally designed for simple power transmission applications, advancements in materials and engineering have led to the development of high-performance helical gears capable of handling substantial loads with reduced noise levels. The introduction of computer-aided design (CAD) and simulation technologies has further refined gearbox design, allowing for more complex configurations that enhance performance and efficiency.

In recent years, the focus has shifted towards integrating digital technologies, such as predictive maintenance and IoT connectivity, which enable real-time monitoring and enhanced operational efficiency. This evolution not only improves reliability and reduces downtime but also aligns with the broader trend of Industry 4.0, where automation and data exchange are paramount. As the industry continues to innovate, B2B buyers must stay informed about technological advancements that could impact their sourcing decisions and operational efficiency.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of helical gearbox

-

What factors should I consider when vetting suppliers of helical gearboxes?

When vetting suppliers, assess their industry experience and reputation. Check for certifications like ISO 9001, which indicate quality management standards. It’s crucial to review their client testimonials and case studies to gauge reliability. Inquire about their manufacturing capabilities and whether they have the necessary machinery to produce your required specifications. Additionally, consider their after-sales support and responsiveness, as these factors can significantly impact your long-term relationship. -

Can I customize the helical gearbox to meet my specific application needs?

Yes, many manufacturers offer customization options for helical gearboxes. You can specify parameters like gear ratio, size, material, and mounting configurations based on your application requirements. It’s essential to communicate your needs clearly during the initial discussions to ensure that the supplier understands your specifications. Be prepared to provide detailed operational conditions, such as load capacity and environmental factors, to facilitate tailored solutions. -

What are the typical minimum order quantities (MOQ) and lead times for helical gearboxes?

MOQs for helical gearboxes can vary significantly depending on the supplier and the complexity of the customization. Standard products may have lower MOQs, while custom gearboxes may require higher orders to justify production costs. Lead times typically range from 4 to 12 weeks, influenced by the supplier’s production schedule and your order size. Always confirm these details upfront to avoid delays and ensure timely delivery for your projects. -

What payment terms should I expect when sourcing helical gearboxes internationally?

Payment terms for international transactions usually include options like upfront deposits (30-50%) with the balance due before shipment or upon delivery. Some suppliers may offer payment through letters of credit or escrow services to enhance security. It’s essential to negotiate favorable terms that align with your cash flow and risk management strategies. Clarify any additional fees related to currency conversion, international transfers, or customs duties beforehand. -

How do I ensure quality assurance and certifications for helical gearboxes?

To ensure quality, request detailed documentation from suppliers, including compliance certificates and testing reports. Many reputable manufacturers adhere to international standards, such as ISO and ANSI, which ensure the gearboxes meet specific quality benchmarks. Additionally, consider asking for third-party inspection or testing before shipment. Regular audits and site visits can also help maintain quality throughout the production process. -

What logistics considerations should I keep in mind when importing helical gearboxes?

Logistics play a critical role in the timely delivery of helical gearboxes. Ensure that your supplier has a clear shipping policy, including responsibilities for shipping costs and customs clearance. Familiarize yourself with import regulations in your country, including tariffs and taxes, to avoid unexpected costs. Collaborate with a reliable freight forwarder to manage the logistics efficiently and mitigate risks associated with international shipping.

-

How can I resolve disputes with suppliers of helical gearboxes?

Dispute resolution should ideally be addressed in the initial contract. Include clauses for mediation or arbitration to handle conflicts amicably. Maintain clear communication with the supplier throughout the process, documenting all interactions related to the issue. If disputes arise, refer to the agreed terms and conditions, and consider involving third-party mediation if necessary. Building a solid relationship with suppliers can often help prevent disputes from escalating. -

What are the best practices for maintaining helical gearboxes post-purchase?

Regular maintenance is essential for the longevity of helical gearboxes. Follow the manufacturer’s guidelines for lubrication, cleaning, and inspection. Establish a routine maintenance schedule to check for wear and tear, as well as alignment issues. Consider training your staff on basic troubleshooting and maintenance techniques. Keeping an open line of communication with the supplier for ongoing support and spare parts availability can also enhance operational efficiency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for helical gearbox

In conclusion, the strategic sourcing of helical gearboxes is crucial for international B2B buyers seeking to optimize their operations and enhance productivity. By leveraging the unique advantages of helical gear designs, such as superior load capacity and quiet operation, businesses can achieve better performance in applications across various sectors, including automotive, manufacturing, and renewable energy.

Key takeaways for buyers include:

- Evaluate Supplier Capabilities: Focus on suppliers that demonstrate innovation and reliability, as these factors are pivotal in ensuring the longevity and efficiency of gear systems.

- Consider Local and Global Options: While sourcing locally can reduce lead times and support regional economies, exploring global suppliers may offer advanced technologies and competitive pricing.

- Emphasize Sustainability: As industries increasingly prioritize eco-friendly practices, opt for suppliers who integrate sustainable materials and processes in their manufacturing.

Looking ahead, the helical gearbox market is expected to flourish, driven by technological advancements and the growing demand for automation. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe should seize this opportunity to forge strategic partnerships and invest in cutting-edge gear solutions that can propel their businesses forward. Engage with trusted suppliers today to secure a competitive edge in this evolving landscape.