Top 30 Motor Shaft Coupling Manufacturers to Consider

Finding the right motor shaft coupling can feel like searching for a needle in a haystack. With so many manufacturers out there, how do you know which one will deliver quality and reliability? Choosing the right supplier isn’t just about price—it’s about performance, durability, and peace of mind. Imagine the confidence you’ll have knowing you partnered with a top-tier factory that understands your needs and delivers exceptional products.

The benefits are endless: reduced downtime, improved efficiency, and ultimately, a smoother operation for your machinery. Curious about which manufacturers stand out from the crowd? Dive into our comprehensive comparison of the top 30 motor shaft coupling factories. You’ll discover insights that can help you make an informed decision. Let’s get started!

Top 30 Motor Shaft Coupling Manufacturers

Theengineerspost – Shaft Couplings Solutions

Domain: theengineerspost.com

Registered: 2018 ( 7 years )

Introduction: The company offers various types of shaft couplings, including rigid and flexible couplings, designed for connecting two rotating shafts for power transmission.

McMaster – Motor Couplings for Shaft Connections

Domain: mcmaster.com

Registered: 1994 ( 31 years )

Introduction: Motor couplings designed for connecting shafts in various applications.

Mikipulley Us – Products

Domain: mikipulley-us.com

Registered: 2013 ( 12 years )

Introduction: Miki Pulley offers a range of high torque shaft couplings, including metal disc couplings, resonance damping couplings, jaw & spider couplings, bellows couplings, slit style couplings, pin & hub couplings, rigid couplings, and spring and coil couplings.

Workshop Insider – Shaft Couplings Solutions

Domain: workshopinsider.com

Registered: 2020 ( 5 years )

Introduction: The company offers various types of shaft couplings, including rigid, flexible, and fluid couplings, designed to connect two shafts securely while allowing independent movement.

Grainger – Shaft Couplings and Universal Joints

Domain: grainger.com

Registered: 1994 ( 31 years )

Introduction: Shaft couplings and universal joints designed for power transmission applications.

Ondrives.US – Misalignment Shaft Couplings Solutions

Domain: ondrivesus.com

Registered: 2007 ( 18 years )

Introduction: Ondrives.US offers a variety of misalignment shaft couplings designed to absorb misalignment between rotating shafts, suitable for high power and high torque applications.

Learnmech – Mechanical Couplings Solutions

Domain: learnmech.com

Registered: 2017 ( 8 years )

Introduction: The company offers various types of couplings used in mechanical applications, including flexible couplings, rigid couplings, and universal joints.

Linquip – Shaft Couplings Solutions

Domain: linquip.com

Registered: 2019 ( 6 years )

Introduction: The company offers various types of shaft couplings, including flexible couplings, rigid couplings, and specialized couplings for different applications.

Engineeringlearn – Mechanical Couplings Solutions

Domain: engineeringlearn.com

Registered: 2020 ( 5 years )

Introduction: The company offers various types of mechanical couplings used to connect two shafts belonging to different machines, facilitating power transfer and reducing shock effects.

Lovejoy Inc – Flexible Couplings Solutions

Domain: lovejoy-inc.com

Registered: 1996 ( 29 years )

Introduction: Lovejoy offers a wide range of flexible couplings designed to connect two shafts end-to-end, transmit power, and compensate for misalignment.

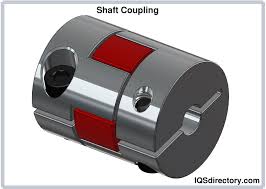

Iqsdirectory – Shaft Couplings Solutions

Domain: iqsdirectory.com

Registered: 2004 ( 21 years )

Introduction: Shaft couplings are components designed to join two shafts, enabling power transmission while accommodating alignment challenges and installation variances. They include rigid and flexible couplings tailored to different operational conditions.

Us – Rigid Shaft Couplings Solutions

Domain: us.misumi-ec.com

Registered: 2007 ( 18 years )

Introduction: Rigid Shaft Couplings – Shaft Couplings

Palmer’s Electric – Electric Motor Couplings

Domain: palmerselectric.com

Registered: 1999 ( 26 years )

Introduction: Palmer’s Electric offers electric motor couplings, specifically Flex Type Couplings and StarFlex Couplings, designed to transmit torque between a drive shaft and a driven part while providing mechanical flexibility to prevent misalignment.

Zero-Max – Flexible Shaft Couplings Solutions

Domain: zero-max.com

Registered: 1996 ( 29 years )

Introduction: Zero-Max offers a range of flexible shaft couplings designed for high performance in various applications. Their product line includes Composite Disc Couplings, ServoClass® Couplings, Control-Flex Shaft Couplings, and Schmidt Couplings, as well as specialized products for wind turbines.

Ruland – Precision Couplings and Shaft Collars

Domain: ruland.com

Registered: 1996 ( 29 years )

Introduction: Ruland offers a range of couplings and collars specifically designed for motor applications, including shaft collars, rigid couplings, servo couplings, and universal joints.

Motion – Shaft Couplings for Power Transmission

Domain: motion.com

Registered: 1994 ( 31 years )

Introduction: Shaft couplings designed for mechanical power transmission applications.

Dir – Motor Shaft Couplings Solutions

Domain: dir.indiamart.com

Registered: 1996 ( 29 years )

Introduction: The company primarily offers a variety of motor shaft couplings including round aluminium motor shaft couplers, steel motor shaft couplings, single disc couplings, serration type motor couplings, and flexible tyre type couplings, among others.

SKF – Power Transmission Couplings

Domain: cdn.skfmediahub.skf.com

Registered: 1996 ( 29 years )

Introduction: SKF offers a wide range of couplings designed to transmit power between shafts while accommodating misalignment. Their product line includes grid couplings, gear couplings, disc couplings, flex couplings, chain couplings, FRC couplings, jaw couplings, and universal joints, available in various types, sizes, and capacity ratings.

Uni Drive – Shaft Couplings and Mechanical Solutions

Domain: uni-drive.com

Registered: 2002 ( 23 years )

Introduction: Uni-Drive offers a wide range of shaft couplings, including tyre couplings, mini-couplings, gear couplings, and various other types designed for different applications in mechanical systems.

Couplingshaft – Motor Shaft Couplings Solutions

Domain: couplingshaft.com

Registered: 2020 ( 5 years )

Introduction: The company offers a range of motor shaft couplings designed to connect two shafts for power transmission in various applications.

Mechanicrealm – Shaft Couplings and Power Transmission Solutions

Domain: mechanicrealm.com

Registered: 2024 ( 1 years )

Introduction: The company offers various types of shaft couplings that connect two rotating shafts for power transmission, accommodating misalignment and reducing vibrations.

Engineerfix – Couplings and Power Transmission Solutions

Domain: engineerfix.com

Registered: 2020 ( 5 years )

Introduction: Couplings are mechanical components used to connect two shafts, enabling power transmission while allowing for some misalignment or movement. They come in various types including rigid, flexible, bellow, fluid, beam, flanged, and gear couplings.

Jlcmc – Shaft Couplings and Power Transmission Solutions

Domain: jlcmc.com

Registered: 2023 ( 2 years )

Introduction: The company offers various types of shaft couplings, including rigid shaft couplings and flexible shaft couplings, designed to connect two shafts for power transmission while accommodating misalignment and absorbing shock.

Robu – Mechanical Couplings for Various Applications

Domain: robu.in

Registered: 2012 ( 13 years )

Introduction: Robu.in offers a variety of mechanical couplings for different applications, available for purchase online at competitive prices in India.

Syk Tw – Motor Shaft Couplings Solutions

Domain: syk-tw.com

Registered: 2022 ( 3 years )

Introduction: Motor shaft couplings, including various types such as flexible couplings, set screw types, and clamp types.

Nbk1560 – Power Transmission Solutions

Domain: nbk1560.com

Registered: 2000 ( 25 years )

Introduction: The company offers a range of power transmission products, including couplings, gearboxes, and other mechanical components designed for various industrial applications.

Abssac – Precision Shaft Couplings Solutions

Domain: abssac.co.uk

Registered: 2000 ( 25 years )

Introduction: ABSSAC offers a comprehensive range of shaft couplings suitable for various applications, including precision miniature and industrial options. They provide custom designs and a wide selection of materials.

Fractory – Industrial Couplings and Solutions

Domain: fractory.com

Registered: 2000 ( 25 years )

Introduction: Fractory offers a range of couplings including flexible couplings, rigid couplings, and specialized couplings designed for various industrial applications.

Easa – Shaft Couplings for Mechanical Systems

Domain: easa.com

Registered: 1997 ( 28 years )

Introduction: Shaft couplings designed for various applications in mechanical systems, providing a connection between two shafts to transmit power and accommodate misalignment.

Stafford Manufacturing – Rigid Shaft Couplings

Domain: staffordmfg.com

Registered: 1995 ( 30 years )

Introduction: Stafford Manufacturing offers a variety of rigid shaft couplings, including one-piece, two-piece, and three-piece split couplings, as well as couplings with keyways and remachinable options.

Category Information

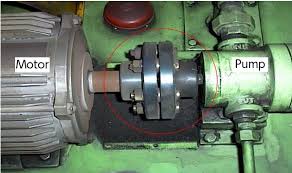

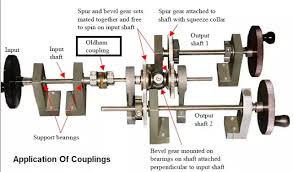

Motor shaft couplings are mechanical devices used to connect two shafts together for the purpose of transmitting power and motion. They play a crucial role in various applications, including industrial machinery, automotive systems, and robotics. By linking the motor shaft to the driven shaft, couplings ensure that rotational energy is efficiently transferred while accommodating misalignments, vibrations, and thermal expansions that may occur during operation.

The significance of motor shaft couplings lies in their ability to enhance the reliability and longevity of machinery. They help prevent damage to connected components by absorbing shocks and misalignments, which can lead to wear and failure if left unaddressed. Additionally, the right coupling selection can improve overall system performance, reduce maintenance costs, and increase operational efficiency, making them essential components in many mechanical systems.

Application Information

Motor shaft couplings are critical components used across various industries to connect and transmit torque between rotating shafts. One of the primary application areas is in industrial machinery, where couplings facilitate the operation of equipment like pumps, compressors, and conveyors, ensuring efficient power transfer and alignment between motor and driven components. Another significant area is automotive engineering, where couplings are employed in drivetrains to link the engine to the transmission, allowing for smooth power delivery and accommodating misalignments.

In aerospace, couplings are utilized in aircraft systems for propulsion and control mechanisms, ensuring reliability under high-stress conditions. Additionally, the renewable energy sector, particularly in wind turbines, relies on couplings to connect generators to rotor shafts, playing a vital role in energy conversion. Lastly, HVAC systems use couplings to link fans and motors, contributing to effective climate control in residential and commercial buildings.

Production Process Information

Manufacturing motor shaft couplings involves several key steps to ensure they meet performance and safety standards. The process begins with design and engineering, where specifications are created based on the intended application, considering factors like torque, speed, and environmental conditions. Next, the material selection stage is crucial, as manufacturers choose durable materials like steel or aluminum to withstand mechanical stress.

Once materials are selected, the machining process begins, where raw materials are shaped into the desired coupling form using techniques like turning, milling, or grinding. Finally, the products undergo quality control tests to ensure they meet industry standards and perform reliably. After passing inspection, the couplings are packaged and distributed for use in various applications, from industrial machinery to automotive systems. Each stage is vital for producing effective and safe motor shaft couplings.

Related Video

Frequently Asked Questions (FAQs)

What should I look for in a motor shaft coupling manufacturer?

When choosing a manufacturer, consider their experience, production capacity, and quality control processes. Look for certifications like ISO to ensure they meet industry standards. Also, check their range of products to see if they offer custom solutions that fit your specific needs.

How can I verify the quality of a coupling manufacturer?

You can verify quality by requesting samples and checking for certifications. Look for customer reviews and testimonials, and consider visiting the factory if possible. Additionally, inquire about their testing methods and materials used in production to ensure durability and performance.

What are the common materials used in motor shaft couplings?

Motor shaft couplings are typically made from materials like aluminum, steel, rubber, and plastic. The choice of material depends on factors like load requirements, environmental conditions, and the specific application. Make sure to discuss your needs with the manufacturer to find the best material for your coupling.

How do I determine the right type of coupling for my application?

To determine the right coupling, consider the torque requirements, shaft alignment, and operational conditions such as temperature and vibration. Consult with the manufacturer or an engineer who can help you assess your specific application and recommend the best coupling type.

What is the typical lead time for ordering couplings from a manufacturer?

Lead times can vary based on the manufacturer and the complexity of your order. Generally, standard couplings may take 2-4 weeks, while custom designs could take longer. Always ask the manufacturer for an estimated lead time when placing your order to ensure it aligns with your project timeline.

![Types of Mechanical Coupling and Their Uses [with Pictures] - motor shaft coupling](https://www.fobindustry.info/wp-content/uploads/2025/06/engineeringlearncom-motor-shaft-coupling-image.jpg)