Master Sourcing Screw Type Bolts: A Comprehensive B2B

Introduction: Navigating the Global Market for screw type bolt

In the complex landscape of global manufacturing and construction, screw type bolts play an essential role in ensuring structural integrity and operational efficiency. As a critical component in various applications—from automotive assembly to heavy machinery and infrastructure projects—these fasteners are indispensable for maintaining safety and durability. For international B2B buyers, particularly those based in Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing screw type bolts is vital for success.

This comprehensive guide is designed to empower procurement professionals and engineering decision-makers with actionable insights. It delves into the various types of screw type bolts available in the market, along with their material compositions and coating options to suit diverse applications. Furthermore, we explore manufacturing and quality control standards essential for compliance, ensuring that your fasteners meet international benchmarks.

Buyers will benefit from strategies for supplier selection, focusing on reliability and cost-effectiveness. The guide also outlines global cost structures and logistical considerations to streamline procurement processes. Additionally, we address common market trends and frequently asked questions, providing you with a well-rounded understanding of the screw type bolt market.

By leveraging the insights presented in this guide, international B2B buyers can make informed sourcing decisions, mitigate risks, and secure a competitive edge in their respective industries.

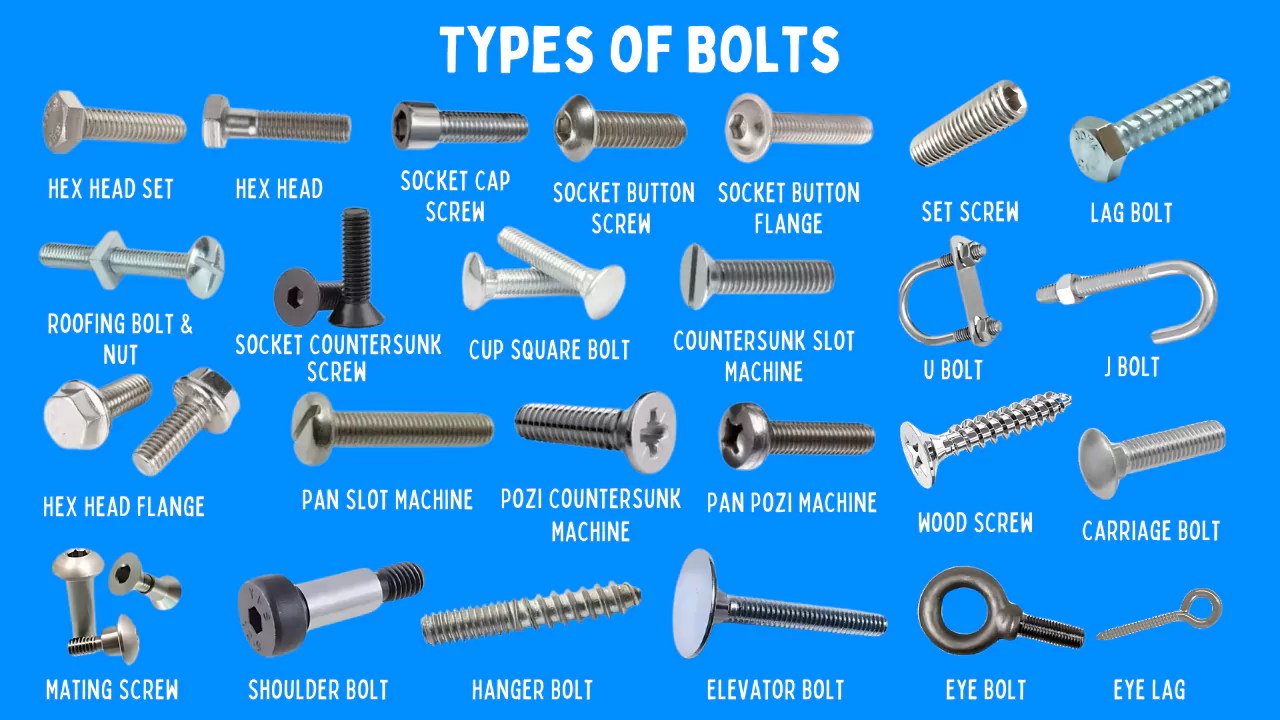

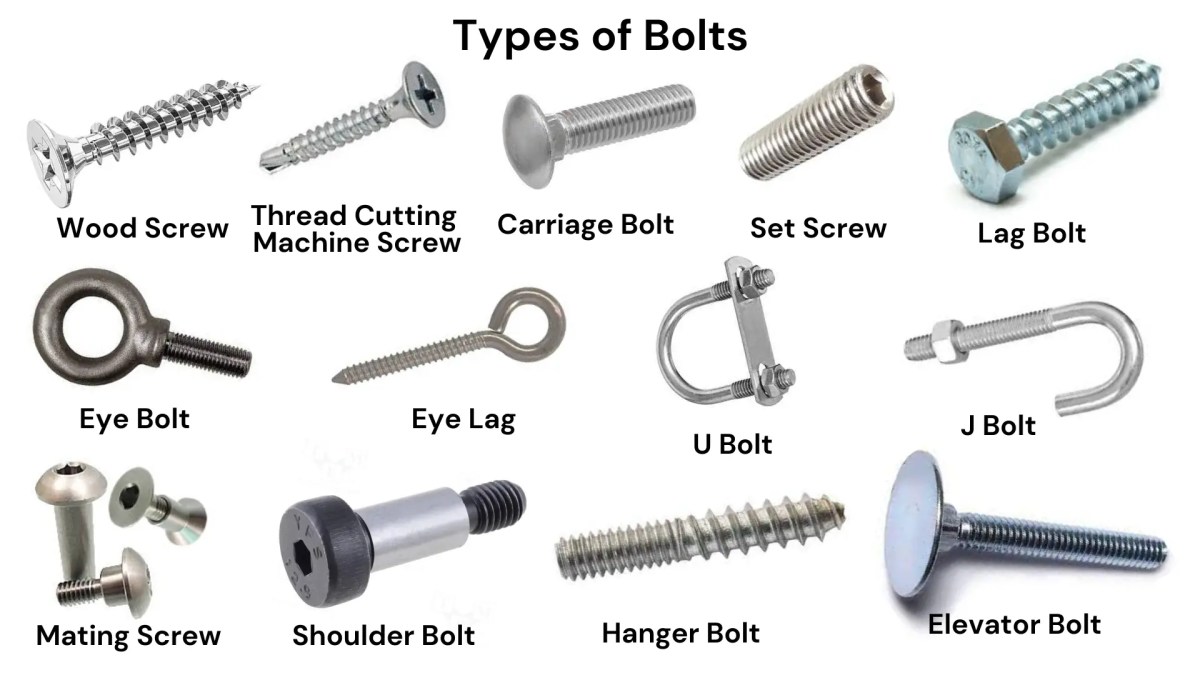

Understanding screw type bolt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hex Head Bolt | Six-sided head; compatible with standard wrenches; various sizes/grades | Construction, automotive, machinery | Pros: Versatile and widely available. Cons: Risk of overtightening or thread stripping. |

| Socket Head Bolt | Cylindrical head with an internal hex; allows for higher torque | Aerospace, automotive, machinery | Pros: High strength, compact design. Cons: Requires specific tools for installation. |

| Carriage Bolt | Domed head with a square neck; prevents rotation | Timber construction, furniture, railways | Pros: Tamper-resistant, smooth finish. Cons: Limited to through-hole applications. |

| Flange Bolt | Integrated flange acts as washer; distributes load evenly | Heavy equipment, automotive, pipelines | Pros: Reduces need for washers, good load distribution. Cons: Bulkier, can be higher in cost. |

| Lag Bolt | Large, heavy-duty screw with coarse threads; designed for wood | Construction, heavy machinery | Pros: Excellent grip in wood, suitable for heavy loads. Cons: Limited to wood applications, requires pre-drilling. |

Hex Head Bolt

Hex head bolts are characterized by their six-sided heads, allowing for easy installation and removal with standard tools. They are available in various sizes and grades, making them suitable for a wide range of applications, including construction, automotive, and machinery. For B2B buyers, it is crucial to assess local availability and preferred grades, ensuring compliance with international standards such as ISO or ASTM. This ensures compatibility with existing inventory and mitigates risks in multi-region projects.

Socket Head Bolt

Socket head bolts feature a cylindrical head with an internal hex drive, which allows for higher torque applications. This design is particularly advantageous in sectors like aerospace and automotive, where strength and precision are paramount. Buyers should consider the specific tools required for installation, as these bolts necessitate a hex key or socket wrench. Ensuring that suppliers provide bolts that meet relevant quality standards will enhance reliability and performance in critical applications.

Carriage Bolt

Carriage bolts have a distinctive domed head and a square neck that prevents rotation when tightened. Commonly used in timber construction, furniture, and railways, they offer tamper resistance and a smooth finish, making them ideal for applications where safety and aesthetics are important. Buyers should confirm the shank length and coatings, especially for outdoor installations in humid climates. Ensuring that bulk shipments include matching nuts can streamline the procurement process.

Flange Bolt

Flange bolts incorporate an extended flange beneath the head, acting as an integrated washer. This design helps distribute load evenly, making them popular in heavy equipment, automotive, and pipeline applications. For buyers, evaluating the flange diameter and thickness relative to load requirements is essential. Some projects may require specific flange designs, so confirming compatibility with project specifications is crucial for successful procurement.

Lag Bolt

Lag bolts, also known as lag screws, are heavy-duty fasteners with coarse threads designed specifically for use in wood. They provide excellent grip and are commonly used in construction and heavy machinery applications. B2B buyers should note that while lag bolts excel in wood applications, they require pre-drilling for installation. Understanding the specific requirements of the project, including load capacities and environmental factors, is key to successful sourcing of lag bolts.

Related Video: Bolt Head Markings: What do they mean? | Fasteners 101

Key Industrial Applications of screw type bolt

| Industry/Sector | Specific Application of screw type bolt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Securing structural frameworks | Ensures safety and stability of buildings and infrastructure | Compliance with local building codes and material standards |

| Automotive | Engine assembly and chassis connection | Enhances performance and durability of vehicles | Certification for automotive-grade fasteners |

| Manufacturing | Equipment assembly in production lines | Streamlines production processes and reduces downtime | Supplier reliability and adherence to quality standards |

| Oil & Gas | Pipeline construction and maintenance | Prevents leaks and ensures operational safety | Corrosion resistance and compliance with industry regulations |

| Aerospace | Aircraft component assembly | Critical for safety and performance of aircraft | High-grade materials and strict quality control requirements |

Construction

In the construction sector, screw type bolts are essential for securing structural frameworks. They provide the necessary strength to hold together beams, columns, and other components, ensuring the safety and stability of buildings and infrastructure. For international buyers, it is crucial to consider compliance with local building codes and material standards. Additionally, sourcing bolts with appropriate corrosion resistance is vital, especially in regions with harsh climates, such as parts of Africa and the Middle East.

Automotive

In the automotive industry, screw type bolts play a significant role in engine assembly and chassis connections. These bolts are designed to withstand high levels of stress and vibration, ensuring the performance and durability of vehicles. B2B buyers must prioritize suppliers that offer automotive-grade fasteners, certified to meet stringent industry standards. Ensuring compatibility with specific vehicle models and compliance with safety regulations is also essential for successful procurement.

Manufacturing

Manufacturing relies heavily on screw type bolts for equipment assembly in production lines. These fasteners facilitate the quick and efficient assembly of machinery, which is critical for maintaining productivity and reducing downtime. For international buyers, it is important to evaluate supplier reliability and ensure adherence to quality standards, such as ISO certifications. Additionally, considering logistics and lead times can help streamline the procurement process.

Oil & Gas

In the oil and gas sector, screw type bolts are crucial for pipeline construction and maintenance. They help prevent leaks and ensure the operational safety of pipelines, which is vital in this high-stakes industry. Buyers should focus on sourcing bolts with high corrosion resistance to withstand harsh environmental conditions. Compliance with industry regulations and standards is also a key consideration when sourcing these fasteners, particularly in regions with strict environmental and safety guidelines.

Aerospace

In aerospace applications, screw type bolts are critical for aircraft component assembly. They ensure the safety and performance of various aircraft systems, from engines to fuselage connections. Given the high stakes involved, B2B buyers must prioritize high-grade materials and strict quality control requirements when sourcing these fasteners. Understanding the specific aerospace standards and certifications is essential to ensure that the sourced bolts will perform reliably in challenging operational environments.

Related Video: Magnetic Force Type Automatic Screw Feeder- SF30M

Strategic Material Selection Guide for screw type bolt

When selecting screw type bolts, the choice of material is critical for ensuring performance, durability, and compliance with industry standards. Below, we analyze four common materials used in screw type bolts, emphasizing their properties, advantages, disadvantages, and considerations for international B2B buyers.

Carbon Steel

Key Properties: Carbon steel bolts are known for their high tensile strength and hardness. They can withstand high temperatures and pressures, making them suitable for a wide range of applications. However, they are prone to corrosion if not properly coated.

Pros & Cons: Carbon steel bolts are relatively inexpensive and widely available, making them a popular choice for many industries. Their durability makes them ideal for heavy-duty applications. However, their susceptibility to rust in humid environments can be a significant drawback, necessitating protective coatings, which can increase costs.

Impact on Application: Carbon steel bolts are ideal for use in construction, automotive, and machinery applications. However, they are not suitable for environments where corrosion is a concern, such as coastal areas or chemical processing plants.

Considerations for International Buyers: Buyers should ensure that the carbon steel bolts meet international standards such as ASTM A307 or DIN 931. In humid regions like parts of Africa and South America, opting for galvanized or coated variants can enhance performance.

Stainless Steel

Key Properties: Stainless steel bolts offer excellent corrosion resistance due to the presence of chromium. They maintain their strength at high temperatures and are non-magnetic, making them suitable for various applications.

Pros & Cons: The primary advantage of stainless steel bolts is their durability and resistance to rust and corrosion, making them ideal for outdoor and marine applications. However, they tend to be more expensive than carbon steel bolts and can be more challenging to machine.

Impact on Application: Stainless steel bolts are particularly well-suited for environments exposed to moisture, chemicals, or extreme temperatures. They are commonly used in the food processing, pharmaceutical, and marine industries.

Considerations for International Buyers: Buyers should look for compliance with standards such as ASTM F593 or ISO 3506. In regions with stringent environmental regulations, stainless steel may be preferred despite the higher cost.

Alloy Steel

Key Properties: Alloy steel bolts are made by adding elements like nickel, chromium, or molybdenum to carbon steel, enhancing their mechanical properties. They offer higher strength and toughness, especially at elevated temperatures.

Pros & Cons: The enhanced strength makes alloy steel bolts suitable for high-stress applications, such as in the automotive and aerospace industries. However, they can be more expensive and may require specialized manufacturing processes.

Impact on Application: Alloy steel bolts are commonly used in applications requiring high strength and resistance to wear, such as in heavy machinery and structural components. Their performance in high-temperature environments is also a key advantage.

Considerations for International Buyers: It is crucial to verify that alloy steel bolts meet relevant standards such as ASTM A325 or JIS B 1180. Buyers should also consider the availability of these materials in their region, as they may not be as readily available as carbon or stainless steel.

Titanium

Key Properties: Titanium bolts are known for their exceptional strength-to-weight ratio and corrosion resistance. They perform well in extreme temperatures and are non-magnetic.

Pros & Cons: The primary advantage of titanium bolts is their lightweight and high strength, making them ideal for aerospace and high-performance applications. However, they are significantly more expensive than other materials and can be challenging to machine.

Impact on Application: Titanium bolts are often used in aerospace, medical, and high-performance automotive applications where weight savings and corrosion resistance are critical.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM F467 or ISO 5832. Given the higher costs, it’s essential to assess whether the benefits justify the investment, particularly in cost-sensitive markets.

| Material | Typical Use Case for screw type bolt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Construction, automotive, machinery | High tensile strength | Prone to corrosion without coating | Medium |

| Stainless Steel | Marine, food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost and machining difficulty | High |

| Alloy Steel | Heavy machinery, aerospace, automotive | Enhanced strength and toughness | More expensive and specialized mfg | Medium to High |

| Titanium | Aerospace, medical, high-performance automotive | Lightweight and strong | Very high cost and machining challenges | High |

This guide provides a comprehensive overview of material options for screw type bolts, equipping international B2B buyers with the insights needed to make informed procurement decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for screw type bolt

Manufacturing Processes for Screw Type Bolts

The manufacturing of screw type bolts involves several key stages, each critical to ensuring the final product meets the required specifications for performance and safety. Understanding these processes can aid international B2B buyers in assessing supplier capabilities and ensuring quality.

Material Preparation

The first step in bolt manufacturing is material preparation, which typically involves selecting the appropriate raw materials. Common materials include carbon steel, stainless steel, and alloy steel, chosen for their mechanical properties and corrosion resistance.

- Material Inspection: Before production begins, materials must undergo inspection to verify their compliance with international standards (e.g., ASTM, ISO). This process often includes checking for chemical composition and mechanical properties.

- Cutting and Shaping: Raw materials are then cut into appropriate lengths, often using methods such as sawing or shearing, to prepare for the next stage of manufacturing.

Forming

The forming stage is where the actual shape of the screw type bolt is created. This process can involve several techniques:

- Cold Heading: This method involves deforming the metal at room temperature using dies to form the head and shank of the bolt. Cold heading is preferred for its efficiency and ability to produce strong, uniform parts.

- Thread Rolling: After the bolt has been formed, threads are created using thread rolling machines. This technique improves the mechanical properties of the bolt compared to cutting threads, as it aligns the grain structure of the metal.

- Heat Treatment: To enhance strength and hardness, bolts may undergo heat treatment processes such as quenching and tempering. This step is vital for applications requiring high tensile strength.

Assembly

For some bolt types, assembly may include the addition of nuts or washers. This step ensures that all components fit together seamlessly.

- Automated Assembly: Many manufacturers utilize automated systems to enhance precision and reduce assembly time, which is crucial for maintaining cost efficiency in high-volume production.

Finishing

The final manufacturing stage involves surface treatments and coatings to enhance the bolt’s performance in various environments.

- Coatings: Common options include galvanization, anodizing, or applying specialized coatings for corrosion resistance. The choice of finish often depends on the bolt’s intended application and the environmental conditions it will face.

- Surface Finishing: This may include processes like polishing or shot blasting to improve aesthetic qualities and reduce friction during assembly.

Quality Assurance in Bolt Manufacturing

Quality assurance is paramount in the bolt manufacturing process, ensuring that the final product meets the necessary safety and performance standards.

International Standards

International standards such as ISO 9001 play a crucial role in maintaining quality in manufacturing. This standard outlines requirements for a quality management system, helping manufacturers ensure consistent quality.

- Industry-Specific Standards: In addition to ISO, certain industries may require compliance with specific standards such as CE marking for construction products or API standards for oil and gas applications.

Quality Control Checkpoints

Quality control (QC) involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials before they are used in production. Ensuring quality at this stage prevents defects from affecting the final product.

- In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is essential. This includes checking dimensions, tolerances, and mechanical properties at various stages of production.

- Final Quality Control (FQC): After production, a thorough examination of the finished bolts is conducted. This may involve testing for tensile strength, hardness, and dimensional accuracy.

Common Testing Methods

Various testing methods are employed to verify the quality and performance of screw type bolts:

- Tensile Testing: Measures the bolt’s ability to withstand tension, which is critical for load-bearing applications.

- Hardness Testing: Assesses the material’s hardness, ensuring it meets the required specifications for durability.

- Corrosion Resistance Testing: Especially important for bolts used in harsh environments, this test evaluates the effectiveness of protective coatings.

Verifying Supplier Quality Control

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure reliability. Here are strategies to consider:

- Supplier Audits: Conducting on-site audits can provide insights into the supplier’s manufacturing processes, QC measures, and adherence to standards. This is particularly important for buyers from regions with strict regulatory requirements.

- Requesting Documentation: Buyers should ask for detailed QC reports, including test results and certifications. These documents provide a clear picture of the supplier’s commitment to quality.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the manufacturer’s quality processes. This is beneficial for buyers who may not have the capacity to conduct thorough audits themselves.

QC Nuances for International Buyers

When sourcing screw type bolts internationally, buyers from Africa, South America, the Middle East, and Europe should be aware of certain nuances in quality control:

- Regulatory Compliance: Different regions may have varying regulations regarding fastener quality. Familiarize yourself with the specific requirements in your industry and region to ensure compliance.

- Cultural Differences: Understanding cultural approaches to business and quality standards can enhance communication with suppliers. This is particularly relevant in regions with differing manufacturing practices.

- Logistics and Supply Chain: Quality assurance does not end with manufacturing. Buyers should consider the entire supply chain, including shipping and handling processes, to mitigate risks of damage or loss of quality during transit.

By navigating these manufacturing processes and quality assurance protocols, international B2B buyers can make informed decisions when sourcing screw type bolts, ensuring they procure reliable products that meet their operational needs.

Related Video: Most Manufacturing Process of Motersycle Back Wheel Hub // Production of U Bolt in Local Factory..

Comprehensive Cost and Pricing Analysis for screw type bolt Sourcing

Analyzing the cost structure and pricing for screw type bolt sourcing is crucial for international B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. Understanding the various cost components and price influencers can lead to more effective purchasing decisions and improved negotiation outcomes.

Cost Components

-

Materials: The choice of materials significantly impacts the cost of screw type bolts. Common materials include carbon steel, stainless steel, and specialized alloys. Prices fluctuate based on global commodity rates and the specific properties required, such as corrosion resistance or tensile strength.

-

Labor: Labor costs vary by region and are influenced by local wage standards. In countries with higher labor costs, such as parts of Europe, the overall production expenses for bolts may increase. Conversely, regions with lower labor costs can offer competitive pricing but may come with concerns regarding quality control.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and administrative expenses. Efficient manufacturing processes can help minimize these costs, which are often passed on to the buyer.

-

Tooling: Custom tooling requirements for specific bolt designs or sizes can add to the initial costs. Buyers should consider whether standardized products are available to reduce these expenses.

-

Quality Control (QC): Rigorous quality control measures are essential for ensuring that bolts meet international standards. Suppliers often include QC costs in their pricing, which is a crucial factor for buyers aiming for reliability and safety in their applications.

-

Logistics: Shipping and handling costs can vary significantly based on the geographical distance between the supplier and the buyer. International shipping may involve additional tariffs, taxes, and duties, which must be factored into the total cost.

-

Margin: Supplier margins can vary widely based on market competition, brand reputation, and the complexity of the product. Understanding the supplier’s pricing model is essential for effective negotiation.

Price Influencers

Several factors can influence the pricing of screw type bolts:

-

Volume/MOQ: Minimum order quantities (MOQ) can affect pricing. Bulk purchases typically lead to lower unit costs due to economies of scale, making it advantageous for buyers to consolidate orders.

-

Specifications/Customization: Custom specifications, such as unique sizes or materials, can increase costs. Standardized products are often more economical, so buyers should evaluate the necessity of customization against budget constraints.

-

Quality/Certifications: Bolts that meet specific international standards (e.g., ASTM, ISO) may carry a premium price due to the assurance of quality and performance. Buyers must weigh the benefits of certification against the potential for cost savings with unregulated products.

-

Supplier Factors: Supplier reliability, reputation, and service levels can influence pricing. Established suppliers may charge higher prices but offer better support and quality assurance.

-

Incoterms: Understanding shipping terms (Incoterms) is vital for calculating the total landed cost. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can alter the overall cost structure significantly.

Buyer Tips

-

Negotiation: Leverage volume purchasing and long-term contracts to negotiate better pricing. Establishing a good relationship with suppliers can also lead to discounts and preferential treatment.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO) rather than just the purchase price. Consider factors like installation, maintenance, and potential failures that may arise from using lower-quality bolts.

-

Pricing Nuances: International buyers should be aware of currency fluctuations, import duties, and local market conditions that can affect pricing. It’s advisable to seek quotes from multiple suppliers to ensure competitive pricing.

-

Local Market Insights: Engage with local suppliers to gain insights into regional pricing trends and potential cost-saving opportunities.

Disclaimer

Prices for screw type bolts can vary significantly based on the factors discussed above and should be viewed as indicative. Buyers are encouraged to conduct thorough market research and supplier evaluations to obtain accurate pricing for their specific requirements.

Spotlight on Potential screw type bolt Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘screw type bolt’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for screw type bolt

Key Technical Properties of Screw Type Bolts

When sourcing screw type bolts, understanding the essential technical properties is crucial for ensuring compatibility and reliability in your applications. Here are several key specifications that B2B buyers should consider:

-

Material Grade

The material grade of a screw type bolt indicates its composition and mechanical properties, such as strength and corrosion resistance. Common materials include carbon steel, stainless steel, and alloy steel. Selecting the right material grade is vital for ensuring that the bolts can withstand the environmental conditions they will face, such as humidity, temperature fluctuations, and exposure to chemicals. -

Tensile Strength

This property defines the maximum amount of tensile (pulling) stress a bolt can withstand before failing. It is typically measured in megapascals (MPa) or pounds per square inch (psi). For B2B buyers, understanding tensile strength is essential to ensure that the bolts can support the intended loads in their applications without risk of breakage. -

Diameter and Length

The diameter and length of a bolt dictate its fit and functionality in assembly. These measurements must align with project specifications to ensure proper engagement with the mating parts. Buyers should assess these dimensions carefully, particularly when dealing with custom applications or replacements in existing structures. -

Thread Pitch

Thread pitch refers to the distance between threads, which can impact how tightly the bolt can be secured. Common thread types include coarse and fine threads, with fine threads offering better tension retention but requiring more precise alignment. Understanding thread pitch is critical for compatibility with nuts and other fasteners in assembly. -

Coating and Finish

The coating on a bolt serves to enhance its resistance to corrosion and wear. Common coatings include zinc plating, black oxide, and hot-dip galvanization. B2B buyers must consider the operating environment when selecting coatings, as they can significantly affect the longevity and performance of the fasteners. -

Tolerance

Tolerance refers to the allowable variation in dimensions. High-tolerance bolts ensure precise fit and function, which is essential in high-stress applications. Buyers should confirm that suppliers can provide bolts that meet the necessary tolerance levels for their specific applications.

Common Trade Terminology

Familiarity with industry jargon can enhance communication and negotiation processes in B2B transactions. Here are some common terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is vital for ensuring that sourced bolts meet the required performance standards for specific machinery or applications. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units that a supplier is willing to sell in a single order. Buyers should be aware of MOQs to effectively plan their procurement strategies and avoid overstocking or stockouts. -

RFQ (Request for Quotation)

An RFQ is a formal request issued to suppliers to provide pricing and terms for specific products. This is an essential step in the procurement process, allowing buyers to compare options and negotiate better terms. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping arrangements. Understanding these terms helps buyers navigate logistics and ensure that they are clear on who bears the risk and costs at various stages of transport. -

Lead Time

Lead time refers to the time it takes from placing an order to the delivery of the product. Buyers must consider lead time when planning their projects to avoid delays that could impact overall timelines. -

Certification

Certification indicates that a product meets specific industry standards for quality and safety, such as ISO or ASTM certifications. For B2B buyers, sourcing certified bolts ensures that they are acquiring reliable products that comply with regulatory requirements.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring that they procure the right screw type bolts for their specific needs while optimizing efficiency and compliance in their operations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the screw type bolt Sector

Market Overview & Key Trends

The global screw type bolt market is witnessing significant growth driven by several factors. Increased infrastructure investments across Africa, South America, the Middle East, and Europe are propelling demand for reliable fastening solutions. Emerging economies are particularly focused on developing infrastructure projects, which necessitate high-quality fasteners to ensure structural integrity and safety.

Current trends in B2B sourcing include a shift towards digital procurement platforms, enabling buyers to streamline their purchasing processes. Technologies such as artificial intelligence (AI) and machine learning are enhancing supplier selection and risk assessment, allowing buyers to make data-driven decisions. Additionally, the rise of Industry 4.0 is influencing manufacturing practices, with a focus on automation and precision engineering, which is critical for producing high-quality bolts.

International buyers must also navigate complex logistics and compliance issues, particularly when sourcing from diverse regions. Understanding local regulations, tariffs, and customs requirements is essential to avoid delays and additional costs. Furthermore, the demand for customized solutions is on the rise, as businesses seek to optimize their operations with fasteners tailored to specific applications and environments.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

Sustainability has become a crucial consideration in the sourcing of screw type bolts. The environmental impact of fastener production, including resource extraction and manufacturing processes, necessitates a shift towards more sustainable practices. Buyers should prioritize suppliers that implement eco-friendly manufacturing techniques, such as reducing energy consumption and minimizing waste.

Ethical sourcing is equally important, as it fosters transparency and accountability within supply chains. B2B buyers should seek suppliers with certifications indicating adherence to environmental standards, such as ISO 14001. Additionally, the use of recycled materials and sustainable production methods should be prioritized. Certifications like the Forest Stewardship Council (FSC) for wood-based products or the Global Recycled Standard (GRS) for recycled materials are indicators of a supplier’s commitment to sustainability.

Investing in “green” fasteners not only benefits the environment but can also enhance a company’s reputation and appeal to increasingly eco-conscious consumers. By aligning procurement strategies with sustainability goals, businesses can ensure compliance with regulations and contribute to global efforts towards reducing carbon footprints.

Illustrative Image (Source: Google Search)

Brief Evolution/History

The screw type bolt has a rich history that dates back to ancient civilizations, where rudimentary forms of screws were utilized in various mechanical devices. Over the centuries, advancements in metallurgy and manufacturing techniques have transformed these fasteners into the highly engineered components used today. The industrial revolution marked a significant turning point, as mass production capabilities allowed for standardized sizes and specifications, enhancing the reliability and availability of bolts.

In the contemporary market, the evolution of fasteners continues with the integration of advanced materials and coatings, improving performance in diverse environments. This ongoing innovation is critical for meeting the demands of modern industries and ensuring the longevity of structures and machinery globally. Understanding this historical context can provide B2B buyers with insights into the reliability and technological advancements in screw type bolts, informing their procurement strategies.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of screw type bolt

-

What should I look for when vetting suppliers for screw type bolts?

When vetting suppliers, focus on certifications that demonstrate compliance with international standards such as ASTM, ISO, or DIN. Request documentation showing quality control processes, including material tests and performance reports. Additionally, assess the supplier’s reputation through customer reviews and industry references. Engaging with suppliers in trade shows or industry networks can also provide insights into their reliability and service levels. -

Can I customize screw type bolts to fit my specific needs?

Yes, many suppliers offer customization options for screw type bolts. This can include alterations in dimensions, materials, coatings, and thread patterns. When seeking customization, clearly communicate your requirements and ensure the supplier has the capability to meet them. Consider obtaining samples before placing a bulk order to verify that the customized bolts meet your specifications. -

What are the typical minimum order quantities (MOQs) and lead times for screw type bolts?

MOQs for screw type bolts can vary significantly based on the supplier, customization requirements, and production capabilities. Generally, standard products may have lower MOQs, while custom designs could require higher quantities. Lead times also depend on factors such as supplier location, production schedules, and shipping logistics. Always inquire about these details upfront to align your project timelines with supplier capabilities. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers should implement rigorous quality assurance measures, including regular testing and inspections at various stages of production. Ensure they provide certifications that validate their products’ compliance with international standards. Additionally, ask for access to technical documentation, such as material safety data sheets and inspection reports, to confirm product quality and reliability. -

How can I ensure smooth logistics when sourcing screw type bolts internationally?

To facilitate smooth logistics, work closely with suppliers who have experience in international shipping. Discuss shipping options, including freight forwarding and customs clearance processes, to avoid unexpected delays. Establish clear timelines and shipping terms, and consider using incoterms to delineate responsibilities. It may also be beneficial to partner with logistics providers familiar with your target markets to streamline the process. -

What steps should I take if a dispute arises with my bolt supplier?

In the event of a dispute, first review the terms outlined in your purchase agreement, including warranties and return policies. Communicate directly with the supplier to address the issue and seek a resolution. If direct negotiation fails, consider involving a third-party mediator or arbitrator familiar with international trade practices. Document all communications and agreements to support your position throughout the dispute resolution process. -

Are there specific certifications I should require for screw type bolts?

Yes, you should require certifications such as ISO 9001 for quality management systems, ASTM standards for material specifications, and any relevant regional certifications that may apply to your market. These certifications ensure that the bolts meet specific performance and safety criteria. Always request copies of these certifications before finalizing your order to ensure compliance with your project requirements. -

What are the best practices for payment when sourcing screw type bolts?

When sourcing internationally, consider secure payment methods such as letters of credit or escrow services, which can provide additional security for both parties. Negotiate payment terms that suit your cash flow while ensuring the supplier is comfortable with the arrangement. It’s advisable to establish a clear payment schedule tied to specific milestones in the production and delivery process to mitigate risks associated with international transactions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for screw type bolt

In summary, effective strategic sourcing of screw type bolts is crucial for international B2B buyers aiming to ensure operational excellence and product safety. Key takeaways include the importance of selecting the right fasteners that meet specific technical specifications and compliance standards, particularly those recognized globally such as ASTM, ISO, and DIN. Buyers should prioritize suppliers who not only offer high-quality materials and manufacturing processes but also demonstrate reliability and responsiveness to customer needs.

As industries across Africa, South America, the Middle East, and Europe continue to evolve, the demand for durable and efficient fasteners will only increase. By leveraging local and online supplier networks, companies can optimize their procurement processes, reduce costs, and enhance project timelines.

Looking ahead, it is imperative for buyers to stay informed about market trends and innovations in bolt technology. Engaging with suppliers at trade shows and maintaining robust relationships will facilitate access to the latest products and solutions. Embrace this opportunity to refine your sourcing strategies, ensuring your projects are supported by the quality fasteners that drive success.