Your Ultimate Guide to Sourcing G Code Simulation

Introduction: Navigating the Global Market for g code simulation

In the rapidly evolving landscape of global manufacturing, G-code simulation emerges as a pivotal tool for B2B buyers aiming to optimize their CNC operations. This sophisticated software enables manufacturers to visualize and debug the tool paths of CNC machines and 3D printers before actual production, significantly reducing the risk of costly errors and enhancing operational efficiency. For international buyers from regions such as Africa, South America, the Middle East, and Europe, mastering G-code simulation is not merely advantageous—it is essential for maintaining a competitive edge.

This comprehensive guide delves into the critical facets of G-code simulation, providing insights into various types of simulators, material considerations, and their applications across manufacturing and quality control. By exploring current supplier trends, cost structures, and market opportunities, the guide equips procurement teams with actionable knowledge to navigate the complexities of sourcing. Additionally, it features FAQs and practical checklists to streamline the decision-making process.

With a focus on empowering international buyers—particularly those in emerging markets like Mexico and Brazil—this guide underscores the importance of informed sourcing decisions. By leveraging the power of G-code simulation, businesses can enhance product quality, minimize downtime, and foster robust supplier relationships, ultimately driving sustainable growth in an increasingly interconnected world.

Understanding g code simulation Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Basic G-Code Simulators | Simple representation of tool paths; often 2D visualizations. | Ideal for beginners and educational purposes. | Cost-effective but limited in functionality and detail. |

| Advanced G-Code Simulators | 3D visualization, collision detection, and error checking. | Professional CNC machining and 3D printing. | High investment but enhances accuracy and reduces errors. |

| Integrated CAM Systems | Combines design, simulation, and toolpath generation. | Comprehensive manufacturing solutions. | Streamlines workflow but may require extensive training. |

| Open-Source G-Code Simulators | Community-driven software with customizable features. | Research, development, and hobbyist projects. | Flexible and adaptable but may lack formal support. |

| Cloud-Based G-Code Simulators | Accessibility from anywhere with real-time collaboration. | Remote teams in global manufacturing. | Enhances teamwork but may raise data security concerns. |

Basic G-Code Simulators

Basic G-code simulators provide a straightforward visual representation of tool paths, typically in 2D. These tools are particularly suitable for beginners and educational settings, allowing users to grasp fundamental concepts without overwhelming complexity. For B2B buyers, especially those in emerging markets, these simulators offer a cost-effective entry point to CNC programming. However, their limited functionality means they may not suffice for more complex machining tasks, necessitating a future upgrade to more advanced solutions.

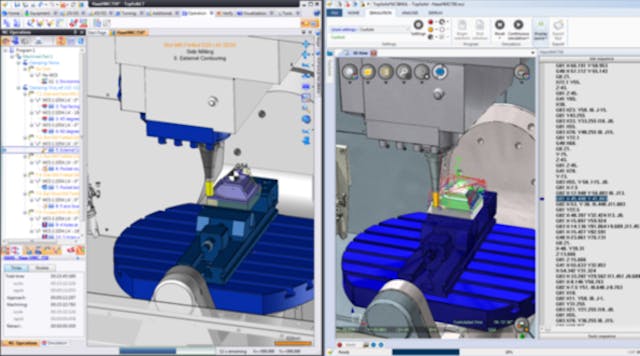

Advanced G-Code Simulators

Advanced G-code simulators offer features such as 3D visualization, collision detection, and detailed error checking. These tools are essential for professionals in CNC machining and 3D printing, as they significantly enhance the precision of the machining process. B2B buyers should consider investing in these simulators for their ability to reduce costly errors and improve production efficiency. While the initial investment may be higher, the potential cost savings from avoiding mistakes in the machining process can justify the expense.

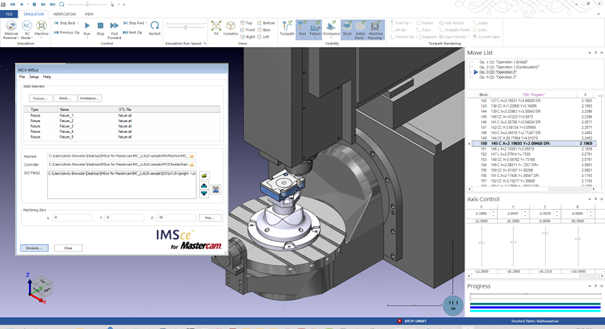

Integrated CAM Systems

Integrated Computer-Aided Manufacturing (CAM) systems combine design, simulation, and toolpath generation into a single platform. These systems are well-suited for comprehensive manufacturing solutions, enabling seamless transitions from design to production. B2B buyers looking for streamlined workflows should prioritize these systems, as they can significantly enhance productivity. However, the complexity of integrated systems may require extensive training for staff, which should be factored into the overall purchasing decision.

Open-Source G-Code Simulators

Open-source G-code simulators are community-driven tools that offer customizable features, making them ideal for research and development, as well as hobbyist projects. These simulators are particularly beneficial for B2B buyers in innovative sectors where flexibility and adaptability are crucial. While they provide significant freedom in terms of functionality, buyers should be aware that the lack of formal support may lead to challenges in troubleshooting or updates.

Cloud-Based G-Code Simulators

Cloud-based G-code simulators enable accessibility from anywhere and facilitate real-time collaboration among team members. This feature is especially advantageous for remote teams operating in global manufacturing environments. B2B buyers should consider these simulators for their potential to enhance teamwork and coordination. However, concerns regarding data security and compliance must be addressed, particularly in industries where sensitive information is handled.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of g code simulation

| Industry/Sector | Specific Application of g code simulation | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Tool path optimization for complex component manufacturing | Reduces material waste and enhances precision in components | Ensure compatibility with aerospace standards and rigorous testing |

| Automotive | Simulation of automated assembly lines | Increases throughput and minimizes production errors | Look for solutions that integrate easily with existing systems |

| Electronics | Prototyping and testing of circuit board fabrication | Accelerates time-to-market for new products | Verify software’s ability to handle diverse PCB designs |

| Medical Devices | Precision machining of surgical instruments | Ensures high-quality, reliable products essential for safety | Focus on suppliers with certifications for medical-grade materials |

| Additive Manufacturing (3D Printing) | Layer-by-layer simulation for complex prints | Identifies potential failures in the printing process | Assess the software’s compatibility with various 3D printers |

Aerospace

In the aerospace sector, G-code simulation is critical for optimizing tool paths when manufacturing complex components, such as turbine blades and airframe structures. By simulating the machining process, manufacturers can identify and rectify potential issues before production, significantly reducing material waste and improving precision. For international buyers, particularly from regions like Africa and the Middle East, it’s vital to source simulation software that meets stringent aerospace standards and has been rigorously tested for reliability.

Automotive

Automotive manufacturers utilize G-code simulation to streamline automated assembly lines, which can involve a multitude of components and processes. This technology allows for the visualization and optimization of the entire production workflow, thereby increasing throughput and minimizing errors that could lead to costly recalls. Buyers from South America and Europe should consider sourcing solutions that can easily integrate with existing manufacturing systems and support continuous improvement efforts.

Illustrative Image (Source: Google Search)

Electronics

In the electronics industry, G-code simulation is employed for prototyping and testing circuit board fabrication processes. By simulating the machining of PCBs, manufacturers can accelerate their time-to-market for new products while ensuring high-quality standards. For B2B buyers, especially in rapidly developing markets like Mexico and Brazil, it is essential to verify that the simulation software can handle diverse PCB designs and comply with local regulations.

Medical Devices

The medical device sector relies heavily on G-code simulation for the precision machining of surgical instruments and implants. This technology ensures that products meet the highest quality and safety standards, which are critical in this industry. Buyers should focus on sourcing suppliers who have certifications for medical-grade materials and can demonstrate a proven track record in producing reliable medical devices.

Additive Manufacturing (3D Printing)

In additive manufacturing, G-code simulation plays a vital role in visualizing the layer-by-layer printing process for complex designs. This allows manufacturers to identify potential failures before the actual printing begins, saving time and materials. For international buyers, especially those in Europe and the Middle East, assessing the software’s compatibility with various 3D printers is crucial to ensure seamless integration into their production processes.

Related Video: G-Code-Driven Machining Simulation in NX CAM

Strategic Material Selection Guide for g code simulation

When selecting materials for G-code simulation in CNC machining and 3D printing, international B2B buyers must consider various factors such as the material’s properties, application suitability, and compliance with regional standards. Below is an analysis of four common materials that are frequently used in G-code simulations, particularly relevant to buyers from Africa, South America, the Middle East, and Europe.

1. PLA (Polylactic Acid)

Key Properties: PLA is a biodegradable thermoplastic made from renewable resources like corn starch or sugarcane. It has a lower melting temperature (around 180-220°C) and is known for its excellent printability and dimensional stability.

Pros & Cons:

– Pros: PLA is easy to print, environmentally friendly, and offers good surface finish. It is also less prone to warping compared to other materials.

– Cons: Its lower heat resistance limits its application in high-temperature environments, making it unsuitable for functional parts that require durability.

Impact on Application: PLA is ideal for prototyping and educational purposes, but its mechanical properties may not withstand rigorous use in industrial applications.

Considerations for International Buyers: Buyers should ensure that PLA complies with local environmental regulations and standards, such as ASTM D6400 for compostability. In regions with a focus on sustainability, PLA may be preferred.

2. ABS (Acrylonitrile Butadiene Styrene)

Key Properties: ABS is a strong thermoplastic known for its toughness and impact resistance. It has a higher melting temperature (around 210-250°C) and offers good chemical resistance.

Pros & Cons:

– Pros: ABS is durable, can withstand higher temperatures, and is suitable for functional prototypes and end-use parts.

– Cons: It can be more challenging to print due to warping and requires a heated bed for optimal results.

Impact on Application: ABS is widely used in automotive and consumer products due to its strength and versatility, making it suitable for applications that require durability.

Considerations for International Buyers: Compliance with safety standards, such as ASTM D3965 for flammability, is crucial. Buyers should also consider the availability of ABS in their region, as it may vary.

3. Nylon (Polyamide)

Key Properties: Nylon is known for its excellent mechanical properties, including high tensile strength and flexibility. It has a higher melting point (around 220-260°C) and is resistant to abrasion and chemicals.

Pros & Cons:

– Pros: Nylon is ideal for producing strong, functional parts and has good wear resistance.

– Cons: It can absorb moisture, which may affect print quality and dimensional stability. Additionally, printing nylon often requires specialized equipment.

Impact on Application: Nylon is suitable for applications in the automotive, aerospace, and consumer goods sectors, where strength and flexibility are paramount.

Considerations for International Buyers: Buyers should be aware of moisture control during storage and printing. Compliance with international standards like ISO 9001 for quality management can enhance supplier reliability.

4. PETG (Polyethylene Terephthalate Glycol)

Key Properties: PETG is a glycol-modified version of PET, known for its clarity, strength, and ease of printing. It has a melting temperature of around 220-250°C and offers good chemical resistance.

Pros & Cons:

– Pros: PETG combines the ease of printing of PLA with the durability of ABS, making it suitable for functional parts and prototypes.

– Cons: While it is less prone to warping, it may still require adjustments to print settings for optimal results.

Impact on Application: PETG is ideal for applications requiring transparency and strength, such as packaging and medical devices.

Considerations for International Buyers: Buyers should ensure that PETG complies with food safety standards (if applicable) and other relevant regulations in their regions.

Summary Table

| Material | Typical Use Case for g code simulation | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PLA | Prototyping, educational models | Environmentally friendly, easy to print | Lower heat resistance | Low |

| ABS | Functional prototypes, consumer products | Durable, high-temperature resistance | Prone to warping, printing challenges | Medium |

| Nylon | Automotive, aerospace parts | High strength and flexibility | Moisture absorption, requires specialized equipment | High |

| PETG | Functional parts, packaging | Strong, easy to print | Requires print setting adjustments | Medium |

This analysis provides a comprehensive overview of the materials relevant to G-code simulation, equipping international B2B buyers with the insights necessary for informed decision-making in their procurement processes.

In-depth Look: Manufacturing Processes and Quality Assurance for g code simulation

In the realm of G-code simulation, understanding the manufacturing processes and quality assurance measures is vital for B2B buyers, particularly those in rapidly evolving markets like Africa, South America, the Middle East, and Europe. This section provides a comprehensive overview of the key stages in manufacturing G-code simulation tools, techniques involved, and the quality control protocols that ensure product reliability and performance.

Manufacturing Processes for G-Code Simulation Tools

The manufacturing process for G-code simulation tools typically involves several key stages:

Material Preparation

The initial phase of manufacturing begins with material selection, which is crucial for the durability and performance of the simulation tools. Common materials include high-grade plastics for housing and metal components for internal mechanisms. Buyers should ensure that suppliers source materials compliant with international standards, as this impacts the longevity and functionality of the equipment.

Forming

In this stage, materials are shaped into the required components using various techniques such as injection molding for plastic parts or CNC machining for metal elements. Each method has implications for precision and production speed. B2B buyers should evaluate suppliers’ capabilities in forming processes, as inconsistencies can lead to defects in simulation output.

Assembly

After forming, components are assembled to create the final G-code simulation tool. This stage may involve manual assembly or automated systems. Buyers should inquire about the assembly processes used by suppliers, as robust assembly practices reduce the likelihood of errors. Automated assembly lines can enhance precision, especially for high-volume production.

Finishing

The finishing stage enhances the aesthetic and functional qualities of the simulation tools. Techniques such as surface treatment, painting, or anodizing are employed to protect components from wear and environmental damage. Buyers should assess whether suppliers use finishing processes that comply with relevant international standards, ensuring a high-quality product that meets industry demands.

Key Techniques in G-Code Simulation

To ensure accurate and efficient G-code simulation, various techniques are employed:

-

Path Visualization: Advanced simulation software provides 3D visualization of tool paths, allowing users to identify potential collisions or errors before actual machining begins. Buyers should prioritize suppliers that integrate sophisticated visualization tools into their offerings.

-

Collision Detection: This technique identifies and resolves potential issues in the simulation phase, reducing the risk of damage to both the machine and the workpiece. B2B buyers should verify that suppliers have robust collision detection capabilities to minimize operational risks.

-

Parameter Testing: Simulators can test various machining parameters, such as feed rates and spindle speeds, to optimize performance. Suppliers should provide buyers with comprehensive parameter testing results to ensure the simulation tool is tailored to specific operational needs.

Quality Assurance Standards

Quality assurance is paramount in the manufacturing of G-code simulation tools. Understanding international and industry-specific standards can help buyers assess supplier reliability.

International Standards

- ISO 9001: This standard outlines the criteria for a quality management system, emphasizing customer satisfaction and continual improvement. B2B buyers should seek suppliers certified under ISO 9001 to ensure adherence to quality processes.

Industry-Specific Standards

-

CE Marking: Required for products sold within the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards. Buyers in Europe should confirm that suppliers possess the CE mark for their G-code simulation tools.

-

API Standards: For buyers in the oil and gas sector, compliance with American Petroleum Institute (API) standards is essential for equipment used in critical applications. Suppliers should demonstrate adherence to these standards to ensure safety and reliability.

Quality Control Checkpoints

Implementing quality control checkpoints throughout the manufacturing process is essential for maintaining product integrity. Common checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards. Buyers should verify that suppliers have rigorous IQC processes in place.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing stages, IPQC ensures that production processes are followed correctly. B2B buyers can request documentation of IPQC measures to understand how suppliers maintain quality throughout production.

-

Final Quality Control (FQC): Before shipment, FQC involves thorough testing of the finished product to ensure it meets all specifications. Buyers should ask for FQC reports, which provide insights into the testing methods used and the results obtained.

Verifying Supplier Quality Control

To ensure that suppliers meet quality standards, B2B buyers should consider the following verification methods:

-

Supplier Audits: Conducting regular audits can help assess supplier compliance with quality standards and production capabilities. Buyers should establish audit schedules to maintain oversight.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC processes and outcomes. These reports should include data on defect rates, testing methodologies, and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control measures. This is particularly useful for buyers in regions with less stringent local standards.

Navigating Quality Control Nuances for International Buyers

For international B2B buyers, particularly those from diverse regions like Africa, South America, and the Middle East, navigating quality control nuances is crucial. Factors to consider include:

-

Regulatory Variability: Different regions may have varying regulatory requirements, impacting the certification and compliance processes for G-code simulation tools. Buyers should familiarize themselves with local regulations and ensure suppliers can meet these standards.

-

Cultural Differences: Understanding the cultural context of suppliers can enhance communication and negotiation. Buyers should engage with suppliers to discuss quality expectations and standards clearly.

-

Local Expertise: In regions with emerging manufacturing sectors, local expertise may be limited. Buyers can benefit from partnering with suppliers who have international experience and can provide guidance on best practices in quality assurance.

By focusing on these manufacturing processes, quality assurance standards, and verification methods, B2B buyers can make informed decisions when sourcing G-code simulation tools, ultimately leading to improved operational efficiency and product quality.

Comprehensive Cost and Pricing Analysis for g code simulation Sourcing

Cost Structure for G-Code Simulation Sourcing

Understanding the cost structure involved in sourcing G-Code simulation tools is crucial for international B2B buyers. The primary cost components include:

-

Materials: This encompasses the software licenses and any necessary hardware. While software costs can vary widely based on the sophistication and capabilities of the simulator, hardware requirements (like computers or dedicated servers) can also contribute significantly to total expenses.

-

Labor: Skilled personnel are essential for operating and maintaining G-Code simulators. Training and support costs should be factored into the overall budget, especially for teams that may need to adapt to specific simulators or programming languages.

-

Manufacturing Overhead: This includes costs associated with running the software, such as server maintenance, software updates, and IT support. For businesses operating in regions with fluctuating electricity costs or internet connectivity issues, these factors can add to overhead expenses.

-

Tooling: Specific G-Code simulation tools may require additional plugins or integration with existing software, which can incur extra costs. It’s essential to assess whether the selected software will work seamlessly with current systems.

-

Quality Control (QC): Ensuring the accuracy of G-Code simulations is vital. Investing in QC processes—such as validation tests and regular audits—can prevent costly mistakes in production.

-

Logistics: If the simulation tools or required hardware are sourced internationally, logistics costs—including shipping, customs duties, and insurance—must be accounted for.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. Understanding the supplier’s pricing strategy can help buyers negotiate better terms.

Price Influencers

Several factors influence the pricing of G-Code simulation tools:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in bulk often leads to discounts. Buyers should evaluate their needs to determine whether bulk buying is feasible.

-

Specifications/Customization: Customized solutions tailored to specific manufacturing processes may come at a premium. Buyers should clearly outline their requirements to ensure they receive accurate quotes.

-

Materials: The choice of software and hardware (open-source vs. proprietary) can greatly affect costs. While open-source options may reduce upfront costs, they might lack some features found in commercial products.

-

Quality/Certifications: Higher-quality simulators with industry certifications typically command higher prices. Ensure that the chosen product meets industry standards relevant to your operations.

-

Supplier Factors: The supplier’s reputation, reliability, and support services can impact pricing. Established suppliers may charge more but often provide better service and support.

-

Incoterms: The terms of sale, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), can influence total costs. Understanding these terms is critical for effective budgeting.

Buyer Tips

To navigate the complexities of G-Code simulation sourcing, consider the following strategies:

-

Negotiation: Leverage multiple supplier quotes to enhance negotiation power. Discuss potential discounts for bulk orders or long-term contracts.

-

Cost-Efficiency: Analyze the total cost of ownership (TCO), which includes not just the purchase price but also ongoing maintenance, training, and operational costs. This holistic view can reveal the most cost-effective solution.

-

Pricing Nuances: For international buyers, currency fluctuations can impact costs. Locking in prices at the time of contract signing can mitigate this risk.

-

Regional Considerations: Buyers from Africa, South America, the Middle East, and Europe should be aware of local regulations and standards that may affect pricing and availability. Engaging local suppliers can sometimes lead to better pricing and support.

Disclaimer

Prices for G-Code simulation tools can vary significantly based on the factors mentioned above. The information provided here serves as a guideline and should be verified with suppliers for the most accurate and current pricing.

Spotlight on Potential g code simulation Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘g code simulation’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for g code simulation

Critical Technical Properties for G-Code Simulation

Understanding the essential technical properties associated with G-code simulation is crucial for international B2B buyers seeking to optimize their CNC operations. Below are key specifications that should be considered:

-

Material Compatibility

– Definition: The ability of the G-code to effectively control machining processes across various materials (e.g., metals, plastics, composites).

– B2B Importance: Different materials require distinct cutting speeds, feeds, and tool paths. Buyers must ensure that their G-code simulations are compatible with the materials they intend to use, as mismatches can lead to poor product quality or equipment damage. -

Tolerance Specifications

– Definition: The permissible limit or limits of variation in a physical dimension or measured value.

– B2B Importance: Tolerance levels dictate the precision needed in machining operations. Accurate G-code simulations help ensure that finished products meet required tolerances, reducing waste and rework costs, which is particularly significant in industries like aerospace and automotive. -

Cycle Time Optimization

– Definition: The time taken to complete one cycle of production, from setup to part completion.

– B2B Importance: Effective G-code simulations can identify bottlenecks in the machining process, allowing buyers to optimize cycle times. Shorter cycle times can lead to increased productivity and lower operational costs, giving businesses a competitive edge. -

Tool Path Accuracy

– Definition: The precision with which the G-code directs the tool’s movement during machining.

– B2B Importance: High tool path accuracy ensures that parts are machined correctly, which is vital for maintaining quality standards. Buyers should prioritize G-code simulators that can visualize and verify tool paths before actual machining to prevent costly errors. -

Post-Processing Capabilities

– Definition: The ability of G-code simulation software to convert CAD designs into machine-readable G-code.

– B2B Importance: Efficient post-processing minimizes the time from design to production. Buyers should look for simulators that support various CAD formats and provide customization options to streamline workflows. -

Collision Detection

– Definition: The ability of the simulation software to identify potential collisions between the tool and workpiece or other machine components.

– B2B Importance: Collision detection is critical for avoiding equipment damage and ensuring operator safety. Buyers should invest in G-code simulators that include robust collision detection features to enhance operational reliability.

Common Trade Terminology in G-Code Simulation

Familiarity with industry jargon can greatly enhance communication and negotiation capabilities for B2B buyers. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships is crucial for sourcing high-quality components and ensuring compatibility across machinery. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers plan their purchases effectively, especially when managing inventory costs and supplier relationships. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and availability for specific products or services.

– Importance: Utilizing RFQs enables buyers to compare costs and services from different suppliers, facilitating better negotiation and decision-making. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms that clarify the responsibilities of buyers and sellers.

– Importance: Familiarity with Incoterms helps buyers understand shipping responsibilities and costs, which is essential for budgeting and risk management in international transactions. -

Lead Time

– Definition: The amount of time from the initiation of an order until its completion.

– Importance: Understanding lead times is vital for planning production schedules and meeting customer deadlines. Buyers should factor lead times into their procurement strategies to maintain operational efficiency. -

Calibration

– Definition: The process of configuring an instrument to provide a result for a sample within an acceptable range.

– Importance: Regular calibration of CNC machines ensures accurate performance, reducing the risk of errors in production. Buyers should prioritize suppliers who emphasize calibration in their service offerings.

By grasping these technical properties and trade terms, B2B buyers can enhance their understanding of G-code simulation, leading to more informed purchasing decisions and optimized operational processes.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the g code simulation Sector

Market Overview & Key Trends

The global market for G-Code simulation is rapidly evolving, driven by advancements in CNC technology, increased automation, and the growing demand for precision in manufacturing processes. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly seeking sophisticated simulation tools to optimize their CNC operations. Key trends include the integration of AI and machine learning in simulation software, which enhances predictive capabilities and reduces the likelihood of costly errors. Additionally, cloud-based solutions are gaining traction, allowing for real-time collaboration and access to simulation tools without the need for extensive local infrastructure.

Moreover, as industries strive for efficiency, buyers are focusing on suppliers that offer comprehensive simulation solutions, including those that can simulate both CNC machining and 3D printing processes. This convergence is particularly relevant for sectors like aerospace and automotive, where the complexity of parts requires robust simulation to ensure quality and performance. The rise of Industry 4.0 technologies is also influencing sourcing strategies; buyers are looking for vendors that can provide integrated solutions encompassing simulation, machining, and data analytics, thereby enabling smarter decision-making.

Another notable trend is the emphasis on user-friendly interfaces and training resources. Suppliers that offer intuitive software and comprehensive training are likely to gain favor among international buyers, as they mitigate the learning curve associated with adopting advanced simulation technologies.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration for B2B buyers in the G-Code simulation sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, is prompting companies to seek out suppliers that prioritize sustainable practices. This includes the use of energy-efficient machines, recyclable materials, and processes that minimize emissions and waste.

Ethical sourcing is equally important, as buyers increasingly demand transparency in their supply chains. Suppliers that can demonstrate ethical labor practices and compliance with international standards are more likely to secure contracts. Certifications such as ISO 14001 for environmental management and ISO 26000 for social responsibility can serve as indicators of a supplier’s commitment to sustainability.

Furthermore, the push for “green” materials in simulation processes is gaining momentum. Buyers should look for simulation tools that incorporate sustainable practices, such as the use of biodegradable filaments in 3D printing or software that optimizes material usage to reduce waste. By prioritizing sustainability and ethical sourcing, companies not only enhance their corporate social responsibility but also position themselves favorably in an increasingly eco-conscious market.

Brief Evolution/History

The evolution of G-Code simulation can be traced back to the early days of CNC machining in the mid-20th century. Initially, G-Codes were developed to control machine movements and operations, but as manufacturing demands grew more complex, the need for effective simulation became evident. The first simulation tools were rudimentary, primarily focused on visualizing tool paths.

Over the decades, advancements in computer technology led to the development of sophisticated simulation software capable of detecting collisions, optimizing tool paths, and integrating with CAD/CAM systems. Today, G-Code simulation is an essential component of the manufacturing process, enabling companies to preemptively identify issues before they result in costly production errors. This historical progression highlights the increasing importance of simulation in enhancing efficiency, safety, and quality in manufacturing operations globally.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of g code simulation

-

What factors should I consider when vetting suppliers for G-code simulation software?

When vetting suppliers, prioritize their experience in the CNC and G-code simulation market. Look for customer testimonials, case studies, and their track record in your specific industry. Ensure they have robust technical support and training services. Verify their software’s compatibility with various CNC machines and check if they offer customization options. Additionally, consider suppliers that provide clear documentation and user manuals, as this can significantly ease the onboarding process for your team. -

Can G-code simulation software be customized to meet specific operational needs?

Yes, many G-code simulation software providers offer customization to cater to the unique requirements of your operations. This can include tailored interfaces, additional features specific to your machining processes, or integration with existing systems. When discussing customization, ensure you communicate your needs clearly and request a demonstration of how their software can adapt to your processes. This ensures that the investment aligns with your production goals and operational workflows. -

What are the typical minimum order quantities (MOQ) and lead times for G-code simulation software?

Minimum order quantities for G-code simulation software can vary significantly based on the supplier and the type of software (e.g., single-user licenses vs. enterprise solutions). Generally, you can expect MOQs for enterprise-level licenses to be higher, while individual licenses may have no MOQ. Lead times typically range from a few days for downloadable software to several weeks for comprehensive packages that require installation and training. Always confirm these details before finalizing your purchase to avoid unexpected delays. -

What payment terms should I expect when purchasing G-code simulation software?

Payment terms for G-code simulation software often include upfront payments, installment plans, or subscription-based models. Suppliers may require full payment before delivery, especially for tailored solutions. Be sure to discuss any available financing options, especially if you’re investing in a high-cost solution. Additionally, clarify the terms regarding renewal fees for subscription models, as these can impact your long-term budgeting and financial planning. -

How can I ensure quality assurance and certification for G-code simulation software?

To ensure quality assurance, request documentation of any relevant certifications or compliance with industry standards from your supplier. Look for software that has undergone rigorous testing and validation processes. Additionally, inquire about the software’s support for updates and maintenance, as ongoing quality assurance is vital for long-term reliability. Suppliers who provide regular updates and have a responsive support system are typically more committed to maintaining quality. -

What logistics considerations should I keep in mind when sourcing G-code simulation software internationally?

When sourcing software internationally, consider the implications of time zone differences on support and training. Ensure that your supplier can provide timely assistance and that they have a clear plan for software delivery, whether via digital download or physical media. Additionally, confirm any regional restrictions on software use and ensure that licensing agreements are clear and compliant with local regulations to avoid legal complications. -

What steps should I take if there is a dispute with my G-code simulation software supplier?

In the event of a dispute, first, attempt to resolve the issue directly with your supplier through clear communication. Document all interactions and maintain records of agreements and deliverables. If the issue remains unresolved, refer to the supplier’s dispute resolution process, often outlined in the contract. Consider mediation or arbitration as alternatives to litigation, as these methods can be less costly and time-consuming. Always consult with legal counsel if necessary to navigate complex international trade regulations. -

What are the potential risks of not using G-code simulation software in my operations?

Failing to use G-code simulation software can lead to costly mistakes, including machining errors, equipment damage, and increased downtime. Without simulation, you may overlook potential collisions or tooling issues that can compromise product quality. This not only impacts production efficiency but can also lead to significant financial losses. In competitive markets, leveraging G-code simulation is essential for maintaining a strategic advantage and ensuring consistent, high-quality outputs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for g code simulation

In conclusion, mastering G code simulation is a pivotal strategy for international B2B buyers aiming to enhance their manufacturing processes. Understanding the nuances of G and M codes allows businesses to streamline operations, minimize errors, and maximize productivity. By strategically sourcing reliable G code simulation tools, companies can significantly reduce risks associated with programming inaccuracies, leading to safer and more efficient production environments.

For buyers in Africa, South America, the Middle East, and Europe, investing in robust G code simulation software is essential for navigating the complexities of modern manufacturing. This not only fosters better communication with suppliers but also ensures compliance with varying regional standards. As global markets continue to evolve, leveraging advanced simulation technologies will be crucial in maintaining a competitive edge.

We encourage international B2B buyers to explore innovative G code simulation solutions and engage with suppliers who can provide tailored support. By prioritizing strategic sourcing, you can unlock new opportunities for growth and drive operational excellence in your manufacturing endeavors. Embrace the future of CNC machining and 3D printing with confidence, knowing that the right tools and partnerships will pave the way for success.