Your Ultimate Guide to Sourcing G-Code Cnc

Introduction: Navigating the Global Market for g-code cnc

In the rapidly evolving landscape of global manufacturing, G-Code CNC stands as the cornerstone of precision engineering, dictating the movements and operations of CNC machines. For international B2B buyers—especially those from Africa, South America, the Middle East, and Europe—grasping the intricacies of G-Code is not merely beneficial; it is essential for maintaining a competitive edge. As industries modernize and the demand for high-quality, efficient production methods rises, understanding G-Code enables buyers to enhance operational efficiency, reduce costs, and ensure product consistency.

This comprehensive guide demystifies G-Code CNC by exploring its various types, including standard motion commands, modal and non-modal codes, and manufacturer-specific variations. Additionally, it addresses critical topics such as materials selection, manufacturing and quality control benchmarks, supplier evaluations, and cost structures. Each section is designed to provide actionable insights, empowering decision-makers to navigate the complexities of CNC programming and supplier relationships effectively.

By equipping procurement officers, plant managers, and technical decision-makers with the knowledge needed to make informed sourcing decisions, this guide fosters robust partnerships and mitigates risks in unfamiliar markets. With detailed FAQs and practical checklists, readers will gain clarity on the evolving standards and practices in G-Code CNC, positioning themselves for success in a competitive global arena.

Understanding g-code cnc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Motion G-Codes | Control tool paths, speed, and geometry (e.g., G00, G01, G02/03) | Milling, turning, CNC routers, complex profiling | Universally recognized; easy to automate, but syntax nuances may exist. |

| Modal and Non-Modal G-Codes | Modal codes remain active until changed; non-modal apply to a single block | Automated lines, multi-stage operations | Simplifies operations, but mismanagement can lead to errors. |

| Miscellaneous M-Codes | Control auxiliary functions (e.g., spindle, coolant, tool change) | Automated tool changing, coolant management | Enhances automation and safety; variations may complicate programming. |

| Canned Cycle G-Codes | Pre-programmed cycles for repetitive tasks (e.g., G81 for drilling) | High-volume drilling, tapping, boring | Increases productivity significantly, but less flexible for custom tasks. |

| Manufacturer-Specific Variants | Unique code sets/extensions per control brand (e.g., FANUC, Siemens) | Multi-vendor production environments | Enable custom functions, but complicate standardization and training. |

Standard Motion G-Codes

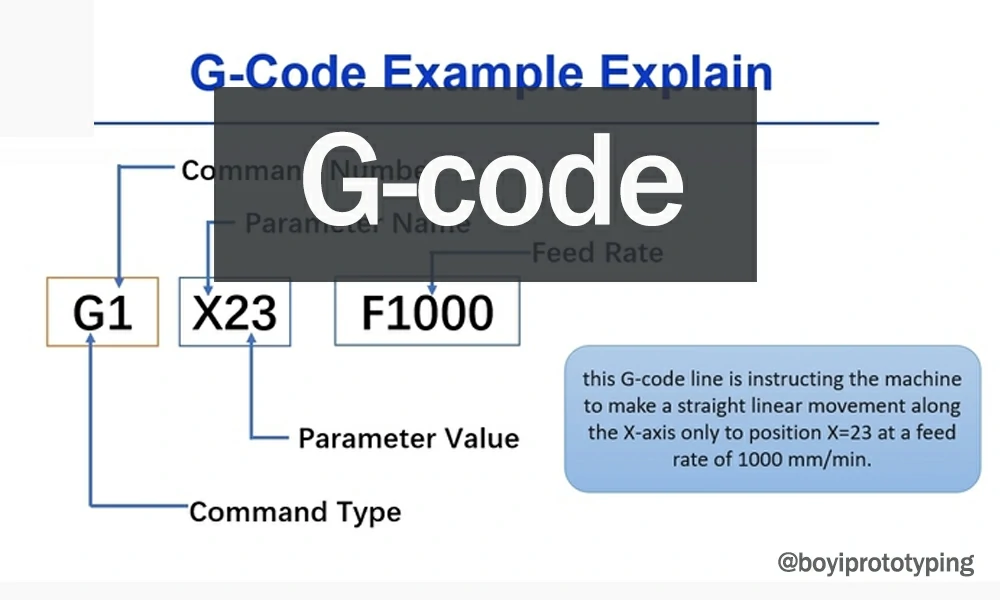

Standard Motion G-Codes, such as G00 (rapid positioning) and G01 (linear interpolation), are foundational for CNC operations. These codes dictate the movement of tools, ensuring precision in machining processes across various applications like milling and turning. For B2B buyers, understanding these codes is crucial as they are universally recognized, facilitating easier integration across different machinery. However, buyers must be aware of potential syntax nuances that may arise from varying machine brands, which could affect operational efficiency.

Modal and Non-Modal G-Codes

Modal and Non-Modal G-Codes offer distinct operational benefits. Modal codes, such as G01, remain active until altered, allowing for streamlined operations in high-volume settings. Non-modal codes execute specific tasks for a single cycle, which can simplify programming. For B2B buyers managing extensive production lines, leveraging these codes can reduce complexity and enhance productivity. However, inadequate training can lead to costly errors, highlighting the importance of vendor-provided training and simulation tools.

Miscellaneous M-Codes

Miscellaneous M-Codes handle essential auxiliary functions, including spindle activation (M03) and coolant control (M08). These codes are vital for optimizing machine operation and enhancing safety in manufacturing environments. For international buyers, particularly those in mixed-technology settings, verifying the consistency of M-Code functionality across various machine brands is essential. Investing in advanced CNC systems that support customizable M-Codes can provide significant operational flexibility and efficiency.

Canned Cycle G-Codes

Canned Cycle G-Codes, like G81 for drilling, are designed for repetitive tasks, significantly boosting productivity in high-volume applications. These pre-programmed cycles simplify the machining process, making them ideal for industries that require consistent output, such as automotive and aerospace. However, their rigidity may limit flexibility for custom operations. B2B buyers should evaluate the suitability of canned cycles based on their production needs and consider the trade-offs between speed and customization.

Manufacturer-Specific Variants

Manufacturer-Specific Variants refer to unique extensions or modifications to standard G/M codes offered by specific CNC brands, such as FANUC or Siemens. These variants can enhance machine capabilities, allowing for tailored solutions in multi-vendor environments. For B2B buyers, understanding these specific codes is critical for effective training and operational standardization. However, the diversity in code sets can complicate the integration of equipment from different manufacturers, necessitating thorough operator training and clear communication across teams.

Related Video: My Go-To G-Code Program for Any New CNC Machine

Key Industrial Applications of g-code cnc

| Industry/Sector | Specific Application of g-code cnc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision component manufacturing | High accuracy and repeatability in producing critical parts | Supplier certifications, adherence to aerospace standards |

| Automotive | Tooling and fixture production | Enhanced efficiency in manufacturing processes | Compatibility with existing systems, local support availability |

| Electronics | PCB (Printed Circuit Board) fabrication | Ability to handle intricate designs with precision | Material sourcing, supplier reliability, and lead times |

| Medical Devices | Custom prosthetics and implants | Tailored solutions for patient-specific needs | Compliance with health regulations, material certifications |

| Metalworking | Custom parts for machinery and equipment | Flexibility in producing low to medium volume custom parts | Access to advanced CNC technology, skilled labor availability |

Aerospace

In the aerospace sector, G-code CNC is crucial for the manufacturing of precision components such as turbine blades and airframe parts. The use of G-code ensures that these components meet stringent tolerances and quality standards required for flight safety. International buyers must prioritize suppliers that hold relevant certifications, such as AS9100, and can demonstrate compliance with aviation industry standards. Additionally, understanding the specific G-code variations used by different CNC machines is vital to avoid compatibility issues.

Automotive

The automotive industry leverages G-code CNC for tooling and fixture production, which are essential for assembly line efficiency. By utilizing G-code, manufacturers can create complex geometries that optimize the assembly process. Buyers in this sector should focus on sourcing equipment that is compatible with existing manufacturing systems and can support rapid prototyping. Furthermore, local support availability is crucial for maintaining uptime and minimizing production delays, especially in regions with evolving automotive standards.

Electronics

In electronics manufacturing, G-code CNC is employed for PCB fabrication, allowing for the precise cutting and drilling of intricate circuit patterns. The ability to produce high-quality PCBs rapidly is critical for meeting market demands in this fast-paced industry. International buyers need to consider material sourcing and the reliability of suppliers, as delays can significantly impact product launches. Additionally, understanding lead times for advanced CNC equipment is essential to ensure timely delivery of electronic components.

Medical Devices

The medical device industry utilizes G-code CNC for creating custom prosthetics and implants tailored to individual patient specifications. This application requires high precision and the ability to adapt designs quickly. Buyers must ensure that their suppliers comply with health regulations, such as ISO 13485, and have the necessary material certifications for biocompatibility. The ability to produce patient-specific solutions can enhance competitive advantage in this sector, making it essential for buyers to prioritize suppliers with advanced CNC capabilities.

Illustrative Image (Source: Google Search)

Metalworking

In the metalworking sector, G-code CNC is used to manufacture custom parts for machinery and equipment, enabling businesses to respond swiftly to market demands. The flexibility offered by CNC technology allows manufacturers to produce low to medium volume custom parts efficiently. Buyers should assess access to advanced CNC technology and the availability of skilled labor when sourcing. Understanding the specific G-code requirements for different materials and processes is also crucial to ensure optimal production outcomes.

Strategic Material Selection Guide for g-code cnc

When selecting materials for G-Code CNC applications, international B2B buyers must consider various factors that impact product performance, manufacturing complexity, and compliance with local standards. Below is an analysis of four commonly used materials in G-Code CNC machining, focusing on their properties, advantages, disadvantages, and specific considerations for buyers in Africa, South America, the Middle East, and Europe.

Aluminum

Key Properties: Aluminum is lightweight, offers excellent corrosion resistance, and has good thermal conductivity. It typically withstands temperatures up to 200°C without significant deformation.

Pros & Cons: Aluminum is durable and easy to machine, making it suitable for complex geometries. However, its cost can be higher than other metals like steel, and it may not be ideal for high-stress applications due to lower tensile strength.

Impact on Application: Aluminum is commonly used in aerospace and automotive components, where weight reduction is crucial. Its compatibility with various media, including water and oils, enhances its versatility.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM B221 or DIN 1725. The availability of aluminum alloys may vary across regions, impacting sourcing decisions.

Steel

Key Properties: Steel exhibits high tensile strength and excellent durability, with temperature ratings that can exceed 400°C depending on the alloy. It also offers good wear resistance.

Pros & Cons: While steel is robust and suitable for heavy-duty applications, it can be more challenging to machine than softer metals, leading to increased manufacturing complexity. Its cost can also vary significantly based on the grade and treatment.

Impact on Application: Steel is widely used in machinery parts, structural components, and tools. Its compatibility with high-stress environments makes it a preferred choice for industries such as construction and manufacturing.

Considerations for International Buyers: Compliance with standards like ASTM A36 or JIS G3101 is essential. Buyers should also consider local availability and the potential for tariffs or import restrictions on certain steel grades.

Plastics (e.g., POM, ABS)

Key Properties: Plastics such as Polyoxymethylene (POM) and Acrylonitrile Butadiene Styrene (ABS) are lightweight, resistant to corrosion, and can operate effectively at temperatures up to 100°C.

Pros & Cons: Plastics are easy to machine and can be cost-effective for low-volume production. However, they may not withstand high temperatures or mechanical stresses as well as metals, limiting their application scope.

Impact on Application: These materials are often used in consumer products, automotive parts, and electronic housings. Their chemical resistance makes them suitable for various media, including acids and bases.

Considerations for International Buyers: Buyers should verify compliance with standards such as ASTM D638 for tensile properties. The availability of specific plastic grades may vary, impacting production timelines.

Titanium

Key Properties: Titanium is known for its high strength-to-weight ratio and excellent corrosion resistance, making it suitable for extreme environments. It can withstand temperatures up to 600°C.

Pros & Cons: While titanium is incredibly strong and durable, it is more expensive and challenging to machine compared to aluminum or steel. The manufacturing process often requires specialized equipment, increasing complexity.

Impact on Application: Titanium is widely used in aerospace, medical devices, and high-performance automotive applications due to its strength and lightweight properties.

Considerations for International Buyers: Compliance with standards such as ASTM F136 for medical-grade titanium is crucial. Buyers should also consider the supply chain for titanium, as it may be less readily available in certain regions.

Summary Table

| Material | Typical Use Case for g-code cnc | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components, automotive parts | Lightweight and corrosion-resistant | Higher cost than some metals | Medium |

| Steel | Machinery parts, structural components | High tensile strength and durability | More challenging to machine | Medium to High |

| Plastics (POM, ABS) | Consumer products, electronic housings | Easy to machine and cost-effective | Limited high-temperature performance | Low |

| Titanium | Aerospace, medical devices | High strength-to-weight ratio | Expensive and difficult to machine | High |

This strategic material selection guide provides essential insights for international B2B buyers, enabling informed decision-making in sourcing G-Code CNC materials that align with their operational needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for g-code cnc

Understanding the Manufacturing Processes for G-Code CNC

The manufacturing process for G-Code CNC involves several critical stages that ensure the efficient production of high-quality parts. Each stage must be meticulously executed to maintain precision and consistency. Below are the main stages of the manufacturing process, along with key techniques used in each stage.

1. Material Preparation

Material preparation is the first step in the CNC manufacturing process. This stage involves selecting the appropriate materials based on the specifications of the final product. Common materials include metals (aluminum, steel, titanium), plastics, and composites.

- Key Techniques:

- Cutting and Sizing: Materials are often cut to size using saws or shears to ensure they fit within the CNC machine’s workspace.

- Surface Treatment: Processes such as deburring, cleaning, and surface conditioning are employed to remove impurities and enhance adhesion for coatings or treatments.

2. Forming

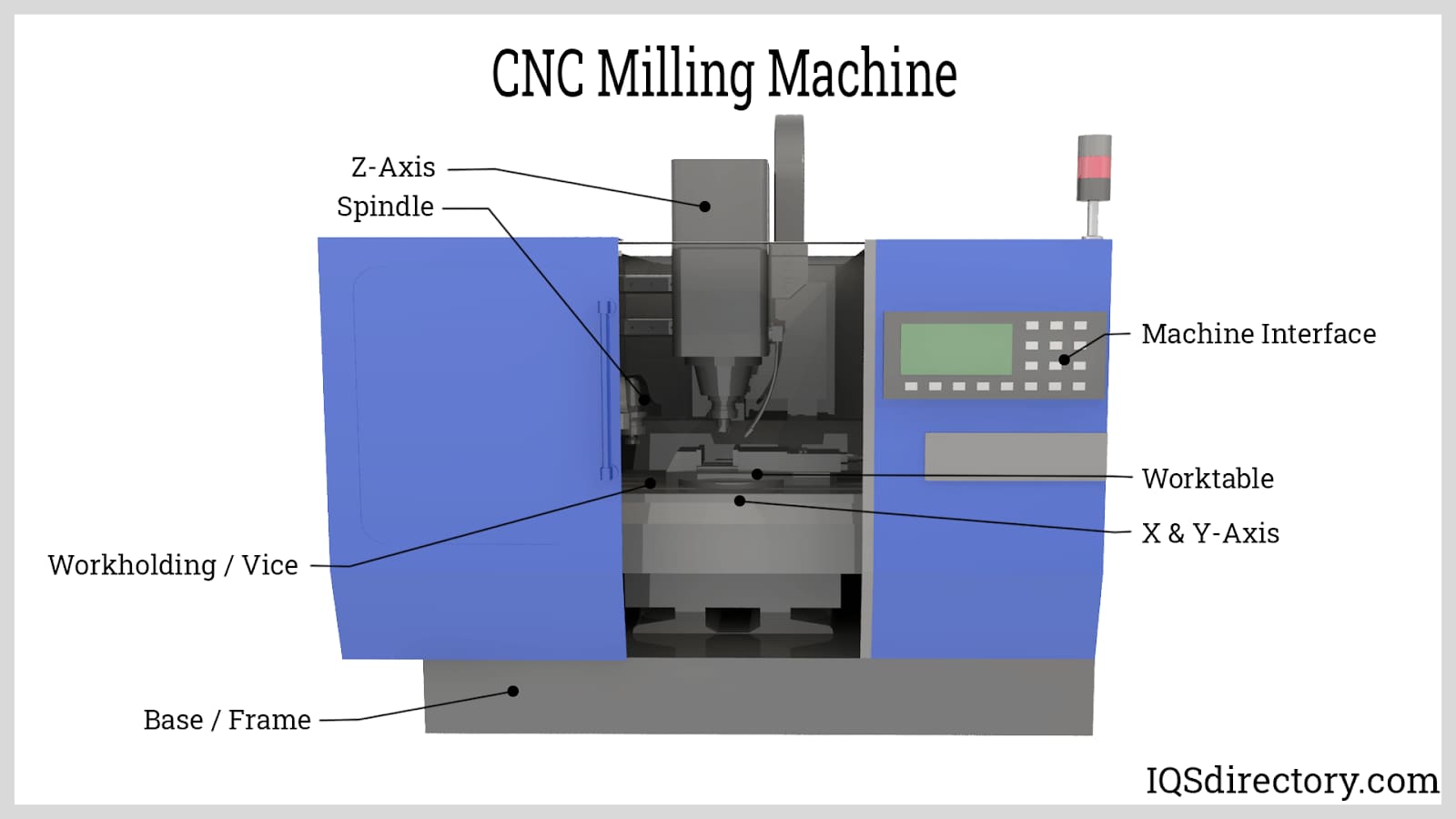

Once materials are prepared, the forming stage begins. This stage involves using CNC machines to shape the material according to the specified G-Code commands.

- Key Techniques:

- Milling: This process removes material using rotating cutting tools and is ideal for creating complex shapes and features.

- Turning: In this method, the material is rotated against a stationary cutting tool, commonly used for cylindrical parts.

- 3D Printing: Emerging as a viable technique for complex geometries, 3D printing can be integrated with CNC processes for rapid prototyping and production.

3. Assembly

After individual components are formed, they may need to be assembled. This stage is crucial, especially for multi-part assemblies.

- Key Techniques:

- Mechanical Fastening: Components are joined using screws, bolts, or rivets.

- Welding: This technique is used for permanent bonding of metal parts.

- Adhesive Bonding: Suitable for both metal and non-metal parts, adhesives can provide strong bonds without the need for mechanical fasteners.

4. Finishing

Finishing processes enhance the aesthetic and functional qualities of the parts produced.

- Key Techniques:

- Coating: Techniques such as anodizing, plating, or painting are applied to protect surfaces and enhance appearance.

- Polishing: This process removes surface imperfections and improves surface finish.

- Inspection and Testing: Finishing often includes rigorous inspection to ensure parts meet specified tolerances and quality standards.

Quality Assurance in G-Code CNC Manufacturing

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that products meet international standards and customer expectations. For international B2B buyers, understanding QA processes is crucial for mitigating risks associated with sourcing.

Relevant International Standards

Several international standards guide the quality assurance processes in CNC manufacturing:

- ISO 9001: This standard focuses on quality management systems (QMS) and is applicable across various industries, ensuring consistent quality in products and services.

- CE Marking: Required for products sold within the European Economic Area, CE marking signifies conformity with health, safety, and environmental protection standards.

- API Standards: Particularly relevant for buyers in the oil and gas industry, API standards ensure quality and reliability in products used in these sectors.

Quality Control Checkpoints

Effective quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials upon arrival. Suppliers should provide certificates of compliance to verify material quality.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring and inspection occur to ensure adherence to specifications. This may involve using measurement tools and gauges to check dimensions and tolerances.

-

Final Quality Control (FQC): After production, a comprehensive inspection is conducted to verify that the finished products meet all quality standards before shipment.

Common Testing Methods

Various testing methods are employed to ensure product integrity:

- Dimensional Inspection: Using calipers, micrometers, and coordinate measuring machines (CMM) to check dimensions against CAD specifications.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, X-ray, and magnetic particle inspection help identify internal flaws without damaging the parts.

- Functional Testing: Ensures that the parts perform as intended under operational conditions.

Verifying Supplier Quality Control

International B2B buyers must implement strategies to verify supplier quality control processes effectively. Here are actionable steps:

-

Supplier Audits: Conduct regular audits of suppliers to assess their QMS, manufacturing processes, and compliance with relevant standards. An on-site visit can provide valuable insights into operational capabilities.

-

Quality Reports: Request detailed quality reports from suppliers, including metrics on defect rates, corrective actions taken, and compliance with international standards.

-

Third-Party Inspections: Engage independent inspection agencies to perform quality checks before shipment. This additional layer of verification can help identify issues that may not be visible during supplier audits.

Navigating Quality Control Nuances for International Buyers

When sourcing CNC manufactured parts internationally, especially from regions such as Africa, South America, the Middle East, and Europe, buyers should be aware of specific nuances:

-

Cultural Differences: Understanding local business practices and cultural attitudes toward quality can impact supplier relationships. Building trust is essential for effective collaboration.

-

Regulatory Compliance: Buyers must ensure that suppliers comply with both local regulations and international standards, as these can vary significantly across regions.

-

Language Barriers: Clear communication is vital. Buyers should consider using professional translators or bilingual staff to facilitate discussions about quality expectations and specifications.

By thoroughly understanding the manufacturing processes and quality assurance protocols associated with G-Code CNC, international B2B buyers can make informed decisions, reduce risks, and ensure they procure high-quality products that meet their operational needs.

Related Video: Factory IO – Production Line Project ( Programmed using Control IO and Tia Portal )

Comprehensive Cost and Pricing Analysis for g-code cnc Sourcing

Understanding the cost structure and pricing dynamics for sourcing g-code CNC solutions is crucial for international B2B buyers. This analysis focuses on the key cost components, price influencers, and actionable tips that can help buyers navigate the complexities of procurement while maximizing value.

Cost Components

-

Materials: The cost of raw materials, such as metals, plastics, and composites, significantly impacts the overall pricing of CNC machined parts. Prices can fluctuate based on global market conditions, making it essential for buyers to stay informed about material costs in their respective regions.

-

Labor: Skilled labor is a critical element in CNC machining. Labor costs can vary widely depending on the local market conditions and the expertise required for programming and operating CNC machines. In regions with labor shortages, such as parts of Africa and South America, costs may be higher.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and facility costs. Efficient operations can reduce overhead costs, but buyers should consider these factors when evaluating supplier pricing.

-

Tooling: Tooling costs can be substantial, especially for custom or specialized parts. Buyers should assess whether suppliers include tooling in their pricing or if additional charges apply for tool wear and replacement.

-

Quality Control (QC): Implementing robust QC processes ensures product consistency and compliance with international standards. While this can add to upfront costs, it is essential for reducing defects and ensuring long-term satisfaction.

-

Logistics: Transportation costs can vary based on distance, mode of transport, and customs duties. International buyers must factor in shipping costs, which may include incoterms that define responsibility for shipping, insurance, and tariffs.

-

Margin: Suppliers typically apply a margin to cover their operational costs and profit. Understanding the market standard for margins in your industry can help in negotiating better pricing.

Price Influencers

-

Volume/MOQ: Higher order volumes often lead to lower per-unit costs due to economies of scale. Establishing a minimum order quantity (MOQ) can influence pricing and should be negotiated based on projected demand.

-

Specifications/Customization: Custom parts generally incur higher costs due to the additional programming and tooling required. Clearly defined specifications can help minimize unexpected costs.

-

Materials: The choice of materials directly affects pricing. High-performance materials may offer better durability but come at a premium.

-

Quality/Certifications: Products that meet specific industry certifications (ISO, AS9100) may command higher prices due to the assurance of quality and reliability.

-

Supplier Factors: The reputation and reliability of suppliers play a significant role in pricing. Established suppliers with proven track records may charge more but offer better service and quality assurance.

-

Incoterms: Understanding incoterms is vital as they dictate shipping responsibilities and costs. Incoterms like FOB (Free on Board) can lead to varying costs depending on the supplier’s location.

Buyer Tips

-

Negotiate: Leverage your understanding of cost structures to negotiate better pricing. Suppliers may be willing to adjust margins for large orders or long-term contracts.

-

Focus on Cost-Efficiency: Consider the Total Cost of Ownership (TCO) rather than just the initial purchase price. This includes ongoing maintenance, operational costs, and potential downtime.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations and how they impact pricing. Additionally, regional trade agreements may affect tariffs and duties.

-

Supplier Vetting: Conduct thorough research on potential suppliers to ensure they meet your quality and reliability standards. Utilizing platforms that aggregate supplier ratings can simplify this process.

Disclaimer

Prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific project requirements. Always seek detailed quotations from multiple suppliers to ensure competitive pricing tailored to your needs.

Spotlight on Potential g-code cnc Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘g-code cnc’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for g-code cnc

Critical Technical Properties of G-Code CNC

Understanding the technical specifications of G-Code CNC machinery is vital for B2B buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe. Here are some essential properties to consider:

-

Material Grade: This refers to the type of material that the CNC machine can effectively process, such as aluminum, steel, or plastics. Each material has specific characteristics, impacting the choice of tools, speeds, and feeds. Knowing the material grade helps buyers select the right machinery for their production needs, ensuring quality and efficiency.

-

Tolerance: Tolerance defines the permissible limit of variation in a physical dimension. Tight tolerances (e.g., ±0.01 mm) are crucial for industries like aerospace and automotive, where precision is paramount. Understanding tolerance specifications allows buyers to align their CNC capabilities with industry standards and customer requirements, minimizing rework and enhancing product reliability.

-

Spindle Speed: This is the rotational speed of the spindle in revolutions per minute (RPM). Different materials require different spindle speeds for optimal cutting performance. Buyers must consider spindle speed capabilities to ensure that their CNC machines can handle the specific demands of their projects, thereby increasing productivity and reducing cycle times.

-

Feed Rate: The feed rate is the speed at which the tool moves through the material. It is typically measured in millimeters per minute (mm/min). An appropriate feed rate ensures smooth cutting, prevents tool wear, and enhances surface finish quality. Understanding feed rate specifications is essential for buyers to optimize machining operations and ensure cost-effective production.

-

Axis Configuration: CNC machines can vary in their axis configurations, such as 3-axis, 4-axis, or 5-axis systems. Each configuration offers different capabilities for machining complex geometries. Buyers should assess their production needs and select the machine with the appropriate axis configuration to achieve desired outcomes efficiently.

Common Trade Terminology in G-Code CNC

Familiarity with industry-specific jargon is crucial for effective communication and negotiation in the B2B landscape. Here are some common terms relevant to G-Code CNC:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding the role of OEMs is essential for buyers when sourcing components or machinery, as it impacts warranty, support, and compatibility.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of a product that a supplier is willing to sell. In CNC machining, knowing the MOQ helps buyers gauge potential costs and inventory management. It allows them to negotiate effectively with suppliers to align order sizes with production needs.

-

RFQ (Request for Quotation): An RFQ is a formal process where buyers request price quotes from suppliers for specific products or services. It is a critical step in the procurement process, enabling buyers to compare costs, terms, and delivery times from different suppliers, ensuring they make informed purchasing decisions.

-

Incoterms (International Commercial Terms): These are international trade terms that define the responsibilities of buyers and sellers in shipping and logistics. Familiarity with Incoterms helps buyers understand their obligations regarding shipping costs, insurance, and liability, ensuring smooth transactions across borders.

-

CNC Controller: This is the device that interprets G-Code commands to control the machine’s movements and operations. Knowledge of different CNC controllers is important for buyers to ensure compatibility with their existing systems and to understand the capabilities of the machinery they are considering.

By grasping these technical properties and industry terms, B2B buyers can navigate the complexities of sourcing G-Code CNC machinery more effectively, leading to better decision-making and enhanced operational efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the g-code cnc Sector

Global drivers are reshaping the landscape of the g-code CNC sector, particularly for B2B buyers in Africa, South America, the Middle East, and Europe. The rapid advancement of automation and Industry 4.0 technologies is a significant catalyst, enhancing operational efficiency and precision. As businesses adopt smart manufacturing practices, the integration of CNC machines with IoT devices and AI is becoming increasingly common. This trend not only increases productivity but also allows for real-time data analysis, helping companies optimize their supply chains and manufacturing processes.

Current sourcing trends indicate a growing preference for suppliers who can offer comprehensive service packages, including training, maintenance, and software support. As the demand for customized solutions rises, B2B buyers are seeking suppliers that can provide flexibility and adaptability in their CNC systems. Additionally, the ongoing globalization of markets is prompting international buyers to establish partnerships with local suppliers to mitigate risks associated with currency fluctuations and trade policies. Countries like Nigeria and Argentina are seeing a surge in investments in CNC technologies, driven by government initiatives and private sector innovation.

Sustainability & Ethical Sourcing in B2B

The environmental impact of CNC machining is a critical concern for B2B buyers. The industry generates considerable waste and energy consumption, making it imperative for companies to adopt sustainable practices. Ethical sourcing plays a pivotal role in this transition, as buyers increasingly prioritize suppliers who demonstrate a commitment to reducing their carbon footprint and implementing sustainable manufacturing processes.

Investing in CNC machines that utilize energy-efficient technologies and recyclable materials can significantly reduce environmental impact. Additionally, certification programs such as ISO 14001 for environmental management systems and adherence to green manufacturing standards are becoming essential. Buyers should seek out suppliers that provide transparency regarding their sourcing practices and materials used in CNC production. This not only aligns with global sustainability goals but also enhances brand reputation and consumer trust in increasingly eco-conscious markets.

Brief Evolution/History

The g-code CNC sector has evolved significantly since its inception in the 1950s. Initially developed as a means to control machine tools with precision, g-code has become the standard language for CNC operations worldwide. Over the decades, advancements in technology have led to the development of sophisticated CNC machines capable of performing complex tasks with high efficiency. The transition from manual programming to automated systems has further streamlined operations, allowing for the rapid production of intricate designs. As the industry continues to innovate, understanding the historical context of g-code and its applications remains vital for B2B buyers navigating the modern manufacturing landscape.

Related Video: A guide to Sustainable Procurement for greener and safer Supply Chains | Benefits and Challenges

Frequently Asked Questions (FAQs) for B2B Buyers of g-code cnc

-

What should I consider when vetting suppliers for G-Code CNC machines?

When vetting suppliers, prioritize their experience with G-Code CNC technologies and their track record in international trade. Check their certifications, such as ISO standards, to ensure quality assurance. Request case studies or testimonials from previous clients in your region to gauge their reliability. Additionally, assess their customer service responsiveness, as timely communication is crucial for resolving issues during procurement and after-sales support. -

Can G-Code CNC machines be customized to meet specific production needs?

Yes, many suppliers offer customization options for G-Code CNC machines. This can include tailored software configurations, specific attachments, or adjustments to meet unique production requirements. When negotiating, clearly outline your needs and inquire about the supplier’s capacity for modifications. Ensure that any customization aligns with industry standards to maintain compatibility with existing systems and processes. -

What are the typical minimum order quantities (MOQ) and lead times for G-Code CNC machines?

MOQs can vary significantly based on the supplier and the complexity of the machine. Generally, established manufacturers may have higher MOQs due to production costs. Lead times often range from a few weeks to several months, depending on customization and logistics. Always clarify these terms during negotiations to plan your inventory and production schedules accordingly, particularly in industries with tight timelines. -

What quality assurance certifications should I look for in G-Code CNC suppliers?

Look for suppliers with certifications like ISO 9001 for quality management and ISO 14001 for environmental management. These certifications indicate a commitment to quality and sustainability practices. Additionally, inquire about their adherence to industry-specific standards relevant to your sector, such as AS9100 for aerospace or IATF 16949 for automotive, to ensure compliance with regulatory requirements.

-

How do logistics and shipping impact the procurement of G-Code CNC machines?

Logistics play a critical role in the procurement process, affecting lead times and overall costs. Consider the supplier’s location, as international shipping can introduce delays and additional tariffs. Evaluate the supplier’s logistics capabilities, including their partnerships with freight forwarders and their experience with customs clearance in your region. Opt for suppliers who can provide detailed shipping timelines and tracking capabilities to mitigate uncertainties. -

What steps should I take if I encounter a dispute with a G-Code CNC supplier?

In the event of a dispute, first, attempt to resolve the issue through direct communication with the supplier. Document all correspondence and keep records of agreements and discrepancies. If direct negotiation fails, refer to the contract terms regarding dispute resolution, which may include mediation or arbitration clauses. Involving local trade authorities or industry associations can also provide additional support in resolving conflicts. -

Are there specific payment terms I should negotiate when purchasing G-Code CNC machines?

Yes, negotiate payment terms that align with your cash flow and financial planning. Common terms include a deposit upfront, with the balance due upon delivery or installation. Consider requesting milestones for payments tied to production stages to mitigate risk. Additionally, explore options for letters of credit or escrow services, especially for high-value purchases, to ensure security for both parties. -

What are the best practices for integrating G-Code CNC machines into existing production lines?

To ensure a smooth integration, conduct a thorough assessment of your current production processes and identify how the new G-Code CNC machine will fit in. Provide training for your operators on the specific G-Code commands and machine features. Develop a phased implementation plan that allows for testing and adjustments before full-scale production. Regularly evaluate performance and gather feedback from operators to optimize the integration process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for g-code cnc

In today’s competitive manufacturing landscape, mastering G-Code is essential for operational excellence and strategic sourcing. By understanding the intricacies of G-Code commands and their applications, B2B buyers can enhance precision, streamline production processes, and foster efficient communication across supply chains. The ability to navigate the diverse global market for CNC solutions not only mitigates risks but also empowers buyers to negotiate effectively with suppliers, ensuring they derive optimal value from their investments.

Illustrative Image (Source: Google Search)

As markets in Africa, South America, the Middle East, and Europe continue to modernize, strategic sourcing becomes increasingly critical. Companies must prioritize robust supplier vetting and invest in operator training to overcome local expertise gaps and variations in technology standards.

Looking ahead, international buyers are encouraged to embrace innovation and adaptability as they source CNC machinery and services. By leveraging a deep understanding of G-Code and related technologies, they can position themselves at the forefront of their respective industries, driving efficiency and profitability. Now is the time to take proactive steps toward optimizing your CNC operations and forging partnerships that will support your growth in a dynamic global marketplace.