Your Ultimate Guide to Sourcing Load Cell Suppliers

Introduction: Navigating the Global Market for load cell suppliers

In today’s increasingly competitive global landscape, load cell suppliers play a pivotal role in various industries, including manufacturing, automotive, and healthcare. These precision instruments are essential for measuring weight and force, ensuring accuracy in production processes and quality control. With the rise of international trade, understanding the nuances of sourcing load cells has become more critical than ever for businesses in regions such as Africa, South America, the Middle East, and Europe.

This comprehensive guide delves into the multifaceted world of load cell suppliers, equipping B2B buyers with the knowledge they need to make informed sourcing decisions. It covers a diverse array of topics, including the types of load cells, materials used in their construction, manufacturing and quality control standards, as well as a detailed overview of suppliers from various regions. Additionally, we explore cost considerations and market dynamics, providing insights into how to navigate pricing structures and potential negotiations.

By leveraging this guide, international buyers can streamline their procurement processes, identify reliable suppliers, and enhance their operational efficiencies. Whether you are in Brazil looking for innovative solutions or in Italy seeking reliable partners, this resource is designed to empower you with the information necessary to make strategic decisions that align with your business goals.

Understanding load cell suppliers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Strain Gauge Load Cells | High accuracy, versatile, used in various environments | Industrial weighing, medical applications | Pros: High precision, wide range of applications. Cons: Sensitive to temperature changes. |

| Hydraulic Load Cells | Uses fluid pressure to measure load, robust design | Heavy machinery, construction, and shipping | Pros: Excellent for heavy loads, durable. Cons: Bulkier and requires maintenance. |

| Pneumatic Load Cells | Operates using air pressure, lightweight | Aerospace, automotive testing | Pros: Lightweight, less wear and tear. Cons: Limited load capacity compared to hydraulic. |

| Digital Load Cells | Integrated electronics for easy data transfer | Automated systems, robotics, and precision tasks | Pros: Real-time data, easy integration. Cons: Higher initial cost, requires power source. |

| Load Pins | Compact design, replaces standard pins in machinery | Crane scales, weighing hoppers | Pros: Space-saving, easy installation. Cons: Limited to specific applications. |

Strain Gauge Load Cells

Strain gauge load cells are among the most commonly used types due to their high accuracy and versatility. They function by measuring the deformation of a material under load, providing precise measurements across various applications, including industrial weighing and medical diagnostics. Buyers should consider the environmental conditions, as strain gauge load cells are sensitive to temperature variations, which can affect their accuracy. Additionally, choosing reputable suppliers that offer calibration services can enhance reliability.

Hydraulic Load Cells

Hydraulic load cells are designed to handle very heavy loads, making them ideal for applications in construction, shipping, and heavy machinery. They utilize fluid pressure to measure weight, providing robust and reliable performance even under extreme conditions. While they are durable, buyers should be aware that hydraulic load cells can be bulkier and may require regular maintenance to ensure optimal performance. Understanding the specific load requirements and operational environment is essential when selecting this type.

Pneumatic Load Cells

Pneumatic load cells operate using air pressure and are known for their lightweight design, making them suitable for applications in aerospace and automotive testing. These load cells experience less wear and tear compared to their hydraulic counterparts, which can lead to lower maintenance costs. However, their load capacity is generally limited, so buyers must assess whether their specific application requires the high capacity that hydraulic systems provide.

Digital Load Cells

Digital load cells incorporate integrated electronics, allowing for easy data transfer and real-time monitoring. They are ideal for automated systems, robotics, and precision tasks where immediate data feedback is critical. While they offer significant advantages in terms of integration and data management, buyers should note that digital load cells may have a higher initial cost and require a power source to operate. Evaluating the total cost of ownership, including maintenance and operational costs, can help in making informed purchasing decisions.

Load Pins

Load pins are compact and versatile devices that can replace standard pins in machinery to measure loads. They are particularly useful in crane scales and weighing hoppers, providing a space-saving solution for load measurement. While their installation is straightforward, buyers should keep in mind that load pins are typically limited to specific applications, which may restrict their usability in broader contexts. Understanding the intended application and ensuring compatibility with existing systems is crucial when considering load pins as a solution.

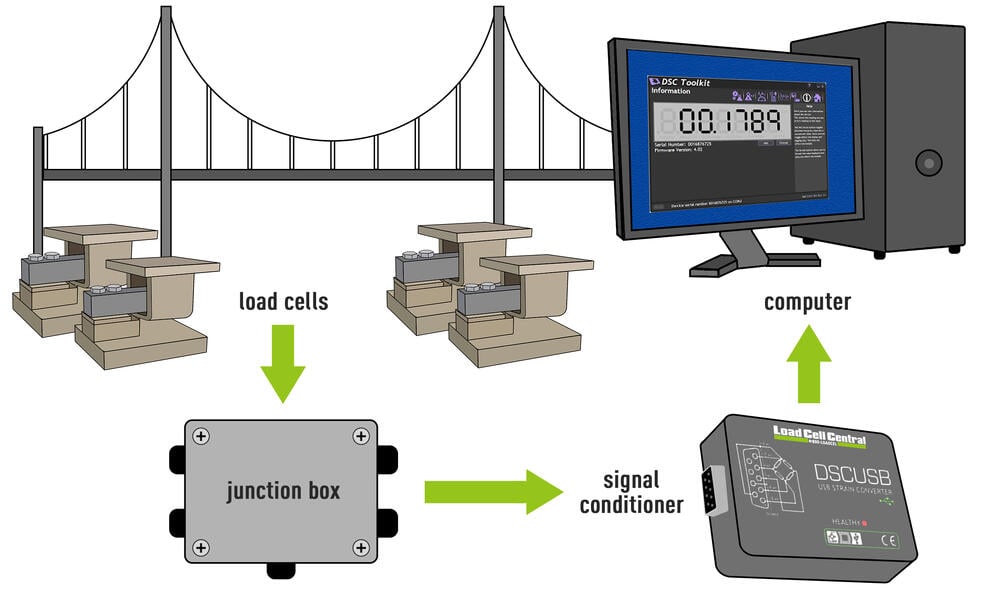

Related Video: The Load Cell: What it is, What it Does, How it Works!

Key Industrial Applications of load cell suppliers

| Industry/Sector | Specific Application of load cell suppliers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Weight measurement in assembly lines | Enhances precision in production, reducing material waste | Compliance with local standards, integration with existing systems |

| Transportation & Logistics | Load monitoring in freight and shipping | Ensures compliance with weight regulations, optimizes logistics | Robustness for varying environments, calibration services |

| Food & Beverage | Ingredient weighing in food processing | Guarantees consistency in product quality, minimizes errors | Hygiene standards, accuracy under varying temperatures |

| Construction | Load testing of structural components | Validates safety and integrity of structures, prevents failures | Certification for safety standards, adaptability to project needs |

| Healthcare | Patient weight monitoring in medical devices | Improves patient care and monitoring accuracy | Compliance with medical regulations, ease of integration |

Manufacturing

In the manufacturing sector, load cell suppliers provide essential weight measurement solutions for assembly lines. These load cells ensure that components are accurately weighed, which enhances production precision and minimizes material waste. For international buyers, sourcing load cells that comply with local manufacturing standards is crucial. Additionally, the ability to integrate these systems into existing processes without significant disruption is a key consideration.

Transportation & Logistics

Load monitoring in freight and shipping is another critical application of load cells. They play a vital role in ensuring compliance with weight regulations, which helps avoid penalties and optimize logistics operations. For buyers, especially in regions with strict transportation regulations, sourcing load cells that are robust enough to withstand varying environmental conditions is essential. Furthermore, suppliers should offer calibration services to maintain accuracy over time.

Food & Beverage

In the food and beverage industry, load cells are used for ingredient weighing during processing. Accurate measurement is crucial for maintaining product consistency and quality, which directly impacts customer satisfaction and brand reputation. International buyers must consider hygiene standards when sourcing load cells, as these devices often come into contact with food. Additionally, the ability to perform accurately under varying temperatures is an important requirement.

Construction

Load testing of structural components is a significant application in the construction industry. Load cells help validate the safety and integrity of structures, preventing potential failures that could lead to catastrophic outcomes. Buyers in this sector should prioritize sourcing load cells that meet safety certifications and can adapt to specific project needs. The ability to provide detailed reporting and analytics is also valuable for compliance and project management.

Healthcare

In healthcare, load cells are crucial for patient weight monitoring in medical devices. Accurate weight measurements enhance patient care by allowing healthcare providers to monitor weight changes effectively. International buyers must ensure that the load cells they source comply with medical regulations and standards. Moreover, ease of integration into existing medical systems is a significant consideration, as it affects the overall functionality and reliability of healthcare devices.

Related Video: A Better Load Cell Design for Tough Process Weighing Applications

Strategic Material Selection Guide for load cell suppliers

When selecting materials for load cells, international B2B buyers must consider various factors that influence performance, durability, and cost. Below is an analysis of four common materials used in load cell manufacturing, focusing on their properties, advantages, disadvantages, and specific considerations relevant to buyers from Africa, South America, the Middle East, and Europe.

Aluminum

Key Properties: Aluminum is lightweight and has a good strength-to-weight ratio. It typically offers excellent corrosion resistance and can withstand moderate temperature variations.

Pros & Cons: The primary advantage of aluminum is its low cost and ease of manufacturing, making it suitable for high-volume applications. However, it has lower stiffness compared to other materials like steel, which may limit its use in high-load applications. Its susceptibility to deformation under extreme loads can also be a concern.

Impact on Application: Aluminum load cells are often used in portable weighing systems and applications where weight is a critical factor. However, they may not be suitable for environments with high humidity or corrosive substances.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM or DIN, especially in regions like Europe where regulations are stringent. Additionally, the availability of aluminum in local markets can vary, impacting lead times.

Stainless Steel

Key Properties: Stainless steel is known for its high strength, durability, and excellent corrosion resistance, making it ideal for harsh environments. It can withstand high temperatures and pressures.

Pros & Cons: The main advantage of stainless steel is its robustness and longevity, which can justify its higher cost. However, the manufacturing process is more complex, which can lead to longer lead times and increased costs.

Impact on Application: Stainless steel load cells are suitable for industrial applications, including food processing and chemical handling, where exposure to corrosive agents is common.

Considerations for International Buyers: Buyers should verify that the stainless steel used meets international standards (e.g., AISI 304 or 316) for corrosion resistance. Additionally, understanding local regulations regarding materials in food and chemical industries is crucial.

Alloy Steel

Key Properties: Alloy steel combines elements such as chromium, nickel, and molybdenum to enhance strength and toughness. It has good fatigue resistance and can handle high-stress applications.

Pros & Cons: The key advantage of alloy steel is its high strength, making it suitable for heavy-duty applications. However, it is generally more expensive than aluminum and may require specialized manufacturing techniques.

Impact on Application: Alloy steel load cells are often used in industrial scales, heavy machinery, and applications requiring precise measurements under high loads.

Considerations for International Buyers: Buyers should consider the specific alloy composition to ensure it meets performance requirements. Compliance with international standards for load-bearing applications is also essential.

Plastic Composites

Key Properties: Plastic composites are lightweight and resistant to corrosion and moisture. They can be engineered for specific performance characteristics, including flexibility and impact resistance.

Pros & Cons: The advantage of plastic composites is their versatility and low weight, making them suitable for portable applications. However, they may not offer the same level of accuracy or durability as metal options, particularly in high-load scenarios.

Impact on Application: These materials are often used in consumer electronics and lightweight applications where portability is essential.

Considerations for International Buyers: Buyers should assess the specific type of plastic composite used and its compatibility with the intended application. Understanding local regulations regarding plastic materials is also important, especially in regions with strict environmental laws.

| Material | Typical Use Case for load cell suppliers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Portable weighing systems | Low cost and lightweight | Lower stiffness and deformation risk | Low |

| Stainless Steel | Food processing and chemical handling | High strength and corrosion resistance | More complex manufacturing | High |

| Alloy Steel | Heavy-duty industrial applications | High strength and fatigue resistance | Higher cost and specialized techniques | Med |

| Plastic Composites | Consumer electronics and lightweight apps | Versatile and low weight | Limited accuracy and durability | Low |

This guide provides a foundational understanding of material selection for load cells, enabling international B2B buyers to make informed decisions based on their specific application needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for load cell suppliers

Manufacturing load cells is a multi-faceted process that requires precision and adherence to stringent quality standards. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance practices of load cell suppliers is essential for making informed purchasing decisions. Below, we explore the key stages of manufacturing, quality control measures, and actionable insights for verifying supplier quality.

Manufacturing Processes for Load Cells

The manufacturing of load cells typically involves several critical stages:

1. Material Preparation

The choice of materials is crucial in load cell manufacturing. Common materials include aluminum, stainless steel, and alloy steel, chosen for their mechanical properties and resistance to environmental factors. During this stage:

– Material Selection: Suppliers should provide documentation on material grades and certifications.

– Cutting and Shaping: Raw materials are cut into specified shapes using CNC machines or laser cutting techniques to ensure precision.

2. Forming

Once the materials are prepared, the next step involves forming them into the required shapes. This may include:

– Machining: Processes like turning, milling, and grinding are used to achieve the desired dimensions and surface finish.

– Welding: For certain types of load cells, components may be welded together to create a robust structure.

3. Assembly

The assembly stage is where the individual components come together:

– Integration of Sensors: Load cells typically utilize strain gauges, which are bonded to the load-bearing element. The accuracy of this step is critical.

– Electrical Connections: Proper wiring and connections are established to ensure signal integrity.

4. Finishing

Finishing processes enhance the durability and functionality of the load cells:

– Coating: Protective coatings may be applied to prevent corrosion, especially for applications in harsh environments.

– Calibration: Each load cell is calibrated to ensure accurate readings. This process involves applying known weights and adjusting the output.

Quality Assurance in Load Cell Manufacturing

Quality assurance is paramount in ensuring that load cells meet international and industry-specific standards. Here are some key aspects of quality control:

Relevant International Standards

Load cell manufacturers should comply with various standards to ensure product quality:

– ISO 9001: This standard outlines requirements for a quality management system (QMS) and is essential for ensuring consistent quality.

– CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

– API Spec Q1: Relevant for load cells used in the oil and gas industry, ensuring that manufacturers meet stringent quality requirements.

Quality Control Checkpoints

A comprehensive quality control process includes several checkpoints:

– Incoming Quality Control (IQC): Materials are inspected upon arrival to verify compliance with specifications.

– In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help catch defects early.

– Final Quality Control (FQC): Finished products undergo rigorous testing and inspection before shipment.

Common Testing Methods

Load cells are subjected to various testing methods to ensure performance:

– Load Testing: Verifying the load cell’s response to known weights to ensure accuracy.

– Temperature Testing: Assessing performance under varying temperature conditions.

– Environmental Testing: Ensuring that the load cells can withstand specific environmental conditions, such as humidity or exposure to chemicals.

Verifying Supplier Quality Control

For B2B buyers, especially in regions like Africa and South America, verifying supplier quality is crucial. Here are actionable steps:

Conduct Supplier Audits

Regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. Look for:

– Documentation: Suppliers should provide QMS documentation and evidence of compliance with relevant standards.

– Facilities: Assess the manufacturing facilities for cleanliness, organization, and technological capability.

Request Quality Reports

Buyers should request quality reports that detail the results of inspections and tests conducted on the load cells. Key points to look for include:

– Test Certificates: Evidence of testing for each batch of load cells.

– Calibration Certificates: Documentation confirming that calibration has been performed according to standards.

Third-Party Inspections

Engaging third-party inspection services can add an additional layer of assurance. These services can provide unbiased evaluations of the manufacturing processes and the quality of the products.

Quality Control Nuances for International Buyers

International buyers should also be aware of specific nuances when dealing with quality control:

– Cultural Differences: Understand that manufacturing practices may vary by region. It’s important to communicate clearly about quality expectations.

– Regulatory Compliance: Ensure that suppliers are aware of and comply with the regulations specific to the buyer’s country. This is particularly important for buyers in Europe, where compliance with CE marking is mandatory.

Conclusion

Understanding the manufacturing processes and quality assurance practices of load cell suppliers is vital for international B2B buyers. By focusing on the key stages of manufacturing, adhering to relevant quality standards, and implementing thorough verification processes, buyers can ensure they source high-quality load cells that meet their specific needs. This knowledge not only helps in selecting reliable suppliers but also strengthens the overall supply chain integrity.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for load cell suppliers Sourcing

When sourcing load cells, understanding the comprehensive cost structure and pricing dynamics is crucial for B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. Here’s an in-depth look at the various cost components, price influencers, and strategic buyer tips to optimize procurement.

Cost Components

-

Materials: The choice of materials significantly impacts the overall cost. Common materials used in load cell manufacturing include aluminum, stainless steel, and various alloys. The cost will vary based on market prices and the supplier’s sourcing capabilities.

-

Labor: Labor costs can fluctuate based on the region where the load cells are manufactured. For example, labor is typically less expensive in developing regions compared to Europe or North America. Understanding local wage standards can provide insights into potential cost savings.

Illustrative Image (Source: Google Search)

-

Manufacturing Overhead: This encompasses all indirect costs related to production, including utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help keep these costs down, which can be beneficial for buyers.

-

Tooling: Custom tooling can be a significant upfront investment, particularly for tailored load cell designs. The cost will depend on the complexity of the tooling required and the scale of production.

-

Quality Control (QC): Ensuring quality through rigorous testing can add to costs but is essential for maintaining reliability and compliance with industry standards. Suppliers with robust QC processes may charge a premium, which buyers should consider against potential warranty and replacement costs.

-

Logistics: Shipping and handling costs can vary widely depending on the supplier’s location and the chosen transportation method. International buyers should be aware of the logistics involved, including tariffs, insurance, and customs fees.

-

Margin: Supplier profit margins can range based on market positioning, competition, and the value-added services offered. Understanding a supplier’s pricing strategy can aid in negotiation.

Price Influencers

-

Volume/MOQ: Purchasing in larger quantities often leads to significant discounts. Buyers should evaluate their needs and consider bulk purchases to lower the per-unit cost.

-

Specifications/Customization: Custom load cells tailored to specific applications usually come at a higher price point. Buyers must balance the necessity for customization against standard options that may be more cost-effective.

-

Materials and Quality Certifications: Load cells that meet international quality certifications (e.g., ISO, OIML) may carry a higher price. However, investing in certified products can reduce long-term risks and maintenance costs.

-

Supplier Factors: Factors such as supplier reputation, reliability, and service offerings can influence pricing. Established suppliers may charge more due to their proven track record, while newer suppliers might offer competitive prices to gain market share.

-

Incoterms: The choice of Incoterms (International Commercial Terms) affects logistics and risk allocation. Understanding these terms can help buyers negotiate better deals and clarify responsibilities for shipping and customs duties.

Buyer Tips

-

Negotiate: Effective negotiation can lead to better pricing and payment terms. Engaging multiple suppliers can create competitive pressure, leading to favorable outcomes.

-

Assess Total Cost of Ownership (TCO): Consider not just the initial purchase price but also installation, maintenance, and operational costs over the load cell’s lifecycle. This approach can reveal hidden costs associated with cheaper options.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, regional market conditions, and local economic factors that may affect pricing. Building relationships with suppliers can also provide insights into pricing trends.

-

Consider Local Suppliers: Sourcing from local suppliers can reduce shipping costs and lead times, and may enhance communication and service support.

Buyers should approach load cell procurement with a comprehensive understanding of these cost structures and pricing dynamics to make informed decisions that align with their operational needs and budget constraints. Always remember that indicative prices can vary significantly based on the factors outlined above.

Spotlight on Potential load cell suppliers Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘load cell suppliers’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for load cell suppliers

Key Technical Properties of Load Cells

Understanding the technical specifications of load cells is crucial for international B2B buyers, particularly when selecting suppliers that can meet their specific needs. Here are several essential properties to consider:

-

Material Grade

Load cells are typically made from materials like stainless steel, aluminum, or alloy steel. The material grade affects the load cell’s durability, corrosion resistance, and accuracy. For example, stainless steel is often preferred for its strength and resistance to harsh environments, making it ideal for outdoor or industrial applications. Selecting the right material grade can enhance product longevity and reduce maintenance costs. -

Tolerance

Tolerance refers to the permissible limits of variation in the load cell’s measurement accuracy. High tolerance indicates that the load cell can measure weight with minimal error, which is vital in precision applications such as pharmaceuticals or aerospace. Understanding tolerance levels ensures that buyers can select load cells that meet their operational standards and regulatory requirements. -

Capacity

The capacity of a load cell is the maximum weight it can accurately measure. This specification is crucial for ensuring that the load cell can handle the intended loads without risk of damage or failure. Buyers should assess their application requirements carefully to choose a load cell with an appropriate capacity, thus ensuring safe and reliable operation.

Illustrative Image (Source: Google Search)

-

Output Signal

Load cells produce an electrical output signal proportional to the applied load, typically in millivolts per volt (mV/V). Different applications may require specific output types, such as analog or digital signals. Buyers should understand the output requirements of their systems to ensure compatibility and optimal performance. -

Environmental Protection Rating

The environmental protection rating, often denoted by the Ingress Protection (IP) code, indicates how well a load cell can withstand environmental factors such as dust and moisture. For example, an IP67 rating means the load cell is dust-tight and can withstand immersion in water. This specification is vital for applications in harsh environments, ensuring that the load cell operates reliably over time.

Common Trade Terminology in Load Cell Procurement

Familiarity with industry jargon can significantly enhance communication and negotiation with suppliers. Here are key terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. When dealing with load cells, OEMs often provide customized solutions tailored to specific applications. Understanding the OEM relationship can help buyers secure specialized products that fit their unique needs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is essential for buyers to understand, as it affects purchasing decisions and inventory management. Suppliers may have different MOQs based on production capabilities, which can impact costs and lead times. -

RFQ (Request for Quote)

An RFQ is a document sent to suppliers to solicit pricing for specific products or services. It typically includes details about required specifications, quantities, and delivery timelines. Buyers should prepare comprehensive RFQs to ensure they receive accurate and competitive quotes from potential suppliers. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping goods. Familiarity with Incoterms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), helps buyers understand shipping costs, insurance, and liability, thus facilitating smoother international transactions. -

Calibration

Calibration is the process of adjusting and verifying the accuracy of a load cell against a known standard. Regular calibration is crucial for maintaining measurement precision and compliance with industry standards. Buyers should ensure that suppliers provide calibration services or documentation to support the accuracy of their load cells.

By understanding these essential properties and terms, international B2B buyers can make informed decisions when sourcing load cells, ultimately leading to improved operational efficiency and product reliability.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the load cell suppliers Sector

In the load cell suppliers sector, international B2B buyers are witnessing a transformative landscape shaped by several market dynamics and technological advancements. The increasing demand for precision measurement across various industries, such as manufacturing, logistics, and healthcare, is a primary driver. This demand is further fueled by the rise of automation and smart manufacturing, where load cells are integral to ensuring operational efficiency and product quality.

Emerging technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) are revolutionizing load cell applications. These technologies enable real-time data collection and analysis, allowing companies to optimize performance and reduce downtime. For buyers in Africa, South America, the Middle East, and Europe, integrating these technologies into their operations can lead to significant cost savings and enhanced decision-making capabilities. Additionally, the trend towards customized solutions is becoming prominent, as businesses seek suppliers who can provide tailored load cell products that meet specific operational needs.

Furthermore, geopolitical factors and trade agreements are influencing sourcing strategies. Buyers must navigate tariffs and import regulations that vary by region, particularly when sourcing from different continents. Building strong relationships with reliable suppliers and understanding local market conditions are critical for successful procurement.

Sustainability & Ethical Sourcing in B2B

The importance of sustainability in the load cell industry cannot be overstated. Environmental concerns are prompting businesses to seek suppliers that prioritize eco-friendly practices. This includes using sustainable materials in manufacturing load cells and adopting energy-efficient production processes. As international regulations tighten around emissions and waste management, B2B buyers are increasingly required to demonstrate compliance with these standards.

Ethical sourcing is also a significant consideration. Companies are expected to ensure that their suppliers adhere to fair labor practices and maintain transparency in their supply chains. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential benchmarks for evaluating potential suppliers. Buyers should prioritize suppliers who can provide evidence of their commitment to sustainability through these certifications and other green initiatives.

Brief Evolution/History

The load cell technology has evolved significantly since its inception in the mid-20th century. Initially used in industrial applications, load cells have seen advancements that have expanded their applications across various sectors, including automotive, aerospace, and healthcare. The integration of digital technology in the 1990s marked a pivotal moment, enhancing accuracy and functionality. Today, the focus is on miniaturization and smart technology, allowing for integration into a broader array of devices and systems, making load cells indispensable in modern industrial applications. Understanding this evolution helps B2B buyers appreciate the technological advancements that drive current sourcing trends and market dynamics.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of load cell suppliers

-

What should I consider when vetting load cell suppliers?

When vetting load cell suppliers, prioritize their industry experience, reputation, and certifications. Look for suppliers with a proven track record in your specific sector, as this indicates familiarity with relevant standards and customer needs. Request references and conduct background checks. Additionally, assess their financial stability and the quality of their customer service. This information can often be found in online reviews and industry forums. -

Can load cells be customized to meet specific requirements?

Yes, many load cell suppliers offer customization options to cater to specific applications. This may include variations in size, capacity, and mounting configurations. When discussing customization, clearly articulate your requirements and expectations. Ensure that the supplier has the technical capabilities and experience to deliver tailored solutions. Always request prototypes or samples to verify that the custom load cells meet your specifications before placing larger orders. -

What are the typical minimum order quantities (MOQs) and lead times for load cells?

MOQs and lead times can vary significantly among suppliers. Generally, larger suppliers may have higher MOQs, while smaller or specialized manufacturers might be more flexible. Lead times can range from a few weeks to several months, depending on the complexity of the order and the supplier’s production capacity. It’s advisable to discuss these details upfront and consider your own inventory management practices to align with the supplier’s timelines. -

How do I ensure quality assurance and necessary certifications for load cells?

To ensure quality assurance, ask suppliers about their quality management systems and the certifications they hold (e.g., ISO 9001). Request documentation for compliance with industry standards relevant to your application, such as OIML or NTEP. Additionally, inquire about their testing procedures and whether they offer warranties or guarantees. Conducting periodic audits on your suppliers can also help maintain quality control over time. -

What logistics considerations should I keep in mind when sourcing load cells internationally?

When sourcing load cells internationally, consider shipping methods, customs regulations, and potential import duties. Choose a reliable logistics partner experienced in handling international shipments to minimize delays. Be proactive in understanding your destination country’s regulations regarding electronic and measurement devices. Additionally, ensure that the supplier provides proper documentation for customs clearance to avoid complications during transit. -

How can I resolve disputes with load cell suppliers effectively?

To resolve disputes effectively, maintain open and clear communication with the supplier. Document all interactions, agreements, and issues as they arise. If a dispute escalates, refer to the terms outlined in your contract, including any arbitration clauses. Consider involving a neutral third party to mediate if necessary. Establishing a good relationship with your supplier from the outset can also help in amicably resolving conflicts. -

What payment options are typically available when sourcing load cells?

Payment options for sourcing load cells can include bank transfers, letters of credit, and credit terms, depending on the supplier’s policies and your creditworthiness. Discuss payment terms upfront to avoid misunderstandings. Be cautious with upfront payments; ensure that the supplier has a solid reputation. Consider using escrow services for large orders to protect both parties until the goods are delivered and meet agreed-upon specifications. -

How can I stay updated on the latest trends and technologies in load cells?

To stay informed about the latest trends and technologies in load cells, subscribe to industry publications, attend trade shows, and engage with professional organizations. Networking with other B2B buyers and suppliers can also provide valuable insights into emerging technologies and best practices. Online forums and social media platforms like LinkedIn can be excellent resources for real-time updates and discussions within the industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for load cell suppliers

In conclusion, effective strategic sourcing for load cell suppliers is vital for international B2B buyers aiming to enhance operational efficiency and product reliability. By focusing on suppliers that offer tailored solutions, robust quality assurance, and innovative technologies, businesses can significantly reduce costs and improve measurement accuracy.

Key takeaways include the importance of establishing strong supplier relationships, leveraging comprehensive market research to identify reliable manufacturers, and understanding regional market dynamics that can affect pricing and availability. As Africa, South America, the Middle East, and Europe continue to experience industrial growth, the demand for high-quality load cells will rise, making strategic sourcing more critical than ever.

Looking ahead, buyers should actively seek partnerships with reputable suppliers who can provide not only the products but also the technical support necessary for seamless integration. Embracing this proactive approach will ensure that your business stays competitive and responsive to market changes. Engage with suppliers today to secure your supply chain and position your company for success in the evolving global marketplace.