Your Ultimate Guide to Sourcing Types Of Flow Meter

Introduction: Navigating the Global Market for types of flow meter

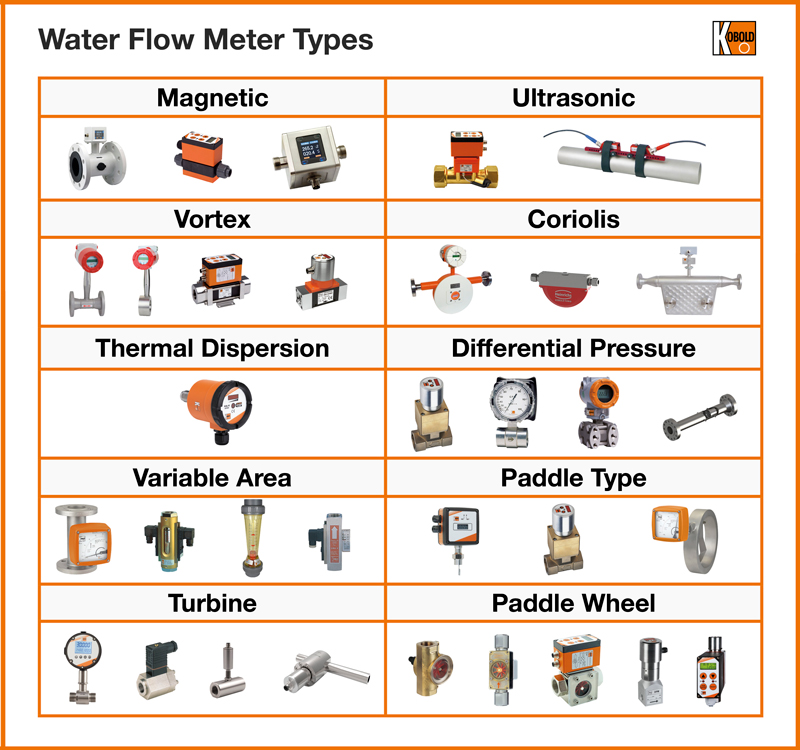

Flow meters are vital instruments in the global marketplace, offering precision and reliability in measuring the flow of liquids and gases across various industries. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the different types of flow meters is essential for optimizing processes and ensuring compliance with industry standards. This comprehensive guide delves into the diverse categories of flow meters, including differential pressure, magnetic, and mass flow meters, among others, providing insights into their unique applications and operational principles.

In addition to exploring types, this guide examines the materials used in flow meter construction, manufacturing and quality control standards, and sourcing considerations. Buyers will gain valuable information on selecting suppliers, understanding cost implications, and navigating the market landscape. With a focus on practical applications, this guide empowers decision-makers to make informed sourcing choices, ensuring they select the most suitable flow measurement solutions for their specific needs.

Whether you are involved in oil and gas, water management, or chemical processing, the insights provided will enhance your understanding of flow measurement technologies. This resource is designed to help international buyers navigate the complexities of flow meter selection and procurement, ultimately driving operational efficiency and cost savings in their organizations.

Understanding types of flow meter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Differential Pressure Meters | Measures flow by pressure drop across a constriction. | Oil & Gas, Water Management | Pros: Cost-effective, reliable. Cons: Requires calibration, not suitable for all fluids. |

| Magnetic Flow Meters | Utilizes Faraday’s law to measure conductive fluids. | Water Treatment, Chemical Processing | Pros: Non-invasive, low maintenance. Cons: Limited to conductive fluids. |

| Coriolis Flow Meters | Measures mass flow using the Coriolis effect. | Oil & Gas, Food & Beverage | Pros: High accuracy, suitable for varying densities. Cons: Higher initial cost. |

| Ultrasonic Flow Meters | Employs ultrasonic waves for flow measurement. | HVAC, Water Management | Pros: Non-intrusive, versatile. Cons: May be less accurate in certain conditions. |

| Positive Displacement Meters | Counts discrete volumes of fluid passing through. | Pharmaceutical, Food Processing | Pros: High accuracy for low flow rates. Cons: Mechanical wear over time. |

Differential Pressure Meters

Differential pressure meters function by detecting the pressure drop across a constriction in the flow path, making them suitable for a variety of applications, particularly in the oil and gas industry. They are cost-effective and reliable, often used in systems where budget constraints are a priority. However, they require regular calibration and may not perform well with all fluid types, which is a critical consideration for buyers.

Magnetic Flow Meters

Magnetic flow meters operate based on electromagnetic induction and are ideal for measuring the flow of conductive fluids, such as water and chemicals. Their non-invasive design means they require minimal maintenance, making them a popular choice in water treatment and chemical processing industries. Buyers should note that these meters are limited to conductive fluids, which can restrict their application in non-conductive environments.

Coriolis Flow Meters

Coriolis flow meters are known for their high precision, measuring mass flow by detecting the Coriolis effect. These meters excel in industries where accurate measurement is crucial, such as oil and gas and food and beverage sectors. While they offer superior accuracy, they come with a higher initial investment, making it essential for buyers to evaluate their long-term ROI against upfront costs.

Ultrasonic Flow Meters

Ultrasonic flow meters utilize sound waves to measure flow, making them versatile for various applications, including HVAC and water management. Their non-intrusive nature allows for easy installation and maintenance, a significant advantage for operations that cannot afford downtime. However, they may be less accurate under certain conditions, which buyers should consider when selecting the appropriate flow measurement solution.

Positive Displacement Meters

Positive displacement meters measure flow by isolating and counting discrete volumes of fluid, making them highly accurate, especially at low flow rates. They are commonly used in the pharmaceutical and food processing industries, where precision is paramount. However, the mechanical components can wear over time, necessitating regular maintenance and replacement, which is an important factor for buyers to keep in mind when making purchasing decisions.

Related Video: Types of Flow Meter

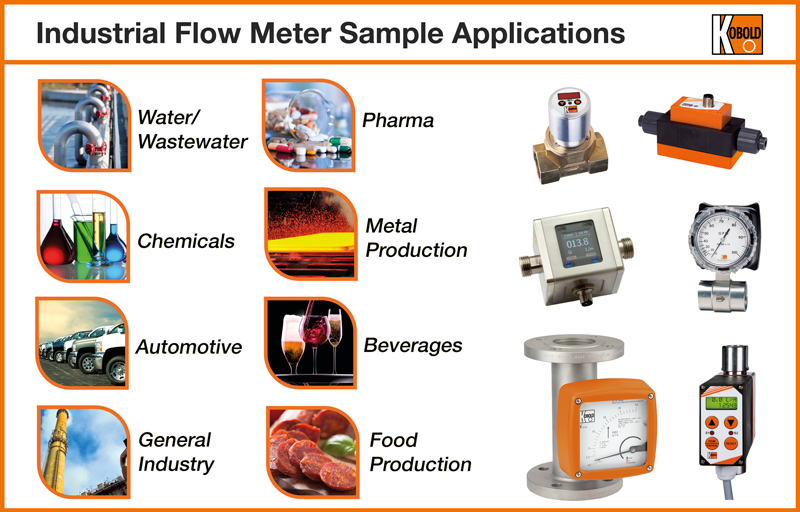

Key Industrial Applications of types of flow meter

| Industry/Sector | Specific Application of types of flow meter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil and Gas | Measurement of crude oil and natural gas flow rates | Enhances operational efficiency and safety | Accuracy, pressure rating, and compatibility with corrosive fluids |

| Water Treatment | Monitoring water flow in treatment plants | Ensures compliance with environmental regulations | Durability, material compatibility, and ease of installation |

| Chemical Processing | Flow measurement of various chemicals in production | Maintains quality control and reduces waste | Chemical resistance, accuracy, and maintenance requirements |

| Food and Beverage | Measuring liquid ingredients during production | Ensures product consistency and safety | Hygiene standards, material certifications, and accuracy |

| HVAC Systems | Monitoring airflow in heating, ventilation, and air conditioning | Optimizes energy efficiency and indoor air quality | Installation flexibility, accuracy, and maintenance needs |

Oil and Gas

In the oil and gas industry, flow meters are essential for measuring the flow rates of crude oil and natural gas. Accurate measurement is critical not only for optimizing production but also for ensuring safety and regulatory compliance. Buyers should consider factors such as pressure rating and compatibility with corrosive fluids when sourcing flow meters, as these parameters can significantly affect measurement accuracy and equipment longevity.

Water Treatment

Flow meters play a vital role in water treatment facilities, where they monitor the flow of water through various treatment processes. This measurement is crucial for ensuring compliance with environmental regulations and for maintaining the quality of treated water. Buyers in this sector should prioritize durability and material compatibility, as flow meters must withstand harsh conditions and potential chemical exposure.

Illustrative Image (Source: Google Search)

Chemical Processing

In chemical processing, flow meters are used to measure the flow of various chemicals during production. This application is critical for maintaining quality control and minimizing waste, as even minor inaccuracies can lead to significant production losses. Buyers should focus on sourcing flow meters that offer high accuracy and are resistant to the chemicals being processed, as well as consider the maintenance requirements for their chosen devices.

Food and Beverage

The food and beverage industry relies on flow meters to measure liquid ingredients during production processes. Accurate flow measurement ensures product consistency and safety, which are paramount in this sector. Buyers should ensure that the flow meters meet hygiene standards and possess the necessary material certifications to avoid contamination. Additionally, accuracy is crucial to minimize waste and ensure compliance with food safety regulations.

HVAC Systems

In HVAC systems, flow meters are used to monitor airflow in heating, ventilation, and air conditioning systems. Accurate airflow measurement is essential for optimizing energy efficiency and ensuring indoor air quality. Buyers should consider the installation flexibility of flow meters, especially in retrofitting scenarios, as well as their accuracy and maintenance needs to ensure long-term reliability and performance.

Strategic Material Selection Guide for types of flow meter

Flow meters are critical instruments in various industries, and the choice of material significantly impacts their performance, durability, and suitability for specific applications. Below is an analysis of four common materials used in flow meter construction, highlighting their properties, advantages, disadvantages, and considerations for international B2B buyers.

Stainless Steel

Key Properties: Stainless steel is renowned for its excellent corrosion resistance, high strength, and ability to withstand elevated temperatures and pressures. It typically has a temperature rating of up to 400°C and can handle pressures exceeding 100 bar, making it suitable for a wide range of applications.

Pros & Cons: The durability of stainless steel ensures a long service life, reducing the need for frequent replacements. However, it is more expensive than other materials, which may impact budget considerations. Manufacturing complexity can also be higher due to the need for specialized welding techniques.

Impact on Application: Stainless steel flow meters are ideal for applications involving corrosive fluids, such as chemicals and pharmaceuticals. They are also suitable for food and beverage industries, where hygiene standards are paramount.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers from regions like Africa and the Middle East should ensure that the selected stainless steel grade is suitable for local environmental conditions, such as humidity and temperature variations.

Brass

Key Properties: Brass offers good corrosion resistance and is capable of handling moderate pressures and temperatures, typically up to 150°C and 16 bar. It is less robust than stainless steel but is often used in less demanding applications.

Pros & Cons: Brass is cost-effective and easier to machine than stainless steel, making it a popular choice for many applications. However, it may not be suitable for highly corrosive environments, which limits its use in certain industries.

Impact on Application: Brass flow meters are commonly used in water supply and HVAC systems, where the fluids are less aggressive. They are also suitable for applications involving non-corrosive liquids.

Considerations for International Buyers: While brass is widely accepted, buyers should verify compliance with local standards. In regions like South America, where specific regulations may apply, it is essential to ensure that brass flow meters meet the necessary certifications.

Plastic (Polypropylene, PTFE)

Key Properties: Plastic materials, particularly polypropylene and PTFE, offer excellent chemical resistance and are lightweight. They can handle temperatures up to 100°C for polypropylene and up to 260°C for PTFE, with pressure ratings varying based on the specific type of plastic.

Pros & Cons: The primary advantage of plastic flow meters is their resistance to aggressive chemicals, making them suitable for a variety of applications. However, they may not be as durable as metal options and can be susceptible to UV degradation if not protected.

Impact on Application: Plastic flow meters are ideal for measuring corrosive liquids in chemical processing and water treatment applications. Their lightweight nature makes them easy to install in various settings.

Considerations for International Buyers: Buyers should ensure that the selected plastic materials comply with local health and safety regulations, especially in the food and beverage industry. Additionally, understanding the environmental impact and recycling options is increasingly important in Europe.

Exotic Alloys (Hastelloy, Inconel)

Key Properties: Exotic alloys like Hastelloy and Inconel provide exceptional corrosion resistance and can withstand extreme temperatures and pressures, often exceeding 1000°C and 200 bar, respectively.

Pros & Cons: These materials are highly durable and suitable for the most demanding applications, such as oil and gas or chemical processing. However, they are significantly more expensive and may involve complex manufacturing processes.

Impact on Application: Exotic alloys are essential in environments where standard materials fail, such as in the presence of aggressive chemicals or extreme conditions. Their use ensures reliability and safety in critical operations.

Considerations for International Buyers: Due to their cost and complexity, buyers should conduct a thorough cost-benefit analysis. Compliance with international standards is crucial, and buyers in regions like the Middle East should consider the availability of these materials locally to avoid long lead times.

Summary Table

| Material | Typical Use Case for types of flow meter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Chemical processing, food & beverage | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Brass | Water supply, HVAC systems | Cost-effective and easy to machine | Limited in corrosive environments | Medium |

| Plastic (PP/PTFE) | Chemical processing, water treatment | Excellent chemical resistance | Less durable, UV degradation risk | Low |

| Exotic Alloys | Oil & gas, extreme conditions | High durability and performance | Very high cost and complex manufacturing | High |

This material selection guide provides essential insights for international B2B buyers, enabling informed decisions based on application requirements, budget constraints, and compliance with industry standards.

In-depth Look: Manufacturing Processes and Quality Assurance for types of flow meter

In the realm of flow meter manufacturing, understanding the intricacies of the production process and quality assurance is crucial for B2B buyers. This knowledge not only informs purchasing decisions but also assures that the products meet industry standards and operational requirements. Below is a detailed exploration of the typical manufacturing processes and quality assurance protocols for various types of flow meters.

Manufacturing Processes

The manufacturing of flow meters involves several key stages that ensure precision, durability, and functionality. Here are the main stages:

Material Preparation

The first step in manufacturing flow meters is the selection and preparation of materials. Common materials include:

- Metals: Stainless steel, brass, and exotic alloys (like Hastelloy) are popular for their durability and resistance to corrosion.

- Plastics: Polypropylene and PTFE are often used for applications involving aggressive chemicals.

Material preparation includes cutting, machining, and treating materials to achieve the required specifications. This stage is critical, as the chosen materials significantly influence the flow meter’s performance and lifespan.

Forming

Once the materials are prepared, they undergo forming processes, which may include:

- Casting: Used for creating complex shapes, particularly in metallic flow meters.

- Molding: Common for plastic components, ensuring uniformity and precision in parts.

- Machining: Precision machining is employed to create intricate components, ensuring tight tolerances that are essential for accurate flow measurement.

During this stage, manufacturers often utilize computer numerical control (CNC) machines for enhanced accuracy and repeatability.

Assembly

The assembly process involves combining various components into a complete flow meter. This typically includes:

- Component Assembly: Individual parts such as sensors, housings, and electronic circuits are carefully assembled.

- Calibration: Flow meters are calibrated during assembly to ensure accurate measurements. This process may involve simulating flow conditions to test responsiveness and precision.

- Integration of Electronics: For electronic flow meters, the integration of sensors and data transmission components is critical. This stage requires precision to ensure that electronic components function correctly within the flow meter.

Finishing

The final stage involves surface treatment and quality checks to enhance the flow meter’s performance and appearance. This includes:

- Coating and Painting: Protective coatings may be applied to prevent corrosion and wear.

- Final Inspection: A thorough inspection is conducted to identify any defects before the product is packaged for shipping. This may include visual inspections, dimensional checks, and functional tests.

Quality Assurance

Quality assurance in flow meter manufacturing is paramount to ensure that the products meet both international standards and specific industry requirements. Here’s a closer look at the quality assurance practices and relevant standards:

International Standards

B2B buyers should be familiar with the following international quality standards:

- ISO 9001: This standard outlines the criteria for a quality management system, ensuring that products meet customer and regulatory requirements consistently.

- CE Marking: For products marketed in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

Industry-Specific Standards

Certain industries may require additional certifications, such as:

- API (American Petroleum Institute): Relevant for flow meters used in the oil and gas sector, ensuring safety and performance.

- ASME (American Society of Mechanical Engineers): Often required for flow meters in pressure applications.

Quality Control Checkpoints

Quality control (QC) is typically structured around several checkpoints:

- Incoming Quality Control (IQC): This involves inspecting materials and components upon arrival at the manufacturing facility to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, operators conduct checks to monitor dimensions, assembly accuracy, and calibration.

- Final Quality Control (FQC): Before packaging, the final product undergoes comprehensive testing to verify its performance and adherence to specifications.

Common Testing Methods

Testing methods for flow meters may include:

- Flow Testing: Simulated flow conditions are applied to test the meter’s accuracy.

- Pressure Testing: Ensures that the flow meter can withstand operational pressures without leakage or failure.

- Calibration Testing: Confirms that the flow meter is accurately measuring flow rates according to established benchmarks.

Verifying Supplier Quality Control

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are some actionable steps:

- Supplier Audits: Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes and quality management systems.

- Requesting Quality Reports: Buyers should ask for documented evidence of quality control measures, including inspection reports and compliance certificates.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control processes and product reliability.

Nuances in Quality Control for International Buyers

B2B buyers from diverse regions must consider the following nuances:

- Regulatory Compliance: Different regions may have varying regulatory requirements. It’s essential to ensure that the flow meters comply with local regulations in the buyer’s country.

- Cultural Considerations: Understanding cultural differences in business practices can facilitate smoother communication and negotiations with suppliers.

- Logistical Challenges: Buyers should account for potential delays in shipping and customs clearance that may affect the timely delivery of flow meters.

By comprehensively understanding the manufacturing processes and quality assurance practices associated with flow meters, B2B buyers can make informed decisions that align with their operational needs and compliance requirements. This knowledge not only enhances supplier relationships but also contributes to the overall efficiency and safety of industrial operations.

Related Video: Inspection and Quality control in Manufacturing

Comprehensive Cost and Pricing Analysis for types of flow meter Sourcing

Cost Structure of Flow Meter Sourcing

When sourcing flow meters, understanding the comprehensive cost structure is vital for international B2B buyers. The cost components typically include:

-

Materials: The choice of materials significantly affects cost. Stainless steel, brass, and plastics like PTFE have varying price points. Exotic alloys, while more expensive, offer durability for demanding environments.

-

Labor: Labor costs are influenced by the complexity of manufacturing processes. Automated production lines may reduce labor costs, whereas intricate designs requiring skilled craftsmanship can increase them.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and administrative expenses. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Custom tooling for specific designs can be a significant investment, particularly for unique flow meter types. Standardized tooling can reduce costs but may limit customization options.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and compliance with industry standards. High-quality certifications can increase costs but are essential for regulatory compliance.

-

Logistics: Transportation and warehousing costs can vary widely based on location and shipping methods. Understanding Incoterms is crucial for determining who bears these costs.

-

Margin: Suppliers’ profit margins can vary based on their market positioning and the level of competition. Established suppliers may charge higher prices but offer better reliability and support.

Price Influencers

Several factors influence the pricing of flow meters, including:

-

Volume/MOQ: Bulk purchases often lead to lower per-unit costs. Understanding the minimum order quantities (MOQs) can help buyers negotiate better terms.

-

Specifications/Customization: Customized solutions tailored to specific applications may incur additional costs. Standard models typically offer cost advantages.

-

Materials: As mentioned, the choice of materials impacts the overall cost. Buyers should balance material quality with budget constraints.

-

Quality/Certifications: Flow meters with higher accuracy and industry certifications tend to be more expensive. However, investing in quality can lead to long-term savings through reduced maintenance and downtime.

-

Supplier Factors: Supplier reputation, service level, and support offerings can also affect pricing. Established suppliers may charge a premium for their reliability and customer service.

-

Incoterms: Understanding shipping terms is essential for managing costs effectively. For example, FOB (Free on Board) shipping can lead to different cost structures compared to CIF (Cost, Insurance, and Freight).

Buyer Tips for Cost-Efficiency

-

Negotiation: Leverage volume discounts and long-term contracts to negotiate better pricing. Building a relationship with suppliers can lead to more favorable terms.

-

Total Cost of Ownership (TCO): Consider not just the initial purchase price but the total cost over the product’s lifecycle, including maintenance, repairs, and energy consumption.

-

Pricing Nuances for International Buyers: Different regions may have varying price structures due to local economic conditions, tariffs, and regulations. Buyers from Africa, South America, the Middle East, and Europe should familiarize themselves with these factors.

-

Research and Compare: Gather multiple quotes from different suppliers. Pay attention to specifications and ensure that you are comparing similar products.

-

Standardization: Where possible, opt for standardized flow meters to reduce costs. Custom solutions should only be pursued when absolutely necessary.

Disclaimer

Pricing for flow meters is indicative and can fluctuate based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with suppliers for the most accurate and current pricing information tailored to your needs.

Spotlight on Potential types of flow meter Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘types of flow meter’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for types of flow meter

Understanding the technical properties and terminology associated with flow meters is crucial for international B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe. This knowledge enables informed decision-making when selecting the right flow meter for specific applications.

Key Technical Properties of Flow Meters

-

Material Grade

– Definition: The material grade refers to the specific composition and quality of the materials used in the flow meter’s construction, such as stainless steel, brass, or exotic alloys.

– B2B Importance: Selecting the right material is essential for ensuring durability and resistance to corrosion or chemical reactions, particularly in harsh environments common in industries like oil and gas or chemical processing. -

Accuracy

– Definition: Accuracy is the degree to which the flow meter’s readings reflect the true flow rate, typically expressed as a percentage of the actual flow.

– B2B Importance: High accuracy is critical in applications where precise measurements are required to maintain product quality and comply with regulatory standards. For example, in pharmaceuticals, even minor discrepancies can result in significant financial loss or safety issues. -

Flow Range

– Definition: The flow range indicates the minimum and maximum flow rates that the meter can accurately measure, often expressed in liters per minute (LPM) or cubic meters per hour (m³/h).

– B2B Importance: Understanding the flow range is vital to ensure the selected flow meter is suitable for the specific application, preventing under or over-sizing that could lead to inefficiencies or measurement errors. -

Pressure Rating

– Definition: This specification indicates the maximum pressure that a flow meter can withstand without failure, typically expressed in psi or bar.

– B2B Importance: Knowing the pressure rating is crucial for applications involving high-pressure systems, as selecting an inadequate flow meter can lead to equipment failure and safety hazards. -

Temperature Range

– Definition: The temperature range specifies the operational limits within which the flow meter can function effectively, usually stated in degrees Celsius or Fahrenheit.

– B2B Importance: Different applications, particularly in industries like food processing or oil refining, may expose flow meters to extreme temperatures. Selecting a meter that can handle these conditions is vital for ensuring longevity and reliability.

Common Trade Terminology in Flow Meter Transactions

-

OEM (Original Equipment Manufacturer)

– Explanation: OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of flow meters, it pertains to the brand that designs and manufactures the flow meter.

– B2B Relevance: Understanding OEM relationships can be important for buyers who need to ensure compatibility and quality when sourcing flow meters from various suppliers. -

MOQ (Minimum Order Quantity)

– Explanation: MOQ is the smallest quantity of a product that a supplier is willing to sell. It can vary widely depending on the manufacturer and product type.

– B2B Relevance: Being aware of MOQs helps buyers plan their purchases and manage inventory effectively, especially when dealing with high-cost items like specialized flow meters. -

RFQ (Request for Quotation)

– Explanation: An RFQ is a formal process where a buyer requests price quotes from suppliers for specific products or services.

– B2B Relevance: Utilizing RFQs allows buyers to compare prices, terms, and specifications from multiple suppliers, leading to better purchasing decisions. -

Incoterms (International Commercial Terms)

– Explanation: Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions.

– B2B Relevance: Familiarity with Incoterms is essential for international buyers to understand shipping responsibilities, risk transfer, and cost implications associated with the purchase of flow meters. -

Calibration

– Explanation: Calibration is the process of adjusting the flow meter to ensure its accuracy by comparing its readings to a known standard.

– B2B Relevance: Regular calibration is necessary to maintain measurement accuracy over time, which is particularly important for industries where precision is critical, ensuring compliance and quality control.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the most suitable flow meters for their operational needs while navigating the complexities of international procurement.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the types of flow meter Sector

Market Overview & Key Trends

The global flow meter market is experiencing significant growth, driven by increasing demand across various industries including oil and gas, water management, and pharmaceuticals. Key factors such as industrial automation, the need for accurate measurement, and stringent regulatory compliance are propelling this demand. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of emerging trends in technology and sourcing.

One notable trend is the shift toward digital flow meters that integrate IoT capabilities, enabling real-time monitoring and data analytics. This innovation helps organizations optimize operations and reduce downtime. Additionally, there is an increasing preference for multi-variable flow meters that can measure flow rate, temperature, and pressure simultaneously, enhancing operational efficiency.

Sourcing trends are also evolving, with buyers seeking suppliers that provide not only competitive pricing but also robust after-sales support and maintenance services. The rise of local suppliers in emerging markets presents an opportunity for buyers to engage with companies that understand regional challenges and can offer tailored solutions. Furthermore, sustainability considerations are influencing purchasing decisions, with a growing demand for energy-efficient and environmentally friendly flow measurement technologies.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical focus for B2B buyers in the flow meter sector. The manufacturing and operation of flow meters can have substantial environmental impacts, particularly in terms of resource consumption and waste generation. As such, buyers should prioritize suppliers who adhere to sustainable manufacturing practices and offer products made from recyclable or sustainably sourced materials.

Ethical sourcing is equally important. Companies are increasingly scrutinizing their supply chains to ensure that their suppliers comply with labor and environmental standards. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management can serve as indicators of a supplier’s commitment to sustainability.

Moreover, the use of “green” materials, such as recyclable plastics or corrosion-resistant alloys, can significantly reduce the environmental footprint of flow meters. Buyers should look for suppliers who transparently disclose their material sourcing and waste management practices, as this not only enhances brand reputation but also aligns with global sustainability goals.

Brief Evolution/History

The evolution of flow meter technology can be traced back to the early 20th century, when simple mechanical devices were used for basic flow measurement. Over the decades, advancements in materials and technology have led to the development of more sophisticated devices such as electromagnetic and ultrasonic flow meters, which offer higher accuracy and reliability.

The integration of digital technology into flow meters marks a significant milestone in their evolution. Today, smart flow meters equipped with IoT capabilities provide real-time data and insights, transforming how industries monitor and manage fluid flow. This evolution reflects a broader trend toward automation and data-driven decision-making, which continues to shape the future of flow measurement technologies. For B2B buyers, understanding this historical context can provide valuable insights into the capabilities and advantages of modern flow meters, helping them make informed purchasing decisions.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of types of flow meter

-

What criteria should I consider when vetting suppliers for flow meters?

When vetting suppliers, prioritize their industry experience, certifications (such as ISO), and customer reviews. Investigate their manufacturing capabilities, as well as their ability to provide technical support and after-sales service. For international buyers, check for compliance with local regulations and standards in your region. Request references from previous clients to gauge reliability and customer satisfaction. Additionally, assess their financial stability to ensure they can meet your ongoing supply needs. -

Can flow meters be customized to meet specific application requirements?

Yes, many manufacturers offer customization options for flow meters. This may include adjustments in size, materials, and specific features tailored to your application. When discussing customization, be clear about your operational requirements, including the type of fluid, temperature, and pressure conditions. Engage with the supplier early in the design process to ensure they can accommodate your needs without significantly affecting lead times or costs. -

What are the typical minimum order quantities (MOQs) and lead times for flow meters?

Minimum order quantities can vary significantly based on the supplier and the type of flow meter. Some suppliers may require a minimum of 10-50 units, while others may accommodate smaller orders. Lead times typically range from 4 to 12 weeks, depending on the complexity of the order and the supplier’s production capacity. For urgent needs, discuss expedited options, but be aware this may incur additional costs. Always confirm MOQs and lead times before finalizing your order. -

What payment terms are commonly offered when purchasing flow meters internationally?

Payment terms can vary by supplier and region, but common options include advance payment, letters of credit, and payment upon delivery. It’s advisable to negotiate terms that align with your cash flow needs while ensuring the supplier feels secure. For larger orders, consider splitting payments into milestones based on production stages. Always review the payment terms in the contract to avoid any misunderstandings that could lead to disputes. -

How can I ensure quality assurance and certification for the flow meters I purchase?

Request documentation confirming that the flow meters meet relevant industry standards and certifications, such as ISO, CE, or ANSI. Ask for quality assurance protocols the manufacturer follows during production and testing. Consider requesting samples for independent testing, especially if the meters are critical to your operations. Establishing a quality control agreement with the supplier can also help ensure that the products meet your specifications consistently. -

What logistical considerations should I be aware of when importing flow meters?

When importing flow meters, consider shipping methods (air vs. sea), costs, and transit times. Understand customs regulations in your country, including tariffs and import duties that may apply. Collaborate with logistics providers experienced in handling industrial equipment to ensure smooth transport and delivery. Additionally, confirm that the supplier provides adequate packaging to prevent damage during transit, especially for sensitive electronic components. -

How can I resolve disputes with suppliers over flow meter orders?

To resolve disputes effectively, establish clear communication channels with the supplier from the outset. Document all agreements, including specifications and delivery terms, to have a reference in case of discrepancies. If a dispute arises, first attempt to resolve it amicably through direct negotiation. If this fails, refer to the dispute resolution clause in your contract, which may include mediation or arbitration. Engaging legal counsel familiar with international trade law can also be beneficial. -

What support should I expect from suppliers after purchasing flow meters?

After purchasing flow meters, you should expect ongoing technical support and customer service. Suppliers should provide installation guidance, troubleshooting assistance, and maintenance recommendations. Ensure they offer warranties or guarantees for their products, which can vary from one to several years. Additionally, inquire about training programs for your staff to help them understand the operation and maintenance of the flow meters, ensuring optimal performance in your applications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for types of flow meter

As we conclude our exploration of flow meter types, it is clear that strategic sourcing plays a pivotal role in optimizing operational efficiency across various industries. Understanding the different flow meter technologies—ranging from differential pressure and velocity flow meters to mass flow and magnetic flow meters—enables B2B buyers to make informed decisions that align with their specific applications and regulatory requirements.

Key takeaways for international buyers include the importance of accurate flow measurement for quality control, compliance, and cost management. The choice of flow meter should be driven not only by the technical specifications but also by the unique environmental conditions and fluid characteristics present in your operations.

Illustrative Image (Source: Google Search)

Looking forward, there is a growing emphasis on integrating smart technology and IoT capabilities into flow measurement solutions, which can enhance data analysis and operational responsiveness. For buyers in Africa, South America, the Middle East, and Europe, embracing these advancements will be crucial in maintaining a competitive edge.

Act now by assessing your current flow measurement needs and exploring innovative solutions that can drive efficiency and sustainability in your operations.