Your Ultimate Guide to Sourcing Isolation Transformer

Introduction: Navigating the Global Market for isolation transformer

In an increasingly interconnected world, isolation transformers play a pivotal role in ensuring electrical safety and enhancing power quality across various industries. These essential devices provide electrical isolation between circuits, safeguarding equipment from electrical noise, interference, and shock hazards. For international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, understanding the nuances of isolation transformers is crucial for optimizing operational efficiency and maintaining compliance with regional safety standards.

This guide is designed to equip buyers with actionable insights into the global market for isolation transformers. It covers a broad spectrum of topics, including various types of isolation transformers, material selection, and manufacturing quality control processes. Buyers will learn how to assess potential suppliers effectively, understand the cost structures and pricing trends that impact procurement decisions, and navigate the complexities of international trade.

By providing clarity on critical issues such as product specifications, regulatory compliance, and market dynamics, this guide empowers B2B buyers to make informed sourcing decisions. Whether you are in Brazil seeking reliable solutions for industrial automation, or in Nigeria looking to enhance the safety of medical equipment, leveraging this comprehensive knowledge can significantly mitigate risks and drive long-term business success.

Understanding isolation transformer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Isolation Transformer | Provides galvanic isolation, typically used in low to medium voltage applications | Medical equipment, industrial automation | Pros: Enhances safety, reduces noise; Cons: Limited power capacity for high-load applications |

| Audio Isolation Transformer | Specialized for audio applications, filters noise and interference | Professional audio systems, broadcasting | Pros: Excellent sound quality, prevents ground loops; Cons: May not handle high voltage applications |

| Medical Isolation Transformer | Designed specifically for medical environments, ensuring patient safety | Hospitals, clinics, diagnostic equipment | Pros: High safety standards, reduces electrical hazards; Cons: Higher cost due to stringent regulations |

| Variable Isolation Transformer | Allows for adjustable voltage output, providing versatility | Laboratories, research facilities | Pros: Customizable voltage; Cons: May require complex installation and setup |

| High-Frequency Isolation Transformer | Designed for high-frequency applications, compact and efficient | Telecommunications, RF applications | Pros: Efficient for high-frequency signals; Cons: Specialized design may limit general applications |

Standard Isolation Transformer

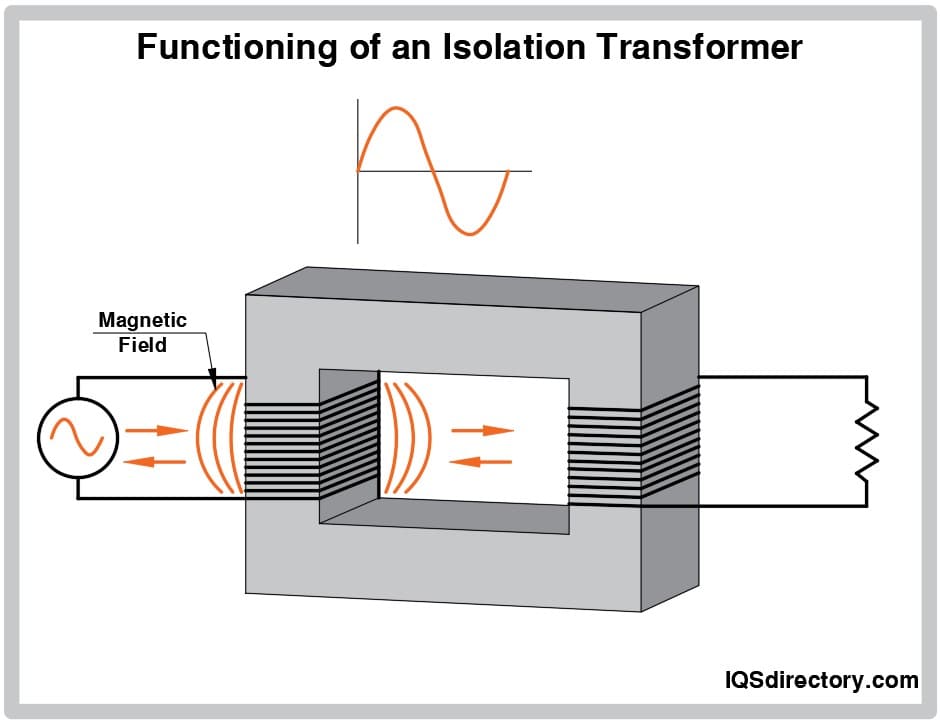

Standard isolation transformers are essential for providing galvanic isolation between circuits, effectively preventing electrical shock and reducing noise. They are widely used in medical equipment and industrial automation, making them suitable for environments where safety and equipment integrity are paramount. B2B buyers should prioritize suppliers who comply with international safety standards and offer robust after-sales support, as these transformers require regular maintenance and testing to ensure optimal performance.

Audio Isolation Transformer

Audio isolation transformers play a crucial role in professional audio systems by filtering out noise and electromagnetic interference. They are particularly valuable in broadcasting and live sound environments where sound quality is critical. Buyers in this sector should assess the transformer’s frequency response and ensure compatibility with existing audio equipment. While they excel in audio fidelity, B2B buyers must be cautious of their limitations in handling high voltage applications.

Medical Isolation Transformer

Designed with stringent safety standards, medical isolation transformers provide essential protection in healthcare settings. They ensure that sensitive medical devices operate safely without risking patient safety. B2B buyers in the healthcare industry must consider the certifications and compliance of these transformers with medical regulations, which can increase initial costs but are necessary for long-term reliability and safety.

Variable Isolation Transformer

Variable isolation transformers offer the flexibility of adjustable voltage outputs, making them ideal for laboratories and research facilities where diverse voltage requirements exist. B2B buyers should evaluate the complexity of installation and the specific voltage range needed for their applications. While they provide significant versatility, their installation may require specialized knowledge, making it essential to partner with experienced suppliers.

High-Frequency Isolation Transformer

High-frequency isolation transformers are engineered for compactness and efficiency, particularly in telecommunications and RF applications. They are designed to handle high-frequency signals, making them a critical component in modern communication systems. Buyers should focus on the transformer’s frequency range and efficiency ratings. However, their specialized design may limit their applicability in other sectors, necessitating a careful assessment of the intended use case before procurement.

Related Video: Attention is all you need (Transformer) – Model explanation (including math), Inference and Training

Key Industrial Applications of isolation transformer

| Industry/Sector | Specific Application of Isolation Transformer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Medical Equipment Isolation | Enhances patient safety by preventing electric shock | Ensure compliance with medical standards and certifications. Verify supplier’s experience with healthcare applications. |

| Industrial Automation | Control Systems for Manufacturing Equipment | Reduces electrical noise, improving system reliability | Look for suppliers with expertise in industrial-grade transformers and robust quality assurance processes. |

| Audio/Video Production | Audio Isolation in Recording Studios | Eliminates ground loop interference for clearer sound | Evaluate suppliers based on their experience in audio applications and their ability to provide tailored solutions. |

| Telecommunications | Signal Isolation for Network Equipment | Protects sensitive equipment from voltage spikes and noise | Assess suppliers for their technical support capabilities and product warranties. |

| Data Centers | Power Supply Isolation for Servers | Increases uptime and protects against electrical faults | Ensure scalability options and reliability of the transformer under continuous load conditions. |

Healthcare

In healthcare settings, isolation transformers are critical for powering medical equipment, ensuring that users are not exposed to electric shocks. These transformers provide galvanic isolation, thereby enhancing patient safety and equipment reliability. For international buyers, especially in regions with varying electrical standards, sourcing isolation transformers that comply with local medical regulations is essential. Buyers should prioritize suppliers who have a proven track record in the healthcare sector and can provide relevant certifications.

Industrial Automation

Isolation transformers play a pivotal role in industrial automation by isolating control systems from electrical noise, which enhances the reliability of manufacturing equipment. This application helps in preventing malfunctions caused by electromagnetic interference. For B2B buyers, particularly in emerging markets in Africa and South America, it is crucial to source transformers that can withstand harsh operational environments. Buyers should assess suppliers for their experience in providing durable and efficient transformers suited for industrial applications.

Audio/Video Production

In the audio and video production industry, isolation transformers are utilized to eliminate ground loop interference, ensuring high-quality sound transmission. This is particularly important in recording studios where audio clarity is paramount. Buyers in this sector should seek suppliers with specialized knowledge in audio applications and the ability to provide customized solutions. It is also vital to consider the transformer’s size and weight, as studio setups often have space constraints.

Telecommunications

Isolation transformers are employed in telecommunications to protect sensitive network equipment from voltage spikes and electrical noise, which can disrupt service continuity. This application is crucial for maintaining the integrity of communication systems, especially in areas with unstable power supply. International buyers should look for suppliers who can demonstrate expertise in telecommunications-grade transformers and offer robust technical support and product warranties.

Data Centers

For data centers, isolation transformers are essential for providing stable power supply to servers, enhancing uptime and protecting against electrical faults. They help to ensure that power fluctuations do not affect critical operations. Buyers should prioritize sourcing transformers that are scalable and reliable under continuous load conditions. Additionally, it is important to evaluate suppliers based on their ability to deliver timely support and maintenance services, especially in high-demand regions.

Related Video: Isolation transformer explained and demonstration

Strategic Material Selection Guide for isolation transformer

When selecting materials for isolation transformers, international B2B buyers must consider various factors that influence performance, durability, and cost. The most common materials used in the construction of isolation transformers include copper, aluminum, silicon steel, and resin. Each material has distinct properties and implications for application, which are critical for decision-making.

Copper

Key Properties: Copper is known for its excellent electrical conductivity, high thermal conductivity, and resistance to corrosion. It can operate effectively at high temperatures, making it suitable for demanding applications.

Pros & Cons: Copper’s high conductivity translates to lower energy losses, which enhances the efficiency of isolation transformers. However, it is more expensive than alternatives like aluminum. Manufacturing processes for copper can be complex, requiring skilled labor and advanced technology.

Impact on Application: Copper is ideal for applications requiring high performance and reliability, such as medical equipment and sensitive electronic devices. Its corrosion resistance ensures longevity, particularly in humid or corrosive environments.

Considerations for Buyers: Buyers in regions such as Africa and South America should ensure compliance with international standards like ASTM and IEC. The higher initial cost of copper may be justified by its long-term performance benefits.

Aluminum

Key Properties: Aluminum is lightweight, has good electrical conductivity (though not as high as copper), and exhibits excellent corrosion resistance, especially when anodized.

Pros & Cons: The primary advantage of aluminum is its lower cost and weight, making it easier to handle and install. However, it has a lower thermal conductivity than copper, which can lead to higher operational temperatures and energy losses in some applications.

Impact on Application: Aluminum is suitable for applications where weight is a critical factor, such as portable equipment. It is also a good choice for environments where corrosion is a concern, such as coastal areas.

Considerations for Buyers: Buyers should be aware of the need for proper joint design and connections, as aluminum can be prone to galvanic corrosion when in contact with dissimilar metals. Compliance with local standards is essential, particularly in Europe where regulations may be stricter.

Silicon Steel

Key Properties: Silicon steel is used primarily for the core of isolation transformers due to its magnetic properties, which enhance efficiency. It has good electrical insulation and can withstand high temperatures.

Pros & Cons: The use of silicon steel reduces energy losses due to its high magnetic permeability. However, it can be brittle and requires careful handling during manufacturing and installation.

Impact on Application: Silicon steel is essential for applications where magnetic efficiency is critical, such as in high-frequency transformers. Its properties help optimize power quality and minimize losses.

Considerations for Buyers: Buyers should ensure that the silicon steel meets international standards for magnetic properties and insulation. In markets like the Middle East, where high temperatures are common, selecting high-grade silicon steel is crucial for performance.

Resin

Key Properties: Resin is often used as an insulating material in dry-type isolation transformers. It provides excellent electrical insulation and is resistant to moisture and chemicals.

Pros & Cons: The primary advantage of resin is its safety and low maintenance requirements. It eliminates the risk of oil leaks associated with traditional transformers. However, resin can be more expensive and may have limitations in high-temperature applications.

Impact on Application: Resin is ideal for indoor applications where safety is a priority, such as hospitals and data centers. It is also suitable for environments with high humidity levels.

Considerations for Buyers: Buyers in Europe and the Middle East should ensure that resin materials comply with fire safety and environmental regulations. The initial investment may be higher, but the long-term safety benefits can outweigh these costs.

| Material | Typical Use Case for isolation transformer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Medical equipment, sensitive electronics | High electrical conductivity | Higher cost and complex manufacturing | High |

| Aluminum | Portable equipment, coastal environments | Lightweight and cost-effective | Lower thermal conductivity | Medium |

| Silicon Steel | High-frequency transformers | Reduces energy losses | Brittle and requires careful handling | Medium |

| Resin | Indoor applications, hospitals, data centers | Excellent insulation and safety | Higher initial cost | High |

In-depth Look: Manufacturing Processes and Quality Assurance for isolation transformer

The manufacturing processes for isolation transformers encompass several critical stages, each designed to ensure the transformer meets stringent quality and performance standards. Understanding these processes is vital for B2B buyers, especially when sourcing from international suppliers in regions like Africa, South America, the Middle East, and Europe.

Manufacturing Process

1. Material Preparation

The first step in manufacturing isolation transformers involves sourcing high-quality raw materials. Key components include:

- Copper or Aluminum Windings: The choice between copper and aluminum can significantly impact the efficiency and cost of the transformer. Copper is more conductive but typically more expensive, while aluminum is lighter and cheaper but has lower conductivity.

- Insulation Materials: High-grade insulation materials such as polyester film or resin are essential to prevent electrical leakage and ensure safety.

- Core Materials: The magnetic core is typically made from silicon steel, which helps in efficient magnetic flux transfer.

Suppliers should provide documentation certifying the quality of these materials, adhering to international standards like ISO 9001.

2. Forming

This stage involves shaping the raw materials into the necessary components. Key techniques include:

- Winding: The copper or aluminum wire is wound around the core to form the primary and secondary windings. Precision in this step is crucial, as improper winding can lead to inefficiencies and failures.

- Core Assembly: The core is assembled, often using laser-cut steel sheets to reduce eddy current losses. The core must be aligned accurately to ensure optimal performance.

3. Assembly

After forming, the next step is assembly, where the various components come together. This includes:

- Connecting Windings: The primary and secondary windings are connected to ensure proper function. This step requires careful attention to detail to avoid short circuits.

- Encapsulation: Many isolation transformers are encapsulated in resin or another protective material to enhance durability and safety.

At this stage, proper handling and assembly procedures are critical to prevent damage to the components.

4. Finishing

The final stage of manufacturing involves finishing processes that enhance the transformer’s performance and reliability. Key activities include:

- Surface Treatment: Protective coatings may be applied to prevent corrosion, especially important for transformers used in harsh environments.

- Testing and Calibration: Each transformer undergoes rigorous testing to ensure it meets specified performance criteria. This may include voltage testing, insulation resistance testing, and operational checks.

Quality Assurance

Quality assurance (QA) is a fundamental aspect of the manufacturing process for isolation transformers. B2B buyers must understand the various QA protocols to ensure they are sourcing reliable products.

International Standards

Compliance with international standards is essential for quality assurance. Key standards include:

- ISO 9001: This standard outlines the criteria for a quality management system, ensuring that manufacturers consistently meet customer and regulatory requirements.

- CE Marking: In Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For transformers used in oil and gas applications, adherence to American Petroleum Institute (API) standards is crucial.

Quality Control Checkpoints

Implementing effective quality control checkpoints throughout the manufacturing process is vital. Typical checkpoints include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify and rectify issues before they escalate.

- Final Quality Control (FQC): A thorough inspection of the finished product ensures it meets all specifications and performance criteria.

Common Testing Methods

B2B buyers should be aware of common testing methods used in the quality assurance of isolation transformers, including:

- Dielectric Testing: Ensures the insulation can withstand high voltages without breaking down.

- Temperature Rise Testing: Evaluates how the transformer performs under load conditions and measures temperature increases.

- Load Testing: Confirms the transformer operates correctly under expected load conditions.

Verifying Supplier Quality Control

To mitigate risks when sourcing isolation transformers, B2B buyers should implement robust supplier verification processes. Key strategies include:

- Supplier Audits: Conducting regular audits of the manufacturing facilities to assess adherence to quality standards and practices.

- Requesting Quality Reports: Buyers should ask suppliers for detailed quality reports, including testing results and compliance certificates.

- Third-Party Inspections: Engaging third-party inspection agencies can provide unbiased assessments of the supplier’s manufacturing processes and quality control measures.

Regional Considerations for International Buyers

For buyers in Africa, South America, the Middle East, and Europe, understanding regional nuances is essential. Factors to consider include:

- Logistics: Ensure that the supplier has a robust logistics plan to handle potential delays in shipping and customs clearance.

- Regulatory Compliance: Familiarize yourself with local regulations regarding electrical equipment, which can vary significantly between regions.

- Cultural and Communication Factors: Establish clear communication channels with suppliers to mitigate misunderstandings related to quality expectations.

By comprehensively understanding the manufacturing processes and quality assurance measures associated with isolation transformers, international B2B buyers can make informed decisions that ensure long-term reliability and safety in their electrical systems.

Comprehensive Cost and Pricing Analysis for isolation transformer Sourcing

Understanding the cost structure and pricing dynamics of isolation transformers is essential for international B2B buyers, particularly those operating in diverse and challenging markets like Africa, South America, the Middle East, and Europe. This analysis will provide actionable insights into the cost components, price influencers, and practical negotiation tips to help buyers navigate the complexities of sourcing isolation transformers effectively.

Cost Components of Isolation Transformers

-

Materials: The primary materials include copper or aluminum for windings, silicon steel for cores, and various insulating materials. The choice of materials significantly impacts performance and durability, influencing overall costs.

-

Labor: Skilled labor is necessary for manufacturing isolation transformers, particularly in assembly and quality control processes. Labor costs vary by region, with some countries in Africa and South America offering competitive rates.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient manufacturing practices can help reduce overhead, benefiting buyers through lower pricing.

-

Tooling: Initial setup costs for molds and specialized equipment can be substantial, particularly for customized units. Buyers should consider how tooling costs are distributed over production volumes.

-

Quality Control (QC): Rigorous QC processes are vital to ensure safety and reliability, particularly for applications in critical sectors like healthcare and industrial automation. Enhanced QC measures can increase costs but also enhance product value.

-

Logistics: Transportation costs can fluctuate based on distance, freight methods, and local regulations. Buyers should account for logistics when calculating total costs, especially when sourcing from overseas suppliers.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary widely based on market conditions and supplier reputation.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly influence pricing. Larger orders often qualify for bulk discounts, making it essential for buyers to assess their needs carefully.

-

Specifications/Customization: Custom features or specifications can lead to higher costs. Buyers should balance the need for customization with budget constraints, as standard models may offer cost advantages.

-

Materials: Fluctuating global prices for raw materials, such as copper, can affect transformer pricing. Buyers should stay informed about market trends that may impact material costs.

-

Quality/Certifications: Products that meet international quality standards or possess specific certifications (e.g., ISO, CE) may command higher prices but offer greater reliability and safety.

-

Supplier Factors: The reputation and reliability of the supplier can influence price. Established suppliers with a proven track record may charge a premium but often provide better quality and support.

-

Incoterms: The agreed Incoterms (International Commercial Terms) can impact pricing. Terms that place more responsibility on the buyer can lead to additional costs, making it crucial to understand the implications of shipping agreements.

Buyer Tips for Cost Efficiency

-

Negotiation: Engage in proactive negotiation with suppliers. Understanding the cost structure can empower buyers to negotiate better terms and pricing.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also installation, maintenance, and operational costs over the product’s lifecycle. This approach ensures a more comprehensive view of value.

-

Leverage Local Knowledge: Utilize local market expertise to navigate regional nuances in pricing and procurement practices. This is particularly important in diverse regions like Africa and South America.

-

Benchmarking: Compare quotes and specifications from multiple suppliers to identify competitive pricing. This practice also helps in understanding the market landscape.

-

Stay Informed on Market Trends: Regularly monitor trends in raw material prices and regulatory changes that may affect costs. Being proactive can help mitigate price increases.

In summary, understanding the comprehensive cost structure, pricing influencers, and practical negotiation strategies will empower international B2B buyers to make informed decisions when sourcing isolation transformers. This knowledge not only aids in securing favorable terms but also enhances the overall value derived from procurement activities.

Spotlight on Potential isolation transformer Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘isolation transformer’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for isolation transformer

When sourcing isolation transformers, understanding their technical properties and the relevant trade terminology is crucial for making informed purchasing decisions. Here are the key specifications and terms that B2B buyers should be familiar with.

Essential Technical Properties

-

Voltage Rating

– Definition: This indicates the maximum voltage that the transformer can handle without breaking down.

– B2B Importance: Selecting the correct voltage rating is critical to ensure the transformer can safely operate within the intended electrical system, preventing potential equipment damage or safety hazards. -

Power Rating (kVA)

– Definition: The power rating specifies the maximum load the transformer can support, typically measured in kilovolt-amperes (kVA).

– B2B Importance: Buyers must match the power rating with their application needs to ensure reliable performance. Under-sizing can lead to overheating, while over-sizing can increase costs unnecessarily. -

Insulation Class

– Definition: This property defines the temperature rating of the insulation materials used in the transformer. Common classes include A, B, F, and H, with each class indicating different temperature limits.

– B2B Importance: Understanding insulation class helps buyers assess the transformer’s durability and suitability for specific environments, particularly in industries with extreme operating conditions. -

Efficiency Rating

– Definition: This refers to the transformer’s efficiency in converting input power to output power, often expressed as a percentage.

– B2B Importance: Higher efficiency translates to lower operational costs and reduced energy losses, which is particularly relevant for buyers focused on sustainability and long-term cost savings. -

Galvanic Isolation

– Definition: A feature of isolation transformers that electrically separates the primary and secondary windings, preventing direct electrical connection.

– B2B Importance: This property enhances safety by reducing the risk of electric shock and noise interference, making isolation transformers ideal for sensitive applications like medical equipment and audio systems. -

Size and Weight

– Definition: The physical dimensions and weight of the transformer, which can vary significantly based on design and materials used.

– B2B Importance: Understanding size and weight is essential for installation planning and ensuring that the transformer can be accommodated within existing infrastructure without requiring extensive modifications.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– B2B Importance: Buyers should consider OEMs for sourcing transformers to ensure quality and compatibility with their systems. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– B2B Importance: Knowing the MOQ is vital for budgeting and inventory planning, especially for smaller companies or those with varying demand. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to solicit price offers from suppliers for specific products or services.

– B2B Importance: Submitting an RFQ helps buyers compare pricing and terms from different suppliers, facilitating better negotiation and procurement decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms that clarify the responsibilities of buyers and sellers in the shipping process.

– B2B Importance: Familiarity with Incoterms is essential for understanding shipping costs, insurance, and risk transfer, which can significantly impact the overall procurement budget.

Illustrative Image (Source: Google Search)

-

Lead Time

– Definition: The time taken from placing an order to the delivery of the product.

– B2B Importance: Understanding lead times is critical for project planning and ensuring that transformers are available when needed, especially in industries with tight deadlines. -

Certification Standards

– Definition: Industry standards and certifications (e.g., ISO, CE) that a product must meet to ensure quality and safety.

– B2B Importance: Buyers should verify certification to ensure compliance with local regulations and industry best practices, which can prevent costly compliance issues later.

By grasping these properties and terms, B2B buyers can navigate the complexities of sourcing isolation transformers more effectively, ensuring they make decisions that align with their operational requirements and strategic goals.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the isolation transformer Sector

In the global market for isolation transformers, several key trends and dynamics are shaping the procurement landscape for international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe. The demand for reliable electrical isolation solutions is driven by the increasing complexity of electrical systems and the need for enhanced safety measures. Isolation transformers are critical for applications ranging from industrial automation to healthcare and telecommunications, where they provide essential protection against electrical noise, interference, and potential hazards.

Emerging technologies, such as smart grid systems and renewable energy integrations, are also influencing sourcing strategies. Buyers should prioritize suppliers that offer advanced isolation transformer models equipped with features like remote monitoring capabilities and enhanced energy efficiency. The trend towards digitalization in procurement processes is also noteworthy; many companies are leveraging online platforms for supplier assessment and product comparisons, enhancing transparency and efficiency in sourcing.

Moreover, geopolitical factors and supply chain disruptions, exacerbated by global events, necessitate a strategic approach to sourcing. Buyers must conduct thorough due diligence on suppliers, focusing on their operational resilience and ability to navigate challenges such as fluctuating material costs and regulatory compliance. Establishing long-term partnerships with reliable manufacturers can mitigate risks associated with procurement and ensure consistent supply chains.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming an increasingly vital consideration in the sourcing of isolation transformers. The environmental impact of manufacturing processes, along with the lifecycle management of electrical equipment, requires buyers to prioritize ethical sourcing practices. B2B buyers should seek suppliers who adhere to international environmental standards and who actively work to minimize their carbon footprint through energy-efficient manufacturing techniques.

Certifications such as ISO 14001 (Environmental Management) and adherence to the RoHS (Restriction of Hazardous Substances) directive are indicators of a supplier’s commitment to sustainability. Additionally, sourcing materials that are recyclable or derived from sustainable processes can contribute to a greener supply chain. This not only helps in reducing the overall environmental impact but also aligns with the growing consumer demand for responsible business practices.

By prioritizing suppliers with robust sustainability credentials, B2B buyers can enhance their brand reputation and comply with increasing regulatory demands across various regions. This shift towards greener practices can also lead to cost savings in the long term, as energy-efficient products typically result in lower operational costs.

Brief Evolution/History

The development of isolation transformers dates back to the early 20th century when electrical safety became a significant concern in industrial applications. Initially used to prevent electric shock and protect sensitive equipment, the technology has evolved significantly over the decades. Advances in materials and manufacturing processes have led to the creation of more efficient and compact designs, enabling broader applications across various sectors, including healthcare and telecommunications.

Today, isolation transformers are recognized not only for their safety benefits but also for their role in enhancing power quality and system reliability. As industries continue to evolve and integrate more sophisticated technologies, the demand for isolation transformers is expected to grow, driving innovation and sustainability in the sector.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of isolation transformer

-

What criteria should I use to vet suppliers of isolation transformers?

When vetting suppliers, focus on their manufacturing capabilities, certifications, and experience in the industry. Request documentation such as ISO certifications, quality assurance processes, and client references. Conduct on-site audits if possible, or utilize third-party inspection services to verify production practices. Evaluate their financial stability and ability to meet your specific needs, including compliance with local regulations in your target market. -

Can isolation transformers be customized to fit specific applications?

Yes, many manufacturers offer customization options for isolation transformers to cater to unique requirements. This can include modifications in voltage ratings, size, and additional features such as surge protection or noise filtering. Communicate your specific needs clearly to the supplier during the initial discussions to ensure they can accommodate your requests while maintaining compliance with international standards. -

What are the typical minimum order quantities (MOQ) and lead times for isolation transformers?

Minimum order quantities can vary significantly based on the supplier and the specifications of the transformers. Generally, MOQs range from a few units to several dozen. Lead times also vary, typically from 4 to 12 weeks depending on the complexity of the order and supplier capacity. It is advisable to discuss these details upfront to align your project timelines with supplier capabilities. -

What payment terms are commonly accepted in international B2B transactions for isolation transformers?

Common payment methods include wire transfers, letters of credit, and payment upon delivery. Terms may vary by supplier, with many offering partial payments upfront and the remainder upon delivery. Negotiate terms that ensure security for both parties, and consider using escrow services for larger transactions to mitigate risks associated with international trade. -

What quality assurance and certification processes should I expect from suppliers?

Suppliers should adhere to international quality standards, such as ISO 9001, which outlines quality management systems. Request documentation of quality control processes, including testing protocols for performance, safety, and compliance with electrical standards (e.g., IEC or UL). Regular audits and third-party certifications are essential indicators of a supplier’s commitment to quality and reliability.

Illustrative Image (Source: Google Search)

-

How can I ensure smooth logistics when sourcing isolation transformers internationally?

Effective logistics planning is crucial. Work with suppliers who have experience in international shipping and can provide detailed shipping schedules. Understand the shipping costs, customs duties, and potential delays associated with your location. Consider using freight forwarders to streamline the process, and ensure that insurance is in place to protect your investment during transit. -

What steps can I take to resolve disputes with suppliers?

To mitigate disputes, establish clear contracts that outline terms, expectations, and processes for conflict resolution. If a dispute arises, maintain open communication with the supplier to address issues promptly. Consider mediation or arbitration as alternatives to litigation, as they can be less costly and time-consuming. Document all communications and agreements to support your position if further action is necessary. -

How do I assess the long-term reliability of an isolation transformer?

Long-term reliability can be gauged by examining the manufacturer’s track record and warranty offerings. Look for transformers with robust designs that meet your operational conditions, and consider units with features that enhance durability, such as high-quality insulation and protective casings. Engage with other users of the same transformer model to gather feedback on performance and longevity to make an informed decision.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for isolation transformer

In conclusion, strategic sourcing of isolation transformers is essential for international B2B buyers aiming to enhance electrical safety and reliability across diverse applications. By understanding the unique functions and advantages of isolation transformers—such as their ability to mitigate electrical noise, improve power quality, and provide robust protection against electric shock—buyers can make informed decisions that align with their operational needs.

For businesses in Africa, South America, the Middle East, and Europe, it is crucial to prioritize supplier due diligence, focusing on quality certifications and proven manufacturing capabilities. Building strong partnerships with credible manufacturers can ensure a steady supply of reliable transformers, which is vital in regions experiencing rapid industrialization and infrastructure development.

As the demand for clean energy solutions and advanced electrical systems continues to grow, so too does the importance of strategic sourcing. B2B buyers are encouraged to explore innovative solutions and suppliers that can provide not only competitive pricing but also value-added services like after-sales support and compliance with local regulations. By leveraging these insights, organizations can secure a competitive edge and drive long-term success in their respective markets.