Your Ultimate Guide to Sourcing Perforated Plastic Sheets

Introduction: Navigating the Global Market for perforated plastic sheets

Perforated plastic sheets have emerged as essential components across a variety of industries, offering solutions that enhance functionality while maintaining aesthetic appeal. These versatile materials are engineered to meet specific requirements, from regulating airflow and light distribution to providing sound attenuation and moisture control. As a B2B buyer, understanding the significance of perforated plastic sheets is crucial for making informed sourcing decisions that can impact project efficiency and product performance.

This comprehensive guide delves into the multifaceted world of perforated plastic sheets, addressing critical aspects such as the different types and materials available, manufacturing processes, quality control measures, and the landscape of global suppliers. We will also explore cost considerations and market trends, ensuring that buyers are well-equipped to navigate the complexities of sourcing these materials effectively.

Particularly for international buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like the UAE and Egypt—this guide provides actionable insights tailored to your specific needs. By leveraging this resource, you will gain a deeper understanding of the options available, enabling you to make strategic purchasing decisions that align with your operational goals. Empower yourself with knowledge to optimize your supply chain and enhance your product offerings in today’s competitive market.

Understanding perforated plastic sheets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Polyethylene (PE) Sheets | Lightweight, flexible, and UV resistant. | Packaging, agriculture, construction. | Pros: Cost-effective, durable. Cons: Limited temperature resistance. |

| Polypropylene (PP) Sheets | Higher chemical resistance, good impact strength. | Automotive, medical, filtration. | Pros: Stronger than PE, versatile. Cons: More expensive than PE. |

| PVC Perforated Sheets | Rigid, excellent chemical resistance. | Construction, signage, HVAC. | Pros: Durable, easy to clean. Cons: Heavier, less flexible. |

| Acrylic Sheets | High clarity, excellent aesthetic appeal. | Displays, architectural applications. | Pros: Visually appealing, good light transmission. Cons: Prone to scratching. |

| HDPE Sheets | Excellent impact resistance, low moisture absorption. | Food packaging, industrial uses. | Pros: Strong, resistant to chemicals. Cons: Can be more costly than other plastics. |

Polyethylene (PE) Sheets

Polyethylene perforated sheets are characterized by their lightweight and flexible nature, making them ideal for various applications, particularly in packaging and agriculture. With UV resistance, they are suitable for outdoor use. Buyers should consider the cost-effectiveness of PE sheets, especially for large-scale projects, but should also be aware of their limited temperature resistance, which may not be suitable for high-heat applications.

Polypropylene (PP) Sheets

Polypropylene sheets stand out for their higher chemical resistance and excellent impact strength, making them popular in automotive, medical, and filtration applications. They are more robust compared to polyethylene, allowing for a wider range of applications. However, buyers should keep in mind that PP sheets tend to be more expensive than PE, which could influence budgetary constraints.

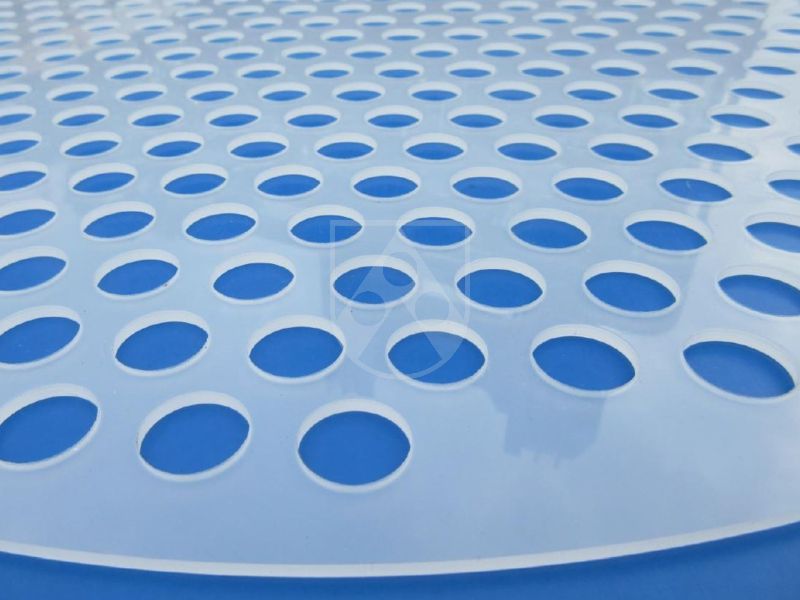

Illustrative Image (Source: Google Search)

PVC Perforated Sheets

PVC perforated sheets are known for their rigidity and exceptional chemical resistance, making them suitable for construction, signage, and HVAC systems. Their durability and ease of cleaning are significant advantages. However, buyers should consider the weight of PVC sheets, which can limit their application in lightweight projects, and they may require more robust support structures.

Acrylic Sheets

Acrylic perforated sheets offer high clarity and aesthetic appeal, making them ideal for displays and architectural applications. Their ability to transmit light effectively enhances their visual attractiveness. However, buyers should be aware that acrylic sheets are prone to scratching, which may require additional protective measures, especially in high-traffic areas.

HDPE Sheets

High-Density Polyethylene (HDPE) sheets are known for their excellent impact resistance and low moisture absorption, making them a reliable choice for food packaging and various industrial uses. Their strength and chemical resistance are significant benefits, although they can be more costly than other plastic options. Buyers should evaluate their specific application needs against the higher price point to ensure cost-effectiveness in their purchasing decisions.

Related Video: What are Transformer Models and how do they work?

Key Industrial Applications of perforated plastic sheets

| Industry/Sector | Specific Application of Perforated Plastic Sheets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Ventilated greenhouse coverings | Enhances air circulation and light penetration, improving crop yield | Material durability and UV resistance; local sourcing for cost efficiency |

| Construction | Noise reduction panels in urban areas | Reduces noise pollution, improving quality of life for residents | Compliance with local building codes; aesthetic design options |

| Packaging | Breathable food packaging | Extends shelf life of perishable goods by allowing gas exchange | Food safety standards; customization for product type |

| Automotive | Interior sound dampening panels | Enhances passenger comfort by reducing road noise | Weight considerations; compatibility with existing vehicle designs |

| Medical | Air filtration in medical devices | Ensures a sterile environment, crucial for patient safety | Compliance with health regulations; specific perforation patterns required |

Agriculture

In the agriculture sector, perforated plastic sheets are widely used for ventilated greenhouse coverings. These sheets allow for optimal air circulation and light penetration, which are essential for promoting healthy crop growth. They help mitigate humidity levels, preventing mold and mildew formation. Buyers must consider material durability and UV resistance to ensure longevity, especially in regions with intense sunlight. Local sourcing can also provide cost efficiencies while supporting regional economies.

Construction

Perforated plastic sheets serve a crucial role in the construction industry, particularly as noise reduction panels in urban areas. They absorb sound, thereby reducing noise pollution and enhancing the quality of life for residents. This application is especially relevant in densely populated regions where construction noise can be a significant concern. Buyers should ensure compliance with local building codes and consider aesthetic design options that align with architectural styles to meet both functional and visual requirements.

Packaging

In the packaging industry, breathable food packaging made from perforated plastic sheets is increasingly popular. These sheets allow for gas exchange, extending the shelf life of perishable goods like fruits and vegetables. This application is vital for suppliers aiming to maintain product quality during transport and storage. When sourcing, businesses must adhere to food safety standards and may require customization of perforation patterns to suit specific product types, ensuring optimal freshness and safety.

Automotive

The automotive sector utilizes perforated plastic sheets for interior sound dampening panels. These panels enhance passenger comfort by significantly reducing road noise, creating a more pleasant driving experience. Buyers in this sector need to consider weight implications, as well as compatibility with existing vehicle designs. The choice of material and perforation size will affect both acoustic performance and overall vehicle efficiency, making it essential to work closely with manufacturers to achieve desired specifications.

Medical

In the medical field, perforated plastic sheets are integral to air filtration systems in medical devices. These sheets ensure a sterile environment, which is critical for patient safety in healthcare settings. When sourcing, compliance with health regulations is paramount, and specific perforation patterns may be required to meet varying filtration needs. Suppliers must also ensure that the materials used are suitable for medical applications, emphasizing safety and reliability in high-stakes environments.

Related Video: How Board Boxes are Made from Corrugated Sheets | Georgia-Pacific

Strategic Material Selection Guide for perforated plastic sheets

When selecting perforated plastic sheets for various applications, understanding the properties and suitability of different materials is crucial for international B2B buyers. Below is an analysis of four common materials used in the production of perforated plastic sheets, focusing on their key properties, advantages, disadvantages, and specific considerations for buyers, particularly from Africa, South America, the Middle East, and Europe.

Polyethylene (PE)

Key Properties: Polyethylene is known for its excellent chemical resistance and low-temperature performance. It typically withstands temperatures up to 80°C (176°F) and is resistant to a wide range of chemicals, making it suitable for various environments.

Pros & Cons: The advantages of PE include its lightweight nature, cost-effectiveness, and good impact resistance. However, it has lower strength compared to other materials and can become brittle at low temperatures, limiting its use in extreme conditions.

Impact on Application: PE is ideal for applications that require moisture resistance, such as drainage systems and agricultural films. Its compatibility with various media makes it a versatile choice.

Considerations for International Buyers: Buyers should ensure compliance with local environmental regulations regarding plastic use. Standards such as ASTM D4976 (for PE) are relevant, particularly in regions like the UAE and Egypt, where sustainability is increasingly emphasized.

Polypropylene (PP)

Key Properties: Polypropylene offers higher temperature resistance than polyethylene, withstanding up to 100°C (212°F). It is also known for its excellent fatigue resistance and chemical stability.

Pros & Cons: The main advantage of PP is its durability and resistance to stress cracking. However, it can be more expensive than PE, and its manufacturing process is more complex, which may affect lead times.

Impact on Application: PP is often used in applications requiring higher strength and rigidity, such as automotive parts and industrial components. Its compatibility with various chemicals makes it suitable for filtration applications.

Considerations for International Buyers: Buyers should be aware of the specific grades of polypropylene that meet their application requirements. Compliance with standards such as ISO 14001 for environmental management may also be relevant, especially in Europe.

Polyvinyl Chloride (PVC)

Key Properties: PVC is highly versatile, with a temperature range of -15°C to 60°C (5°F to 140°F). It exhibits excellent chemical resistance and is flame-retardant.

Pros & Cons: PVC’s advantages include its durability and ability to be molded into complex shapes. However, it can be heavier than other materials and may require special handling during installation due to its rigidity.

Impact on Application: PVC is commonly used in construction and building applications, including sound attenuation panels and architectural features. Its resistance to moisture makes it suitable for outdoor use.

Considerations for International Buyers: Compliance with fire safety standards (e.g., EN 13501 in Europe) is critical for construction applications. Buyers should also consider the environmental impact of PVC and look for suppliers who adhere to sustainable practices.

High-Density Polyethylene (HDPE)

Key Properties: HDPE is known for its high strength-to-density ratio and can withstand temperatures up to 120°C (248°F). It is highly resistant to impact and chemicals.

Pros & Cons: The key advantage of HDPE is its exceptional durability and resistance to environmental stressors. However, it can be more expensive than other plastics and may require specialized equipment for perforation.

Impact on Application: HDPE is ideal for demanding applications such as industrial containers and agricultural products. Its toughness makes it suitable for heavy-duty uses.

Considerations for International Buyers: Buyers should ensure that HDPE products meet relevant standards such as ASTM D3350. Additionally, understanding local recycling regulations is essential, as HDPE is widely recyclable.

Summary Table

| Material | Typical Use Case for perforated plastic sheets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene (PE) | Agricultural films, drainage sheets | Lightweight and cost-effective | Lower strength at low temperatures | Low |

| Polypropylene (PP) | Automotive parts, industrial components | High durability and rigidity | Higher cost and complex manufacturing | Medium |

| Polyvinyl Chloride (PVC) | Construction panels, sound attenuation | Excellent durability and versatility | Heavier and requires careful handling | Medium |

| High-Density Polyethylene (HDPE) | Industrial containers, heavy-duty applications | Exceptional durability | Higher cost and specialized equipment needed | High |

This guide provides a comprehensive overview of material selection for perforated plastic sheets, enabling international B2B buyers to make informed decisions based on performance, application, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for perforated plastic sheets

Perforated plastic sheets are integral components across various industries, and understanding their manufacturing processes and quality assurance protocols is vital for international B2B buyers. This section delves into the typical manufacturing stages, key techniques, and the quality control measures that ensure the final product meets the required specifications.

Manufacturing Processes for Perforated Plastic Sheets

The production of perforated plastic sheets involves several key stages, each critical to achieving the desired specifications and quality. The main stages include:

-

Material Preparation

The first step involves selecting the appropriate type of plastic, which can range from polyethylene (PE) and polypropylene (PP) to polyvinyl chloride (PVC) and high-density polyethylene (HDPE). The choice of material will depend on the intended application, as each plastic type has unique characteristics such as strength, flexibility, and chemical resistance. Once selected, the material is cut into sheets of specified thickness and dimensions. -

Forming

The forming stage is where the perforation occurs. Various techniques are employed depending on the required hole size, pattern, and production volume:

– Hot and Cold Pin Rotary Perforation: Utilizes rotating pins to create holes, with the hot pin method also sealing the edges to prevent fraying.

– Laser Perforation: Offers high precision and is ideal for applications requiring micro-perforations.

– Die Punching: Involves using a die to create specific shapes and sizes of perforations.

Each method has its advantages and is chosen based on factors such as cost, speed, and the complexity of the design.

-

Assembly

After perforation, the sheets may undergo additional processes such as cutting, trimming, or coating to enhance their functionality or aesthetic appeal. In some applications, multiple sheets may be layered or assembled with other materials to create composite products. -

Finishing

The final stage involves applying any necessary surface treatments, such as coatings for UV resistance or anti-static properties. This stage is crucial for ensuring the longevity and performance of the perforated sheets in their intended environment.

Quality Assurance Protocols

Quality assurance is essential in the manufacturing of perforated plastic sheets, ensuring that the products meet both international standards and customer specifications. Here are the key components of the quality assurance process:

International Standards

- ISO 9001: This is the most recognized quality management standard worldwide, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: For products sold in the European Economic Area, CE marking indicates compliance with safety and environmental protection standards.

- API Standards: Particularly relevant for applications in the oil and gas industry, ensuring materials can withstand specific environmental conditions.

Quality Control Checkpoints

- Incoming Quality Control (IQC): This phase involves inspecting raw materials before production. Ensuring that materials meet specifications is crucial for the overall quality of the final product.

- In-Process Quality Control (IPQC): During manufacturing, various checkpoints are established to monitor the production process. This includes verifying the accuracy of perforation patterns and dimensions at regular intervals.

- Final Quality Control (FQC): After production, the final products undergo thorough inspection and testing to ensure they meet all specifications before being shipped.

Common Testing Methods

- Dimensional Inspection: Measuring the thickness, length, and width of sheets to ensure they conform to specifications.

- Tensile Strength Testing: Assessing the strength of the material to ensure it meets application requirements.

- Chemical Resistance Testing: Evaluating how well the material withstands exposure to various chemicals, important for applications in harsh environments.

Verifying Supplier Quality Control

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential. Here are actionable steps to ensure quality:

- Supplier Audits: Conducting regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. This can be done by visiting the facility or hiring a third-party service.

- Requesting Quality Reports: Suppliers should provide documentation of their quality control processes, including results from IQC, IPQC, and FQC stages. This documentation should also include details on compliance with relevant international standards.

- Third-Party Inspections: Engaging third-party inspection services can help verify the quality of the products before shipment, ensuring that they meet both specifications and regulations.

QC and Certification Nuances for International Buyers

Understanding the nuances of quality control and certification is crucial for international buyers. Different regions may have varying regulations and standards that affect the acceptance of perforated plastic sheets. For instance, products imported into the EU must comply with CE marking requirements, while buyers in the Middle East may require adherence to local standards that differ significantly.

Additionally, buyers should consider the certifications held by suppliers, such as ISO 9001, to ensure they are partnering with manufacturers committed to quality. Engaging with suppliers who demonstrate a strong commitment to quality assurance can mitigate risks associated with product failures and enhance overall supply chain reliability.

Conclusion

The manufacturing processes and quality assurance protocols for perforated plastic sheets are critical for ensuring the delivery of high-quality products that meet diverse industry needs. By understanding these processes and implementing thorough verification strategies, international B2B buyers can make informed decisions that enhance their supply chain efficiency and product reliability.

Related Video: Glenroy’s Flexible Packaging Manufacturing Process

Comprehensive Cost and Pricing Analysis for perforated plastic sheets Sourcing

Cost Structure of Perforated Plastic Sheets

When sourcing perforated plastic sheets, understanding the cost structure is crucial for international B2B buyers. The main cost components include:

-

Materials: The choice of plastic, such as polyethylene (PE), polypropylene (PP), or polyvinyl chloride (PVC), significantly affects costs. Higher-quality materials may lead to better performance but also come with a higher price tag.

-

Labor: The complexity of the perforation process requires skilled labor. Labor costs can vary based on the region and the manufacturing method employed.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Overhead rates can differ widely depending on the geographical location of the manufacturer.

-

Tooling: Initial setup costs for tooling can be substantial, especially for custom designs. The type of perforating machinery used (e.g., hot pin rotary, laser) can influence these costs.

-

Quality Control (QC): Maintaining high standards in production necessitates robust QC processes, which add to the overall cost. Certifications and compliance with international standards can further increase costs but are often necessary for market entry.

-

Logistics: Shipping and handling costs are critical, especially for international transactions. Factors such as distance, mode of transport, and local regulations can affect these costs significantly.

-

Margin: Suppliers typically add a margin to cover their risks and profit expectations. This can vary based on the supplier’s market position and relationship with the buyer.

Price Influencers

Several factors can influence the pricing of perforated plastic sheets:

-

Volume/MOQ: Bulk orders generally attract lower unit prices. Understanding minimum order quantities (MOQs) is essential for negotiating better deals.

-

Specifications and Customization: Custom perforations or specific material properties can increase costs. Buyers should weigh the need for customization against potential price increases.

-

Material Quality and Certifications: Higher-grade materials and those with necessary certifications (e.g., ISO, FDA) come at a premium but can enhance product reliability and marketability.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can impact pricing. Established suppliers may offer better quality assurance but at higher rates.

-

Incoterms: Understanding the shipping terms (e.g., FOB, CIF) is crucial for accurate cost calculations. These terms define responsibility for shipping costs and risk, which can affect the total landed cost.

Buyer Tips for Cost Efficiency

International B2B buyers should consider the following strategies to optimize their sourcing of perforated plastic sheets:

-

Negotiate Effectively: Leverage volume commitments or long-term relationships to negotiate better terms. Be prepared to discuss specific needs to foster collaboration.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, durability, and performance over time. This holistic view can lead to better long-term decisions.

-

Understand Pricing Nuances: Be aware that international pricing may vary due to exchange rates, tariffs, and local market conditions. Regularly review market trends to adjust sourcing strategies accordingly.

-

Request Detailed Quotes: When engaging suppliers, ask for itemized quotes that break down costs. This transparency helps identify areas for potential savings and ensures that all necessary components are included.

-

Build Relationships with Multiple Suppliers: Establishing a diverse supplier base can provide leverage in negotiations and reduce dependency on a single source, which can be particularly beneficial in volatile markets.

Disclaimer

Prices for perforated plastic sheets can vary widely based on the factors discussed above. This analysis serves as a guideline and should not be interpreted as definitive pricing. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to make informed purchasing decisions.

Spotlight on Potential perforated plastic sheets Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘perforated plastic sheets’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for perforated plastic sheets

Understanding the technical properties and terminology related to perforated plastic sheets is essential for international B2B buyers. This knowledge aids in making informed purchasing decisions, ensuring compliance with specific applications, and fostering effective communication with suppliers.

Key Technical Properties of Perforated Plastic Sheets

-

Material Grade

– Definition: The classification of the plastic used, such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), or high-density polyethylene (HDPE).

– Importance: Different grades offer unique properties such as durability, chemical resistance, and temperature tolerance. Selecting the appropriate material grade ensures that the perforated sheet meets the specific requirements of the intended application, whether for agriculture, automotive, or construction. -

Thickness

– Definition: The measurement of the sheet’s depth, typically expressed in millimeters or inches.

– Importance: Thickness impacts the strength and rigidity of the perforated plastic sheet. Thicker sheets are generally more robust and resistant to deformation, making them suitable for heavy-duty applications. Buyers must assess the load-bearing needs of their projects to choose the right thickness. -

Hole Size and Pattern

– Definition: The dimensions and configuration of the perforations in the sheet.

– Importance: Hole size influences airflow, drainage, and light passage. Different applications require specific hole sizes and patterns (e.g., round, square, or custom designs). Understanding these specifications helps buyers optimize the performance of the sheets for tasks such as filtration or ventilation. -

Tolerance

– Definition: The allowable variation in the dimensions of the perforations and the sheet itself.

– Importance: Tolerance levels are crucial for ensuring the consistency and quality of the product. High tolerance precision is necessary for applications that require exact measurements, such as medical devices or packaging solutions. Buyers should verify that suppliers can meet their tolerance requirements to avoid costly production errors. -

Chemical Resistance

– Definition: The ability of the plastic material to withstand exposure to chemicals without degradation.

– Importance: In sectors like agriculture and pharmaceuticals, perforated sheets may come into contact with various substances. Buyers should select materials with appropriate chemical resistance to ensure the longevity and effectiveness of the sheets in their specific environments.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships can help buyers identify reliable suppliers who can provide high-quality perforated sheets tailored to specific applications. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ is essential for budget planning and inventory management. Buyers should negotiate terms that align with their needs to avoid excess inventory or missed opportunities. -

RFQ (Request for Quote)

– Definition: A document sent to suppliers to request pricing and terms for specific products.

– Relevance: Submitting a detailed RFQ can streamline the procurement process, allowing buyers to receive tailored quotes that meet their specifications, including material grade, thickness, and hole pattern. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms that outline the responsibilities of buyers and sellers.

– Relevance: Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risk management. This knowledge is crucial when negotiating contracts with international suppliers. -

Lead Time

– Definition: The time taken from placing an order to the delivery of the product.

– Relevance: Understanding lead times is vital for project planning. Buyers must consider lead times when scheduling production or construction activities to ensure timely delivery of perforated plastic sheets.

By grasping these properties and terms, B2B buyers can navigate the complex landscape of perforated plastic sheets more effectively, ensuring they make informed decisions that align with their operational needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the perforated plastic sheets Sector

Market Overview & Key Trends

The global market for perforated plastic sheets is witnessing significant growth driven by diverse applications across various industries including packaging, construction, automotive, and agriculture. Key factors propelling this trend include the increasing demand for lightweight and durable materials, as well as the rising emphasis on aesthetics and functionality in design. For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed sourcing decisions.

Emerging B2B tech trends such as automation and advanced manufacturing processes are reshaping the production landscape. The adoption of laser and CNC perforation technologies enhances precision and efficiency, allowing manufacturers to meet specific customer requirements with greater speed. Additionally, buyers are increasingly leveraging digital platforms and marketplaces for sourcing, enabling them to compare suppliers and streamline procurement processes.

Market dynamics are also influenced by regional considerations. For instance, buyers in the UAE and Egypt may prioritize suppliers that can navigate local regulations and provide timely deliveries. In South America, factors such as local sourcing capabilities and tariff considerations play a vital role in shaping purchasing decisions. Understanding these regional nuances can help buyers optimize their sourcing strategies and build resilient supply chains.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a central theme in the perforated plastic sheets sector, driven by increasing environmental awareness and regulatory pressures. The production of plastic materials often has a significant environmental impact, prompting buyers to seek out suppliers who prioritize sustainable practices. This includes using recycled materials, implementing energy-efficient production processes, and minimizing waste throughout the manufacturing cycle.

Ethical sourcing is equally important, as businesses are increasingly held accountable for the social and environmental practices of their supply chains. Buyers should look for suppliers who possess recognized green certifications, such as ISO 14001, which demonstrates a commitment to environmental management. Additionally, sourcing from manufacturers that utilize biodegradable or recyclable materials can enhance a company’s sustainability profile and appeal to environmentally-conscious consumers.

Investing in sustainable products not only mitigates environmental impact but can also lead to cost savings in the long term. By prioritizing sustainability, B2B buyers can improve their brand reputation and align with global trends towards responsible sourcing.

Brief Evolution/History

The perforated plastic sheets industry has evolved significantly over the past few decades. Initially, perforated sheets were primarily used in industrial applications, but advancements in technology and materials have broadened their usage across various sectors. The introduction of precision perforation techniques, such as laser cutting, allowed for intricate designs and patterns, enhancing aesthetic appeal and functionality.

Today, perforated plastic sheets are recognized for their versatility, being employed in applications ranging from architectural design to filtration systems. This evolution reflects a growing trend towards customization and innovation in manufacturing, enabling buyers to source products that meet specific needs and enhance their operational efficiencies. As the market continues to evolve, staying abreast of these developments will be critical for B2B buyers aiming to leverage the full potential of perforated plastic sheets.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of perforated plastic sheets

-

How do I vet suppliers of perforated plastic sheets?

When sourcing perforated plastic sheets, it is crucial to conduct thorough supplier vetting. Start by checking for certifications such as ISO 9001, which indicates a commitment to quality management. Request samples to assess product quality and ensure they meet your specifications. Additionally, review customer testimonials and case studies to gauge reliability. Engaging with suppliers that have a proven track record in your region, like those in Africa or the Middle East, can also provide added assurance of their capabilities. -

Can perforated plastic sheets be customized?

Yes, many manufacturers offer customization options for perforated plastic sheets. Buyers can specify dimensions, hole sizes, shapes, and patterns based on their unique requirements. When discussing customization, communicate your needs clearly and ask for CAD drawings to visualize the final product. This process not only enhances functionality but also allows for better integration into existing designs. Be sure to confirm any additional costs and lead times associated with custom orders. -

What are the typical minimum order quantities (MOQs) and lead times?

Minimum order quantities for perforated plastic sheets can vary significantly based on the supplier and the complexity of the order. Generally, MOQs can range from 100 to 1,000 sheets. Lead times typically depend on the production method, customization, and supplier location, often ranging from 2 to 6 weeks. For international buyers, it’s advisable to discuss these terms upfront to align expectations and avoid delays, especially when planning for projects with strict timelines. -

What payment terms are commonly offered?

Payment terms for perforated plastic sheets often include options such as upfront payment, partial payment upon order confirmation, and balance upon delivery. International buyers should consider using secure payment methods like letters of credit or escrow services to mitigate risks. Always clarify payment terms before placing an order and ensure that they are documented in your purchase agreement. This transparency helps prevent disputes and ensures both parties are aligned.

-

How do I ensure quality assurance and certifications?

To ensure quality assurance, request documentation of the supplier’s quality control processes and relevant certifications. Many suppliers adhere to international standards such as ISO 9001 or ASTM specifications for material quality. Conducting an on-site audit can also be beneficial if feasible. Additionally, consider implementing a third-party inspection service to verify product quality before shipment, especially for larger orders or when sourcing from regions like South America or Africa. -

What logistics considerations should I keep in mind?

Logistics is a critical aspect of sourcing perforated plastic sheets internationally. Assess shipping options, costs, and timelines based on your location. Understand the customs regulations of your country to ensure compliance and avoid delays. Additionally, consider the packaging used to protect the sheets during transit, as damage can occur if they are not adequately secured. Collaborating with a freight forwarder experienced in handling plastic products can simplify the logistics process. -

How should I handle disputes with suppliers?

To effectively manage disputes with suppliers, it is essential to establish clear communication channels from the outset. Document all agreements, specifications, and changes in writing to provide a reference point. In the event of a dispute, start by addressing the issue directly with the supplier to seek a resolution. If necessary, consider mediation or arbitration as alternative dispute resolution methods. Having a well-defined contract that includes clauses for dispute resolution can also help mitigate risks. -

What are the common applications for perforated plastic sheets?

Perforated plastic sheets have diverse applications across various industries, including construction, packaging, filtration, and automotive sectors. They are commonly used for items like ventilation panels, drainage systems, and aesthetic architectural features. Understanding your industry’s specific needs can help in selecting the right type of perforated sheet. Engage with suppliers who have experience in your sector to gain insights into the best solutions for your application, ensuring optimal performance and compliance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for perforated plastic sheets

In conclusion, strategic sourcing of perforated plastic sheets offers significant advantages to international B2B buyers across diverse industries, particularly in Africa, South America, the Middle East, and Europe. By understanding the manufacturing processes, material options, and customization capabilities, buyers can make informed decisions that align with their specific needs. The versatility of perforated plastic sheets, which include applications in packaging, filtration, and construction, underscores their importance in enhancing operational efficiency and product quality.

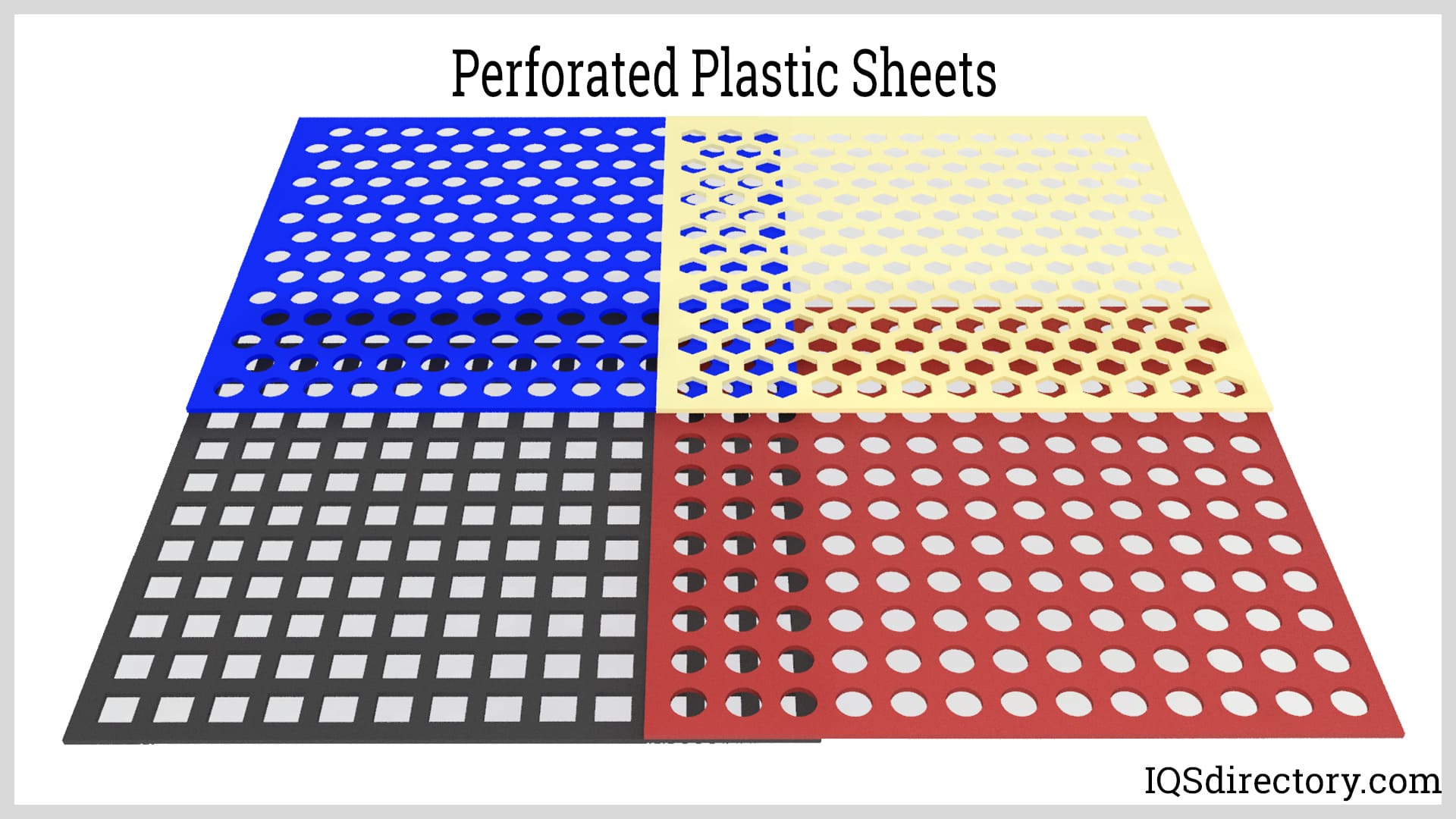

Illustrative Image (Source: Google Search)

Moreover, engaging with reputable suppliers ensures access to innovative solutions that can drive competitive advantage. Buyers should prioritize suppliers who utilize advanced perforation technologies, such as hot pin rotary and laser methods, which deliver precision and durability.

Looking ahead, the demand for perforated plastic sheets is expected to grow, driven by sustainability trends and the need for lightweight, durable materials. B2B buyers are encouraged to explore new partnerships and sourcing strategies that leverage these trends. By doing so, they can position themselves favorably in an evolving market landscape. Embrace the opportunity to innovate and elevate your supply chain by investing in perforated plastic solutions that meet the future’s challenges.