Your Ultimate Guide to Sourcing 316 Stainless

Introduction: Navigating the Global Market for 316 stainless

In the competitive landscape of global industrial materials, 316 stainless steel emerges as a vital asset for businesses seeking durability and performance. Renowned for its exceptional resistance to corrosion, especially in harsh environments, this alloy is indispensable across various sectors, including marine engineering, chemical processing, and medical manufacturing. For international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, understanding the intricacies of sourcing 316 stainless steel can significantly influence project outcomes and overall cost-effectiveness.

This guide provides a comprehensive roadmap for navigating the complexities of the 316 stainless steel market. It delves into the various types and grades, detailing their specific applications and benefits. Additionally, it covers manufacturing standards and quality control measures that are crucial for ensuring material integrity. Buyers will also gain insights into evaluating reliable suppliers and manufacturers worldwide, tailored to regional dynamics.

Moreover, this guide addresses cost management strategies, emerging market trends, and regulatory considerations that are essential for informed decision-making. By leveraging these insights, procurement professionals can optimize their sourcing strategies, ensuring they acquire high-quality 316 stainless steel at competitive prices. Ultimately, this resource empowers buyers to make strategic choices that enhance project longevity and operational efficiency, securing their position in the global market.

Understanding 316 stainless Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 316 Stainless Steel | Contains 16% Cr, 10% Ni, 2% Mo; standard composition for corrosion resistance | Marine hardware, chemical processing, medical devices | Excellent corrosion resistance; higher cost but durable in harsh environments |

| 316L Stainless Steel | Low carbon (<0.03%); improved weldability | Pharmaceutical equipment, marine applications, food processing | Superior weldability; suitable for sanitary environments but slightly more expensive |

| 316Ti Stainless Steel | Titanium stabilized; resists high-temperature sensitization | Heat exchangers, chemical plants, petrochemical equipment | Maintains strength at elevated temperatures; higher cost with potential for longer lead times |

| 316H Stainless Steel | High carbon (0.04–0.10%); enhanced high-temperature strength | Power plants, boiler components, high-temperature piping | Excellent high-temperature performance; suitable for demanding environments but requires quality assurance |

| 316N Stainless Steel | Nitrogen alloyed; improved strength and corrosion resistance | Aerospace, high-performance marine applications | Enhanced mechanical properties; suitable for specialized needs but may have limited availability |

316 Stainless Steel

316 stainless steel is recognized for its robust corrosion resistance, particularly against chlorides and industrial chemicals. This makes it ideal for marine applications, chemical processing, and medical devices. For B2B buyers, sourcing certified 316 stainless steel is crucial to ensure compliance with industry standards and project longevity. While its higher price point reflects its performance benefits, the investment is justified in applications where durability and resistance to harsh environments are non-negotiable.

316L Stainless Steel

The low-carbon variant, 316L, is specifically designed for improved weldability and resistance to intergranular corrosion. This makes it particularly suitable for the pharmaceutical and food processing industries, where stringent sanitary conditions are essential. B2B buyers should prioritize suppliers that offer consistent quality assurance and traceability for 316L. Although it may come at a slightly elevated cost, the advantages of reduced maintenance and enhanced durability often provide a favorable return on investment.

316Ti Stainless Steel

316Ti is stabilized with titanium, allowing it to maintain structural integrity at high temperatures, making it ideal for applications such as heat exchangers and chemical reactors. For buyers, sourcing this variant may require engaging specialized suppliers, as not all manufacturers produce 316Ti. While it carries a higher price tag, its performance in extreme conditions justifies the cost. Buyers should also ensure that suppliers provide necessary certifications to avoid issues related to material quality.

316H Stainless Steel

With a higher carbon content, 316H offers enhanced strength in high-temperature environments, making it suitable for power plants and boiler components. B2B buyers need to assess supplier capabilities to ensure the production of high-quality, high-carbon alloys that meet stringent industrial standards. Although 316H can be more expensive, its superior performance can lead to lower long-term maintenance costs, making it a wise investment for demanding applications.

316N Stainless Steel

316N is nitrogen-alloyed, providing improved mechanical properties and corrosion resistance. This variant is often utilized in aerospace and high-performance marine applications where specialized strength is required. B2B buyers should be aware of potential availability challenges and ensure that their sourcing strategy includes suppliers capable of providing certified 316N. While it may not be as widely available as other types, its unique properties can deliver significant value in specialized applications.

Related Video: What Makes Large Language Models Expensive?

Key Industrial Applications of 316 stainless

| Industry/Sector | Specific Application of 316 Stainless | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine Engineering | Ship components and hardware | Enhanced durability and corrosion resistance in seawater environments | Verify supplier certifications and track record in marine applications |

| Chemical Processing | Tanks and piping systems | Reliable performance in handling corrosive chemicals | Ensure compliance with international standards and quality certifications |

| Food Processing | Kitchen equipment and food processing tools | Hygiene and corrosion resistance for food safety | Look for suppliers with experience in food-grade materials and certifications |

| Medical Devices | Surgical instruments and implants | Biocompatibility and ease of sterilization | Focus on suppliers with proven quality assurance processes and traceability |

| Construction | Architectural elements in coastal areas | Long-lasting structures resistant to environmental degradation | Evaluate local availability and supplier capabilities in high-performance alloys |

Marine Engineering

In the marine industry, 316 stainless steel is extensively used for ship components, including fittings, fasteners, and hardware exposed to seawater. Its exceptional corrosion resistance ensures longevity and reliability, reducing maintenance costs and downtime. For international buyers, especially those in coastal regions of Africa and South America, sourcing from suppliers with experience in marine-grade materials is crucial. Buyers should also confirm the alloy’s certification to ensure it meets the rigorous standards required for marine applications.

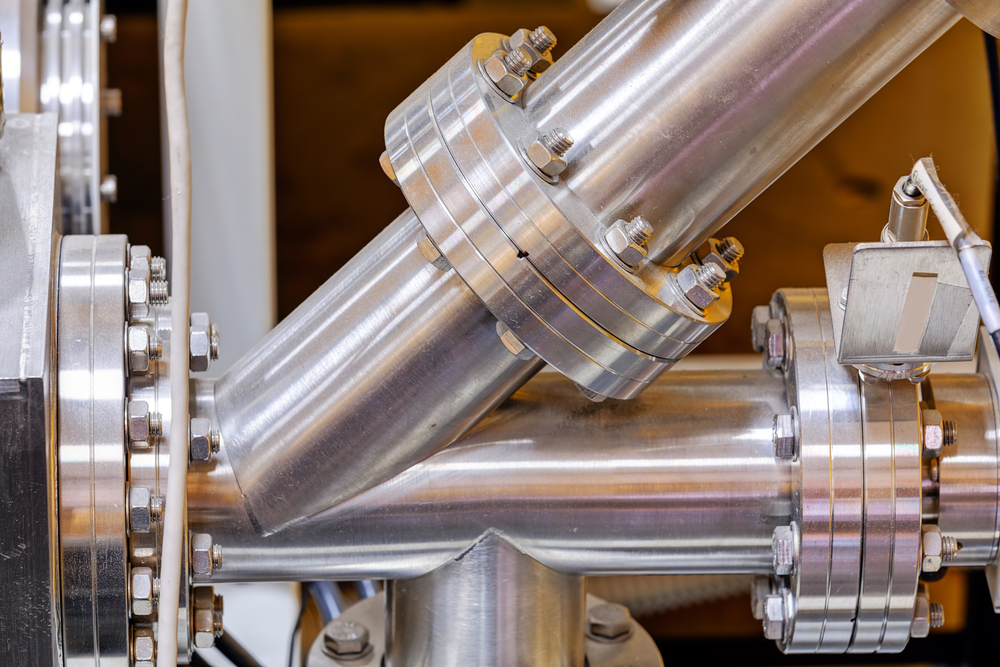

Chemical Processing

316 stainless steel is a preferred material for tanks, pipes, and valves in the chemical processing sector due to its ability to withstand harsh chemicals and high temperatures. It effectively resists pitting and crevice corrosion, ensuring safety and durability in operations. Buyers from the Middle East and Europe must prioritize suppliers who adhere to international safety and quality standards, as compliance is vital for mitigating risks in chemical handling and processing environments.

Illustrative Image (Source: Google Search)

Food Processing

In food processing, 316 stainless steel is utilized for kitchen equipment, food processing tools, and storage containers. Its hygienic properties and resistance to corrosion are essential for maintaining food safety standards. B2B buyers should seek suppliers that specialize in food-grade materials, ensuring compliance with local regulations and certifications. This focus on quality can significantly reduce the risk of contamination and enhance the operational efficiency of food manufacturing processes.

Medical Devices

The medical field relies on 316 stainless steel for surgical instruments, implants, and cleanroom equipment due to its biocompatibility and ease of sterilization. The alloy’s corrosion resistance is critical for ensuring the safety and effectiveness of medical devices. International buyers, particularly in Europe and the Middle East, should prioritize suppliers with stringent quality assurance processes and traceability systems to ensure compliance with medical device regulations and standards.

Construction

In construction, particularly in coastal areas, 316 stainless steel is used for architectural elements, handrails, and structural components. Its durability against environmental degradation is a significant advantage, extending the lifespan of structures. Buyers from regions like Germany and Saudi Arabia should evaluate local suppliers’ capabilities to provide high-performance alloys, considering factors such as lead times and material certifications to ensure project specifications are met effectively.

Related Video: Steel Types – Stainless Steel Vs Carbon Steel Explained.

Strategic Material Selection Guide for 316 stainless

When selecting materials related to 316 stainless steel, it is crucial to understand the various types and their specific applications. Each variant offers unique properties that can significantly impact performance, cost, and suitability for different environments. Below, we analyze four common materials associated with 316 stainless steel from a B2B perspective.

316 Stainless Steel

Key Properties:

316 stainless steel is known for its excellent corrosion resistance, particularly in chloride-rich environments. It typically withstands temperatures up to 870°C (1600°F) and has a tensile strength of approximately 515 MPa (75 ksi). Its molybdenum content enhances its resistance to pitting and crevice corrosion.

Pros & Cons:

The primary advantage of 316 stainless steel is its durability and resistance to harsh chemicals, making it ideal for marine and chemical processing applications. However, its higher cost compared to other stainless steels can be a limitation for budget-sensitive projects. Additionally, its manufacturing complexity may require specialized equipment and expertise.

Impact on Application:

316 stainless steel is widely used in marine hardware, chemical processing, and medical devices. Its compatibility with aggressive media such as seawater and various acids makes it a preferred choice for applications requiring long-term durability.

Considerations for International Buyers:

Buyers from regions such as Africa, South America, the Middle East, and Europe should ensure compliance with international standards such as ASTM, DIN, and JIS. Understanding local regulations and the availability of certified suppliers is essential for maintaining quality and performance.

316L Stainless Steel

Key Properties:

316L stainless steel features a lower carbon content, enhancing its weldability and resistance to intergranular corrosion. It maintains a similar tensile strength to standard 316 but offers improved performance in welded structures.

Pros & Cons:

The key advantage of 316L is its superior weldability, making it suitable for complex fabrications. However, it can be slightly more expensive than standard 316 due to its specialized manufacturing process.

Impact on Application:

This variant is ideal for pharmaceutical and food processing applications, where sanitary conditions are paramount. Its ability to resist contamination makes it a preferred choice for equipment in these sectors.

Considerations for International Buyers:

Buyers should verify the supplier’s quality assurance practices and certifications, as consistent chemical composition is critical for compliance in regulated industries.

316Ti Stainless Steel

Key Properties:

316Ti stainless steel is titanium-stabilized, which prevents carbide precipitation during high-temperature exposure. It is suitable for applications with temperatures exceeding 870°C (1600°F).

Pros & Cons:

The primary advantage of 316Ti is its enhanced performance in high-temperature environments, making it ideal for heat exchangers and chemical reactors. However, it typically comes at a higher cost and may have limited availability in some regions.

Impact on Application:

This material is particularly effective in petrochemical applications where high-temperature stability is essential. Its corrosion resistance in extreme conditions ensures long-term operational reliability.

Considerations for International Buyers:

Sourcing 316Ti requires careful evaluation of supplier capabilities, as not all manufacturers produce this variant. Buyers should prioritize suppliers with robust certifications to ensure traceability and quality.

316H Stainless Steel

Key Properties:

316H stainless steel has a higher carbon content, which enhances its strength at elevated temperatures. It is well-suited for applications involving high-temperature piping and boiler components.

Pros & Cons:

The advantage of 316H is its ability to maintain structural integrity under extreme heat, reducing the need for frequent replacements. However, its higher carbon content can make it more susceptible to corrosion in certain environments.

Impact on Application:

This material is commonly used in power plants and other high-temperature applications where strength and durability are critical. Its performance in demanding conditions makes it a reliable choice for heavy-duty applications.

Considerations for International Buyers:

Buyers should ensure that their suppliers can meet the stringent quality standards required for high-carbon alloys. Understanding local regulations regarding material specifications is also crucial.

Summary Table

| Material | Typical Use Case for 316 stainless | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 316 | Marine hardware, chemical processing | Excellent corrosion resistance | Higher cost compared to other grades | High |

| 316L | Pharmaceutical, food processing | Superior weldability | Slightly more expensive | Medium |

| 316Ti | Heat exchangers, petrochemical | Enhanced high-temperature performance | Limited availability in some regions | High |

| 316H | Power plants, high-temperature piping | Maintains strength at elevated temps | Susceptible to corrosion in some cases | High |

This strategic material selection guide provides B2B buyers with critical insights into the various types of 316 stainless steel, helping them make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 316 stainless

The manufacturing processes and quality assurance protocols for 316 stainless steel are critical to ensuring that the final product meets the rigorous demands of various industries. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these processes can significantly influence sourcing decisions, product performance, and compliance with international standards.

Manufacturing Processes

The manufacturing of 316 stainless steel involves several key stages, each crucial to maintaining the quality and performance of the alloy. Here’s a breakdown of the main stages:

Material Preparation

The first step in the manufacturing process is the selection and preparation of raw materials. The primary components include:

- Iron Ore: The base element for stainless steel.

- Alloying Elements: These include chromium, nickel, molybdenum, and others, which are added in specified proportions to achieve desired properties.

During this stage, the materials are carefully weighed and mixed to ensure compliance with the specific grade standards of 316 stainless steel. This step is essential for maintaining the chemical composition, which directly affects corrosion resistance and mechanical properties.

Forming

Once the materials are prepared, they undergo several forming processes, which may include:

- Casting: Molten metal is poured into molds to create ingots or slabs.

- Hot Rolling: The cast ingots are heated and passed through rollers to achieve desired thickness and shape.

- Cold Rolling: Further refinement is achieved through cold rolling, which enhances surface finish and dimensional accuracy.

These processes ensure that the stainless steel is formed into sheets, plates, bars, or other shapes suitable for specific applications.

Assembly

In many cases, 316 stainless steel components are assembled into larger systems or products. This may involve:

- Welding: Various techniques, such as TIG (Tungsten Inert Gas) welding, are employed to join stainless steel parts, particularly for 316L, which offers superior weldability.

- Machining: Components are machined to precise specifications, ensuring they fit correctly in their intended applications.

Proper assembly techniques are vital to maintaining the integrity of the alloy, particularly in applications where high corrosion resistance is required.

Finishing

The final stage involves surface finishing processes that enhance both aesthetics and performance:

- Pickling and Passivation: These chemical treatments remove impurities and enhance corrosion resistance by forming a protective oxide layer.

- Polishing: This process improves surface smoothness and can also enhance the alloy’s appearance.

Finishing processes are essential for applications in the medical, food processing, and marine industries, where hygiene and appearance are critical.

Quality Assurance

Quality assurance is a fundamental aspect of manufacturing 316 stainless steel, ensuring that products meet both international standards and specific customer requirements. Here are the key components of quality assurance:

International Standards

B2B buyers should be aware of relevant international standards that govern the manufacturing and quality assurance of stainless steel. Some key standards include:

- ISO 9001: This standard outlines the requirements for a quality management system, focusing on continuous improvement and customer satisfaction.

- ASTM A240: This specification covers the standard for chromium and chromium-nickel stainless steel plate, sheet, and strip for pressure vessels and for general applications.

- EN 10088: A European standard that specifies the technical delivery conditions for stainless steels.

Understanding these standards helps buyers assess supplier capabilities and ensure compliance with industry norms.

Industry-Specific Certifications

Depending on the application, certain industry-specific certifications may also be necessary. For example:

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

- API Spec Q1: Relevant for suppliers to the oil and gas industry, ensuring quality management systems are in place.

Buyers should verify that suppliers hold the necessary certifications for their specific industry.

Quality Control Checkpoints

Quality control involves several critical checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Regular inspections during production ensure adherence to process parameters and specifications.

- Final Quality Control (FQC): The finished products undergo rigorous testing and inspection before shipment.

These checkpoints help identify issues early in the manufacturing process, reducing the risk of defects in final products.

Common Testing Methods

Several testing methods are commonly employed to ensure the quality of 316 stainless steel, including:

- Chemical Composition Analysis: Verifying the alloy’s composition using methods like spectroscopy.

- Mechanical Testing: Assessing properties such as tensile strength, yield strength, and elongation through standardized tests.

- Corrosion Testing: Evaluating resistance to various corrosive environments, particularly for marine and chemical applications.

Buyers should inquire about the testing methods used by suppliers to ensure they meet industry standards.

Verifying Supplier Quality Control

To ensure that suppliers adhere to stringent quality control measures, B2B buyers can take several steps:

- Supplier Audits: Conducting audits can provide insights into a supplier’s manufacturing processes and quality assurance practices.

- Requesting Quality Reports: Suppliers should be able to provide detailed quality reports, including results from testing and inspections.

- Third-Party Inspections: Engaging third-party inspection services can offer unbiased evaluations of a supplier’s quality control processes.

Quality Control and Certification Nuances

For international B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is crucial. Factors such as regional standards, availability of certified suppliers, and the ability to meet local regulations can significantly impact sourcing decisions.

Buyers should also consider the implications of sourcing from regions with varying levels of quality assurance practices. Engaging with suppliers who have established quality management systems and international certifications can mitigate risks associated with substandard materials.

By thoroughly understanding the manufacturing processes and quality assurance protocols for 316 stainless steel, international B2B buyers can make informed decisions that enhance project success, ensure compliance with industry standards, and optimize value in their procurement strategies.

Related Video: Amazing factories | Manufacturing method and top 4 processes | Mass production process

Comprehensive Cost and Pricing Analysis for 316 stainless Sourcing

In the global sourcing landscape for 316 stainless steel, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. This knowledge enables effective decision-making, ensuring procurement aligns with both budgetary constraints and quality requirements. Below is an analysis of the cost components, price influencers, and strategic tips for navigating pricing nuances.

Cost Components

-

Materials: The primary cost driver in 316 stainless steel procurement is the raw materials. The alloy’s composition, which includes chromium, nickel, and molybdenum, significantly influences price volatility based on market demand and availability. As these materials are subject to global market fluctuations, buyers should monitor trends and consider bulk purchasing to mitigate costs.

-

Labor: Labor costs encompass the workforce involved in production and fabrication. Regions with higher labor costs will reflect this in the final pricing. Buyers should evaluate suppliers based on their labor practices and cost structures, as this can impact overall pricing.

-

Manufacturing Overhead: This includes expenses related to production facilities, utilities, and administrative costs. Suppliers with efficient manufacturing processes may offer more competitive prices. Buyers should inquire about operational efficiencies that suppliers implement.

-

Tooling: The initial investment in tooling for producing specific 316 stainless steel products is a critical factor. Custom tooling can increase upfront costs, particularly for specialized items. Buyers must weigh these costs against their long-term needs and potential volume discounts.

-

Quality Control (QC): Ensuring compliance with industry standards and certifications requires investment in quality control processes. Suppliers that prioritize QC may charge higher prices, but this can lead to reduced risks and lower Total Cost of Ownership (TCO) in the long run.

-

Logistics: Transportation and logistics costs can vary significantly based on the supplier’s location and the destination market. Buyers should consider factors such as shipping methods, lead times, and import duties when calculating total costs.

-

Margin: Suppliers typically build a profit margin into their pricing, which can vary by region and market competition. Understanding the competitive landscape can help buyers negotiate better terms.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) can dramatically affect pricing. Higher volumes often lead to lower per-unit costs, incentivizing bulk purchases. Buyers should assess their needs to leverage volume discounts effectively.

-

Specifications/Customization: Customized products may incur additional costs related to design and manufacturing changes. Buyers should clearly define specifications to avoid unexpected price increases.

-

Materials and Quality Certifications: The quality of raw materials and the presence of certifications (e.g., ASTM, ISO) can influence pricing. Suppliers who provide verifiable quality assurances may charge a premium, but the benefits often justify the investment.

-

Supplier Factors: Supplier reputation, reliability, and relationship history can impact pricing. Long-term partnerships may result in more favorable terms, while new suppliers might require more stringent negotiations.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can affect logistics costs and responsibilities. Buyers should select terms that align with their logistical capabilities and cost structures.

Buyer Tips

-

Negotiation: Leverage competitive bids from multiple suppliers to negotiate pricing. Establishing long-term relationships can also provide leverage for better terms.

-

Cost-Efficiency: Focus on the Total Cost of Ownership rather than just the purchase price. Consider maintenance, operational efficiency, and potential downtime when evaluating suppliers.

-

Pricing Nuances: Be aware that international sourcing can introduce complexities, such as currency fluctuations and regulatory changes. Buyers should account for these factors in their budgeting.

-

Market Research: Stay informed about global market trends affecting stainless steel prices. This knowledge can empower buyers to make timely purchasing decisions and avoid market peaks.

Disclaimer

The prices mentioned are indicative and may vary based on market conditions, supplier negotiations, and specific project requirements. Buyers are encouraged to conduct thorough research and engage with multiple suppliers to obtain accurate pricing tailored to their needs.

Spotlight on Potential 316 stainless Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘316 stainless’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for 316 stainless

Understanding the technical properties and terminology associated with 316 stainless steel is crucial for B2B buyers, especially when navigating procurement processes across different regions. Here are the essential specifications and terms that will aid in making informed decisions.

Key Technical Properties

-

Material Grade

– Definition: 316 stainless steel is categorized under various grades based on its chemical composition and mechanical properties. The most common grades are 316, 316L (low carbon), and 316H (high carbon).

– Importance: Selecting the appropriate grade is vital for ensuring material performance in specific applications, such as high-temperature environments or those requiring enhanced corrosion resistance. Buyers should evaluate their project requirements against the properties of each grade. -

Tensile Strength

– Definition: This refers to the maximum amount of tensile (pulling) stress that a material can withstand before failure, typically measured in megapascals (MPa) or pounds per square inch (psi).

– Importance: For B2B buyers, understanding tensile strength is essential when assessing a material’s ability to withstand operational stresses in applications ranging from marine engineering to chemical processing. Higher tensile strength often translates to better durability and longevity. -

Corrosion Resistance

– Definition: The ability of stainless steel to resist degradation caused by environmental factors, such as moisture, chemicals, and saltwater.

– Importance: Given that 316 stainless steel is particularly resistant to pitting and crevice corrosion, it is ideal for applications in corrosive environments. Buyers should prioritize suppliers that provide certifications verifying the corrosion resistance of their materials. -

Yield Strength

– Definition: The stress at which a material begins to deform plastically. Yield strength is typically lower than tensile strength and is a critical factor in structural applications.

– Importance: Understanding yield strength helps buyers determine how much load a component can handle before it permanently deforms. This is crucial for ensuring safety and reliability in high-stress applications. -

Elongation at Break

– Definition: This property measures how much a material can stretch or deform before breaking, expressed as a percentage.

– Importance: High elongation indicates good ductility, which is beneficial for applications requiring forming or bending. B2B buyers should ensure that the materials they procure can accommodate the required processing methods without compromising integrity.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships is crucial for buyers who need to source parts that meet specific standards or compatibility with existing systems. -

MOQ (Minimum Order Quantity)

– Definition: The smallest amount of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers plan their procurement strategies, especially when considering budget constraints and storage capacities. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting a quote for specific products or services.

– Importance: An RFQ is essential for comparing prices and terms from multiple suppliers, enabling informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A series of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers.

– Importance: Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risks, ensuring smoother transactions in international trade. -

Lead Time

– Definition: The time it takes from placing an order to receiving the product.

– Importance: For B2B buyers, understanding lead times is critical for project planning and inventory management. Delays can impact production schedules and profitability.

By grasping these essential properties and terminologies, B2B buyers can enhance their sourcing strategies, leading to better procurement decisions and project outcomes.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the 316 stainless Sector

Global drivers significantly shape the market for 316 stainless steel, influencing sourcing strategies and procurement decisions among international B2B buyers. Key trends include increasing demand for corrosion-resistant materials in marine and chemical industries, driven by rising infrastructure projects in coastal regions and harsher environmental regulations. The growing adoption of digital sourcing platforms allows buyers from Africa, South America, the Middle East, and Europe to access a wider range of suppliers and compare pricing and quality more effectively. Additionally, supply chain diversification is becoming essential, as companies seek to mitigate risks posed by geopolitical tensions and pandemic-related disruptions. Buyers are encouraged to prioritize suppliers with robust quality assurance practices and reliable certifications to ensure compliance with international standards, which is particularly vital in markets like Germany and Saudi Arabia.

Emerging technologies such as AI and blockchain are also transforming sourcing processes, enabling better tracking of materials and enhancing transparency in the supply chain. For instance, blockchain can help verify the provenance of 316 stainless steel, which is crucial for buyers concerned about quality and ethical sourcing. Furthermore, sustainability is increasingly influencing procurement decisions, with companies focusing on sourcing materials that minimize environmental impact while meeting performance requirements.

Sustainability & Ethical Sourcing in B2B

The environmental impact of sourcing 316 stainless steel cannot be overstated. The production process, particularly the extraction of raw materials, contributes to carbon emissions and resource depletion. Therefore, it’s imperative for B2B buyers to consider ethical sourcing practices. This includes choosing suppliers who adhere to sustainable mining and manufacturing practices, thereby reducing their ecological footprint.

Green certifications such as ISO 14001 for environmental management and certifications related to recycled content are becoming more important in procurement decisions. Buyers should seek suppliers that demonstrate a commitment to sustainability through the use of recycled stainless steel or eco-friendly production methods. This not only enhances the brand reputation but also aligns with global sustainability goals, which is increasingly important for customers and regulatory bodies alike.

In the context of the 316 stainless sector, employing a comprehensive sustainability strategy can lead to improved long-term viability and cost savings while addressing the growing consumer demand for environmentally responsible products.

Brief Evolution/History

The development of 316 stainless steel dates back to the 1920s when it was first introduced as an improvement over the earlier 304 grade. Its formulation included molybdenum to enhance corrosion resistance, especially in chloride environments. Over the decades, 316 stainless steel has evolved to meet the needs of various industries, leading to the creation of variants like 316L, 316H, and 316Ti, each tailored for specific applications. This evolution reflects the growing complexity of industrial requirements and the ongoing need for materials that can withstand increasingly harsh conditions, thus solidifying 316 stainless steel’s position as a preferred choice for B2B applications worldwide.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of 316 stainless

-

What factors should I consider when vetting suppliers for 316 stainless steel?

When vetting suppliers, prioritize certifications such as ISO 9001, which ensure quality management systems. Assess their production capacity and lead times to meet your project timelines. Investigate their reputation through customer reviews and industry references. Evaluate their quality assurance processes, including material traceability and testing methods, to confirm compliance with international standards. Lastly, consider their geographical location and logistical capabilities, especially if you’re sourcing from regions with complex supply chains. -

Can 316 stainless steel be customized to meet specific project requirements?

Yes, many suppliers offer customization options for 316 stainless steel products. This includes variations in dimensions, finishes, and mechanical properties to fit your specific needs. When requesting customization, provide detailed specifications and drawings to avoid misunderstandings. It’s essential to confirm with the supplier whether they can meet your quality standards and lead times for customized orders. Additionally, inquire about any extra costs associated with customization to ensure it aligns with your budget. -

What are typical minimum order quantities (MOQs) and lead times for 316 stainless steel?

MOQs for 316 stainless steel can vary widely based on the supplier and product type, often ranging from 500 kg to several tons. Lead times typically range from 2 to 12 weeks, depending on the supplier’s inventory, production capacity, and your order’s complexity. It’s crucial to communicate your needs upfront to negotiate favorable terms. Keep in mind that longer lead times may be necessary for customized products or suppliers located in regions with less robust manufacturing infrastructures. -

What payment options are commonly available for international transactions involving 316 stainless steel?

Payment options for international transactions may include wire transfers, letters of credit, or escrow services. Wire transfers are common, but letters of credit provide additional security for both parties, ensuring that payment is made only upon meeting specified conditions. Discuss payment terms early in negotiations to avoid misunderstandings. Be aware of currency fluctuations and consider using hedging strategies if you are making large purchases in a foreign currency to protect your budget.

Illustrative Image (Source: Google Search)

-

How can I ensure the quality of 316 stainless steel products I am sourcing?

To ensure quality, request material test reports and certificates of compliance from suppliers. These documents should detail the chemical composition and mechanical properties of the steel. Engage third-party inspection services if necessary to conduct quality assurance audits at the supplier’s facility. Familiarize yourself with international standards such as ASTM A240 for stainless steel to set benchmarks. Additionally, consider establishing a quality control plan that includes periodic checks throughout the production and delivery processes. -

What logistics considerations should I keep in mind when sourcing 316 stainless steel internationally?

Logistics considerations include shipping methods, customs regulations, and import duties that may apply to your region. Evaluate whether you will use air freight for faster delivery or sea freight for cost-effectiveness, especially for bulk orders. Work with a logistics partner experienced in international trade to navigate customs documentation and compliance. Additionally, consider the supplier’s ability to handle logistics, including packaging and transportation, to ensure safe delivery and minimize delays. -

How should I handle disputes with suppliers of 316 stainless steel?

To handle disputes effectively, first, refer to your contractual agreement for terms related to conflict resolution. Open a line of communication with the supplier to address issues directly and seek an amicable resolution. If necessary, involve a neutral third party for mediation. Document all communications and agreements to support your position. In cases of unresolved disputes, consider legal avenues based on the terms of the contract, which may specify arbitration or litigation procedures and the governing law. -

What are the key certifications to look for when sourcing 316 stainless steel?

When sourcing 316 stainless steel, look for certifications such as ISO 9001 for quality management and ISO 14001 for environmental management. Additionally, ASTM and ASME certifications confirm compliance with specific material and manufacturing standards. For specialized applications, such as medical devices or food processing, inquire about FDA or EU regulations compliance. These certifications not only ensure the quality and safety of the materials but also enhance your credibility when presenting sourced materials to clients or regulatory bodies.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for 316 stainless

In summary, effective strategic sourcing of 316 stainless steel is vital for B2B buyers looking to enhance project longevity and operational efficiency. The unique properties of 316 stainless steel, including its exceptional corrosion resistance and mechanical strength, make it a preferred choice across various industries such as marine engineering, chemical processing, and medical applications. By carefully evaluating suppliers, understanding the nuances of different grades, and ensuring compliance with international standards, buyers can secure high-quality materials that meet their specific needs.

As international markets evolve, particularly in regions like Africa, South America, the Middle East, and Europe, the demand for reliable and durable materials will continue to grow. Buyers are encouraged to leverage this opportunity by establishing strong relationships with reputable suppliers and staying informed about market trends. Emphasizing strategic sourcing will not only optimize procurement processes but also contribute to sustainable business practices.

Looking ahead, now is the time to capitalize on the advantages offered by 316 stainless steel. Engage with trusted suppliers, explore innovative sourcing strategies, and position your business for success in an increasingly competitive landscape.