Master Sourcing Loudspeaker Voice Coils: Your Comprehensive

Introduction: Navigating the Global Market for loudspeaker voice coil

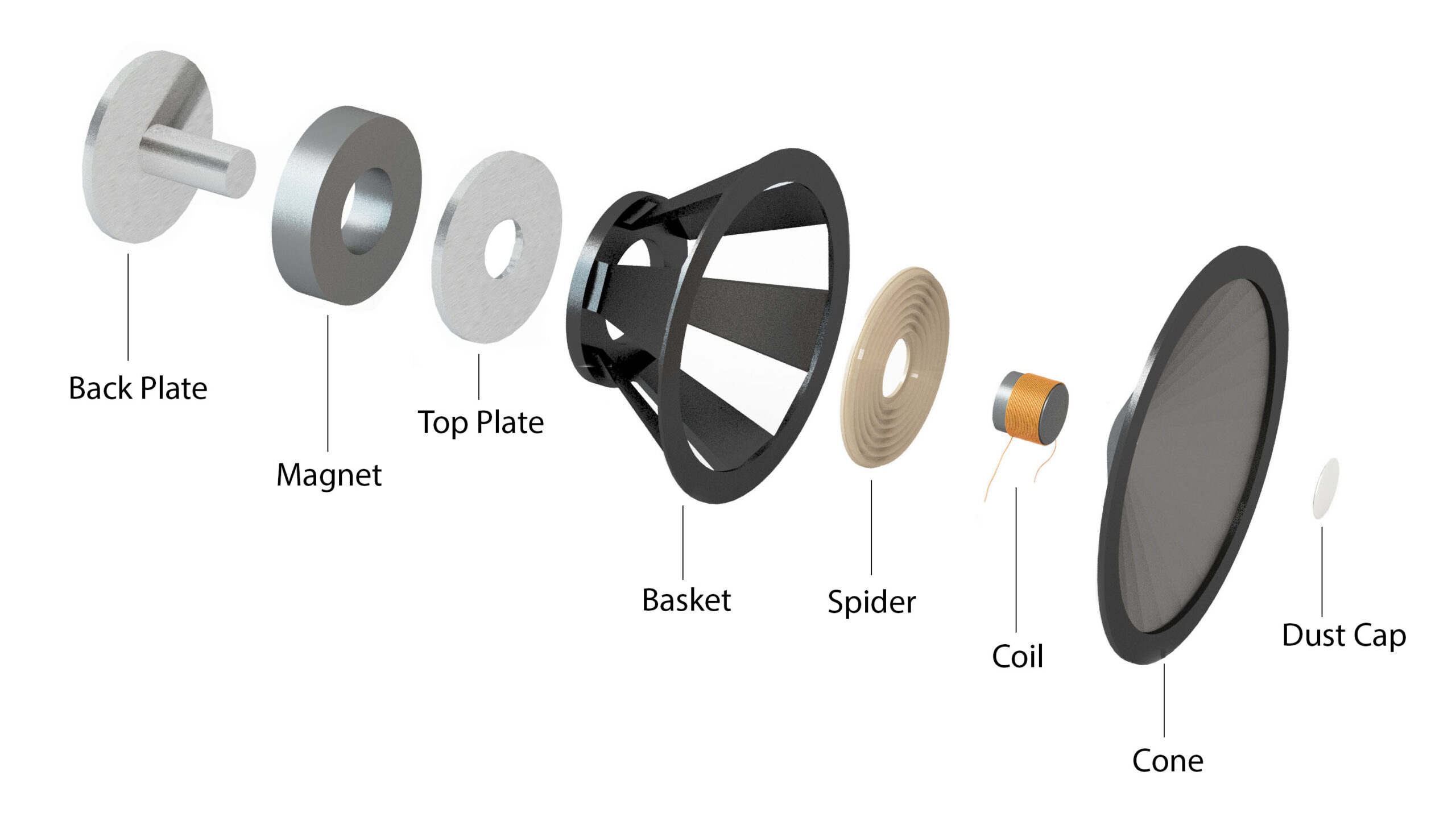

Navigating the global market for loudspeaker voice coils requires a keen understanding of their pivotal role in audio technology. As the component that converts electrical signals into the mechanical vibrations that produce sound, the voice coil is fundamental to the performance of any loudspeaker system. Whether you’re sourcing components for professional audio equipment or consumer electronics, the quality and specifications of voice coils can significantly influence sound fidelity and reliability.

This comprehensive guide is designed to empower international B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe. It covers a range of essential topics such as types of voice coils, materials used, manufacturing processes, quality control, leading suppliers, and cost considerations. Additionally, a dedicated FAQ section addresses common queries, helping buyers navigate complexities with ease.

By equipping you with actionable insights and detailed knowledge, this guide aims to enhance your sourcing decisions, ensuring that you select the right voice coil components tailored to your specific needs. In a competitive global market, understanding these nuances not only aids in optimizing product performance but also supports cost-effective procurement strategies, ultimately driving business growth and customer satisfaction in your respective markets.

Understanding loudspeaker voice coil Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Copper Voice Coils | Made from copper wire; excellent conductivity. | High-fidelity audio systems, public address systems. | Pros: Great sound quality, efficient energy conversion. Cons: Prone to overheating, heavier. |

| Aluminum Voice Coils | Lighter than copper; often used in portable systems. | Mobile audio, consumer electronics. | Pros: Lightweight, better thermal management. Cons: Less efficient than copper, can distort at high volumes. |

| Flat Wire Voice Coils | Uses flat wire for winding; higher power handling. | Professional audio equipment, subwoofers. | Pros: Handles more power, reduces distortion. Cons: More complex manufacturing process, costlier. |

| High-Temperature Voice Coils | Designed to withstand extreme temperatures. | Industrial applications, high-performance audio. | Pros: Durable under high stress, long lifespan. Cons: Higher cost, may require specialized suppliers. |

| Custom Voice Coils | Tailored designs for specific applications. | Niche markets, specialized audio systems. | Pros: Perfect fit for unique needs, optimized performance. Cons: Longer lead times, potentially higher costs. |

Copper Voice Coils

Copper voice coils are the standard in many loudspeaker applications due to their excellent electrical conductivity. This type is particularly suited for high-fidelity audio systems and public address systems where sound quality is paramount. When purchasing, buyers should consider the balance between sound quality and the potential for overheating, especially in high-power applications. Copper coils offer superior performance but can be heavier, which may affect portability.

Aluminum Voice Coils

Aluminum voice coils are favored in portable audio equipment due to their lightweight nature. They are commonly used in mobile audio systems and consumer electronics. Buyers should weigh the benefits of lower weight and improved thermal management against the fact that aluminum coils can be less efficient and may distort at higher volumes. For applications where weight and portability are critical, aluminum voice coils are a strong choice.

Flat Wire Voice Coils

Flat wire voice coils are designed to handle higher power levels and are often used in professional audio equipment and subwoofers. Their design minimizes distortion, making them suitable for high-performance audio applications. However, they come with a more complex manufacturing process, which can increase costs. Buyers looking for robust performance in demanding audio environments should consider flat wire options, keeping in mind the investment required.

High-Temperature Voice Coils

High-temperature voice coils are engineered to withstand extreme operating conditions, making them ideal for industrial applications and high-performance audio systems. They offer durability and a longer lifespan under stress. However, these coils can be more expensive and may require sourcing from specialized suppliers. B2B buyers should evaluate the necessity of high-temperature capabilities against their budget and application requirements.

Custom Voice Coils

Custom voice coils are designed to meet specific application needs, providing a tailored solution for niche markets and specialized audio systems. While they offer optimized performance and a perfect fit, buyers must be prepared for longer lead times and potentially higher costs. For companies with unique requirements, custom voice coils can deliver significant advantages, but careful planning and consideration of the associated costs are essential.

Related Video: The Making of a loudspeaker voice coil

Key Industrial Applications of loudspeaker voice coil

| Industry/Sector | Specific Application of loudspeaker voice coil | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Consumer Electronics | Home Audio Systems | Enhanced sound quality and user experience | Ensure compatibility with existing systems and quality certifications |

| Automotive | In-Car Entertainment Systems | Improved audio fidelity and customer satisfaction | Focus on durability and resistance to environmental factors |

| Public Address Systems | Event Sound Reinforcement | Reliable sound delivery in large venues | Consider power handling capacity and installation requirements |

| Professional Audio | Live Sound Equipment | High-performance audio for concerts and events | Look for high-temperature performance and customization options |

| Industrial Automation | Machine Alarm Systems | Effective alert systems for safety and operational efficiency | Evaluate the voice coil’s response time and integration capabilities |

Consumer Electronics

In the consumer electronics sector, loudspeaker voice coils are critical components in home audio systems. They convert electrical signals into sound, enhancing the audio quality of music and movies. Buyers should prioritize sourcing voice coils that ensure compatibility with various audio formats and devices. Additionally, certifications for sound fidelity and safety standards are essential to guarantee a superior user experience, particularly in competitive markets like Europe and South America.

Automotive

For the automotive industry, loudspeaker voice coils are integral to in-car entertainment systems. They are responsible for producing high-quality sound that enhances the driving experience. Buyers need to consider the durability of voice coils, as they must withstand vibrations and temperature fluctuations within vehicles. Sourcing from manufacturers that provide robust testing and quality assurance can mitigate potential failures and improve customer satisfaction, especially in regions with diverse climates like Africa and the Middle East.

Public Address Systems

In public address systems, loudspeaker voice coils play a vital role in sound reinforcement for events and gatherings. They ensure that announcements and music are delivered clearly across large areas. Buyers should focus on sourcing voice coils that offer high power handling capabilities to manage extensive sound pressure levels. Moreover, understanding the installation requirements and ensuring the components are suitable for the specific venue types can significantly enhance sound delivery and audience engagement.

Professional Audio

The professional audio sector relies on high-performance loudspeaker voice coils for live sound equipment used in concerts and events. These voice coils must deliver excellent audio fidelity and can handle high power levels without distortion. Buyers should seek suppliers that offer customization options to meet specific sound requirements and environmental conditions. Additionally, sourcing voice coils with high-temperature performance can prevent overheating during prolonged use, a critical consideration for live events.

Industrial Automation

In industrial automation, loudspeaker voice coils are utilized in machine alarm systems to alert personnel of operational issues or safety hazards. These systems require voice coils that can respond quickly and operate reliably in demanding environments. Buyers should evaluate the response time of the voice coils and their integration capabilities with existing alarm systems. Ensuring that the voice coils meet industry standards for safety and reliability is crucial, particularly in sectors such as manufacturing and logistics.

Strategic Material Selection Guide for loudspeaker voice coil

When selecting materials for loudspeaker voice coils, international B2B buyers need to consider several factors that impact performance, durability, and cost. The most common materials used for voice coils include copper, aluminum, polyimide, and fiberglass. Each material has distinct properties, advantages, and limitations that can affect the final product’s performance and suitability for various applications.

Copper

Key Properties: Copper is known for its excellent electrical conductivity, which is essential for efficient sound production. It typically operates well under high temperatures, with a melting point of around 1,984°F (1,085°C).

Pros & Cons: The primary advantage of copper is its superior conductivity, leading to better sound quality and lower energy loss. However, it is relatively heavy and can be more expensive than alternatives. Additionally, copper is prone to corrosion, which can affect long-term durability.

Impact on Application: Copper is ideal for high-performance audio applications where sound fidelity is paramount. Its weight may be a concern in portable applications.

Considerations for International Buyers: Buyers should ensure compliance with international standards for electrical components, such as IEC and ASTM. In regions like Europe and South America, the preference for high-quality audio products may favor copper despite its higher cost.

Aluminum

Key Properties: Aluminum offers good electrical conductivity, though not as high as copper. It is lightweight, with a melting point of about 1,221°F (660°C), making it suitable for applications where weight is a critical factor.

Pros & Cons: The lightweight nature of aluminum makes it an excellent choice for portable speakers. It is also more resistant to corrosion compared to copper. However, it has lower conductivity, which can impact sound quality.

Impact on Application: Aluminum is often used in consumer electronics and portable audio devices, where weight savings are crucial.

Considerations for International Buyers: Aluminum’s lower cost and lightweight properties can appeal to manufacturers in developing regions like Africa and South America, where cost efficiency is vital. Compliance with local standards is essential, particularly in terms of material sourcing and environmental regulations.

Polyimide

Key Properties: Polyimide is a high-performance polymer known for its excellent thermal stability and chemical resistance. It can withstand temperatures up to 500°F (260°C) without significant degradation.

Pros & Cons: The key advantage of polyimide is its ability to maintain structural integrity under extreme conditions, making it suitable for high-power applications. However, it is more expensive than traditional metals and may require specialized manufacturing processes.

Impact on Application: Polyimide is ideal for high-end audio systems where performance under stress is critical. Its use in voice coils can enhance the longevity of the product.

Considerations for International Buyers: Buyers should be aware of the specific manufacturing capabilities required to work with polyimide. Compliance with international safety and environmental standards is crucial, especially in Europe, where regulations are stringent.

Fiberglass

Key Properties: Fiberglass is a composite material known for its strength and lightweight properties. It has good electrical insulation properties and can withstand moderate temperatures.

Pros & Cons: Fiberglass is cost-effective and provides good durability, making it suitable for a variety of applications. However, it lacks the electrical conductivity of metals, which can limit its use in high-fidelity audio applications.

Impact on Application: Fiberglass is often used in lower-end speaker systems where cost is a significant factor. It can provide adequate performance in less demanding applications.

Considerations for International Buyers: Buyers in emerging markets may find fiberglass appealing due to its low cost. However, they should ensure compliance with local environmental regulations regarding composite materials.

Summary Table

| Material | Typical Use Case for loudspeaker voice coil | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | High-performance audio systems | Superior conductivity | Heavy and prone to corrosion | High |

| Aluminum | Portable and consumer electronics | Lightweight and corrosion-resistant | Lower conductivity than copper | Medium |

| Polyimide | High-end audio systems | Excellent thermal stability | Higher manufacturing complexity | High |

| Fiberglass | Budget-friendly speaker systems | Cost-effective and durable | Poor electrical conductivity | Low |

This guide provides a comprehensive overview of materials used in loudspeaker voice coils, helping international B2B buyers make informed decisions based on their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for loudspeaker voice coil

Loudspeaker voice coils are critical components in audio systems, and their manufacturing processes and quality assurance measures are paramount for ensuring optimal performance and reliability. This section provides an in-depth look at the manufacturing stages, key techniques involved, and the quality control measures that B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should consider when sourcing these components.

Manufacturing Processes

The manufacturing of loudspeaker voice coils involves several key stages, each requiring precision and expertise. The main stages are as follows:

1. Material Preparation

The quality of the materials used significantly impacts the final product. Key materials include:

- Wire: Typically made from copper or aluminum, chosen for their electrical conductivity.

- Bobbin: Often crafted from lightweight, durable materials that can withstand the heat generated during operation.

- Adhesives: Selected based on their curing properties and temperature tolerance, crucial for maintaining structural integrity.

Before production, these materials undergo thorough inspections to ensure they meet specified standards.

2. Forming

This stage includes the initial shaping of the voice coil components:

- Winding the Coil: The wire is wound around the bobbin to create the coil. This can be done using automated winding machines that ensure consistent tension and alignment.

- Bobbin Shaping: The bobbin is formed to fit precisely within the loudspeaker’s magnetic gap, minimizing the risk of rubbing or damage during operation.

Attention to detail in this stage is critical, as the geometry of the coil affects both performance and sound quality.

3. Assembly

Once the individual components are prepared, they are assembled:

- Bonding: The voice coil is attached to the cone using high-performance adhesives. This process often requires precise application to avoid excess adhesive that could dampen sound quality.

- Final Assembly: The completed voice coil assembly is integrated into the loudspeaker chassis, ensuring that all components align correctly for optimal performance.

4. Finishing

The finishing stage involves protective treatments and final inspections:

- Coating: Some manufacturers apply protective coatings to enhance durability and resistance to environmental factors.

- Curing: Post-assembly, the coils may undergo a curing process to solidify adhesives and enhance their thermal resistance.

Key Techniques

Several techniques are employed throughout the manufacturing process to ensure quality and performance:

- Wet Winding: This technique involves applying adhesive during the winding process, allowing for better bonding and heat resistance.

- Thermal Management: Proper heat dissipation techniques are essential to prevent damage during high-power operations.

Quality Assurance

Quality assurance is critical to maintaining product reliability and performance. The following international standards and checkpoints should be considered:

International Standards

- ISO 9001: This standard outlines requirements for a quality management system, ensuring that manufacturers consistently meet customer and regulatory requirements.

- CE Marking: For products sold within the European Economic Area, CE marking ensures compliance with safety and environmental protection standards.

Industry-Specific Standards

- API Standards: In some regions, adherence to API standards may be relevant, particularly for high-performance or specialized applications.

Quality Control Checkpoints

Quality control (QC) is integral at various stages of the manufacturing process:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitoring production processes to identify and rectify issues in real-time.

- Final Quality Control (FQC): Conducting thorough inspections of finished products, including functional testing and performance assessments.

Common Testing Methods

To ensure that voice coils meet the required specifications, several testing methods are commonly employed:

- Electrical Testing: Verifying resistance and inductance to ensure proper function.

- Thermal Testing: Assessing performance under heat stress to simulate real-world operating conditions.

- Acoustic Testing: Evaluating sound output quality and frequency response to ensure alignment with design specifications.

Verification of Supplier QC

For B2B buyers, particularly those in diverse regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential:

- Supplier Audits: Conduct regular audits of suppliers to assess their adherence to quality standards and manufacturing processes.

- Quality Reports: Request detailed quality assurance reports that outline testing results and compliance with international standards.

- Third-Party Inspections: Engage third-party inspection services to provide an unbiased assessment of product quality and compliance.

QC/Cert Nuances for International B2B Buyers

When sourcing loudspeaker voice coils internationally, buyers should be aware of specific nuances:

- Cultural Differences: Understanding local manufacturing practices and quality expectations can help in establishing effective communication with suppliers.

- Regulatory Compliance: Ensure that products meet the regulatory requirements of the target market, particularly regarding safety and environmental standards.

- Cost vs. Quality: While competitive pricing is essential, prioritize suppliers that demonstrate a commitment to quality assurance over those that offer the lowest prices.

By comprehensively understanding the manufacturing processes and quality assurance measures for loudspeaker voice coils, B2B buyers can make informed decisions that enhance their product offerings and ensure customer satisfaction.

Comprehensive Cost and Pricing Analysis for loudspeaker voice coil Sourcing

The cost structure and pricing analysis for sourcing loudspeaker voice coils is essential for B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. Understanding the cost components and price influencers can significantly impact your procurement strategy.

Cost Components

-

Materials: The primary materials used in voice coil manufacturing include copper or aluminum wire, bobbin substrates (often made from lightweight materials), adhesives, and insulation. The choice of materials directly affects the cost, with higher-quality or specialty materials commanding premium prices.

-

Labor: Labor costs vary by region and depend on the complexity of the voice coil design. Skilled labor is essential for precise winding and assembly, especially for high-performance coils. In regions with lower labor costs, manufacturers may offer competitive pricing, but this can come at the expense of quality.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, equipment maintenance, and administrative expenses. Manufacturers with advanced production facilities may have higher overheads but can offer better quality assurance and faster turnaround times.

-

Tooling: Initial tooling costs can be significant, especially for custom voice coils. These costs include the design and production of molds and fixtures necessary for specific configurations. Buyers should inquire about tooling amortization in pricing, especially for larger orders.

-

Quality Control (QC): Effective QC processes are crucial for ensuring product reliability. Costs associated with testing and inspection should be factored into the total price. Buyers should seek suppliers with robust QC certifications, as this can prevent costly returns and replacements.

-

Logistics: Shipping costs vary widely based on distance, shipping method, and the Incoterms agreed upon. Understanding the total logistics costs, including customs duties and taxes, is critical for accurate budgeting.

-

Margin: Supplier margins can vary based on market conditions and competition. A clear understanding of market pricing can help buyers negotiate better deals.

Price Influencers

-

Volume/MOQ: Prices often decrease with larger order volumes. Understanding the minimum order quantity (MOQ) for different suppliers can help buyers optimize their costs.

-

Specifications and Customization: Custom voice coils tailored to specific applications or with unique specifications typically incur additional costs. Be prepared for higher prices if you require specialized designs.

-

Materials and Quality: Higher-quality materials and certifications (e.g., ISO, RoHS compliance) can increase costs but often result in better performance and durability.

-

Supplier Factors: The reputation and reliability of the supplier play a significant role in pricing. Established suppliers with a proven track record may charge more, but they often provide better service and product quality.

-

Incoterms: The terms of shipping can significantly influence the final cost. Common terms like FOB (Free on Board) or CIF (Cost, Insurance, Freight) affect who bears the shipping costs and risks, impacting overall pricing.

Buyer Tips

-

Negotiation: Always negotiate terms, especially for large orders. Leverage volume commitments to secure better pricing or additional services.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, shipping, and potential maintenance costs. Cheaper options may lead to higher long-term costs due to lower reliability.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import tariffs, and local taxes that can affect pricing when sourcing from different regions. Establishing relationships with local suppliers can mitigate some of these risks.

-

Due Diligence: Conduct thorough research on suppliers, including reviews and certifications, to ensure product quality and reliability. This will help avoid costly mistakes and ensure a steady supply chain.

Disclaimer

Prices can vary significantly based on market conditions, supplier negotiations, and specific order requirements. The information provided is for indicative purposes only and should be verified with suppliers.

Spotlight on Potential loudspeaker voice coil Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘loudspeaker voice coil’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for loudspeaker voice coil

Loudspeaker voice coils are essential components in audio systems, converting electrical signals into sound. Understanding the technical properties and trade terminology associated with voice coils is crucial for B2B buyers in various regions, including Africa, South America, the Middle East, and Europe. This knowledge aids in making informed purchasing decisions, ensuring compatibility and performance in their audio applications.

Key Technical Properties

-

Material Grade

– Voice coils are typically made from copper or aluminum wire, which are chosen for their excellent conductivity. The material grade affects the coil’s efficiency and thermal performance. Higher-grade materials can withstand more heat, which is vital for high-power applications, reducing the risk of failure during prolonged use. -

Winding Configuration

– The winding configuration refers to how the wire is wound around the bobbin. This can be single-layer or multi-layer, with various geometries like flat or round wire. The choice of winding impacts the coil’s impedance and power handling capabilities, influencing the overall performance of the loudspeaker. -

Bobbin Height and Diameter

– The bobbin serves as the core around which the wire is wound. Its height and diameter are critical for determining the voice coil’s clearance within the magnetic gap. Tighter tolerances can improve sound quality by reducing distortion, making this specification crucial for high-fidelity audio applications. -

Impedance Rating

– Impedance, measured in ohms, is a key specification that determines how much electrical resistance the voice coil offers. Common values include 4, 6, or 8 ohms. Understanding impedance is vital when matching voice coils with amplifiers to ensure optimal performance and avoid damage. -

Power Handling Capacity

– This specification indicates the maximum power the voice coil can handle without overheating or failing. It is expressed in watts and is crucial for buyers to ensure their speakers can operate effectively within the required power range of their audio systems. -

Thermal Stability

– The ability of the voice coil to maintain performance under varying temperatures is essential, especially in high-power applications. Thermal stability is often enhanced through the use of specific adhesives and materials that can withstand heat without degrading, ensuring longevity and reliability.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is important for buyers looking for specific voice coil configurations or custom solutions tailored to their applications. -

MOQ (Minimum Order Quantity)

– MOQ represents the smallest number of units a supplier is willing to sell. This term is critical for B2B buyers, as it directly affects inventory management and cost-efficiency. Knowing the MOQ can help businesses negotiate better terms and plan their purchases accordingly. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and availability for specific products or services. For buyers, this is an essential step in procurement, allowing them to gather competitive bids and make informed purchasing decisions. -

Incoterms

– International Commercial Terms (Incoterms) define the responsibilities of buyers and sellers in international trade. Understanding these terms helps B2B buyers navigate shipping, insurance, and delivery responsibilities, reducing the risk of disputes and ensuring smooth transactions. -

Lead Time

– Lead time refers to the amount of time it takes from placing an order to receiving the goods. For B2B buyers, understanding lead times is crucial for project planning and inventory management, ensuring that they can meet their operational deadlines.

Illustrative Image (Source: Google Search)

- Customization

– This term refers to the ability to alter standard products to meet specific customer requirements. Customization is increasingly important for B2B buyers who need tailored voice coil solutions to fit unique applications or performance criteria.

By grasping these essential technical properties and trade terminologies, international B2B buyers can make more strategic decisions regarding loudspeaker voice coils, enhancing their audio offerings while ensuring compatibility and performance.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the loudspeaker voice coil Sector

Market Overview & Key Trends

The loudspeaker voice coil market is witnessing significant transformation driven by advancements in technology, evolving consumer preferences, and sustainability initiatives. Global demand for high-quality audio products is increasing, particularly in regions like Africa, South America, the Middle East, and Europe. This growth is fueled by rising disposable incomes, urbanization, and a burgeoning entertainment industry that is heavily reliant on audio technologies.

One of the key trends impacting the market is the shift towards miniaturization and enhanced performance. Manufacturers are focusing on developing smaller, more efficient voice coils that deliver superior sound quality while using less power. This trend is particularly relevant for portable audio devices, which are gaining traction in emerging markets. Additionally, the integration of smart technology into audio devices is influencing sourcing strategies, as buyers seek components that are compatible with IoT and smart home systems.

Illustrative Image (Source: Google Search)

Emerging sourcing strategies are also shaping the market dynamics. International buyers are increasingly looking for suppliers who can provide not only high-quality products but also flexibility in production and customization. Companies that can adapt to varying market demands and offer rapid prototyping are becoming more desirable partners. Furthermore, as competition intensifies, buyers are emphasizing long-term partnerships with suppliers that can ensure consistent product quality and reliability.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a cornerstone of sourcing strategies in the loudspeaker voice coil sector. Environmental concerns are driving companies to evaluate the lifecycle of their products, from raw materials to end-of-life disposal. The impact of voice coil production on natural resources and carbon emissions is prompting buyers to prioritize suppliers who adopt eco-friendly practices.

Ethical sourcing is crucial for fostering a responsible supply chain. Buyers should seek suppliers that adhere to international labor standards and promote fair working conditions. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as benchmarks for evaluating suppliers’ commitment to sustainability.

Moreover, the use of “green” materials—such as recycled metals for wire and biodegradable bobbins—can enhance a company’s market appeal while reducing its environmental footprint. As consumers become more eco-conscious, companies that can demonstrate a commitment to sustainability are likely to gain a competitive edge, making it essential for B2B buyers to integrate these values into their sourcing decisions.

Brief Evolution/History

The loudspeaker voice coil has evolved significantly since its inception in the early 20th century. Initially crafted from simple materials, advancements in technology have led to the development of sophisticated designs that enhance performance and durability. The introduction of new materials, such as advanced adhesives and specialized wire types, has improved the efficiency and sound quality of voice coils.

During the late 20th century, the globalization of manufacturing shifted much of the production to Asia and Mexico, driven by cost efficiencies. However, the focus has increasingly moved towards high-performance coils that cater to niche markets, such as professional audio and high-fidelity home systems. This evolution reflects a broader trend in the audio industry, where quality and performance have become paramount, influencing sourcing decisions for international B2B buyers in today’s competitive landscape.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of loudspeaker voice coil

-

What should I look for when vetting suppliers of loudspeaker voice coils?

When vetting suppliers, focus on their industry experience, production capabilities, and reputation. Verify their certifications, such as ISO 9001, to ensure quality management standards. Request samples to assess the quality of their voice coils and inquire about their manufacturing processes. Consider their ability to provide customization options tailored to your specific needs, as well as their responsiveness to inquiries. Lastly, assess their logistics capabilities to ensure they can meet your delivery timelines. -

Can I customize loudspeaker voice coils for my specific applications?

Yes, many suppliers offer customization options for loudspeaker voice coils, including variations in winding techniques, wire gauge, and bobbin materials. Be clear about your requirements, such as impedance, power handling, and size, when communicating with suppliers. Discuss any specific performance characteristics you need, such as enhanced thermal resistance or reduced distortion. Engaging in a collaborative design process can lead to a more effective product tailored to your unique application. -

What are the typical minimum order quantities (MOQ) and lead times for voice coils?

Minimum order quantities can vary significantly among suppliers, often ranging from 50 to 500 units depending on the complexity of the voice coil design. Lead times typically range from 2 to 8 weeks, influenced by factors such as customization, production schedules, and shipping logistics. Discuss your project timelines upfront to ensure that the supplier can accommodate your needs. Some suppliers may offer expedited services for urgent orders, but this could come at a premium. -

What payment terms are common in international B2B transactions for voice coils?

Common payment terms include a deposit upfront (usually 30-50%) with the balance due upon completion or prior to shipping. Some suppliers may accept letters of credit (LC) or payment through escrow services for added security. Ensure you clarify payment terms before placing an order to avoid misunderstandings. Additionally, consider the implications of currency exchange rates and transaction fees when negotiating terms, especially when dealing with suppliers from different regions. -

How can I ensure quality assurance and certifications for the voice coils I purchase?

Request documentation of quality assurance practices, including test reports and certifications. Reputable suppliers often provide details about their testing protocols, such as impedance and thermal performance assessments. Inquire about their adherence to international standards, like RoHS or REACH, especially if you’re sourcing from regions with strict regulatory requirements. Regular audits of your suppliers can also help maintain quality assurance and ensure compliance with industry standards. -

What logistics considerations should I keep in mind when sourcing voice coils internationally?

When sourcing internationally, consider shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder familiar with the specific requirements of your destination country. Ensure that the supplier provides proper documentation, including invoices and packing lists, to facilitate smooth customs clearance. Additionally, evaluate shipping insurance options to protect your investment against potential damages during transit. -

What steps can I take to resolve disputes with suppliers?

To address disputes effectively, maintain open communication with the supplier to clarify misunderstandings. Document all correspondence and agreements to provide a clear record. If issues persist, refer to the terms outlined in your purchase agreement regarding dispute resolution, which may include mediation or arbitration. It’s advisable to engage legal counsel familiar with international trade laws if the situation escalates. Establishing a good relationship with your supplier can also help prevent disputes from arising. -

What are the common challenges faced when sourcing loudspeaker voice coils internationally?

Common challenges include language barriers, differing quality standards, and variations in lead times. Cultural differences may also impact business practices and communication styles. To mitigate these challenges, invest time in researching potential suppliers and their business practices. Build strong relationships with suppliers through regular communication and visits if possible. Understanding the local market dynamics and regulations can also aid in smoother transactions and better negotiation outcomes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for loudspeaker voice coil

In the evolving landscape of loudspeaker technology, strategic sourcing for voice coils remains paramount for international B2B buyers. Understanding the complexities of voice coil design—including materials, winding techniques, and performance specifications—enables buyers to select suppliers that align with their quality and cost objectives.

Key Takeaways:

- Quality Assurance: Prioritize suppliers who demonstrate expertise in manufacturing high-performance voice coils. This ensures reliability and sound fidelity in your products.

- Market Trends: Stay informed about shifts in production capabilities, particularly as sourcing increasingly moves to regions like Asia and Mexico. Leverage relationships with suppliers that maintain high standards in voice coil production.

- Customization Needs: Assess the specific requirements of your product line. Custom voice coils can enhance sound quality and differentiate your offerings in competitive markets.

As we look ahead, the demand for innovative audio solutions will continue to rise, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By investing in strategic sourcing now, you can position your business for success, ensuring that you meet the diverse needs of your customers with cutting-edge loudspeaker technology. Engage with suppliers today to secure a competitive edge in this dynamic industry.