Top 30 Beveled Gear Manufacturers for Quality Solutions

Are you struggling to find a reliable beveled gear manufacturer that meets your quality and performance standards? You’re not alone! Many businesses face the daunting task of sourcing high-quality components that ensure smooth operations. Finding the right supplier can save you time, money, and headaches in the long run. The best manufacturers not only deliver precision-engineered products but also provide exceptional customer service and innovative solutions tailored to your needs.

Imagine partnering with a factory that understands your requirements and helps you stay ahead of the competition. Ready to discover the top 30 beveled gear manufacturers that can elevate your business? Dive into our article and uncover the best options available today!

Top 30 Beveled Gear Manufacturers

Mcmaster – Metal Miter Gears Solutions

Domain: mcmaster.com

Registered: 1994 ( 31 years )

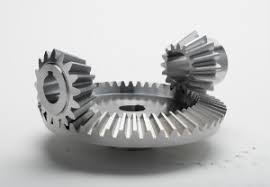

Introduction: The company offers a variety of metal miter gears, including carbon steel and stainless steel options, designed for connecting two shafts at an angle without changing speed or torque.

Iqsdirectory – Bevel Gears and Mechanical Solutions

Domain: iqsdirectory.com

Registered: 2004 ( 21 years )

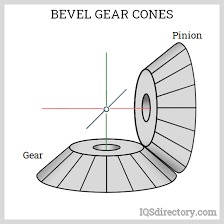

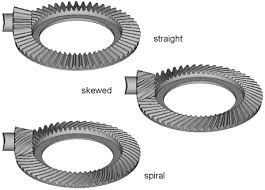

Introduction: Bevel gears are toothed, rotating devices designed to transmit mechanical energy or power between intersecting shafts, often at right angles. They include types such as straight bevel gears, spiral bevel gears, zerol bevel gears, and hypoid gears.

KHK Gears – Bevel Gears and Gear Solutions

Domain: khkgears.net

Registered: 2015 ( 10 years )

Introduction: KHK offers a variety of bevel gears including straight bevel gears and spiral bevel gears, manufactured primarily using the Gleason method. They provide gears made from various materials such as machine structural carbon steel, alloy steel, and engineering plastics, with options for polishing and different tooth finishes.

Engineers Guidebook – Bevel Gear Solutions

Domain: engineersguidebook.com

Registered: 2024 ( 1 years )

Introduction: Bevel gears are a crucial component in mechanical power transmission, designed for shafts that intersect at an angle, commonly 90 degrees. They include types such as straight bevel gears, spiral bevel gears, hypoid bevel gears, zerol bevel gears, and miter gears.

Mechanic Times – Bevel Gears for Power Transmission

Domain: mechanictimes.com

Registered: 2022 ( 3 years )

Introduction: Bevel gears designed for various mechanical applications, providing efficient power transmission at different angles.

Gearsolutions – Bevel Gear Transmission Systems

Domain: gearsolutions.com

Registered: 2008 ( 17 years )

Introduction: Bevel gears are mechanical components used to transmit power between shafts that are at an angle to each other, typically at 90 degrees.

Industrial Gearbox Solutions – Bevel Gears Specialist

Domain: industrialgearboxsolutions.com

Registered: 2024 ( 1 years )

Introduction: Bevel gears are mechanical components used to transfer power between shafts that intersect at an angle, typically 90 degrees. The company offers various types of bevel gears including straight, spiral, Zerol, and miter gears.

Linquip – Bevel Gears & Power Transmission Solutions

Domain: linquip.com

Registered: 2019 ( 6 years )

Introduction: Bevel gears are power transmission parts used to modify the direction of shaft rotation and reduce speed while improving torque between non-parallel spinning shafts. They are categorized by tooth shape into straight and curved types.

Tec Science – Bevel Gears and Solutions

Domain: tec-science.com

Registered: 2017 ( 8 years )

Introduction: Bevel gears are used to change the spatial direction of rotation, with axes typically at right angles. They include straight cut bevel gears, spiral bevel gears, planar crown gears, and crown gears.

Aludiecasting – Precision Bevel Gears Manufacturer

Domain: aludiecasting.com

Registered: 2018 ( 7 years )

Introduction: Bevel gears are mechanical components used to transmit rotation between two axes that intersect at right angles. They come in various types including straight bevel gears, spiral bevel gears, zerol bevel gears, hypoid gears, and miter gears.

Fg Machine – Bevel Gears Solutions

Domain: fg-machine.com

Registered: 2021 ( 4 years )

Introduction: Bevel gears, including straight bevel gears, spiral bevel gears, zerol bevel gears, hypoid bevel gears, and mitre gears.

Arrow Gear – Precision Bevel Gears Solutions

Domain: arrowgear.com

Registered: 1995 ( 30 years )

Introduction: Arrow Gear offers a range of bevel gears including Hypoid Gears, Spiral Bevel Gears, Right Angle Gears, Straight Bevel Gears, and Zerol® Bevel Gears.

Jlcmc – Precision Bevel Gears for Power Transmission

Domain: jlcmc.com

Registered: 2023 ( 2 years )

Introduction: Bevel gears designed for power transmission, suitable for connecting intersecting shafts, typically at a 90° angle.

Link – Bevel Gear Solutions

Domain: link.springer.com

Registered: 1997 ( 28 years )

Introduction: The company primarily offers products related to bevel gears, including technical literature and resources on their design and application.

Sciencedirect – Bevel Gears Solutions

Domain: sciencedirect.com

Registered: 1997 ( 28 years )

Introduction: Bevel gears are conical gears used to transmit rotational power between shafts that are typically at an angle of 90° to each other. They include straight bevel gears, spiral bevel gears, and zerol bevel gears.

Cnclathing – Precision Gear Solutions

Domain: cnclathing.com

Registered: 2018 ( 7 years )

Introduction: The company primarily offers a range of gears including spur gears, helical gears, bevel gears, and worm gears, focusing on their classification, functions, and technical specifications.

Linn Gear – Custom Steel Bevel Gears

Domain: linngear.com

Registered: 1995 ( 30 years )

Introduction: Linn Gear manufactures a variety of steel bevel gears with diametral pitches ranging from 3 to 16 and a 20° pressure angle. They offer stock parts and made-to-order options up to 60″ in diameter for custom ratios, materials, or configurations.

Grainger – Bevel Gears for Power Transmission

Domain: grainger.com

Registered: 1994 ( 31 years )

Introduction: Bevel gears designed for power transmission applications, available in various sizes and materials.

Boston Gear – Miter Bevel Gears Solutions

Domain: bostongear.com

Registered: 1997 ( 28 years )

Introduction: Miter Bevel Gears are part of the Open Gearing product line offered by Boston Gear, designed for applications requiring angular motion transfer.

Us – Bevel Gears for Power Transmission

Domain: us.misumi-ec.com

Registered: 2007 ( 18 years )

Introduction: Bevel gears for rotary power transmission.

Qtcgears – Bevel Gears and Gear Solutions

Domain: qtcgears.com

Registered: 1996 ( 29 years )

Introduction: KHK stock bevel gears are available in two types, spiral and straight tooth, with gear ratios of 1.5 through 5, and offered in a variety of modules, numbers of teeth, materials, and styles.

Tandler – Bevel Gearboxes Manufacturer

Domain: tandler-gearboxes.com

Registered: 2017 ( 8 years )

Introduction: Bevel gearboxes manufactured in Germany by TANDLER.

Gear Sprocket – Bevel Gears and Power Transmission

Domain: gear-sprocket.com

Registered: 2018 ( 7 years )

Introduction: Bevel gears are mechanical devices with conical teeth used to change the direction of shaft rotation, transmitting power between axes at right angles.

Globalspec – Bevel and Miter Gears Solutions

Domain: globalspec.com

Registered: 1998 ( 27 years )

Introduction: Bevel and miter gears are mechanical components used to transmit power and motion between shafts that are at right angles to each other. They are characterized by their conical shape and are available in various designs and specifications.

Hanswerner – Precision Bevel Gears Solutions

Domain: hanswerner.net

Registered: 2023 ( 2 years )

Introduction: Bevel gears are a special type of gear used in applications where the shafts intersect, usually at 90 degrees. They are conical in shape with angled teeth, allowing them to transmit power between shaft axes and change the direction of rotation.

Gearmotions – Custom Bevel Gear Manufacturing Services

Domain: gearmotions.com

Registered: 1997 ( 28 years )

Introduction: Bevel gear manufacturing services including custom designs and various types of bevel gears.

Circle Gear – Precision Bevel Gear Solutions

Domain: circlegear.com

Registered: 1996 ( 29 years )

Introduction: Circle Gear & Machine Co. specializes in the manufacturing of bevel gears and spiral bevel gears, offering custom solutions with a focus on high-quality materials and precision engineering.

Roymech – Bevel Gears for Power Transmission

Domain: roymech.org

Registered: 2019 ( 6 years )

Introduction: Bevel gears for various applications including power transmission and machinery.

igus – High-Performance Plastic Bevel Gears

Domain: igus.com

Registered: 1995 ( 30 years )

Introduction: Plastic bevel gears offered by igus® are designed for various applications requiring precise motion transfer and are made from high-performance plastic materials.

ZHY Gear – Hypoid Gear Solutions

Domain: zhygear.com

Registered: 2018 ( 7 years )

Introduction: ZHY Gear specializes in the design and manufacturing of hypoid gears, which are used in various mechanical applications due to their unique design and advantages.

Category Information

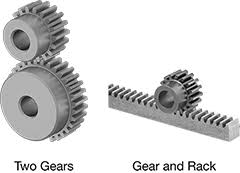

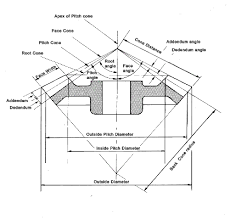

Beveled gears are mechanical components used to transmit power and motion between shafts that are typically oriented at right angles to each other. They feature conical shapes with teeth that are cut on an angle, allowing for efficient engagement and rotation. Common types of beveled gears include straight, spiral, and hypoid gears, each offering unique advantages in terms of load capacity, noise reduction, and efficiency.

The significance of beveled gears lies in their ability to facilitate complex mechanical movements in various applications, ranging from automotive transmissions to industrial machinery. Their design allows for smooth operation and the ability to change the direction of force, making them essential in systems where space constraints and alignment are critical. Overall, beveled gears play a crucial role in enhancing the functionality and performance of mechanical systems.

Application Information

Beveled gears are essential components in various mechanical systems, primarily used to transmit power between shafts that are oriented at right angles. One key application area is in the automotive industry, where beveled gears are employed in differential systems to allow for smooth turning and handling of vehicles. They are crucial in transferring torque from the engine to the wheels while accommodating speed variations between them.

Another significant application is in industrial machinery, where beveled gears facilitate the operation of conveyor systems, mixers, and milling machines. Their ability to efficiently change the direction of motion makes them ideal for complex machinery setups. Additionally, they are utilized in aerospace applications, such as in gearboxes for engines and landing gear systems, ensuring reliability and performance in high-stress environments. Overall, beveled gears play a vital role in enhancing the functionality and efficiency of various mechanical systems across multiple industries.

Production Process Information

Manufacturing beveled gears involves several key steps that ensure precision and functionality. The process begins with design and engineering, where specifications such as size, shape, and material are determined based on the intended application. Engineers create detailed blueprints to guide production. Next, the material selection stage takes place, where suitable metals or alloys are chosen for their strength and durability.

Following this, the actual machining process begins, which includes cutting, shaping, and grinding the gears to achieve the desired dimensions and surface finish. This step often utilizes advanced tools like CNC machines for accuracy. Finally, the gears undergo quality control to ensure they meet industry standards and performance criteria. This may involve testing for strength, precision, and wear resistance.

Once approved, the beveled gears are ready for assembly into machinery or sold as individual components, ensuring they effectively transmit motion and power in various applications.

Related Video

Frequently Asked Questions (FAQs)

What should I look for in a beveled gear manufacturer?

When choosing a beveled gear manufacturer, prioritize their experience in producing bevel gears, quality certifications (like ISO), and their ability to customize products to your specifications. Additionally, check their production capacity, lead times, and customer reviews to ensure reliability and quality.

How can I evaluate the quality of beveled gears?

To evaluate the quality of beveled gears, request samples and inspect them for precision, material quality, and finish. You can also ask for test reports or certifications that verify their adherence to industry standards. A manufacturer’s reputation and customer feedback can also provide insights into their quality.

What is the typical lead time for beveled gear production?

Lead times can vary based on the manufacturer and order complexity, but typically range from 4 to 12 weeks. It’s essential to discuss your timeline upfront and confirm the manufacturer’s ability to meet your deadlines to avoid any disruptions in your project.

Are there minimum order quantities (MOQs) for beveled gears?

Many manufacturers have MOQs, which can vary widely depending on the complexity and customization of the gears. It’s best to inquire directly with potential suppliers about their MOQs, as some may offer flexibility for smaller orders or prototypes.

How can I ensure good communication with my chosen manufacturer?

Good communication is key to a successful partnership. Ensure the manufacturer has a dedicated point of contact, preferably someone fluent in your language. Establish clear expectations regarding updates, progress reports, and any issues that may arise during production to maintain a smooth workflow.