Master Pressure SW Sourcing: Unlock Efficiency and Cost

Introduction: Navigating the Global Market for pressure sw

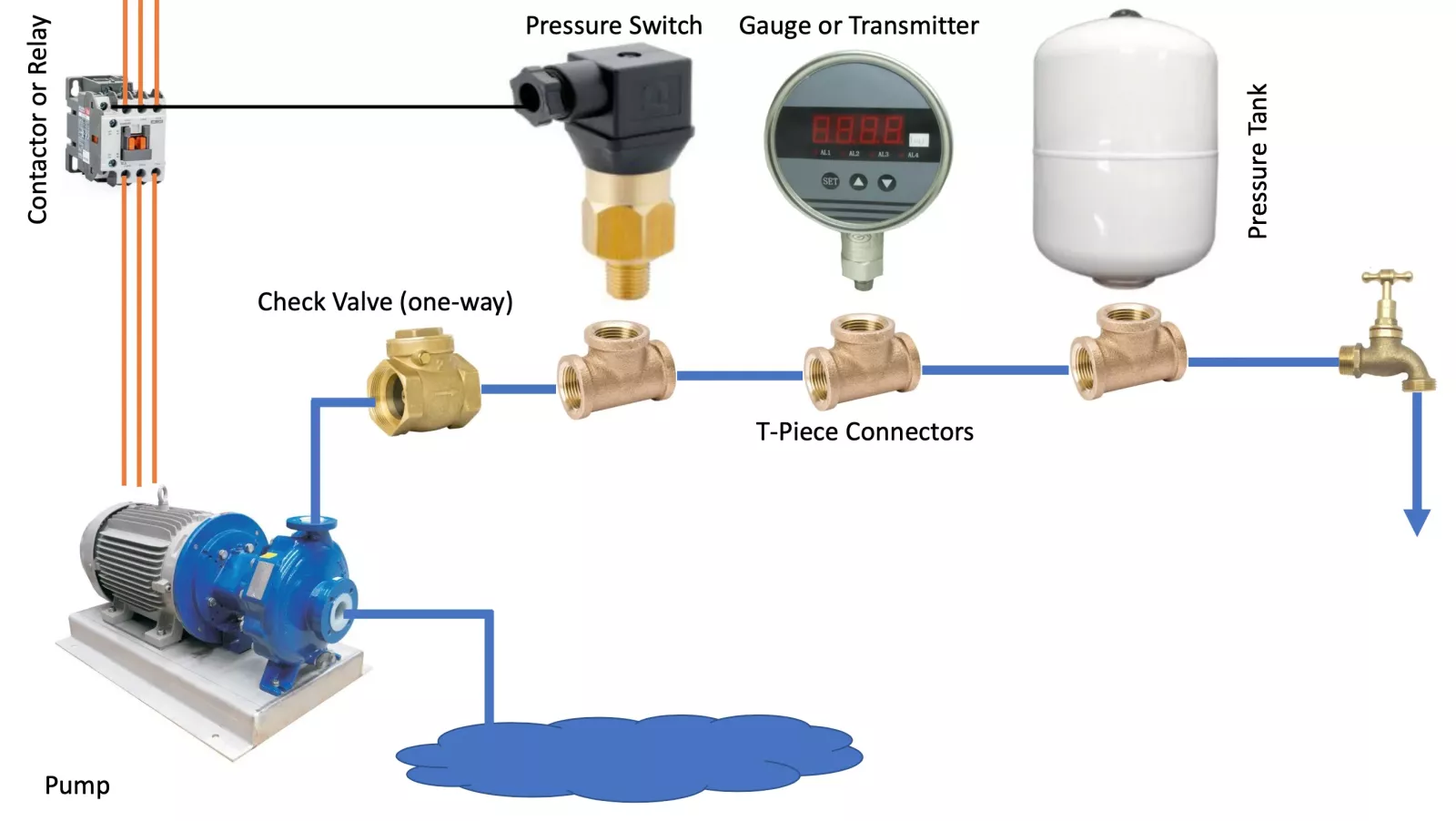

Navigating the global market for pressure switches (pressure sw) presents a significant opportunity for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. As critical components in various industries, including manufacturing, automotive, and HVAC, pressure switches ensure operational efficiency and safety. Their role in monitoring and controlling pressure levels cannot be overstated, making them indispensable in maintaining system integrity and performance.

This comprehensive guide delves into the multifaceted world of pressure switches, providing valuable insights into the various types available, the materials used in their construction, and the manufacturing and quality control processes that ensure reliability. Buyers will gain a clear understanding of the leading suppliers in the market, enabling them to make informed decisions about sourcing. Additionally, the guide will explore cost considerations, market trends, and frequently asked questions, ensuring that buyers are well-equipped to navigate procurement challenges.

Illustrative Image (Source: Google Search)

By empowering B2B buyers with crucial information and actionable insights, this guide aims to enhance sourcing strategies, optimize procurement processes, and ultimately drive business success. Whether you are a procurement manager in Mexico or a supply chain director in Spain, understanding the nuances of pressure switches will enable you to achieve better pricing, quality, and lead times, ensuring your operations run smoothly and efficiently.

Understanding pressure sw Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mechanical Pressure Switch | Uses a diaphragm or piston to mechanically close or open a circuit. | HVAC systems, industrial machinery | Pros: Simple design, low cost. Cons: Limited accuracy and can be affected by vibration. |

| Electronic Pressure Switch | Utilizes electronic sensors for more precise pressure readings. | Oil and gas, pharmaceuticals, water systems | Pros: High accuracy, adjustable settings. Cons: Higher cost and potential complexity. |

| Differential Pressure Switch | Monitors the difference between two pressure points. | Filtration systems, HVAC, process control | Pros: Effective for monitoring flow and filter conditions. Cons: More complex installation and calibration. |

| Smart Pressure Switch | Integrates IoT capabilities for remote monitoring and alerts. | Manufacturing, energy management | Pros: Real-time data, predictive maintenance. Cons: Higher initial investment, requires network infrastructure. |

| Vacuum Pressure Switch | Designed to operate under vacuum conditions, triggering at low pressures. | Packaging, food processing, laboratory | Pros: Essential for vacuum applications. Cons: Limited to specific use cases, can be sensitive to environmental conditions. |

Mechanical Pressure Switch

Mechanical pressure switches are among the simplest forms of pressure switches, utilizing a diaphragm or piston mechanism to open or close an electrical circuit based on pressure changes. They are widely used in HVAC systems and industrial machinery due to their straightforward design and cost-effectiveness. When considering this type, buyers should evaluate their application requirements, as mechanical switches may not provide the precision needed in more sensitive environments.

Electronic Pressure Switch

Electronic pressure switches employ advanced sensors to deliver precise pressure measurements. They are suitable for applications in the oil and gas industry, pharmaceuticals, and water systems, where accuracy is critical. B2B buyers should consider the benefits of adjustable settings and high performance, although the initial costs and potential complexity of installation can be drawbacks.

Differential Pressure Switch

Differential pressure switches are designed to monitor the pressure difference between two points, making them ideal for filtration systems and process control applications. They provide effective monitoring of flow and filter conditions, which is crucial for maintaining system efficiency. Buyers should weigh the advantages of their functionality against the complexity of installation and calibration, which may require specialized knowledge.

Smart Pressure Switch

Smart pressure switches incorporate Internet of Things (IoT) technology, allowing for remote monitoring and data collection. This feature is particularly beneficial in manufacturing and energy management, where real-time data can enhance operational efficiency and facilitate predictive maintenance. While the investment may be higher, the long-term benefits of reduced downtime and improved system performance can justify the cost for many businesses.

Vacuum Pressure Switch

Vacuum pressure switches are specifically designed to operate under vacuum conditions, triggering at low pressure levels. They are commonly found in packaging, food processing, and laboratory environments. Buyers should ensure that their application is compatible, as these switches are tailored for specific use cases and can be sensitive to environmental factors, limiting their versatility.

Key Industrial Applications of pressure sw

| Industry/Sector | Specific Application of pressure sw | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Monitoring pipeline pressure | Enhances safety by preventing leaks and ruptures | Ensure compliance with industry standards and certifications. |

| Water Treatment | Regulation of water pressure in treatment plants | Optimizes operational efficiency and reduces energy costs | Look for suppliers with proven reliability and performance metrics. |

| Manufacturing | Pressure control in hydraulic systems | Increases production efficiency and minimizes downtime | Assess the durability and compatibility with existing systems. |

| HVAC Systems | Pressure monitoring in HVAC installations | Improves energy efficiency and system longevity | Evaluate the integration capabilities with current HVAC systems. |

| Chemical Processing | Managing pressure in reactors | Ensures product quality and safety in chemical reactions | Focus on suppliers with experience in high-pressure applications. |

Oil & Gas

In the oil and gas industry, pressure switches are vital for monitoring pipeline pressure to prevent leaks and ruptures. These devices help maintain safe operational levels, which is crucial given the potential environmental and financial repercussions of a failure. For international buyers, especially in regions like Africa and the Middle East, sourcing pressure switches that meet local safety regulations and standards is essential. Additionally, suppliers should provide robust after-sales support and maintenance services to ensure long-term reliability.

Water Treatment

Pressure switches are extensively used in water treatment plants to regulate water pressure. This application is critical for optimizing operational efficiency and reducing energy costs associated with pumping and filtration systems. Buyers in South America and Europe should prioritize suppliers that can demonstrate a history of reliability in similar environments. Furthermore, understanding the local regulatory landscape regarding water quality and safety can guide sourcing decisions.

Manufacturing

In manufacturing, pressure switches are integral to hydraulic systems, allowing for precise pressure control. This precision enhances production efficiency and minimizes downtime, directly impacting profitability. B2B buyers from various regions should consider the compatibility of pressure switches with their existing machinery and the durability of the components, especially in high-demand environments. Suppliers with a strong track record in the manufacturing sector will be more reliable partners.

HVAC Systems

Pressure switches in HVAC systems play a crucial role in monitoring and regulating pressure to ensure optimal performance. This application not only improves energy efficiency but also extends the lifespan of HVAC units, leading to significant cost savings. For buyers in Europe and the Middle East, it is vital to evaluate the integration capabilities of pressure switches with current systems. Suppliers should provide comprehensive technical support to facilitate installation and maintenance.

Chemical Processing

In the chemical processing industry, managing pressure within reactors is critical for ensuring product quality and safety. Pressure switches help monitor and control the conditions necessary for chemical reactions, reducing the risk of hazardous incidents. International buyers should focus on sourcing from suppliers with expertise in high-pressure applications and those that adhere to strict safety standards. Additionally, understanding the specific chemical compatibility of pressure switches is crucial for maintaining operational integrity.

Illustrative Image (Source: Google Search)

Strategic Material Selection Guide for pressure sw

When selecting materials for pressure switches (pressure sw), it is essential to consider various factors that influence performance, durability, and cost. The choice of material directly impacts the pressure switch’s ability to operate effectively under specific conditions. Below, we analyze four common materials used in pressure switches, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Stainless Steel

Key Properties: Stainless steel is known for its excellent corrosion resistance and high strength, making it suitable for high-pressure and high-temperature applications. It typically has a temperature rating of up to 400°F (204°C) and can withstand pressures exceeding 10,000 psi.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to environmental factors, which makes it ideal for harsh conditions. However, it is more expensive than other materials, which can increase the overall cost of the pressure switch. Manufacturing complexity is moderate, as stainless steel requires specialized machining.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive fluids, making it a preferred choice in industries such as oil and gas, food processing, and pharmaceuticals.

Considerations for International Buyers: Buyers in regions like Europe and the Middle East should ensure compliance with standards such as ASTM and DIN, which dictate material specifications. Additionally, the higher cost may be a consideration for buyers in developing markets like Africa and South America.

Brass

Key Properties: Brass offers good corrosion resistance and is suitable for moderate temperature and pressure applications, typically rated up to 250°F (121°C) and 1,500 psi.

Pros & Cons: Brass is relatively cost-effective and easy to machine, making it a popular choice for many applications. However, it is less durable than stainless steel and can corrode in certain environments, particularly when exposed to saltwater or acidic substances.

Impact on Application: Brass is commonly used in applications involving water or air, but its limitations in corrosive environments may restrict its use in certain industries.

Considerations for International Buyers: Buyers should verify the material’s compliance with local regulations and standards, especially in regions with stringent environmental regulations. The cost-effectiveness of brass can be appealing for projects with budget constraints.

Plastic (Polymer)

Key Properties: Plastics, particularly high-performance polymers like polyamide or polycarbonate, are lightweight and resistant to corrosion. They can typically handle temperatures up to 200°F (93°C) and pressures around 1,000 psi.

Pros & Cons: The main advantage of plastic is its low cost and ease of manufacturing. However, plastics may not be suitable for high-pressure applications and can degrade over time when exposed to UV light or certain chemicals.

Impact on Application: Plastic pressure switches are often used in non-corrosive environments, such as HVAC systems and water management applications. Their compatibility with various media is limited compared to metals.

Considerations for International Buyers: B2B buyers in South America and Africa may find plastics appealing due to lower costs, but they should be mindful of the material’s limitations in harsher environments. Compliance with local standards is also crucial.

Aluminum

Key Properties: Aluminum is lightweight and has good corrosion resistance, with temperature ratings up to 300°F (149°C) and pressure ratings around 1,500 psi.

Pros & Cons: The lightweight nature of aluminum makes it easy to handle and install. However, it is not as strong as stainless steel and may be more susceptible to corrosion in certain environments, particularly in marine applications.

Impact on Application: Aluminum is suitable for applications where weight is a critical factor, such as in automotive and aerospace industries. However, its limitations in high-pressure environments can restrict its use.

Considerations for International Buyers: Buyers in Europe and the Middle East should consider the environmental regulations regarding aluminum use, especially in applications involving corrosive substances. The cost is generally moderate, making it a viable option for various projects.

Summary Table

| Material | Typical Use Case for pressure sw | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Oil and gas, pharmaceuticals | Excellent corrosion resistance | Higher cost | High |

| Brass | Water and air applications | Cost-effective | Corrosion in harsh environments | Low |

| Plastic | HVAC systems, water management | Lightweight and low cost | Limited pressure resistance | Low |

| Aluminum | Automotive, aerospace applications | Lightweight | Not suitable for high pressure | Med |

This material selection guide provides a comprehensive overview for international B2B buyers, enabling informed decisions based on performance requirements, cost considerations, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for pressure sw

Manufacturing Processes for Pressure Switches

The manufacturing of pressure switches (pressure sw) involves several critical stages that ensure the final product meets the required specifications and performance standards. Understanding these processes is essential for B2B buyers to evaluate suppliers effectively.

Main Stages of Manufacturing

-

Material Preparation

The first stage involves selecting and preparing the raw materials, which typically include metals such as stainless steel or brass for housings, and various plastics for insulation and internal components. Material quality is paramount; hence, suppliers must ensure that materials meet specific chemical and physical properties. Buyers should verify that suppliers conduct material testing and certification according to international standards. -

Forming

This stage encompasses processes such as machining, stamping, and molding. Machining is often used for precise components, while stamping is common for producing metal parts. Techniques like injection molding are utilized for plastic components. Each technique requires specialized equipment and skilled labor to ensure dimensional accuracy and surface finish. Buyers should inquire about the technology and machinery used by suppliers, as this can impact the quality and consistency of the final product. -

Assembly

In the assembly phase, components are brought together to form the complete pressure switch. This may involve manual assembly or automated processes, depending on the scale of production. Key aspects include ensuring proper alignment and secure connections between components. Suppliers should be able to demonstrate assembly line processes that minimize errors and facilitate quick turnaround times. Buyers should assess the supplier’s assembly capabilities, including workforce training and assembly methodologies. -

Finishing

The finishing stage includes surface treatments such as plating, painting, or anodizing to enhance corrosion resistance and aesthetics. Additionally, the final inspection is performed to ensure that all components are correctly assembled and function as intended. Buyers should request information on finishing processes and materials used, as these can significantly affect the durability and performance of the pressure switch.

Quality Assurance in Manufacturing

Quality assurance (QA) is a critical component of the manufacturing process, ensuring that the final product meets both regulatory and customer expectations.

International Standards

B2B buyers should be familiar with relevant international standards that govern quality assurance in manufacturing. Key standards include:

- ISO 9001: This standard outlines the criteria for a quality management system and is applicable to any organization, regardless of its size or industry. Suppliers certified to ISO 9001 demonstrate their commitment to consistent quality and continuous improvement.

- CE Marking: In Europe, products like pressure switches must comply with specific directives to obtain CE marking, indicating that they meet EU safety, health, and environmental protection requirements.

- API Standards: For pressure switches used in the oil and gas industry, compliance with American Petroleum Institute (API) standards is crucial. These standards ensure the reliability and safety of equipment in hazardous environments.

Quality Control Checkpoints

Effective quality control (QC) processes typically include several checkpoints throughout the manufacturing cycle:

-

Incoming Quality Control (IQC)

This initial checkpoint involves inspecting raw materials upon receipt to ensure they meet specified standards. Buyers should verify that suppliers perform IQC and maintain detailed records of material inspections. -

In-Process Quality Control (IPQC)

During the manufacturing process, IPQC is implemented to monitor production stages. This ensures that any deviations from the quality standards are identified and rectified promptly. B2B buyers should ask suppliers about their IPQC procedures and how they manage production anomalies. -

Final Quality Control (FQC)

The FQC stage involves a comprehensive inspection of the finished product to ensure it meets all specifications. This may include functional testing, pressure testing, and visual inspections. Buyers should request details on the FQC processes, including the types of tests performed and acceptance criteria.

Common Testing Methods

Testing methods for pressure switches include:

- Functional Testing: Ensures that the pressure switch operates correctly under specified conditions.

- Pressure Testing: Validates the switch’s performance under various pressure levels to ensure reliability.

- Electrical Testing: Checks electrical components for continuity and resistance, ensuring they meet safety standards.

Buyers should ensure that suppliers provide documentation of testing results, as this serves as proof of compliance and quality assurance.

Verifying Supplier Quality Control

B2B buyers must establish a robust verification process to assess supplier quality effectively:

-

Supplier Audits: Conducting on-site audits can provide firsthand insight into a supplier’s manufacturing processes, quality control measures, and adherence to standards. Audits should assess both the physical facilities and the documentation practices.

-

Quality Reports: Requesting regular quality reports can help buyers track supplier performance over time. These reports should include defect rates, non-conformance reports, and corrective actions taken.

-

Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased evaluation of supplier quality. This is especially useful for buyers in regions with less stringent local regulations.

Quality Control Considerations for International Buyers

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe (e.g., Mexico, Spain), understanding the nuances of quality control is critical. Here are some considerations:

-

Regulatory Compliance: Ensure that suppliers comply with local and international regulations relevant to your market. This is particularly important for products sold in regions with stringent safety standards.

-

Cultural Differences: Be aware that different regions may have varying approaches to quality management and supplier relationships. Building strong relationships with suppliers can help bridge these gaps.

-

Logistical Challenges: Consider potential logistical issues that may affect quality control, such as shipping delays or customs regulations. Establish clear communication channels with suppliers to address these challenges proactively.

By comprehensively understanding the manufacturing processes and quality assurance practices associated with pressure switches, international B2B buyers can make informed decisions and establish strong partnerships with reliable suppliers.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for pressure sw Sourcing

In the realm of sourcing pressure switches (pressure sw), understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. This analysis focuses on the various cost components, pricing influencers, and actionable buyer tips that can aid procurement strategies, particularly for stakeholders in Africa, South America, the Middle East, and Europe.

Cost Components of Pressure Switches

-

Materials: The cost of raw materials is a significant portion of the overall expenditure. Common materials include metals, plastics, and electronic components. Prices can fluctuate based on market conditions and availability, making it critical to monitor these trends.

-

Labor: Labor costs vary depending on the production location. Countries with lower labor costs may provide a competitive edge, but this could also impact quality. It’s vital to assess labor standards and the skill level of the workforce involved in manufacturing.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, and administrative expenses. Efficient manufacturing processes can reduce overhead, contributing to lower overall costs.

-

Tooling: Initial tooling costs for creating molds and dies can be substantial, particularly for custom-designed pressure switches. These costs should be amortized over production volume to understand their impact on unit pricing.

-

Quality Control (QC): Implementing stringent QC measures is essential to ensure product reliability and compliance with international standards. The costs associated with testing and certification processes should be factored into the pricing.

-

Logistics: Shipping and handling costs significantly affect the total cost of ownership. This includes transportation fees, customs duties, and insurance. Incoterms play a crucial role in determining who bears these costs and risks.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the typical margin for pressure switches in your target market can aid in negotiations.

Price Influencers

Several factors can influence the pricing of pressure switches:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower unit prices due to economies of scale. Buyers should consider negotiating for bulk discounts.

-

Specifications/Customization: Custom designs or specific features can increase costs. Clearly defining requirements upfront can help avoid unexpected charges later.

-

Material Quality/Certifications: Higher quality materials and certifications (e.g., ISO, CE) usually come at a premium. Buyers must balance quality needs with budget constraints.

-

Supplier Factors: Supplier reliability and reputation can impact pricing. Established suppliers may charge more for their products due to perceived quality and service levels.

-

Incoterms: Understanding the implications of Incoterms can help buyers manage logistics costs more effectively. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate responsibility for shipping costs and risks.

Buyer Tips

To navigate the complexities of pressure switch sourcing, international buyers should consider the following strategies:

-

Negotiation: Engage in negotiations to secure better pricing and terms. Leverage volume commitments and long-term partnerships to strengthen your position.

-

Cost-Efficiency: Assess the Total Cost of Ownership (TCO), which includes purchase price, logistics, and maintenance costs. This holistic view can uncover potential savings.

-

Pricing Nuances: Be aware of regional pricing differences and market conditions. For example, buyers in Europe might face stricter regulations compared to those in Africa, affecting costs and supplier options.

-

Supplier Diversification: Avoid reliance on a single supplier. Having multiple suppliers can enhance bargaining power and mitigate risks related to supply chain disruptions.

Disclaimer

While this analysis provides a framework for understanding the costs and pricing of pressure switches, prices can vary significantly based on market conditions, specifications, and supplier negotiations. Buyers are encouraged to conduct thorough market research and supplier evaluations to obtain the most accurate pricing information tailored to their specific needs.

Spotlight on Potential pressure sw Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘pressure sw’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for pressure sw

Understanding the technical properties and terminology associated with pressure switches (pressure sw) is essential for international B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. This knowledge aids in making informed procurement decisions and enhances supplier communication.

Critical Technical Specifications

-

Material Grade

– Definition: Refers to the type of materials used in the construction of the pressure switch, such as stainless steel, brass, or plastic.

– B2B Importance: The choice of material impacts the durability, corrosion resistance, and temperature tolerance of the switch, which is vital in various industrial applications. Buyers should ensure the material grade aligns with the operational environment to avoid premature failure. -

Pressure Range

– Definition: The minimum and maximum pressure levels that the pressure switch can accurately measure and control.

– B2B Importance: Understanding the pressure range is crucial for ensuring that the switch will function effectively in specific applications. Incorrect pressure ranges can lead to operational inefficiencies or equipment damage. -

Electrical Rating

– Definition: This indicates the voltage and current that the switch can handle, often expressed in volts (V) and amperes (A).

– B2B Importance: Buyers must ensure that the pressure switch’s electrical rating matches their system requirements to avoid electrical failures, which can be costly and hazardous. -

Tolerance

– Definition: This is the allowable deviation from a specified value, often expressed as a percentage.

– B2B Importance: Tolerance levels are critical in precision applications where accurate pressure readings are essential. High tolerance levels can ensure better product performance and reliability. -

Switching Type

– Definition: Refers to the mechanism of the pressure switch, such as mechanical, electronic, or digital.

– B2B Importance: Different switching types offer various advantages, including response time, reliability, and compatibility with different systems. Understanding these can guide buyers in selecting the right switch for their applications. -

Environmental Ratings

– Definition: Specifications that indicate the pressure switch’s ability to withstand environmental factors like moisture, dust, and temperature extremes (often referred to as IP ratings).

– B2B Importance: Knowing the environmental ratings helps buyers choose switches suitable for outdoor or harsh conditions, ensuring long-term performance and reducing maintenance costs.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance for Buyers: Understanding OEM relationships can help buyers identify trusted suppliers and ensure they are sourcing genuine components that meet industry standards. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance for Buyers: Knowing the MOQ is essential for budgeting and planning inventory. It helps buyers avoid excess stock or the need for multiple orders. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting a quote for the supply of goods or services.

– Importance for Buyers: Issuing an RFQ helps buyers gather competitive pricing and terms from multiple suppliers, facilitating better negotiation and decision-making. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international sales terms published by the International Chamber of Commerce, outlining the responsibilities of buyers and sellers.

– Importance for Buyers: Understanding Incoterms helps buyers clarify shipping responsibilities, costs, and risks, which is crucial for international transactions. -

Lead Time

– Definition: The time taken from placing an order to the delivery of the product.

– Importance for Buyers: Knowing the lead time is critical for planning operations and inventory management. It helps avoid delays in production and ensures timely project execution. -

Warranty

– Definition: A guarantee provided by the manufacturer regarding the condition of the product and the commitment to repair or replace it if necessary.

– Importance for Buyers: A robust warranty can indicate product quality and provides peace of mind, reducing long-term costs associated with product failures.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can enhance their procurement strategies, ensuring they make informed decisions that align with their operational needs and market conditions.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the pressure sw Sector

Market Overview & Key Trends

The pressure switch (pressure sw) market is experiencing significant growth driven by global industrialization, technological advancements, and increasing demand for automation in various sectors. Key drivers include the surge in manufacturing activities, particularly in emerging markets like Africa and South America, where industries are expanding rapidly. Additionally, the push towards energy efficiency and automation in sectors such as oil and gas, automotive, and HVAC (heating, ventilation, and air conditioning) is propelling the demand for pressure switches.

Emerging technologies such as the Internet of Things (IoT) and Industry 4.0 are reshaping sourcing trends in the pressure sw sector. B2B buyers are increasingly looking for smart devices that offer remote monitoring and data analytics capabilities, enhancing operational efficiency. The integration of AI in predictive maintenance is also gaining traction, allowing companies to anticipate failures and reduce downtime. Furthermore, the trend towards digital procurement solutions is streamlining the sourcing process, enabling buyers to access a broader supplier base and make data-driven decisions.

International B2B buyers, particularly from regions like Europe and the Middle East, are prioritizing suppliers that demonstrate innovation and adaptability. This shift highlights the importance of establishing strong relationships with suppliers who can offer customized solutions and technical support. As the market evolves, buyers must stay informed about regional regulations and standards to ensure compliance and optimize their procurement strategies.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration in the pressure switch industry, with environmental impacts influencing procurement decisions. B2B buyers are increasingly focused on sourcing from suppliers who prioritize sustainable practices, including the use of eco-friendly materials and processes. The pressure switch sector is no exception, as manufacturers adopt greener technologies to reduce their carbon footprint and comply with international environmental standards.

Ethical sourcing is equally important, as buyers seek to ensure that their supply chains are free from exploitation and harmful practices. This includes evaluating suppliers based on their labor practices, sourcing of raw materials, and overall corporate social responsibility (CSR) initiatives. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

The demand for ‘green’ certifications and materials is on the rise, prompting manufacturers to innovate and offer products that meet eco-friendly standards. B2B buyers should actively seek suppliers who provide transparent information about their sustainability efforts and certifications, which can enhance their brand image and meet the expectations of environmentally conscious consumers.

Brief Evolution/History

The pressure switch has evolved significantly since its inception in the early 20th century. Initially used in basic mechanical applications, advancements in technology have transformed these devices into sophisticated electronic components integral to modern automation systems. The introduction of digital pressure switches in the 1980s marked a significant milestone, allowing for enhanced precision and functionality.

As industries have evolved, so too have the applications for pressure switches, now spanning a wide array of sectors including manufacturing, energy, and healthcare. The ongoing integration of smart technologies and IoT is pushing the boundaries further, allowing for real-time monitoring and improved operational efficiency. This evolution presents a unique opportunity for international B2B buyers to leverage innovative solutions that not only enhance productivity but also align with sustainability goals.

Related Video: Global trade will never be the same again, says Christine Lagarde | Power & Politics

Frequently Asked Questions (FAQs) for B2B Buyers of pressure sw

-

What criteria should I use for vetting suppliers of pressure switches?

When vetting suppliers, focus on their industry experience, customer reviews, and certifications. Verify their financial stability through credit checks and assess their compliance with international standards such as ISO 9001. It’s also beneficial to check their production capabilities and whether they have the necessary quality assurance processes in place. Engaging in direct communication and requesting samples can further confirm their reliability and product quality. -

Can pressure switches be customized to meet specific requirements?

Yes, many suppliers offer customization options for pressure switches to accommodate unique specifications such as pressure range, electrical connections, and materials. When discussing customization, clearly outline your requirements and ask for detailed information on the supplier’s capabilities and lead times. Additionally, inquire about any additional costs associated with customizations and the minimum order quantities (MOQ) involved. -

What are the typical lead times and minimum order quantities (MOQ) for pressure switches?

Lead times can vary significantly based on the supplier, location, and whether the order is standard or customized. Generally, lead times range from 2 to 12 weeks. Minimum order quantities also differ; some suppliers may have an MOQ of 50 units, while others might cater to smaller orders. Always clarify these details upfront to align your procurement strategy with your operational needs. -

What payment terms should I expect when sourcing pressure switches internationally?

Payment terms can vary by supplier and region. Common arrangements include advance payments, letters of credit, or net payment terms (e.g., net 30 or 60 days). It’s essential to negotiate terms that protect your interests while ensuring a smooth transaction. Consider using escrow services for large orders to mitigate risks associated with international trade. -

What quality assurance certifications should I look for in pressure switches?

Key certifications to look for include ISO 9001 for quality management systems, CE marking for compliance with EU regulations, and UL listing for safety standards. Suppliers may also have specific industry certifications that demonstrate their commitment to quality and reliability. Always request documentation to verify these certifications and ensure they are up to date. -

How can I ensure smooth logistics when importing pressure switches?

To facilitate smooth logistics, work with experienced freight forwarders familiar with international shipping regulations. Understand the incoterms (e.g., FOB, CIF) that dictate the responsibilities of buyers and sellers. Additionally, ensure that all necessary documentation, such as customs declarations and import permits, is prepared in advance. Establish clear communication channels with your supplier to track shipments effectively. -

What steps should I take if I encounter a dispute with a supplier?

In the event of a dispute, first attempt to resolve the issue amicably through direct communication with the supplier. Document all correspondence and agreements to ensure clarity. If resolution fails, refer to any contractual agreements regarding dispute resolution, such as mediation or arbitration clauses. Involve legal counsel if necessary, particularly for international contracts, to navigate jurisdictional complexities. -

Are there any specific regulations I need to consider when importing pressure switches?

Yes, various regulations may apply depending on your destination country. Common considerations include compliance with safety standards, environmental regulations, and import tariffs. For example, in the EU, products may need to comply with the Restriction of Hazardous Substances (RoHS) directive. Research the specific regulations in your target market and ensure your supplier can provide necessary documentation to facilitate compliance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for pressure sw

In conclusion, a well-structured strategic sourcing approach for pressure switch (pressure sw) procurement is essential for international B2B buyers aiming to optimize their supply chains and enhance operational efficiency. Key takeaways include the importance of developing comprehensive procurement catalogs, segmenting suppliers effectively, and establishing robust procurement policies. These strategies not only facilitate better supplier management but also ensure compliance and alignment with organizational goals.

As global markets continue to evolve, particularly in regions such as Africa, South America, the Middle East, and Europe, staying attuned to sourcing market trends and insights is crucial. By embracing a dynamic procurement strategy, businesses can achieve significant cost savings, reduce lead times, and enhance product quality.

Looking forward, international buyers are encouraged to leverage technology and data analytics to refine their sourcing strategies continually. Engaging with local suppliers, understanding regional market dynamics, and fostering collaborative relationships will be pivotal in navigating the complexities of global procurement. Now is the time to take proactive steps toward enhancing your sourcing strategy for pressure switches, ensuring your business remains competitive in an increasingly interconnected world.