Your Ultimate Guide to Sourcing Concealed Hinges

Introduction: Navigating the Global Market for concealed hinges

In the rapidly evolving world of interior design and construction, concealed hinges have emerged as a pivotal component for achieving modern aesthetics while ensuring functionality. These discreet hardware solutions not only enhance the visual appeal of spaces but also contribute to the seamless operation of doors and cabinetry. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of concealed hinges is essential for making informed sourcing decisions.

This comprehensive guide delves into the multifaceted world of concealed hinges, covering critical aspects such as types, materials, manufacturing processes, quality control, and suppliers. We will explore the varying costs associated with different hinge options, alongside an analysis of current market trends, ensuring that buyers are equipped with the knowledge necessary to navigate this vital segment of the hardware industry.

Furthermore, this resource addresses frequently asked questions, clarifying common uncertainties and empowering buyers to select the most suitable products for their specific needs. By providing actionable insights and expert analysis, this guide aims to streamline the sourcing process, enabling businesses to enhance their offerings with high-quality concealed hinges that meet both aesthetic and functional requirements. Embrace this opportunity to elevate your procurement strategy and drive success in your projects.

Understanding concealed hinges Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Overlay Concealed Hinge | Door overlays cabinet frame; minimal reveal; sleek appearance. | Kitchen cabinetry, retail displays | Pros: Modern look; easy installation. Cons: Limited adjustment options. |

| Half Overlay Concealed Hinge | Allows two doors to meet; covers part of the frame; cranked arm. | Multi-door cabinets, office furniture | Pros: Space-efficient; smooth operation. Cons: Requires precise measurements. |

| Inset Concealed Hinge | Door sits flush within the cabinet frame; fully recessed. | High-end cabinetry, custom furniture | Pros: Elegant finish; secure fit. Cons: Complex installation; may need professional help. |

| Pivot Concealed Hinge | Allows door to pivot open; minimal visible hardware. | Lightweight and industrial cabinets | Pros: Space-saving; discreet design. Cons: Limited weight capacity. |

| Adjustable Concealed Hinge | Multi-directional adjustability for precise alignment. | Commercial spaces, internal doors | Pros: Easy to fine-tune; versatile. Cons: May be more expensive than standard hinges. |

Full Overlay Concealed Hinge

The full overlay concealed hinge is designed for cabinet doors that completely cover the cabinet frame, providing a seamless look. This type is particularly popular in modern kitchen cabinetry and retail displays where aesthetics are paramount. B2B buyers should consider the installation requirements, as they offer straightforward mounting but may have limited adjustment options, making precise measurements crucial for a flawless finish.

Half Overlay Concealed Hinge

The half overlay concealed hinge is ideal for cabinets where two doors meet in the middle, allowing each door to partially cover the cabinet frame. This hinge type is commonly used in multi-door cabinets and office furniture, providing an effective solution for maximizing space while maintaining a clean appearance. Buyers should ensure accurate measurements are taken, as this hinge requires careful alignment to function smoothly.

Illustrative Image (Source: Google Search)

Inset Concealed Hinge

Inset concealed hinges are designed for doors that sit flush within the cabinet frame, creating a sophisticated, fully recessed finish. This type is favored in high-end cabinetry and custom furniture, where a refined appearance is essential. B2B buyers should be aware that installation can be complex, often necessitating professional assistance to ensure the door aligns perfectly with the cabinet edges, which can impact overall aesthetic quality.

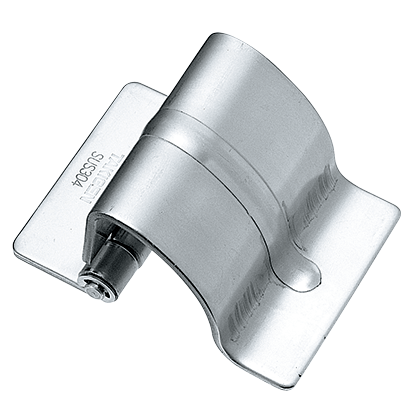

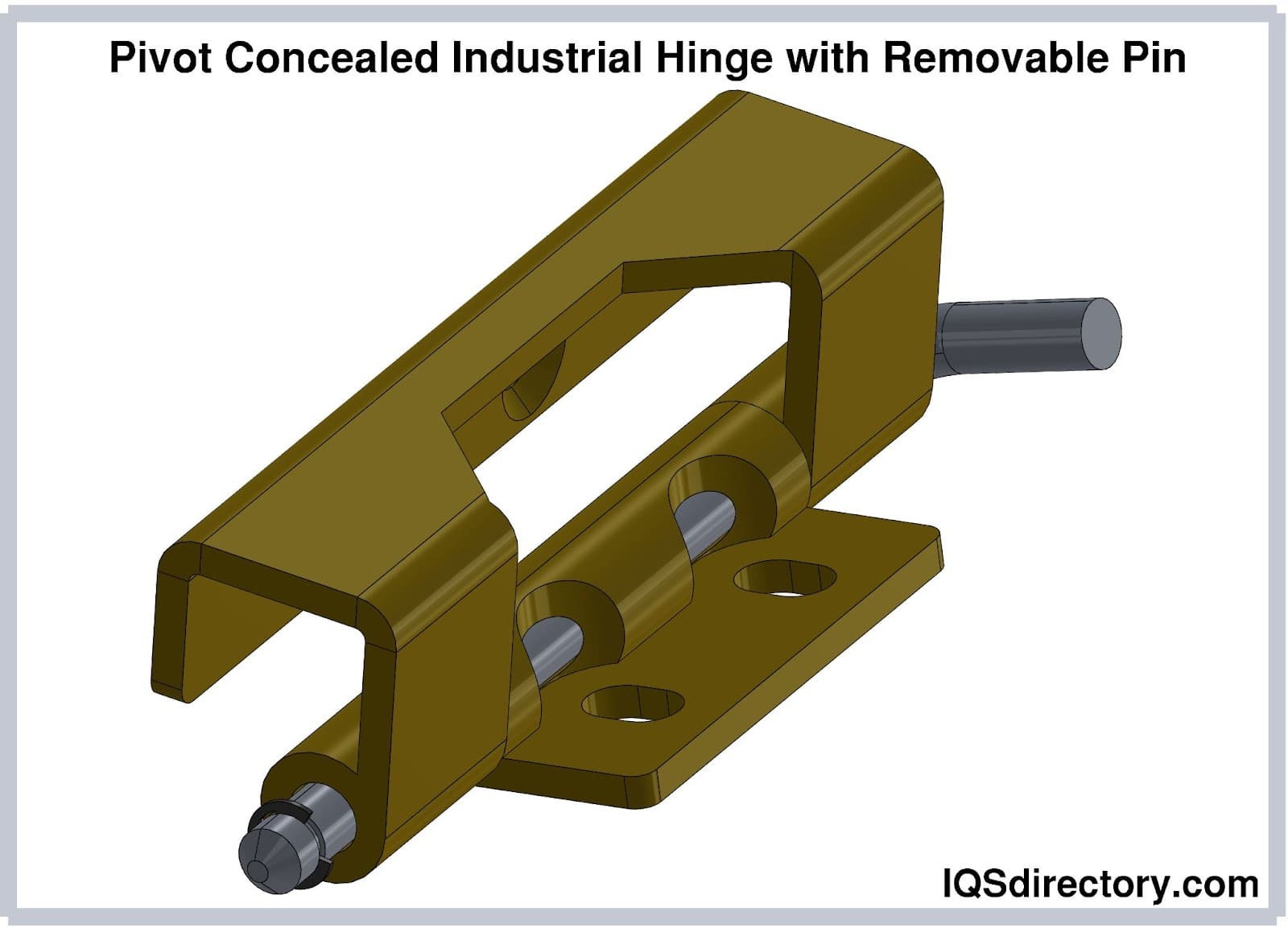

Pivot Concealed Hinge

Pivot concealed hinges allow doors to pivot open rather than swing, making them an excellent choice for lightweight cabinets and industrial applications where space is limited. Their discreet design is particularly advantageous in environments where minimal visible hardware is desired. Buyers should note the weight capacity limitations of this hinge type, ensuring it aligns with the intended use to avoid functionality issues.

Adjustable Concealed Hinge

Adjustable concealed hinges come with multi-directional adjustability, allowing for precise alignment during installation. This versatility makes them suitable for a range of applications, from commercial spaces to internal doors. B2B buyers should consider the investment in these hinges, as they may be more costly than standard options, but the ease of adjustment can save time and labor costs in the long run.

Key Industrial Applications of concealed hinges

| Industry/Sector | Specific Application of Concealed Hinges | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | High-end cabinetry and custom furniture designs | Enhances aesthetics and functionality, appealing to premium markets | Source eco-friendly materials; ensure hinges support weight capacity for larger designs |

| Hospitality | Doors in hotels and restaurants | Provides a sleek look while ensuring durability and security | Consider soft-close features; assess ease of installation for quick renovations |

| Retail | Display cases and storage solutions | Improves visual appeal and customer experience, facilitating product visibility | Look for tamper-resistant designs; prioritize hinges that allow for easy adjustments |

| Commercial Spaces | Office partitions and meeting room doors | Creates a modern and minimalistic look while maximizing space | Evaluate load-bearing capacity; ensure compatibility with various wall materials |

| Residential Construction | Internal doors and built-in wardrobes | Provides a clean aesthetic and smooth operation, enhancing home value | Assess installation requirements; consider variations for different door overlays |

Furniture Manufacturing

In the furniture manufacturing sector, concealed hinges are crucial for high-end cabinetry and custom furniture designs. They allow for a seamless integration of doors and panels, enhancing the overall aesthetic appeal. For international buyers, especially those in markets like Africa and South America, sourcing hinges that support larger door sizes and weights is essential. Additionally, the trend towards sustainability means that buyers should prioritize suppliers who offer eco-friendly materials and manufacturing processes.

Hospitality

In the hospitality industry, concealed hinges are widely used in hotels and restaurants to maintain a polished, modern look. These hinges not only enhance the visual appeal of doors but also offer durability and security, which are paramount in high-traffic environments. Buyers in this sector, particularly from the Middle East and Europe, should consider soft-close features to improve guest experience and ease of maintenance during renovations. Additionally, ease of installation is a key factor, as quick upgrades can minimize downtime.

Retail

Retail spaces leverage concealed hinges in display cases and storage solutions to create a visually appealing environment that enhances the customer experience. These hinges facilitate better product visibility and contribute to a clean aesthetic that aligns with modern retail trends. For B2B buyers in regions like South America, it is vital to look for tamper-resistant designs that ensure security while allowing easy adjustments. Suppliers that provide hinges compatible with various display materials will be particularly advantageous.

Commercial Spaces

In commercial spaces, concealed hinges are ideal for office partitions and meeting room doors. They help create a modern and minimalistic look while maximizing the usability of space. Buyers should assess the load-bearing capacity of these hinges to ensure they can support heavier doors, particularly in busy environments. Compatibility with various wall materials is also crucial for international buyers, particularly in Europe and the Middle East, where architectural styles may vary significantly.

Residential Construction

Concealed hinges are increasingly popular in residential construction, particularly for internal doors and built-in wardrobes. They provide a clean aesthetic that enhances the overall value of homes. B2B buyers in Africa and South America should consider the installation requirements of these hinges, as some may need specialized tools or techniques. Additionally, variations in hinge design for different door overlays should be evaluated to ensure a perfect fit for various residential applications.

Related Video: How to install concealed hinges

Strategic Material Selection Guide for concealed hinges

When selecting materials for concealed hinges, international B2B buyers must consider various factors that influence performance, durability, and compliance with regional standards. Below is an analysis of four common materials used in the manufacturing of concealed hinges, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Steel

Key Properties: Steel is known for its high tensile strength and durability. It typically has excellent temperature and pressure ratings, making it suitable for various applications. Additionally, stainless steel variants offer enhanced corrosion resistance.

Pros & Cons: Steel hinges are robust and can withstand heavy loads, making them ideal for commercial applications. However, they can be prone to rust if not properly coated or if used in humid environments. The manufacturing process can be complex, particularly for stainless steel, which may increase costs.

Impact on Application: Steel hinges are compatible with heavy doors and high-traffic areas. However, they may not be suitable for environments with high moisture unless treated with protective coatings.

Considerations for Buyers: Buyers should ensure compliance with local standards such as ASTM or DIN for strength and corrosion resistance. In regions like Egypt or Colombia, where humidity can be high, selecting treated or stainless steel is advisable.

Zinc Alloy

Key Properties: Zinc alloy is lightweight and offers good strength-to-weight ratios. It has moderate corrosion resistance and can be easily cast into intricate shapes.

Pros & Cons: Zinc alloy hinges are cost-effective and suitable for lighter applications. They are easier to manufacture and can be produced in various finishes. However, they may not withstand heavy loads as well as steel and can be susceptible to corrosion over time.

Impact on Application: Ideal for residential applications and lighter commercial use, zinc alloy hinges work well in environments where aesthetics are essential but load-bearing capacity is less critical.

Considerations for Buyers: Buyers should verify that the zinc alloy used complies with local standards. In regions with strict regulations on metal quality, such as Europe, ensuring the material meets specific certifications is crucial.

Brass

Key Properties: Brass is known for its excellent corrosion resistance and aesthetic appeal. It has good mechanical properties and can handle moderate loads.

Pros & Cons: The primary advantage of brass hinges is their resistance to tarnishing and corrosion, making them ideal for decorative applications. However, they are generally more expensive than steel or zinc alloy and may not be suitable for heavy-duty applications.

Impact on Application: Brass hinges are often used in high-end residential and commercial settings where appearance matters. They are less suitable for environments with extreme wear and tear.

Considerations for Buyers: Buyers should look for compliance with international standards, especially in Europe, where quality assurance is paramount. The cost may be a limiting factor in budget-sensitive projects.

Plastic Composites

Key Properties: Plastic composites are lightweight and resistant to corrosion and moisture. They can be engineered for specific applications, offering flexibility in design.

Pros & Cons: These materials are cost-effective and can be manufactured in various colors and finishes. However, they may not provide the same load-bearing capacity as metals and can degrade under UV exposure.

Impact on Application: Plastic composite hinges are suitable for applications where moisture resistance is critical, such as in kitchens or bathrooms. They are less suitable for heavy-duty applications.

Considerations for Buyers: Buyers should ensure that the plastic composites used comply with local environmental regulations, especially in regions with strict sustainability standards. In markets like South America, where plastic waste management is a concern, eco-friendly options may be preferred.

Summary Table

| Material | Typical Use Case for concealed hinges | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty commercial doors | High strength and durability | Prone to rust without treatment | Medium |

| Zinc Alloy | Residential cabinets | Cost-effective and lightweight | Limited load capacity | Low |

| Brass | High-end residential applications | Corrosion resistant and aesthetic | Higher cost and limited load capacity | High |

| Plastic Composites | Moisture-prone environments | Lightweight and corrosion resistant | Lower load capacity and UV sensitivity | Low |

By understanding these materials’ properties and implications, B2B buyers can make informed decisions that align with their project requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for concealed hinges

Concealed hinges are essential components in modern construction and furniture design, providing both aesthetic appeal and functional performance. Understanding the manufacturing processes and quality assurance measures for these hinges is crucial for B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This section will delve into the typical manufacturing stages, key techniques employed, and the quality control measures that ensure product reliability and compliance with international standards.

Manufacturing Processes for Concealed Hinges

The manufacturing of concealed hinges generally involves several key stages:

1. Material Preparation

The first stage in the manufacturing process is material preparation. High-quality concealed hinges are typically made from robust materials such as stainless steel, brass, or zinc alloys. Manufacturers are increasingly focusing on sourcing eco-friendly materials, including recycled metals, to reduce their environmental footprint.

- Material Selection: Suppliers should ensure that the metals used are lead-free and cadmium-free, aligning with global health and safety standards.

- Pre-processing: Materials are cut to size and inspected for defects before being moved to the next stage.

2. Forming

Once the materials are prepared, the forming stage begins. This process shapes the metal into the desired hinge components.

- Techniques Used: Common techniques include stamping, forging, and CNC machining. CNC machines are particularly beneficial as they allow for precision and reduced waste by optimizing material usage.

- Forming Quality: The formed parts undergo preliminary inspections to ensure they meet dimensional specifications and tolerances.

3. Assembly

The assembly stage involves putting together the various components of the concealed hinge.

- Component Integration: This includes integrating the hinge cups and mounting plates, ensuring that they fit seamlessly to achieve the desired functionality.

- Automation: Many manufacturers are adopting automated assembly processes to enhance efficiency and consistency while minimizing human error.

4. Finishing

The finishing stage is critical for both aesthetic and functional qualities.

- Coating and Plating: Concealed hinges are often coated or plated to enhance durability and resistance to corrosion. Techniques such as powder coating or electroplating are commonly used.

- Final Inspection: After finishing, hinges are subjected to a thorough inspection to check for surface defects and to ensure that coatings meet quality standards.

Quality Assurance (QA) in Manufacturing

Ensuring the quality of concealed hinges is vital for maintaining brand reputation and customer satisfaction. The following quality assurance processes are typically employed:

International Standards

Manufacturers must comply with various international standards that govern product quality:

- ISO 9001: This standard ensures that organizations meet customer and regulatory requirements and demonstrate continuous improvement.

- CE Marking: For products sold in the European market, CE marking indicates compliance with health, safety, and environmental protection standards.

Quality Control Checkpoints

Quality control is integrated throughout the manufacturing process, with specific checkpoints to monitor quality at each stage:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, regular checks are conducted to verify that processes are adhering to quality requirements.

- Final Quality Control (FQC): Before packaging, a final inspection assesses the hinges for defects and functionality.

Common Testing Methods

Testing methods for concealed hinges can include:

- Load Testing: Ensuring that the hinges can withstand the intended weight and usage conditions.

- Corrosion Resistance Testing: Assessing the durability of coatings and materials against environmental factors.

- Functional Testing: Checking for smooth operation and alignment of hinges.

Verification of Supplier Quality Control

B2B buyers should take proactive steps to verify the quality control measures of potential suppliers:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control systems firsthand.

- Quality Assurance Reports: Requesting documented quality assurance reports can provide insights into the supplier’s adherence to standards and their historical performance.

- Third-Party Inspections: Engaging independent inspection agencies can offer an unbiased evaluation of product quality and compliance with specifications.

Considerations for International Buyers

When sourcing concealed hinges from suppliers in different regions, B2B buyers must consider several nuances:

- Regional Standards Compliance: Be aware of local regulations and standards that may differ from international norms. For instance, products sold in the EU must comply with CE marking requirements.

- Cultural Factors: Understanding local business practices and communication styles can facilitate smoother transactions and negotiations.

- Logistics and Supply Chain Transparency: Ensure that suppliers can provide clear visibility into their supply chains, especially regarding the sourcing of materials and production processes.

In summary, the manufacturing processes and quality assurance measures for concealed hinges are integral to ensuring product reliability and performance. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ultimately leading to better product outcomes and satisfaction in their projects.

Related Video: How Millions of Door Hinges are Produced in a Chinese Stainless Steel Factory

Comprehensive Cost and Pricing Analysis for concealed hinges Sourcing

When sourcing concealed hinges, understanding the comprehensive cost structure is essential for B2B buyers. The costs can be broken down into several components, each influencing the final pricing.

Cost Components

-

Materials: The choice of materials significantly impacts cost. Common materials include stainless steel, brass, and eco-friendly options like recycled metals. High-quality finishes, such as lead-free or bio-based coatings, also add to the expense. Buyers should consider the long-term benefits of investing in durable materials that enhance the product’s lifespan.

-

Labor: Labor costs vary by region and depend on the complexity of hinge design. In countries with higher wage standards, labor-intensive processes such as custom fabrication may increase costs. Conversely, regions with lower labor costs can provide competitive pricing but may compromise on quality or craftsmanship.

-

Manufacturing Overhead: This includes fixed costs associated with production facilities, utilities, and administrative expenses. Efficient manufacturing processes, such as automation and lean production methods, can help reduce overhead costs, which can be passed on to buyers.

-

Tooling: Custom tooling for specific hinge designs can be a significant upfront cost. This is particularly relevant for B2B buyers looking for specialized or customized solutions. While tooling costs may be high initially, they can lead to lower per-unit costs in larger production runs.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and compliance with industry standards. While implementing stringent QC measures may increase costs, they reduce the risk of defects and returns, ultimately saving money in the long run.

-

Logistics: Shipping costs can vary widely depending on the distance and mode of transport. Buyers should account for import duties, taxes, and insurance when calculating total logistics costs. Leveraging local suppliers may reduce shipping expenses and lead times.

-

Margin: Supplier margins vary based on market conditions and competition. Understanding the typical margin in the hinge market can help buyers gauge fair pricing and negotiate effectively.

Price Influencers

Several factors influence the pricing of concealed hinges:

-

Volume/MOQ: Bulk purchases often lead to discounts. Understanding minimum order quantities (MOQs) can help buyers negotiate better terms.

-

Specifications/Customization: Custom designs or specific performance requirements may come at a premium. Buyers should evaluate whether the added cost aligns with their project needs.

-

Materials: As mentioned earlier, the choice of materials can significantly affect pricing. Eco-friendly or high-performance materials usually entail higher costs.

-

Quality/Certifications: Compliance with international quality standards and certifications can impact pricing. Buyers should inquire about certifications to ensure product reliability.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more for their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding shipping terms is crucial for cost management. Buyers should clarify who is responsible for shipping costs, insurance, and customs duties to avoid unexpected expenses.

Buyer Tips

-

Negotiation: Always negotiate pricing, especially for bulk orders. Suppliers may have flexibility in their pricing structures, particularly for long-term contracts.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO) rather than just the initial purchase price. Higher-quality hinges may have a higher upfront cost but lead to lower maintenance and replacement costs over time.

-

Pricing Nuances: International buyers should be aware of currency fluctuations and regional pricing differences. Establishing relationships with local suppliers can mitigate risks associated with currency exchange and logistics.

-

Disclaimer for Indicative Prices: Keep in mind that prices can vary based on market conditions, supplier negotiations, and specific project requirements. Always request detailed quotes to understand the complete cost structure.

By analyzing these components and factors, B2B buyers from Africa, South America, the Middle East, and Europe can make informed decisions when sourcing concealed hinges, ensuring they achieve both cost efficiency and product quality.

Spotlight on Potential concealed hinges Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘concealed hinges’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for concealed hinges

Concealed hinges are critical components in modern furniture and architectural design, offering functionality and aesthetic appeal. For B2B buyers, understanding the essential technical properties and industry terminology related to concealed hinges is vital for making informed purchasing decisions.

Key Technical Properties of Concealed Hinges

-

Material Grade

– Definition: The type of material used, often categorized by grade, which affects strength, durability, and corrosion resistance.

– Importance: Higher-grade materials, such as stainless steel, provide better resistance to wear and environmental factors, making them suitable for high-traffic areas. Buyers should prioritize material grade to ensure longevity and performance, especially in diverse climates. -

Load Capacity

– Definition: The maximum weight the hinge can support without failure.

– Importance: Knowing the load capacity is essential for selecting the right hinge for specific applications, such as heavy doors or cabinets. This prevents premature wear and potential safety hazards, especially in commercial settings. -

Tolerance

– Definition: The allowable deviation in the hinge dimensions during manufacturing.

– Importance: Tighter tolerances result in better alignment and functionality of doors, ensuring smooth operation. For B2B buyers, choosing hinges with precise tolerances minimizes installation issues and enhances overall performance. -

Finish Type

– Definition: The surface treatment applied to the hinge, affecting aesthetics and durability.

– Importance: Options such as powder coating or anodizing not only enhance appearance but also provide protection against corrosion. Selecting the appropriate finish is crucial for maintaining the hinge’s integrity, especially in humid or corrosive environments. -

Adjustability

– Definition: The ability to fine-tune the hinge position after installation.

– Importance: Hinges with built-in adjustability allow for easy realignment of doors, which is particularly beneficial in environments where doors may shift over time. This feature enhances user satisfaction and reduces maintenance costs. -

Opening Angle

– Definition: The maximum angle at which the door can open.

– Importance: Different applications may require different opening angles. Understanding this property helps buyers select hinges that fit their spatial requirements, ensuring functionality without compromising design.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships helps buyers identify reliable sources for high-quality components that meet industry standards. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps businesses plan their inventory and budget effectively. This is crucial for international buyers to avoid excess stock or insufficient supplies. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and terms for specific products.

– Importance: An RFQ allows buyers to compare offers and negotiate better terms, ensuring they get the best value for their investment. -

Incoterms

– Definition: International commercial terms that define the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities, aiding in smoother logistics and compliance with international trade regulations. -

Lead Time

– Definition: The amount of time it takes from placing an order to receiving the product.

– Importance: Understanding lead times is essential for project planning and ensuring that production schedules are met, particularly in regions with longer shipping durations.

Illustrative Image (Source: Google Search)

- Certification Standards

– Definition: Regulations and standards that products must meet to be deemed safe and reliable.

– Importance: Buyers should look for hinges that comply with relevant certification standards to ensure quality and safety in their applications, particularly in regulated industries.

By grasping these technical properties and trade terms, international B2B buyers can make strategic purchasing decisions that align with their operational needs and market demands.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the concealed hinges Sector

Market Overview & Key Trends

The concealed hinges market is experiencing robust growth, driven by a surge in the construction and furniture sectors globally. As modern design trends favor minimalist aesthetics, the demand for concealed hinges has increased, especially in regions like Europe, Africa, South America, and the Middle East. Buyers are now prioritizing products that offer a seamless look while ensuring functionality.

Technological advancements in manufacturing, such as the use of CNC and laser-cutting machines, are transforming sourcing trends. These innovations not only enhance precision but also minimize waste, making production processes more efficient. Additionally, the rise of automation and robotics in manufacturing has improved operational efficiency, allowing suppliers to meet the increasing demand without compromising on quality.

Emerging markets, particularly in Africa and South America, present significant opportunities for international B2B buyers. Here, the construction industry is rapidly evolving, with a growing emphasis on modern designs and sustainable practices. Buyers from these regions should focus on suppliers who can provide innovative solutions that align with local market needs while ensuring compliance with international standards.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a non-negotiable aspect of the concealed hinges sector. The environmental impact of manufacturing hinges is significant; thus, B2B buyers must prioritize suppliers who adopt eco-friendly practices. This includes sourcing recycled metals, utilizing bio-based finishes, and implementing energy-efficient manufacturing processes.

Ethical supply chains are crucial for maintaining brand integrity. Buyers should seek suppliers who are transparent about their sourcing practices and can provide certifications for sustainable materials. The use of ‘green’ certifications, such as LEED (Leadership in Energy and Environmental Design) or Cradle to Cradle, can serve as indicators of a supplier’s commitment to sustainability. Additionally, opting for hinges made from biodegradable composites or lead-free materials can further enhance a company’s environmental credentials.

By prioritizing sustainability, B2B buyers not only contribute to environmental conservation but also align with the growing consumer preference for responsible products. This shift can enhance brand loyalty and open new market opportunities, particularly in regions where sustainability is increasingly valued.

Brief Evolution/History

The evolution of concealed hinges can be traced back to the need for aesthetic solutions in modern architecture and furniture design. Initially, hinges were bulky and visible, detracting from the sleek lines of contemporary designs. However, as architectural styles evolved, so did the demand for more discreet hardware solutions.

By the late 20th century, the development of concealed hinges revolutionized the market, allowing for a seamless integration of doors and cabinetry. This innovation not only improved the visual appeal of interiors but also enhanced functionality, with features such as multi-directional adjustability. Today, concealed hinges are a staple in both residential and commercial applications, reflecting a blend of form and function that meets the needs of modern buyers.

International B2B buyers are encouraged to stay abreast of these historical trends, as they can inform purchasing decisions and strategies in a rapidly evolving market landscape.

Related Video: Concealed Cabinet Door Hinges – Everything You Need to Know #concealedHinges

Frequently Asked Questions (FAQs) for B2B Buyers of concealed hinges

-

What criteria should I use to vet suppliers of concealed hinges?

When vetting suppliers, prioritize their experience and reputation in the industry. Look for certifications such as ISO 9001 for quality management systems and environmental certifications like ISO 14001. Evaluate their product range and ability to provide customized solutions. Check for client testimonials and case studies, and request samples to assess product quality. Additionally, consider their production capacity and lead times to ensure they can meet your demands. -

Can I customize concealed hinges to meet specific project requirements?

Yes, many manufacturers offer customization options for concealed hinges. You can specify dimensions, weight capacity, finishes, and additional features such as soft-close mechanisms. Communicate your requirements clearly during initial discussions and ask for design prototypes or CAD drawings to ensure the final product aligns with your needs. Keep in mind that custom orders may have longer lead times and potentially higher costs. -

What are typical minimum order quantities (MOQ) and lead times for concealed hinges?

MOQs for concealed hinges can vary significantly depending on the supplier and the complexity of the product. Generally, you might encounter MOQs ranging from 100 to 1,000 units. Lead times typically range from 4 to 12 weeks, influenced by factors such as customization, production schedules, and shipping logistics. It’s advisable to confirm these details upfront and inquire about the possibility of smaller trial orders if you’re testing a new supplier. -

What payment terms should I expect when sourcing concealed hinges?

Payment terms can differ between suppliers, but common practices include a deposit (usually 30-50%) upfront, with the balance due prior to shipment. Some suppliers may offer net 30 or net 60 terms for established clients. Ensure you understand the payment methods accepted, whether through bank transfers, letters of credit, or other means. Always clarify any potential additional costs, such as currency conversion fees or transaction charges. -

How can I ensure quality assurance and certification for concealed hinges?

Quality assurance is crucial when sourcing concealed hinges. Request documentation proving compliance with international standards, such as CE marking for European markets or ANSI certification in the U.S. Ask about the supplier’s quality control processes, including testing methods for durability and functionality. Regular audits and inspections can also be beneficial, so consider establishing a quality assurance agreement to ensure consistent product quality. -

What logistics considerations should I keep in mind when importing concealed hinges?

Logistics play a vital role in the timely delivery of concealed hinges. Factor in shipping methods (air vs. sea), customs clearance processes, and potential duties or tariffs applicable to your region. Collaborate with a reliable freight forwarder who understands international trade regulations. Additionally, maintain open communication with your supplier regarding shipment tracking and any potential delays to ensure a smooth delivery process. -

How should I handle disputes or quality issues with suppliers?

Establish clear communication channels with your supplier to address any disputes or quality issues promptly. Document all concerns with photos and detailed descriptions to provide evidence. Refer to the terms outlined in your purchase agreement for dispute resolution processes. If necessary, escalate the issue through formal channels, such as mediation or arbitration, especially for larger contracts. Building a strong relationship with your supplier can help mitigate disputes in the future. -

What are the best practices for maintaining a long-term relationship with hinge suppliers?

To foster a productive long-term relationship, maintain regular communication and provide feedback on product performance. Share your future project needs to help suppliers plan and optimize their production. Establish clear expectations regarding quality, delivery timelines, and pricing. Consider engaging in joint development projects for new products or improvements, which can lead to mutual growth and innovation. Regularly review performance metrics together to ensure alignment and address any issues proactively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for concealed hinges

In conclusion, the strategic sourcing of concealed hinges presents a unique opportunity for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. By prioritizing sustainability and innovation, buyers can align their procurement strategies with the evolving demands of environmentally conscious consumers and modern design aesthetics.

Key takeaways include the importance of sourcing from manufacturers that utilize eco-friendly materials and energy-efficient processes. This not only supports corporate responsibility but also enhances brand reputation in a competitive market. Additionally, opting for hinges that offer versatility and ease of installation can streamline operations and reduce long-term costs.

Looking ahead, the market for concealed hinges is poised for growth as demand for sleek, minimalistic designs continues to rise. International buyers should actively seek partnerships with manufacturers that embrace transparency in their supply chains and demonstrate a commitment to sustainable practices. By doing so, they will not only secure high-quality products but also contribute to a more sustainable future in the hardware industry. Engage now in this transformative journey to elevate your sourcing strategy and meet the expectations of a discerning global marketplace.